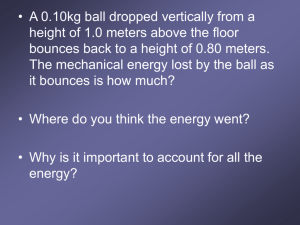

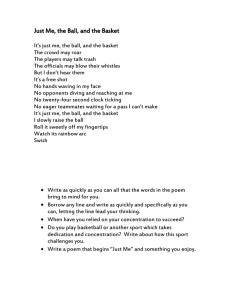

Lab Guidelines

advertisement

Roller Coaster Energy Losses

Background

This lab is designed to collect information and calculate various forms of energy

losses in your roller coaster design. Some of the calculations will allow you to

determine coefficients which can be used in a spreadsheet that roughly models

some of the energy losses and calculates the resultant velocities of the ball as it

rolls down the track through the various features. Other calculations will give you

a better understanding of losses not included in the spreadsheet model. The lab

has two major parts:

Part 1: Rolling and Static Friction

Part 2: Additional Energy Losses

Student teams will work at their tables on Part 2 during the entire lab time. The

instructor will notify individual groups to perform Part 1 one-at-a-time during the

course of the lab at a special table at the front of the class.

Roller Coaster Energy Analysis Spreadsheet

Students will be introduced to the Roller Coaster Energy Analysis Spreadsheet during a

classroom lecture. The spreadsheet is shown below. To use this spreadsheet with friction

effects, three energy loss coefficients are needed (as indicated below). The three

coefficients are:

• dE/ds: Frictional losses on straight track sections

• dE/ds/dv: Losses associated with speed (i.e. air resistance)

• dE/ds/dNC: Losses associated with “G” forces (centripetal acceleration)

Rev A 01/08/03

ROLLER COASTER ENERGY ANALYSIS

Ball mass

0.0100

g

9.80

Ball geometric radius

0.01270

Ball rolling radius

0.01016

Mass Moment of Inertia, I 6.452E-07

h1

v1

s1

PE1

TKE1

RKE1

E1

E

kg

m/s^2

m

m

kg*m^2

Copyright 2004: The Ohio State University

-dE/ds ?

-dE/ds/dv ?

-dE/ds/dNC ?

Pos 1

0.455 m

0.000 m/s

0.000 m

0.04459

0.00000

0.00000

0.04459

J

J

J

J

J/m

J*s/m^2

J/m/g

h2

v2

s2

Dh

Dv

dN

dC

For Loops

0.00

0.00

0.000

0.000

m

m

g

g

PE2

TKE2

RKE2

E2

Pos 2

0.000 m

2.332 m/s

1.000 m

0.00000

0.02719

0.01699

0.04419

J

J

J

J

E loss_1_to_2: #VALUE! J >>>>>> >>>>>>>> #VALUE!

0.04459 J

E #VALUE! J

^--------------------------- Same ??? Then OK ----------------------------------^

1

NOTE: You will only be calculating the first coefficient (dE/ds) in this lab. The remaining

two coefficients will be given to you. You will collect information for the calculation of the

coefficient in Part 1 of this lab when instructed to do so by your instructor.

The Roller Coaster Energy Analysis Spreadsheet does not account for all losses.

This occurs partly because of:

• energy losses due to deformation of the structure

• inadequate snap-fit spacing

• horizontal curves

When you complete your roller coaster, you'll be asked to instrument some of the features

on your coaster to compare your actual energy losses with this spreadsheet.

The objectives of this lab are

to learn how to calculate one of the three above coefficients based on

measured data from the lab

to understand how to use production speed sensors to calculate energy

losses in a coaster feature

to learn how to measure the energy losses in a horizontal curve as a function

of g-forces

to explore the design limitations that these unaccounted for energy losses

create

2

PART 1: Static and Rolling Friction

You will be directed by your instructor to go to a table at the front of the lab

when it is your team’s turn to do Part 1. In the meantime work on Part 2.

Method

The student teams will use three different apparatuses; two different sized circular arcs to

measure rolling friction and a linear ramp to measure static friction. Geometric

measurements of each apparatus will be supplied for use in data reduction calculations.

For the circular arc apparatus, the ball will be released at different starting points. The

length of time and number of oscillations before the ball comes to a stop will be recorded.

For the linear ramp, conjoined ball-pairs will be placed on the ramp. The angle of elevation

(inclination) of the ramp will be slowly increased and recorded when the pair just begins

to slide on the ramp.

Lab Guidelines

The GUIDELINES that MUST be followed AT ALL TIMES in the lab are:

No student will adjust or otherwise change any apparatus (other than for changing

the ramp elevation or plugging/unplugging the electrical power adaptor). Electrical

connections are pre-made by staff. If something is not working or is obviously wrong,

immediately notify an instructional staff member.

No dangling jewelry or loose clothes.

No ‘open’ shoes. Close-toed shoes or boots only.

No climbing or standing on chairs or tables.

Be aware of sharp corners and edges which may exist on tables or on apparatus and

tools.

Always know the location of the phone and of the first-aid kit.

Report to the instructor ALL injuries occurring during lab.

Lab Room Logistics

A table will be placed in the front of the lab room. It will contain two circular arc

apparatus and one linear ramp apparatus. Data will be collected at the table by each

team.

Teams will rotate to the front table and collect data on the three apparatus.

INSTRUCTOR will notify each group when it is their turn to rotate to the front

table. Each team will record the data they acquire on an apparatus summary

worksheet at each table and on the computer at the instructor’s station. The

apparatus worksheet is obtained from and started by the first team that tests a

given apparatus; and the sheet stays with the apparatus until the lab is completed!

The data sheet is to be left on the table for the instructional staff to collect. The

instructional staff will email the summarized data to each student.

Certain geometric measurements from each apparatus are needed for data

reduction. These necessary geometric measurements will be provided to the

students. The values are contained in a table of values on the apparatus itself.

3

Lab Equipment

On the front table you should find:

1. the three apparatus (two circular arcs with different radii and one linear ramp)

2. a single test ball (for circular arc) and conjoined ball set (for ramp apparatus)

3. a meter stick (for ramp apparatus)

4. a table-of-geometric-values related to the apparatus (on the apparatus itself; not

used for ramp apparatus).

Note: All Ohio State-issued materials will remain on the lab tables and in the

lab in general. The teams will experiment with test lab setups and circuit

components. The student will immediately notify the staff about any

missing, damaged, or non-operating parts or devices.

4

CIRCULAR ARC APPARATUS

Arc

Lengths

( Ssp )

At Rest

( Hrest )

1 Starting

Position

( Hsp )

Figure 1: Circular Arc Apparatus

Circular arc sections of track are used to find the energy loss and related rolling friction of

a given ball on the track rails. Reduced data from all the circular arc apparatus in the lab

can be compared to see what if any affect the track segment radius and/or average

velocity has on the performance of the ball. The main intent is to obtain a single value

which represents the energy loss per unit distance traveled if in a 1g (gravitational

acceleration only) environment.

Figure 2: Staging the Ball for Release

5

Circular Arc Test Procedure

1. Prepare to use the stop watch on the table.

2. Record on Worksheet A1 or A2 the apparatus identifier, the height of the ball at

rest (Hrest), the arc radius, the initial starting height (Hsp), the initial arc length

(Ssp). (see Figure 1)

3. Stage the ball at the marked starting point R3 (see Figure 2). Use your BuckID or equivalent to hold the ball in starting position. The ‘downhill’ face of a

starting point snap-fit is the reference used for all AGT height and arc

measurements.

4. Remove the ‘holding’ object in the direction of travel to start the ball rolling,

and start the stopwatch at the same time.

5. Count the number of times the ball returns to the starting side of the apparatus

(number of cycles) and continue counting cycles and timing until the ball

finishes its last ‘definite’ cycle just before coming to rest.

6. Be sure to stop the timing as the ball finishes that ‘last’ cycle!

7. Record the number of cycles, and total time for those cycles to occur.

8. Repeat steps 4 through 8 to obtain 3 trials (runs) at the same starting position.

9. Make sure all results are recorded on the apparatus worksheet and on the

computer at your instructor’s station.

10. When collecting your data please leave the worksheet at the table for the

instructional staff to collect!

11. The instructional staff will collect the worksheets and e-mail the summarized

data to each student.

12. If lab time remaining is sufficient, read the data reduction and analysis section of

this procedure document. Ensure you understand what is required, and ask

questions of the instructional staff before leaving the lab. Generally, further data

processing will be done outside of lab class after raw data has been appropriately

shared amongst teams.

6

Lab 2 - Part 1: Worksheet A1 (Circular Arc Apparatus)

Note: Before you proceed to take readings, fill in the shaded cells by referring to the AGT of the respective apparatus

APPARATUS ID

Hrest =

Arc Radius =

Hsp =

Ssp =

NOTE: Units==mm & seconds

Group A

Trial #

1

2

3

Avg

Group D

Cycles Time

Group B

Trial #

1

2

3

Avg

Trial #

1

2

3

Avg

Group G

Cycles Time

Group E

Cycles Time

Trial #

1

2

3

Avg

Trial #

1

2

3

Avg

Cycles Time

Group H

Cycles Time

Trial #

1

2

3

Avg

Cycles Time

H1

Group C

Trial #

1

2

3

Avg

Group F

Cycles Time

Trial #

1

2

3

Avg

Group I

Cycles Time

NOTE: Use the same Hsp and Ssp values as the first group

7

Trial #

1

2

3

Avg

Cycles Time

Lab 2 - Part 1: Worksheet A2 (Circular Arc Apparatus)

Note: Before you proceed to take readings, fill in the shaded cells by referring to the AGT of the respective apparatus

APPARATUS ID

Hrest =

Arc Radius =

Hsp =

Ssp =

NOTE: Units==mm & seconds

Group A

Trial #

1

2

3

Avg

Group D

Cycles Time

Group B

Trial #

1

2

3

Avg

Cycles Time

Group E

Cycles Time

Group C

Trial #

1

2

3

Avg

Trial #

1

2

3

Avg

Group G

Trial #

1

2

3

Avg

Trial #

1

2

3

Avg

Cycles Time

Trial #

1

2

3

Avg

Cycles Time

Group I

Cycles Time

NOTE: Use the same Hsp and Ssp values as the first group

8

Cycles Time

Group H

Group F

Cycles Time

Trial #

1

2

3

Avg

Trial #

1

2

3

Avg

Cycles Time

LINEAR RAMP APPARATUS

The linear ramp is used to provide information allowing the calculation of the static

friction coefficient for the given ball type on the given rails. The rails are typical of

those used for the roller coaster designs. The tower assembly is used only as a way

to steady the hand of a team member who slowly moves an end of the ramp upward.

Note: The static friction coefficient is important for ramp design (regarding allowable

steepness before ball slippage occurs).

H1

L

Figure 3: Linear Ramp

9

(a) Straddle

(b) Left (higher than (a))

(c) Right (lower than (a))

Figure 4: Conjoined Ball-Set Staging on Ramp

Linear Ramp Test Procedure

1. Place the conjoined ball-pair on the ramp somewhere near the mid-point of the

ramp length, with the conjoined ball pair ‘straddling’ a snap-fit, and with the ramp

still on the table (see Figure 4(a)).

2. Slowly lift one end of the ramp until the conjoined pair just starts to move, and

hold that ramp position. Use the meter stick as a guide to help maintain a steady

position.

3. While one team member holds the ramp steady, have another team member

make and record measurements to allow later calculation of the elevation angle

(incline) of the ramp. Measure H1 from table top to ramp bottom-edge and the

length L of the ramp (see Figure 5). Use Worksheet B to note the values.

Figure 5: Measure H1 and L

4. Repeat steps 1 through 3 with the conjoined pair until three ‘runs’ at the same

starting point are obtained.

5. Repeat steps 1 through 4 but use a slightly different starting location of the

conjoined balls for each sequence. Since ‘straddling’ a snap-fit location was used

for the first, try a location on each side of a snap fit location. (see Figure 4 (b) and

(c)).

6. Again repeat steps 1 through 4 but use a slightly different starting location of the

conjoined balls for each sequence. If you used a location left of the original

‘straddling’ position, now use a position to the right and vice-versa.

7. Make sure all results are recorded on the apparatus worksheet and on the

computer at your instructor’s station.

Leave the worksheet at the table!

8. The instructional staff will collect the worksheets and e-mail the summarized

data to each student. .

10

9. If lab time allows, read the data reduction and analysis section of the procedure

document. The full data reduction and analysis is generally done outside of lab

class, but may be started during lab if all raw data has been obtained.

11

Lab 2 - Part 1: Worksheet B (Ramp Apparatus)

Apparatus ID:

Length (L):

GROUP A

Trial

1

Straddle

Straddle

2

3

Average

Left

1

2

3

Straddle

Left

Average

Right

Right

1

2

3

Straddle

Right

Average

GROUP C

Trial

1

Straddle

2

3

Average

1

Left

2

3

Average

1

Right

2

3

Average

Left

GROUP F

Trial

1

Straddle

2

3

Average

1

Left

2

3

Average

1

Right

2

3

Average

Within each team's measurements,

L must be a constant!

All measurements should be in millimeters

1

2

3

Average

1

2

3

Right

Average

H1

H1

1

2

3

Average

1

2

3

Average

1

2

3

1

2

3

GROUP H

Trial

H1

Average

1

2

3

1

2

3

Average

GROUP E

Trial

H1

2

3

Average

1

2

3

Right

Average

Left

Left

Average

GROUP B

Trial

H1

Average

1

2

3

Average

Average

Straddle

Straddle

2

3

Left

1

2

3

GROUP G

Trial

1

H1

Average

1

2

3

Average

Right

GROUP D

Trial

1

H1

1

2

3

Average

H1

H1

12

GROUP I

Trial

1

Straddle

2

3

Average

1

Left

2

3

Average

1

Right

2

3

Average

H1

Straddle

Avg All

H1

Left

Avg All

H1

Right

Avg All

H1

PART 2: Additional Energy Losses

A.

SETUP

1.

LOCATE the following PIECES and PARTS in the bin (the numbers in the

parenthesis indicate number of parts required).

I. Tower (1)

II. Tee (9)

III. Elbow (4)

IV. Drop Ear Elbow (5)

V. 6 in. pipe (6)

VI. 4 in. pipe (6)

VII. 3 in. pipe (4)

VIII. 2 in. pipe (3)

IX. 18 in. pipe (2)

X. 12 in. pipe (5)

XI. Nylon tubing (2) {to be used as track}

XII. Snap Fits (20)

XIII. Bolts and nuts (10)

XIV. Nylon straps (10)

2.

Construct the ramp and horizontal curve shown in figures 6 and 7 using the

parts exactly as shown. Use duct tape, if necessary, so that the nylon

straps fit snugly on the pipes.

13

Figure 6: RC Energy Losses - Part 2 support structure

14

Figure 7: RC Energy Losses – Part 2 support structure with track

15

3.

Try to release the ball from Release Point 1 (indicated in Figure 7). See if the

ball stays on the track, rolls smoothly, and doesn’t hit any snap-fits. Bank the

horizontal curve as needed to make the ball roll smoothly. Release the

ball from Release Point 1 a couple of times to verify that the ball travels

consistently till the end of the track.

4.

Measure the radius of the horizontal curve, RH and record in Lab 2 - Part 2:

Data Sheet.

Radius of the horizontal curve (RH): _____________ m.

5.

Attach sensors to the beginning and end of the horizontal curve respectively,

as shown in Figure 7.

6.

Insert one end of the telephone cable to the telephone jack of a sensor and

the other end to the telephone jack of the Arduino board. Repeat for the other

sensor. The telephone jacks on the Arduino board are labeled from 1-8. Use

the first two telephone jacks. The piano pins on the side of the Arduino board

should be pushed down to activate the sensors which are connected to

Arduino. Only push down the pins of the corresponding telephone jacks being

used.

7.

Connect the 9V power supply to the Arduino board.

8.

Once the Arduino is connected the alignment of red LED and photo transistor

on the sensors must be verified and the sensors must be checked. Press reset

to see this menu:

Figure 8: Arudino Display

Press B1 to align the sensors. A value of 0.4 volts or less is acceptable to continue.

If greater than 0.4, manually align the sensors and realign.

Press B2 to test the sensors. The Arduino will display “Brk Me” until the beam is

interrupted and will display “Good”. Verify that all the sensors are functioning

properly. Once these checks have been completed press B3 to record velocities.

16

The Arduino will record the velocity in meters per second and the time the coaster

ball takes to pass through the speed sensor beam in milliseconds. The time the

ball takes to pass through the sensor is measured by recording the leading edge

(LE) and trailing edge (TE) times.

B.

DATA COLLECTION

1.

Use the spreadsheet called Lab 2 – Part 2: Data Sheet below to record the

velocities measured in this lab.

2.

The next step has to be performed fairly quickly or you will receive a timeout

error message. Read the next step carefully before you proceed.

3.

Have one member of your team press B3 to “Get Velocities”. A second

member needs to release the ball from Release Point 1 a total number of

three times. This should generate six velocities and six sensor leading edge

and trailing edge times. Record the velocities and pulse times.

4.

Repeat steps 2-6 for release points 2, 3 and 4respectively.

****You will have to change the bank angles for the track between

release points to ensure that the ball travels as smoothly as possible to the

end of the track. This means the ball does not bounce or hit snap-fits and runs

very smoothly during its journey to the end of the track.

17

Lab 2 - Part 2: Data Sheet

Radius of the horizontal curve (R H) =

Release Point 1

No.

Sensor 1 Velocity

(m/s)

Release Point 2

Sensor 2 Velocity

(m/s)

No.

1

2

3

Average

Sensor 2 Velocity

(m/s)

1

2

3

Average

Release Point 3

No.

Sensor 1 Velocity

(m/s)

Sensor 1 Velocity

(m/s)

Release Point 4

Sensor 2 Velocity

(m/s)

No.

1

2

3

Average

1

2

3

Average

18

Sensor 1 Velocity

(m/s)

Sensor 2 Velocity

(m/s)

POST-LAB DATA ANALYSIS

PART 1: Static and Rolling Friction (use all groups’ data)

Make sure that you receive the excel file containing the group data from your

Instructor.

In the excel file, below the group data, you will see a calculation worksheet template.

You will use the group data and the appropriate formulae (discussed below) to

populate the calculation template. Use the data from all groups.

Make use of cell referencing feature in excel for accurate and efficient calculations.

You need to email an electronic copy of the completed calculation worksheet

template to the instructor within 2 days of the completion of the lab. Make sure to

name the file as Eng1182_Lab2_Group *.xls where * represents your group letter A,

B, C ... The instructor will then provide feedback.

Pay special attention to the units used in the calculations.

BALL PARAMETERS

Use the following parameters for the ball wherever applicable:

Geometric radius of the ball, r = 0.01272 m

Effective rolling radius of the ball on the track, r’ = 0.01018 m

Mass of the ball, m = 0.0097 Kg

Weight of the ball, W = 0.0951 N

UNITS TO BE USED IN DATA ANALYSIS

Use SI units to be consistent throughout the data analysis. Specifically, use the units as

mentioned below for the following quantities:

Length: meters

Speed: m/s

Acceleration: m/s2

If the collected data appears to be in units other than the above mentioned, make sure to

convert them to appropriate units before you proceed to analyze your data.

CIRCULAR ARC APPARATUS

The calculation steps given below will result in “energy loss per meter of travel”, Es which

will be used to calculate the coefficient “dE/ds”

dE/ds=overall average value of Es from all apparatuses and starting points.

19

Circular Arc Apparatus Data Reduction

Reducing data from the circular arc apparatus generally requires some knowledge of

simple harmonic motion. To make this data reduction reasonable, an assumption has

been made which results in a simple expression for the distance the ball travels. The

expression is:

S

where:

S

N

Ssp

4NSsp

2

is the total distance traveled (length units),

is the number of cycles the ball experienced and,

is the initial arc distance from starting point to resting point

(length units).

{This expression is only a crude approximation to the actual distance traveled, but is

sufficient for the comparison purposes of this lab. It assumes a linear decay in the

amplitude of oscillation. This assumption is simplifying for our case, but would not be a

good assumption for real-world engineering. The use of the above expression results

in estimates of distance traveled that are as much as 20% too large}.

1. Calculate the total distance, S, traveled by the ball

Spreadsheet tip:

a. It should be noticed that once all the cells in the “Circular Arc Worksheet” are

populated, then the corresponding Circular arc apparatus (in grey and red) in the

“Class Data & Calc. Temp” worksheet should also be populated.

b. Use the value of Ssp for one of the circular arcs and its computed average value

of N.

2. Calculate the average speed, Vavg of the ball.

V avg

where:

Vavg

S

t

S

t

is the average speed (m/s),

is total distance traveled (m),

is the time the ball was in motion (s).

Do not forget that the total distance travelled (i.e. S) in the spreadsheet is measured

in millimeters and time is in seconds. The calculated velocity should be in m/s.

3. Calculate the average rolling friction coefficient, μr,:

μr

Hsp Hrest

S

where:

Hsp is the height of the ball at the starting point (m).

Hrest is the height of the ball at its resting position (m).

4. Calculate the centripetal acceleration, ac:

20

ac

where:

R

Vavg

2

R

is the effective radius of the arc segment (m).

Remember that the radius is measured in mm in the spreadsheet whereas

acceleration should be in m/s2

5. Calculate the normalized centripetal acceleration, n:

n 1

where:

g

ac

g

is the gravitational constant (9.81 m/s2)

6. Adjust the rolling friction coefficient for normalized acceleration by:

μr c

μr

n

7. Calculate the energy loss per meter of travel, Es.

E s μ r cW

where:

W

is the weight of the ball (force units).

(Note that Es has units of force).

8. Repeat steps 1 through 7 for the other circular arc apparatus. Be aware of units

on values!

9. At this point, you should have final data values for both circular arc

apparatus.

10. Calculate a single overall average value of Es from both apparatus. Use this

single value as the dE/ds coefficient in the Roller Coaster Energy Analysis

spreadsheet.

21

LINEAR RAMP APPARATUS

The calculation steps given below will result in “maximum angle for a no-ball-slippage

condition”, (θc).

Slippage will occur when the inclined track sections of the roller coaster have inclination

angles greater than θc. More energy is lost when the ball slips instead of rolling ‘cleanly’.

Slippage can also cause unrepeatable results.

Ramp Apparatus Data Reduction

Using the averaged class data at each starting position:

1. Use geometry to calculate the incline angle (β) at which the conjoined ball-set just

started to move.

H1

L

β

Spreadsheet tip: For calculating β use the trigonometric identity sin-1 = (H1/L)

2. Calculate the static friction coefficient (μ0) and the maximum angle for a no-ballslippage condition (θc) :

0 tan( ) ,

3. where

β is the average incline angle

2

5 r '

θ c tan μ 0 1 ,

2 r

1

where, θc

r

r’

is the angle in radians (i.e., track slope) below which the ball will not

slip as it rolls.

is the geometric radius of the ball (see BALL PARAMETERS).

is the effective rolling radius of the ball on the track (see BALL

PARAMETERS).

This calculated θc that is in radians. It needs to be converted to

degrees by multiplying by the appropriate conversion factor

4. Average all θc angle data to obtain one final angle in degrees. Refer to this value

as you design incline sections of your roller coaster.

22

Slippage will occur when the translational acceleration of the ball is greater than

the rotational acceleration of the ball. Remember the value of θc as you design

inclined track sections. More energy is lost when the ball slips instead of rolling

‘cleanly’. Slippage can also cause unrepeatable results.

RANGE OF VALUES FOR ENERGY LOSS COEFFICIENTS

For reference purposes, the following table is provided to give an idea of the range of values of

the three coefficients.

Coefficients

Range

(dE/ds)

0.00045 – 0.00075

(dE/ds/dv)

0.001 – 0.002

(dE/ds/dNC)

0.010 – 0.0130

23

PART 2: Additional Energy Losses (use your own group’s data)

1. Calculation of energy losses

You obtained average inlet and exit speeds of the roller coaster ball with the help of the

sensors for different release points and configurations.

Calculate the energy loss experienced by the ball when it travels between sensor

1 and sensor 2 of the horizontal curve for each release point and configuration.

Summarize the results in a tabular format (Table 1). (The two sensors are located

at the same vertical height, so the energy loss can be estimated by calculating the

difference in the kinetic energies at the two sensor locations.)

For the specific case at hand (spherical ball rolling on a pair of cylindrical rails) the total

mechanical energy of the ball can be written as:

1 r 2

2 1

E m gH V

2

2

5

r

'

where

r is the geometric radius of the ball = 0.01272 m,

r’ is the effective rolling radius of the ball on the track = 0.01018 m

m is the mass of the ball = 0.0097 kg

Since the two sensors are at the same height, the change in mechanical energy (energy losses)

is given by

E Loss _ actual

1 1 r2

m(V V )

2

2

5

r

2

1

2

2

,

where V1 is the average inlet speed (Sensor 1)

V2 is the average exit speed (Sensor 2)

2. Plot ELoss_actual versus Inlet Velocity V1 for each release point and call it Plot 1. Your vertical

axis will be “energy loss”. Your horizontal axis will be “inlet velocity”.

(Use “scatter with data points connected by smoothed lines” option in Excel to plot

data). Label the axes and legend appropriately.

3. G-forces: G-forces in a given location of a horizontal loop are estimated by

mv2

RH

mg

v2

RH g

where m is the mass of the ball, RH is the radius of the horizontal curve, v is the velocity of

the ball at that given location and g is the acceleration due to gravity.

Estimate the average G-force in the horizontal partial loop by taking the average of the

G-forces at the inlet and exit of the horizontal curve for all release points

Average G force = [(Vin + Vout) /2]2 /(RH ×g)

24

Summarize the results in the form of Table 1 as shown below. Use the energy loss

values ELoss_actual calculated in step 1.

Plot ELoss_actual versus average G force. This is Plot 2.

Table 1 G-force and E_loss_actural

Release point Number

ELoss_actual (Joules)

Average G force

1

2

3

4

4. Comparison with respect to Excel Spreadsheet calculations: Recall that you used an Energy

Analysis spreadsheet for your initial roller coaster design calculations. The design

spreadsheet also gives an estimate of energy losses as indicated by Figure 9. Use the

design spreadsheet to calculate the energy losses in the horizontal partial loop of the lab 2

setup for all the release points and configurations. (Use the sensor 1 speed for ‘v1’ in the

Rev A 01/08/03

ROLLER

COASTER

ENERGY

2004: Theand

Ohio

State

spreadsheet.

You can

approximate

the ANALYSIS

horizontal curveCopyright

as a semi-circle

use

it’s University

Ball mass

0.0100

g

9.80

Ball geometric radius 0.01270

Ball rolling radius 0.01016

Mass Moment of Inertia, I 6.452E-07

h1

v1

s1

PE1

TKE1

RKE1

E1

kg

m/s^2

m

m

kg*m^2

-dE/ds

-dE/ds/dv

-dE/ds/dNC

Pos 1

0.455 m

0.000 m/s

0.000 m

0.04459

0.00000

0.00000

0.04459

J

J

J

J

Dh

Dv

dN

dC

E loss_1_to_2:

E

0.0000 J/m

0.0000 J*s/m^2

0.0000 J/m/g

For Loops

0.00

0.00

0.000

0.000

m

m

g

g

h2

v2

s2

Pos 2

0.000

2.332

1.000

PE2

TKE2

RKE2

E2

0.00000

0.02719

0.01699

0.04419

J >>>>>>

>>>>>>>>

0.04459 J

E

0.04419

^--------------------------- Same ??? Then OK ----------------------------------^

circumference for ‘s2’. ‘h1’ and ‘h2’ will both be equal to 0.19m. And then estimate ‘v2’).

Figure 9: Energy loss prediction by spreadsheet

Subtract the energy loss (ELoss_calc) you obtain from the Energy Analysis spreadsheet from

the corresponding energy loss (ELoss_actual) obtained in Table 1.

Call the subtracted value “ELoss_actual - ELoss_calc” (actual “minus” calc).

25

Summarize the results in the form of Table 2 as shown below. (Average G forces will

remain the same as calculated in step 3 above.

Insert one sample Energy loss spreadsheet (properly filled out) for one release

point/configuration. Then show a sample calculation ELoss_actual - ELoss_calc for this release

point/configuration.

Plot “ELoss_actual - ELoss_calc” versus average G-force obtained for each configuration (in the

same graph). This is Plot 3.

Table 2 Comparison of Actual and Calculated E_loss

Release

Point

1

2

3

4

ELoss_calc (J)

Average G Force

26

ELoss_actual - ELoss_calc (J)

DISCUSSION QUESTIONS

1. In your own words, briefly describe what is meant by the conservation of energy principle.

2. Communicate in your own words, your understanding of static friction and rolling friction.

3. Make observation about the static friction test. How much did results vary in regards to

different teams doing the same measurements? Why is static friction important to your roller

coaster design? What is the maximum track angle of inclination you should consider if you

wish to minimize energy loss due to slippage of the ball?

4. Explain with educated reasoning how each of the concepts learned in this lab exercise might

help you estimate the ball speed at a given point along the roller coaster track your team

designs.

5. What is the effect of velocity and G-forces on the energy losses in a horizontal curve?

6. How do the losses you observed compare with the energy loss predictions of the excel

spreadsheet as a function of release point?

7. Comment on what impact the additional energy losses create for your design.

Notes:

Refer to Memo grading guidelines for exact organization of the report and points breakdown.

Due:

At the beginning of next Lab

27

Energy Losses Lab Memo Grading Guidelines

Points

Worth

Content

Header Information

5 pts

Introduction

10 pts

1. Brief Introduction of objectives/ goals of the labs.

2. Introduction to contents of the report.

Rolling and Static Friction

8

2

60 pts

1. Show samples hand calculations for: (Use values from your group data) (Total - 10)

a. Circular arc apparatus: S , Vavg, μr, ac, n, μrc, Es

b. Linear Ramp: β, μ0, θc

10

( 1 point for each calculation)

This includes every calculation and all formulas you used to complete your calculation worksheet

template. Refer the reader to the page number where the respective raw data worksheet is

placed.

2. Circular arc apparatus observations & conclusions

There were 2 circular arc apparatus, each with a different radius. Using the values from

the calculation Worksheet, create a table (Table 1) summarizing the resultant average

rolling friction coefficients (μrc) values and the average energy loss values (Es) along

with the corresponding effective radii for the 2 arc apparatus. Plot (Figure 1) the average

rolling friction coefficient, μrc (vertical axis) versus the effective arc radius, R (horizontal

axis).

3.

4.

5.

6.

Similarly construct a table (Table 2) to summarize the rolling friction, μrc and average Vavg

values for each the two arc apparatus. Construct a graph (Figure 2) by plotting μrc versus

Vavg for the 2 different apparatus radii (in other words, plot μrc versus Vavg for all the

different arc radii in the same graph).

15

15

Discussion Question 1

Discussion Question 2

Discussion Question 3

Discussion Question 4

5

5

5

5

Supplementary Documents

20 pts

o

Email your INSTRUCTOR an electronic copy of the Completed Calculation Worksheet

Template that you used for data analysis. Make sure to name the file as

Eng1182_Lab2_Group *.xls where * represents you group letter A,B,C ...Also, make sure

to enter the correct formulae in the excel cells while completing the spreadsheets.

Additional Energy Losses

1. Completed Part 2 data sheet

2. Table 3: Create a table listing inlet velocity, exit velocity, and energy loss for each release

point (step 1, data analysis). Show sample calculations for energy losses for a combination of

release points

28

20

80 pts

10

10

Point

Value

3. Figure 3: ELoss_actual vs. Input Velocity for each release point.

4. Table 4: Create a table listing average G-Force and energy loss for each release point (step 3,

data analysis). Show sample calculations for avg G-force for a combination of release points.

Average G force = [(Vin + Vout) /2]2 /(RH ×g)

5. Figure 4: ELoss_actual vs. average G-force for each release point.

6. Table 5: Create a table listing energy loss calculation (ELoss_calc) from excel spreadsheet,

Average G-forces, and ELoss_actual - ELoss_calc for each release point (step 4, data analysis). .

7. Figure 5: ELoss_actual - ELoss_calc vs. average G-force for each release point.

8. Figure 6: Insert one sample Energy loss spreadsheet (properly filled out) for one release point

Then show a sample calculation ELoss_actual - ELoss_calc for this release point

9. Discussion Question 5

10. Discussion Question 6

11. Discussion Question 7

Conclusions

o Briefly state the goals achieved by undertaking this lab activity.

o Briefly mention any difficulties that you came across during this lab.

5

5

5

20 pts

15

5

Weekly Checklist & Lab Participation Agreement

5 pts

6

10

6

10

6

6

**Sample Calculations- Show correct formulae and substitute appropriate values to calculate the final

result.

29