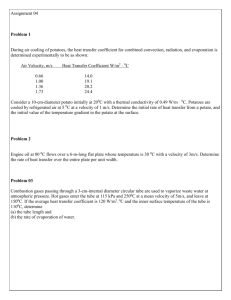

Tube-side coefficient

advertisement