D Powered Reentry Vehicle

advertisement

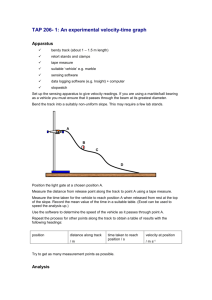

Powered Re-entry Vehicle David Lammers ASTE 527 Concept 13 December 2011 Why and What is Powered Re-entry? Take advantage of on orbit refueling ΔV burn to decrease re-entry velocity Light weight Lower heat of re-entry = no heavy heat shield tiles • Easier on passengers (lower decelerations) • Easier on vehicle = reusability • Unlimited cross range capability • • • • – Land anywhere on the Earth you desire Fuel Depot Game changing technology to utilize future on-orbit fuel depots Powered Re-entry Vehicle • Small vehicle – Lightweight – Decreases up and down propellant requirement • Designed for a small crew only – 3-6 astronauts • Horizontal landing – May incorporate air breathing/turboprop propulsion for in-atmosphere range extension PRV • Must be delivered to space – Ex. X-37 • X-37 architecture • Build on sub-orbital platform – Space Ship 2, Lynx, Super Mod, etc. • Low weight materials – Carbon composites – Less (or no)TPS Case Study: X-37 • • • • Phased design Designed for a 3.1 km/s ΔV and 270 days in orbit launch weight of ~ 5000 kg Upgraded X-37C design announced 2011 – 165-180% scale of X-37B – Carry up to 6 astronauts in modified cargo bay Reported Cost ($ in millions) • 1999: NASA 109, USAF 16, Boeing 67 • 2002: Boeing awarded additional 310 under SLI • Total of $500 million Case Study: Space Ship Two • • • Suborbital (~110km) Max velocity ~ Mach 3 (SS1) Increase drag through “feathering” – Highly stable – Low skin temperature • Allows use of light weight carbon composites without heat shield Velocity Profile of Shuttle Propellant Requirement • Uses Ideal Rocket Equation which neglects all forces other than thrust 9000 8000 "Final" Velocity (m/s) 7000 6000 Peak Heating Region 5000 4000 3000 5000 kg initial mass (X-37B) 2000 5000kg burnout mass 1000 1200kg burnout mass 0 0 5000 10000 15000 Propellant Mass (kg) 20000 25000 30000 Size Comparisons of X-37 and Shuttle • Shuttle loaded mass 381,600 kg (estimate) – 81,600 kg dry mass • X-37B loaded mass 4,990 kg – 2,600 kg dry mass (estimate) Reusability is Key • Low mechanical stress and low heat buildup on vehicle should lead to a highly reusable system • Need to keep turnaround costs down – Est. $450 million per shuttle launch – Ideally the craft could be reused quickly with almost zero cycle cost Multiple PRV’s • Economies of scale • More customers – Nations – Private industry – Individuals Credit: Buzz Aldrin Future Work • Feasibility – Would a system like this really work • Simulation comparing reentry velocity, drag, delta V, aerothermal simulation, etc. • Figure out maximum velocity that the “feathering” technique could be employed – Initial thought it needs to be done at the apex of a trajectory, thus a very low (almost zero) velocity References http://www.af.mil/information/factsheets/factsheet.asp?fsID=16639 http://www.protechcomposites.com/pages/High-Temp-Panels.html http://blogs.voanews.com/science-world/files/2011/09/iss.jpg http://scienceblogs.com/startswithabang/upload/2009/05/could_an_ast eroid_have_wiped_o/impact3.jpg http://spacesolarpower.info/wpcontent/uploads/2011/10/fotovoltaico_spaziale.jpg http://up-ship.com/blog/?p=639 http://buzzaldrin.com/space-vision/rocket_science/multi-crew-modules/ http://www.nasa.gov/centers/kennedy/about/information/shuttle_faq.h tml blogs.airspacemag.com/.../10/x37-still-aloft/ http://www.boeing.com/defense-space/space/hsfe_shuttle/facts.html Powered Re-entry Vehicle BACKUP SLIDES Reentry, as it is Now Shuttle – Mach 25 at 120 km – TPS = 8574 kg (30,000 tiles) • Includes all types of tiles FRSI, LRSI (FIB), HRSI, and RCC FRSI < 371 C FIB < 649 C HRSI < 1260 C RCC > 1260 C