Technology for Air Pollution Control

advertisement

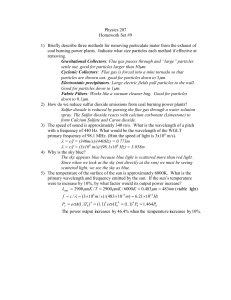

TECHNOLOGY FOR AIR POLLUTION CONTROL TECHNIQUES WITHOUT USING EMISSIONS CONTROL DEVICES Process Change Wind, Geothermal, Hydroelectric, or Solar Unit instead of Fossil fired Unit. Change in Fuel e.g. Use of Low Sulfur Fuel, instead of High Sulfur fuel. Good Operating Practices Good Housekeeping Maintenance Plant Shutdown COMMONLY USED METHODS FOR AIR POLLUTION CONTROL PARTICULATE Cyclones Electrostatic Precipitators Fabric Filter Wet Scrubbers GASES Adsorption Towers Thermal Incernation Catalytic Combustion SOx CONTROL GENERAL METHODS FOR CONTROL OF SO2 EMISSIONS Change to Low Sulfur Fuel Natural Gas Liquefied Natural Gas Low Sulfur Oil Low Sulfur Coal Use Desulfurized Coal and Oil Increase Effective Stack Height Build Tall Stacks Redistribution of Stack Gas Velocity Profile Modification of Plume Buoyancy GENERAL METHODS FOR CONTROL OF SO2 EMISSIONS (CONTD.) Use Flue Gas Desulfurization Systems Use Alternative Energy Sources, such as Hydro-Power or Nuclear-Power FLUE GAS DESULFURIZATION SO2 scrubbing, or Flue Gas Desulfurization processes can be classified as: Throwaway or Regenerative, depending upon whether the recovered sulfur is discarded or recycled. Wet or Dry, depending upon whether the scrubber is a liquid or a solid. Flue Gas Desulfurization Processes The major flue gas desulfurization ( FGD ), processes are : Limestone Scrubbing Lime Scrubbing Dual Alkali Processes Lime Spray Drying Wellman-Lord Process LIMESTONE SCRUBBING Limestone slurry is sprayed on the incoming flue gas. The sulfur dioxide gets absorbed The limestone and the sulfur dioxide react as follows : CaCO3 + H2O + 2SO2 ----> Ca+2 + 2HSO3-+ CO2 CaCO3 + 2HSO3-+ Ca+2 ----> 2CaSO3 + CO2 + H2O LIME SCRUBBING The equipment and the processes are similar to those in limestone scrubbing Lime Scrubbing offers better utilization of the reagent. The operation is more flexible. The major disadvantage is the high cost of lime compared to limestone. The reactions occurring during lime scrubbing are : CaO + H2O -----> Ca(OH)2 SO2 + H2O <----> H2SO3 H2SO3 + Ca(OH)2 -----> CaSO3.2 H2O CaSO3.2 H2O + (1/2)O2 -----> CaSO4.2 H2O DUAL ALKALI SYSTEM Lime and Limestone scrubbing lead to deposits inside spray tower. The deposits can lead to plugging of the nozzles through which the scrubbing slurry is sprayed. The Dual Alkali system uses two regents to remove the sulfur dioxide. Sodium sulfite / Sodium hydroxide are used for the absorption of sulfur dioxide inside the spray chamber. The resulting sodium salts are soluble in water,so no deposits are formed. The spray water is treated with lime or limestone, along with makeup sodium hydroxide or sodium carbonate. The sulfite / sulfate ions are precipitated, and the sodium hydroxide is regenerated. LIME – SPRAY DRYING Lime Slurry is sprayed into the chamber The sulfur dioxide is absorbed by the slurry The liquid-to-gas ratio is maintained such that the spray dries before it reaches the bottom of the chamber The dry solids are carried out with the gas, and are collected in fabric filtration unit This system needs lower maintenance, lower capital costs, and lower energy usage WELLMAN – LORD PROCESS This process consists of the following subprocesses: Flue gas pre-treatment. Sulfur dioxide absorption by sodium sulfite Purge treatment Sodium sulfite regeneration. The concentrated sulfur dioxide stream is processed to a marketable product. The flue gas is pre - treated to remove the particulate. The sodium sulfite neutralizes the sulfur dioxide : Na2SO3 + SO2 + H2O -----> 2NaHSO3 WELLMAN – LORD PROCESS (CONTD.) Some of the Na2SO3 reacts with O2 and the SO3 present in the flue gas to form Na2SO4 and NaHSO3. Sodium sulfate does not help in the removal of sulfur dioxide, and is removed. Part of the bisulfate stream is chilled to precipitate the remaining bisulfate. The remaining bisulfate stream is evaporated to release the sulfur dioxide, and regenerate the bisulfite. NOX CONTROL BACKGROUND ON NITROGEN OXIDES There are seven known oxides of nitrogen : NO NO2 NO3 N2O N2O3 N2O4 N2O5 NO and NO2 are the most common of the seven oxides listed above. NOx released from stationary sources is of two types GENERAL METHODS FOR CONTROL OF NOX EMISSIONS NOx control can be achieved by: Fuel Denitrogenation Combustion Modification Modification of operating conditions Tail-end control equipment Selective Catalytic Reduction Selective Non - Catalytic Reduction Electron Beam Radiation Staged Combustion FUEL DENITROGENATION o One approach of fuel denitrogenation is to remove a large part of the nitrogen contained in the fuels. Nitrogen is removed from liquid fuels by mixing the fuels with hydrogen gas, heating the mixture and using a catalyst to cause nitrogen in the fuel and gaseous hydrogen to unite. This produces ammonia and cleaner fuel. This technology can reduce the nitrogen contained in both naturally occurring and synthetic fuels. COMBUSTION MODIFICATION Combustion control uses one of the following strategies: Reduce peak temperatures of the flame zone. The methods are : increase the rate of flame cooling decrease the adiabatic flame temperature by dilution Reduce residence time in the flame zone. For this we, change the shape of the flame zone Reduce Oxygen concentration in the flame one. This can be accomplished by: decreasing the excess air controlled mixing of fuel and air using a fuel rich primary flame zone MODIFICATION OF OPERATING CONDITIONS The operating conditions can be modified to achieve significant reductions in the rate of thermal NOx production. the various methods are: Low-excess firing Off-stoichiometric combustion ( staged combustion ) Flue gas recirculation Reduced air preheat Reduced firing rates Water Injection TAIL-END CONTROL PROCESSES o Combustion modification and modification of operating conditions provide significant reductions in NOx, but not enough to meet regulations. For further reduction in emissions, tail-end control equipment is required. Some of the control processes are: Selective Catalytic Reduction Selective Non-catalytic Reduction Electron Beam Radiation Staged Combustion SELECTIVE CATALYTIC REDUCTION (SCR) In this process, the nitrogen oxides in the flue gases are reduced to nitrogen During this process, only the NOx species are reduced NH3 is used as a reducing gas The catalyst is a combination of titanium and vanadium oxides. The reactions are given below : 4 NO + 4 NH3 + O2 -----> 4N2 + 6H2O 2NO2 + 4 NH3+ O2 -----> 3N2 + 6H2O Selective catalytic reduction catalyst is best at around 300 too 400 oC. Typical efficiencies are around 80 % ELECTRON BEAM RADIATION This treatment process is under development, and is not widely used. Work is underway to determine the feasibility of electron beam radiation for neutralizing hazardous wastes and air toxics. Irradiation of flue gases containing NOx or SOx produce nitrate and sulfate ions. The addition of water and ammonia produces NH4NO3, and (NH4)2SO4 The solids are removed from the gas, and are sold as fertilizers. STAGED COMBUSTION PRINCIPLE Initially, less air is supplied to bring about incomplete combustion Nitrogen is not oxidized. Carbon particles and CO are released. In the second stage, more air is supplied to complete the combustion of carbon and carbon monoxide. 30% to 50% reductions in NOx emissions are achieved. CARBON MONOXIDE CONTROL FORMATION OF CARBON MONOXIDE Due to insufficient oxygen Factors affecting Carbon monoxide formation: Fuel-air ratio Degree of mixing Temperature GENERAL METHODS FOR CONTROL OF CO EMISSIONS Control carbon monoxide formation. Note : CO & NOx control strategies are in conflict. Stationary Sources Proper Design Installation Operation Maintenance Process Industries Burn in furnaces or waste heat boilers. CARBON DIOXIDE CONTROL SOURCES OF CARBON DIOXIDE Human-Related Sources Combustion of fossil fuels: Coal, Oil, and Natural Gas in power plants, automobiles, and industrial facilities Use of petroleum-based products Industrial processes: Iron and steel production, cement, lime, and aluminum manufactures Natural Sources Volcanic eruptions Ocean-atmosphere exchange Plant photosynthesis SOURCES OF CO2 EMISSIONS IN THE U.S. (x-axis units are teragrams of CO2 equivalent) Source: USEPA CO2 EMISSIONS FROM FOSSIL FUEL COMBUSTION BY SECTOR AND FUEL TYPE (y-axis units are teragrams of CO2 equivalent) Source: USEPA GENERAL METHODS FOR CONTROL OF CO2 EMISSIONS Reducing energy consumption, increasing the efficiency of energy conversion Switching to less carbon intensive fuels Increasing the use of renewable sources Sequestering CO2 through biological, chemical, or physical processes CONTROL OF MERCURY EMISSIONS MERCURY EMISSIONS Mercury exists in trace amounts in Fossil fuels such as Coal, Oil, and Natural Gas Vegetation Waste products Mercury is released to the atmosphere through combustion or natural processes It creates both human and environmental risks Fish consumption is the primary pathway for human and wildlife exposure United states is the first country in the world to regulate mercury emissions from coal-fired power plants (March 15, 2005). Types of Sources Source: Seingeur, 2004 and Mason and Sheu, 2002. Worldwide Distribution of Emissions Source: Presentation by J. Pacyna and J. Munthe at mercury workshop in Brussels, March 29-30, 2004 CONTROL TECHNOLOGIES FOR MERCURY EMISSIONS Currently installed control devices for SO2, NOX, and particulates, in a power plant, remove some of the mercury before releasing from the stack Activated Carbon Injection: Particles of activated carbon are injected into the exit gas flow, downstream of the boiler. The mercury attaches to the carbon particles and is removed in a particle control device Thief process for the removal of mercury from flue gas: It is a process which extracts partially burned coal from a pulverized coalfired combustor using a suction pipe, or "thief," and injects the resulting sorbent into the flue gas to capture the mercury. PARTICULATE MATTER CONTROL GENERAL METHODS FOR CONTROL OF PARTICULATE EMISSIONS Five Basic Types of Dust Collectors : Gravity and Momentum collectors Settling chambers, louvers, baffle chambers Centrifugal Collectors Cyclones Mechanical centrifugal collectors Fabric Filters Baghouses Fabric collectors GENERAL METHODS FOR CONTROL OF PARTICULATE EMISSIONS (CONTD.) Electrostatic Precipitators Tubular Plate Wet Dry Wet Collectors Spray towers Impingement scrubbers Wet cyclones Peaked towers Mobile bed scrubbers PARTICULATE COLLECTION MECHANISM Gravity Settling Centrifugal Impaction Inertial Impaction Direct Interception Diffusion Electrostatic Effects INDUSTRIAL SOURCES OF PARTICULATE EMISSIONS Iron & Steel Mills, the blast furnaces, steel making furnaces. Petroleum Refineries, the catalyst regenerators, air-blown asphalt stills, and sludge burners. Portland cement industry Asphalt batching plants Production of sulfuric acid Production of phosphoric acid Soap and Synthetic detergent manufacturing Glass & glass fiber industry Instant coffee plants EFFECTS OF PARTICULATE EMISSIONS Primary Effects • Reduction of visibility • • • • • size distribution and refractive index of the particles direct absorption of light by particles direct light scattering by particles 150 micro g / m3 concentration ~ average visibility of 5 miles ( satisfactory for air and ground transportation ) Soiling of nuisance • • • increase cost of building maintenance, cleaning of furnishings, and households threshold limit is 200 - 250 micro g / m3 ( dust ) levels of 400 - 500 micro g / m3 considered as nuisance CYCLONES Principle • The particles are removed by the application of a centrifugal force. The polluted gas stream is forced into a vortex. the motion of the gas exerts a centrifugal force on the particles, and they get deposited on the inner surface of the cyclones Overall collection η Ci Co inlet concentration outlet concentration CYCLONES (CONTD.) Construction and Operation The gas enters through the inlet, and is forced into a spiral. • At the bottom, the gas reverses direction and flows upwards. • To prevent particles in the incoming stream from contaminating the clean gas, a vortex finder is provided to separate them. the cleaned gas flows out through the vortex finder. CYCLONES (CONTD.) Advantages of Cyclones • Cyclones have a lost capital cost • Reasonable high efficiency for specially designed cyclones. • They can be used under almost any operating condition. • Cyclones can be constructed of a wide variety of materials. • There are no moving parts, so there are no maintenance requirements. Disadvantages of Cyclones • They can be used for small particles • High pressure drops contribute to increased costs of operation. FABRIC FILTERS Principle The filters retain particles larger than the mesh size Air and most of the smaller particles flow through. Some of the smaller particles are retained due to interception and diffusion. The retained particles cause a reduction in the mesh size. The primary collection is on the layer of previously deposited particles. DESIGN OF FABRIC FILTERS The equation for fabric filters is based on Darcy’s law for flow through porous media. Fabric filtration can be represented by the following equation: S = Ke + Ksw Where, S = filter drag, N-min/m3 Ke = extrapolated clean filter drag, N-min/m3 Ks = slope constant. Varies with the dust, gas and fabric, N-min/kg-m W= Areal dust density = LVt, where L = dust loading (g/m3), V = velocity (m/s) Both Ke and Ks are determined empirically from pilot tests. Fabric Filters ΔP Total pressure drop Δ Pf Pressure drop due to the fabric Δ Pp Pressure drop due to the particulate layer Δ Ps Pressure drop due to the bag house structure ADVANTAGES OF FABRIC FILTERS Very high collection efficiency They can operate over a wide range of volumetric flow rates The pressure drops are reasonably low. Fabric Filter houses are modular in design, and can be pre-assembled at the factory FABRIC FILTERS (CONTD.) Disadvantages of Fabric Filters Fabric Filters require a large floor area. The fabric is damaged at high temperature. Ordinary fabrics cannot handle corrosive gases. Fabric Filters cannot handle moist gas streams A fabric filtration unit is a potential fire hazard Darcy’s equation ΔPf Pressure drop N/m2 ΔPp Pressure drop N/m2 Df Depth of filter in the direction of flow (m) Dp Depth of particulate layer in the direction of flow (m) μ Gas viscosity kg/m-s V superficial filtering velocity m/min Kf, Kp Permeability (filter & particulate layer m2) 60 Conversion factor δ/min V = Q/A Q volumetric gas flow rate m3/min A cloth area m2 Dust Layer L t ρL Dust loading kg/m3 time of operation min Bulk density of the particulate layer kg/m3 ΔP = ΔPf + ΔPp Filter Drag S = ΔP/V Areal dust density W = LVt S= k1+k2W ELECTROSTATIC PRECIPITATOR Principle The particles in a polluted gas stream are charged by passing them through an electric field. The charged particles are led through collector plates The collector plates carry charges opposite to that on the particles The particles are attracted to these collector plates and are thus removed from the gas steam Construction and Operation of Electrostatic Precipitator Charging Electrodes in the form of thin wires are placed in the path of the influent gas. The charging electrodes generate a strong electric field, which charges the particles as they flow through it. The collector plates get deposited with the particles. the particles are occasionally removed either by rapping or by washing the collector plates. DESIGN OF ELECTROSTATIC PRECIPITATORS The efficiency of removal of particles by an Electrostatic Precipitator is given by η = fractional collection efficiency w = drift velocity, m/min. A = available collection area, m2 Q = volumetric flow rate m3/min MIGRATION VELOCITY Where, q = charge (columbos) Ep = collection field intensity (volts/m) r = particle radius (m) μ = dynamic viscosity of gas (Pa-S) c = cunningham correction factor Cunningham correction factor where, T = absolute temperature (°k) dp = diameter of particle (μm) ELECTROSTATIC PRECIPITATOR (CONTD.) Advantages of Electrostatic Precipitators Electrostatic precipitators are capable very high efficiency, generally of the order of 99.5-99.9%. Since the electrostatic precipitators act on the particles and not on the air, they can handle higher loads with lower pressure drops. They can operate at higher temperatures. The operating costs are generally low. Disadvantages of Electrostatic Precipitators The initial capital costs are high. Although they can be designed for a variety of operating conditions, they are not very flexible to changes in the operating conditions, once installed. Particulate with high resistivity may go uncollected. WET SCRUBBERS Principle Wet scrubbers are used for removal of particles which have a diameter of the order of 0.2 mm or higher. Wet scrubbers work by spraying a stream of fine liquid droplets on the incoming stream. The droplets capture the particles The liquid is subsequently removed for treatment. Construction and Operation A wet scrubber consists of a rectangular or circular chamber in which nozzles are mounted. The nozzles spray a stream of droplets on the incoming gas stream The droplets contact the particulate matter, and the particles get sorbed. The droplet size has to be optimized. WET SCRUBBERS (CONTD.) o Construction and Operation (contd.) Smaller droplets provide better cleaning, but are more difficult to remove from the cleaned stream. The polluted spray is collected. Particles are settled out or otherwise removed from the liquid. The liquid is recycled. Wet scrubbers are also used for the removal of gases from the air streams. SCRUBBER Efficiency where, k = Scrubber coefficient (m3 of gas/ m3 of liquid) R = Liquid-to-gas flow rate (QL/QG) ψ = internal impaction parameter Internal impaction parameter where, c = cunningham correction factor ρp = particle density (kg/m3) Vg = speed of gas at throat (m/sec) dp = diameter of particle (m) dd = diameter of droplet (m) μ = dynamic viscosity of gas, (Pa-S) WET SCRUBBERS (CONTD.) Advantages of Wet Scrubbers Wet Scrubbers can handle incoming streams at high temperature, thus removing the need for temperature control equipment. Wet scrubbers can handle high particle loading. Loading fluctuations do not affect the removal efficiency. They can handle explosive gases with little risk. Gas adsorption and dust collection are handled in one unit. Corrosive gases and dusts are neutralized. Disadvantages of Wet Scrubbers High potential for corrosive problems Effluent scrubbing liquid poses a water pollution problem. CYCLONE SPRAY CHAMBERS These scrubbers combine a cyclone with a spray nozzle. The added centrifugal force permits good separation of the droplets, hence a smaller droplet size can be used. Cyclone spray chambers provide up to 95% removal of particles > 5 micron. ORIFICE SCRUBBERS The gas is impacted onto a layer of the scrubbing liquid. The gas passes through the liquid, thus removing almost all the particulate matter, and a large portion of the probable gases. After coming out of the liquid, the gas is passed through baffles to remove the liquid droplets. IMPINGEMENT SCRUBBERS In Impingement scrubbers, the gas impacts a layer of liquid/froth through a perforated tray. Passing through this layer removes the particulate matter. The wet gas stream is then passed through a mist collector. VENTURI SCRUBBERS The dirty gas is led in to the chamber at high inlet velocities. At the inlet throat, liquid at low pressure is added to the gas stream This increases the relative velocity between the gas and the droplets, thus increasing the efficiency of removal. Efficiencies of the range of 95% for particles larger than 0.2 mm have been obtained. VENTURI SCRUBBER Absolute Pressure Drop Δp = pressure drop ( cm of water) ug = gas velocity (cm/s) Qt = liquid volume flow rate Qg = gas volume flow rate HYDROCARBON CONTROL GENERAL METHODS FOR CONTROL OF HYDROCARBON EMISSIONS Incineration or after burning Direct flame incineration Thermal incineration Catalytic incineration VOC INCINERATORS Principle VOC incinerators thermally oxidize the effluent stream, in the presence of excess air. The complete oxidation of the VOC results in the formation of carbon monoxide and water. The reaction proceeds as follows: CxHy + ( x + y/4 ) O2 x CO2 + (y/2) H2O Operation The most important parameters in the design and operation of an incineration system are what are called the ' three T's ' Temperature, Turbulence, and residence Time. VOC INCINERATORS (CONTD.) Temperature o Timing o The reaction kinetics are very sensitive to temperature The higher the temperature, the faster the reaction A certain time has to be provided for the reaction to proceed Turbulence Turbulence promotes mixing between the VOC's and oxygen Proper mixing helps the reaction to proceed to completion in the given time. VOC INCINERATORS (CONTD.) The various methods for incineration are: Elevated fires, for concentrated streams Direct thermal oxidation, for dilute streams Catalytic oxidation, for dilute streams. Xi volume of i component in the mixture Xm volume of mixture LELi LEL of i component GASES AIR POLLUTION CONTROL FOR GASES Adsorption Towers Thermal Incernation Catalytic Combustion ADSORPTION TOWERS Principle Adsorption towers use adsorbents to remove the impurities from the gas stream. The impurities bind either physically or chemically to the adsorbing material. The impurities can be recovered by regenerating the adsorbent. Adsorption towers can remove low concentrations of impurities from the flue gas stream. ADSORPTION TOWERS (CONTD.) Construction and Operation Adsorption towers consist of cylinders packed with the adsorbent. The adsorbent is supported on a heavy screen Since adsorption is temperature dependent, the flue gas is temperature conditioned. Vapor monitors are provided to detect for large concentrations in the effluent. Large concentrations of the pollutant in the effluent indicate that the adsorbent needs to be regenerated. Advantages of Adsorption Towers Very low concentrations of pollutants can be removed. Energy consumption is low. Do not need much maintenance. Economically valuable material can be recovered during regeneration. ADSORPTION TOWERS (CONTD.) Disadvantages of adsorption Towers Operation is not continuous. They can only be used for specific pollutants. Extensive temperature pre-conditioning equipment to be installed. Despite regeneration, the capacity of the adsorbent decreases with use. INITIAL PLUME RADIUS Initial Standard Deviation: Where, M = mass of liquid ρ = density of the plume σ = R/2.15 Adjustment – 1 where, w = initial width of the plume h = initial width of the plume Adjustment -2 where, H = length scale of the spill PROBLEM Estimate the net cloth area for a shaker bag house that must filter 40,000 cfm of air with 10 grams of flour dust per cubic foot of air. Also specify the number of components to be used and calculate the total number of bags required if each bag is 8 feet long and 0.5 feet in diameter. The maximum filtering velocity for flour dust is 2.5 ft/min. SOLUTION Step 1: Calculate total area and number of components required. A = Q/V Step 2: Calculate the area of each bag. A = Π(d)l Step 3: Calculate the total number of bags required. Number of bags required = Total area / Area per bag = 1270 bags