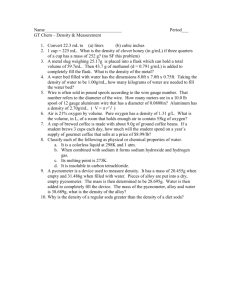

Distillation Column

advertisement

Distillation Column By Jesse Reeves Outline Where we are, where we want to be. How to get there. What we used and what we got. The trouble. The model. What we have 12 tray bubble-cap distillation column Isoproply alcohol water separation What we want Same distillation column Ethanol water separation How to get there Operate column at total reflux Determine stage efficiency Model the column in Aspen Compare Aspen model to real IPA separation results Apply the Aspen model to an Ethanol separation Theory to get there Equilibrium curve 1, 2 x1 y1 1 x1 ( 1, 2 1) Rectifying operating line Ln D y n1 xn xD Vn1 Vn1 Stripping operating line y m 1 L B x m xb V V Murphree-vapor efficiency E mv y i , n 1 y i , n y i , n 1 y i*, n Theory in a graph Generic Equilibrium Curve mole fraction of the light key component in vapor 1 0.8 0.6 0.4 0.2 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 mole fraction of the light component in liqu 0.9 1 Total Condenser The Column Stage 2 Stage 3 Distillation Collumn Stage 4 Stage 5 Stage 6 Stage 7 Stage 8 Stage 9 Stage 10 Stage 11 Stage 12 Reboiler Feed Tank Pump The Data Calibration Stage State 2 Liquid 3 Method Mass%IPA Error y* Mass% Ave Error Emv eq Error Pycnometer 83.2014 2.7145 85.0 2.5 Liquid Pycnometer 81.4879 2.9938 84.0 2.5 68.2106 192.6003 4 Liquid Pycnometer 78.4166 2.6494 83.0 2.5 67.0089 102.1962 5 Liquid Pycnometer 81.6113 2.7021 84.0 2.5 -133.7437 -259.9631 6 Liquid Pycnometer 77.0589 2.5954 82.0 2.5 92.1339 101.3146 7 Liquid Pycnometer 54.8630 2.1294 79.0 2.5 91.9579 18.7079 8 Liquid Pycnometer 53.5125 2.1461 79.0 2.5 5.2986 11.8814 9 Liquid Pycnometer 23.9760 1.6605 75.0 2.5 57.8874 6.3146 10 Liquid RI 4.8889 0.5748 55.0 2.5 38.0896 4.0122 11 Liquid RI 1.7778 0.5691 35.0 2.5 9.3645 2.5398 12 Liquid RI 5.5556 0.5752 60.0 2.5 -6.9388 -1.5218 The Trouble 120 S 2 2 2 2 2 100 S 2 2 2 2 2 2 S 2 2 2 2 2 80 60 S 2 2 2 2 2 40 20 0 16:19:12 16:33:36 16:48:00 17:02:24 17:16:48 17:31:12 17:45:36 S 2 2 2 2 2 2 S 2 2 2 The IPA separation 1 Y-x for WATER/ETHAN-01 0.2 Vapor Massfrac ETHAN-01 0.4 0.6 0.8 12.696 psi 0 0.2 0.4 0.6 Liquid Massfrac ETHAN-01 0.8 1 The ETOH separation 1 Y-x for WATER/ETHAN-01 0.2 Vapor Massfrac ETHAN-01 0.4 0.6 0.8 12.696 psi 0 0.2 0.4 0.6 Liquid Massfrac ETHAN-01 0.8 1 The model The IPA Aspen model -4.7% at the top +8.4% at the bottom The three important stages 7, 9, and 10 Murphreevapor efficiencies were 91.9+18.7%, 57.9+6.3%, 38.4+4.0% Overall column efficiency 8.3% Stage efficiency did not matter The Aspen model for ETOH Max flow rate: 2.13 GPM Steam flow rate: 1.67 kg/min Condenser heat duty: -1739 kJ/min Feed composition: 2.5 wt% ETOH Distillate composition: 40 wt% ETOH ETOH recovery: 99.4% Recomendations Replace the automatic control valve for the steam flow to the reboiler. Replace the leaky manual steam valve. Refine the ETOH model with steady state data. Special thanks to team-J Jaron Stanley: Team Leader James Gardner: Operator Jesse Reeves: Team player References Seader, J. D., Henley, Ernest J., Separation Process Principles, John Wiley & Sons, Inc. pp. 44, 301, 358-397 (1998). Distillation Column Manual, unpublished printed notes, Univ. of Utah, Salt Lake City, Utah 1997. Questions ?