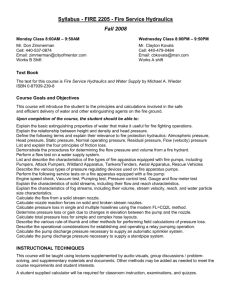

Pumping Apparatus Driver/Operator

advertisement

Pumping Apparatus Driver/Operator — Lesson 16 Pumping Apparatus Driver/Operator Handbook, 2nd Edition Chapter 16 — Apparatus Testing Learning Objectives 1. Select facts about various preservice tests. 2. List the minimum pumper service tests required by NPFA 1911. 3. Select facts about the site considerations for pumper service tests. (Continued) Pumping Apparatus Driver/Operator 16–1 Learning Objectives 4. State the equation for determining the correct pump discharge pressure for pump service tests. 5. Calculate corrected net pump discharge pressure. 6. List equipment needed to perform pumper (Continued) service tests. Pumping Apparatus Driver/Operator 16–2 Learning Objectives 7. List equipment recommended, but not required, to perform pumper service tests. 8. State the safety precautions to be followed when performing fire pump service testing. 9. Perform an engine speed service test. (Continued) Pumping Apparatus Driver/Operator 16–3 Learning Objectives 10. Perform a vacuum service test. 11. Perform a hard intake hose service test. 12. Prepare the pumper and perform a pumper service test. (Continued) Pumping Apparatus Driver/Operator 16–4 Learning Objectives 13. Perform a pressure control service test. 14. Perform discharge gauge and flowmeter operational service tests. 15. Perform a tank-to-pump flow service test. (Continued) Pumping Apparatus Driver/Operator 16–5 Learning Objectives 16. Select facts about reviewing test results. 17. List causes of problems that may occur during service testing. 18. Perform foam proportioning equipment service tests. Pumping Apparatus Driver/Operator 16–6 Manufacturer’s Tests • If the requirements of NFPA 1901 are included in the apparatus bid specifications, the manufacturer is required to perform two specific tests in addition to the pump certification tests discussed later. These two tests are the road test and the hydrostatic test. Pumping Apparatus Driver/Operator 16–7 Road Tests • Road tests must be conducted on the fire apparatus after its construction is complete. • The apparatus should be fully loaded in the same manner as it would be once in service. (Continued) Pumping Apparatus Driver/Operator 16–8 Road Tests • Road tests should be conducted in a location and manner that will not violate any applicable traffic laws or motor vehicle codes. • The test surface should be a flat, dry, paved road surface that is in good condition. (Continued) Pumping Apparatus Driver/Operator 16–9 Road Tests • At a minimum: – The apparatus must accelerate to 35 mph (56 km/h) from a standing start within 25 seconds. This test must consist of two runs, in opposite directions, over the same surface. – The apparatus must achieve a minimum top speed of 50 mph (80 km/h). This requirement may be dropped for specialized wildland apparatus not designed to operate on public roadways. (Continued) Pumping Apparatus Driver/Operator 16–10 Road Tests • At a minimum: – The apparatus must come to a full stop from 20 mph (32 km/h) within 35 feet (10.7 m). – The apparatus parking brake must conform to the specifications listed by the braking system manufacturer. • Beyond minimums, road tests are specific to the department taking delivery. Pumping Apparatus Driver/Operator 16–11 Hydrostatic Tests • The hydrostatic tests determine whether the pump and pump piping can withstand pressures normally encountered during fire fighting operations. • Pumps are tested hydrostatically at 250 psi (1 725 kPa) for three minutes. (Continued) Pumping Apparatus Driver/Operator 16–12 Hydrostatic Tests • The tank fill line, tank-to-pump line, and bypass line valves should be closed during this test. • Discharged valves should be opened and capped. (Continued) Pumping Apparatus Driver/Operator 16–13 Hydrostatic Tests • Intake valves should be closed and/or capped. • The test pressure should be maintained on the system for a minimum of three minutes without the failure of any component of the system. Pumping Apparatus Driver/Operator 16–14 Pump Certification Tests • Pump certification tests are performed to make sure that the fire pump system operates in the manner for which it was designed after the pump and components are installed on the apparatus chassis. • These tests must be conducted by an independent testing organization, such as (Continued) Underwriters Laboratories. Pumping Apparatus Driver/Operator 16–15 Pump Certification Tests • These tests are conducted either at the manufacturer’s plant or at the fire department after delivery. • These tests assure both the fire department and the insurance companies that the apparatus will perform as expected after being placed into service. (Continued) Pumping Apparatus Driver/Operator 16–16 Pump Certification Tests • The results of these tests are required to be stamped into a plate that is affixed to the pump panel of the apparatus. • These tests must be required in the apparatus bid specifications, either by referencing NFPA 1901 or by specific wording. (Continued) Pumping Apparatus Driver/Operator 16–17 Pump Certification Tests • NFPA 1901 requires the following pump certification tests for apparatus that are equipped with a 750 gpm (3 000 L/min) or larger fire pump: – Pumping test – Pumping engine overload test – Pressure control system test – Priming device test (Continued) Pumping Apparatus Driver/Operator 16–18 Pump Certification Tests • NFPA 1901 requires the following pump certification tests for apparatus that are equipped with a 750 gpm (3 000 L/min) or larger fire pump (continued): – Vacuum test – Water tank-to-pump flow test – Internal intake pressure relief valve test (if so equipped) (Continued) Pumping Apparatus Driver/Operator 16–19 Pump Certification Tests • Apparatus equipped with a fire pump that has a rated capacity of less than 750 gpm (3 000 L/min) are required to undergo the same certification tests, with the exception of the pumping engine overload test. Pumping Apparatus Driver/Operator 16–20 Acceptance Testing • These tests are conducted to assure the purchaser that the apparatus meets bid specifications at the time of delivery. • A representative of the manufacturer is present during testing. (Continued) Pumping Apparatus Driver/Operator 16–21 Acceptance Testing • The types of tests and test criteria vary widely with local jurisdiction preference and conditions. • These tests should include another pump test, even if a certification test was performed at the factory. (Continued) Pumping Apparatus Driver/Operator 16–22 Acceptance Testing • If the apparatus fails to perform according to the requirements detailed in the bid specifications, it should be rejected. Pumping Apparatus Driver/Operator 16–23 Minimum Pump Service Tests Required by NFPA 1911 • Engine speed check • Priming device tests • Vacuum test • Pumping test • Overload test (Continued) Pumping Apparatus Driver/Operator 16–24 Minimum Pump Service Tests Required by NFPA 1911 • Pressure control test • Gauge and flowmeter test • Tank-to-pump flow rate test • Internal intake pressure relief valve test (if so equipped) Pumping Apparatus Driver/Operator 16–25 Site Considerations for Pumper Service Tests • NFPA 1911 says that pumper service tests may be conducted using either a fire hydrant or static body of water as a supply source. Most jurisdictions prefer to draft from a static source during testing because this is a true test of the pump’s capability. (Continued) Pumping Apparatus Driver/Operator 16–26 Site Considerations for Pumper Service Tests • When using a static water supply source, the water must be at least 4 feet (1.2 m) deep. The strainer must be submerged at least 2 feet (0.6 m) below the surface of the water. The surface of the water may be no more than 10 feet (3 m) below the centerline of the pump intake, and 20 feet (6 m) of hard intake hose should be used for drafting during testing. (Continued) Pumping Apparatus Driver/Operator 16–27 Site Considerations for Pumper Service Tests (Continued) Pumping Apparatus Driver/Operator 16–28 Site Considerations for Pumper Service Tests • The atmospheric air temperature during testing should be between 0ºF and 100ºF (-18ºC and 38ºC). • The water being used for testing should be between 35ºF and 90ºF (2ºC and 32ºC) because hotter water has less surface tension and could affect test results. (Continued) Pumping Apparatus Driver/Operator 16–29 Site Considerations for Pumper Service Tests • The barometric pressure should be at least 29 in.Hg (98.2 kPa), corrected to sea level. (Continued) Pumping Apparatus Driver/Operator 16–30 Site Considerations for Pumper Service Tests • Table 16.1 on page 487 shows the minimum hard intake hose arrangements that are necessary to perform tests on pumps of varying capabilities. These figures are good for tests that are performed at altitudes of up to 2,000 feet (610 m) above sea level. (Continued) Pumping Apparatus Driver/Operator 16–31 Site Considerations for Pumper Service Tests • Beyond that figure, it may be necessary to increase intake hose diameter or the number of intake hoses used to pump the rated capacity. Altitude affects pump performance: lifting ability drops about 1 foot (0.3 m) per 1,000 feet (300 m) increase in altitude; gasoline engines have 3.5 percent less efficiency per 1,000 feet (300 m) increase in (Continued) altitude. Pumping Apparatus Driver/Operator 16–32 Site Considerations for Pumper Service Tests • It is also necessary to lay out a sufficient number of discharge hoses and nozzles to pump the rated capacity of the fire pump; 2½-inch (65 mm) hose is the minimum size hose that may be used for this application. Larger hoses may be used if available. (Continued) Pumping Apparatus Driver/Operator 16–33 Site Considerations for Pumper Service Tests • Scribe a mark where the hose and couplings meet. While the pump testing is proceeding, regularly check the couplings to make sure that the hose is not starting to pull loose of the coupling. Pumping Apparatus Driver/Operator (Continued) 16–34 Site Considerations for Pumper Service Tests • If the scribe mark moves more than 3/8-inch (9.5 mm) away from the coupling, stop the test and replace the hose. Pumping Apparatus Driver/Operator (Continued) 16–35 Site Considerations for Pumper Service Tests • Tables 16.2 a and b on page 488 show the minimum hose and nozzle arrangements needed to discharge sufficient water for various size pumps being tested. Pumping Apparatus Driver/Operator 16–36 Determining Correct Pump Discharge Pressure for Pump Service Tests • Customary Pressure correction = Lift (ft.) + intake hose friction loss 2.3 (Continued) Pumping Apparatus Driver/Operator 16–37 Determining Correct Pump Discharge Pressure for Pump Service Tests • Metric Pressure correction = Lift (m) + intake hose friction loss 0.1 Pumping Apparatus Driver/Operator 16–38 Equipment Needed to Perform Pumper Service Tests • A gauge to check the pump intake pressure – This gauge should have a range of 30 in.Hg (100 kPa) to zero for a vacuum gauge, or 30 in.Hg vacuum to 150 psi (1 050 kPa) for compound gauges. • A gauge to check the pump discharge – This gauge should be capable of a range from at (Continued) least 0 to 400 psi (0 kPa to 2 800 kPa). Pumping Apparatus Driver/Operator 16–39 Equipment Needed to Perform Pumper Service Tests • Pitot tube with knife edge and air chamber rated at least from 0 psi (kPa) to 160 psi (1 110 kPa). – This is not needed if a flowmeter is used. • Straight stream nozzles of correct sizes to match the volumes pumped for the different tests. – If a flowmeter is used, fog nozzles may be used (Continued) provided they are rated for the necessary flows. Pumping Apparatus Driver/Operator 16–40 Equipment Needed to Perform Pumper Service Tests • Rope, chain, or test stand for securing test nozzle(s) • Revolution counter or hand tachometer • Fire department or insurance agency forms Pumping Apparatus Driver/Operator 16–41 Equipment Recommended to Perform Pumper Service Tests • Two 6-foot (2 m) lengths of ¼-inch (7 mm), 300 psi (2 100 kPa) hose with screw fittings – These are used to connect the test gauges to the test gauge fittings at the pump operator’s panel. • Clamp to hold pitot tube to test nozzle (Continued) Pumping Apparatus Driver/Operator 16–42 Equipment Recommended to Perform Pumper Service Tests • Test stand for gauges • Thermometer • Stopwatch or watch with sweep second hand Pumping Apparatus Driver/Operator 16–43 Safety Precautions to be Followed When Performing Fire Pump Service Testing • All personnel should wear protective headgear and hearing protection (if exposed to noise in excess of 90 dB). • Prevent water hammer: Open and close all valves and nozzles slowly. (Continued) Pumping Apparatus Driver/Operator 16–44 Safety Precautions to be Followed When Performing Fire Pump Service Testing • Do not stand over or straddle hose. • Manipulate the engine throttle slowly. Prevent sudden pressure changes, which can damage equipment and injure personnel. • Tie down test nozzles and devices securely. (Continued) Pumping Apparatus Driver/Operator 16–45 Safety Precautions to be Followed When Performing Fire Pump Service Testing • Cover all open manholes at the test pit. • Be aware of the location of all personnel in the test area in relation to hoselines. Pumping Apparatus Driver/Operator 16–46 Reviewing Test Results • At no time during the tests should the pumping system or pumping engine show signs of overheating, power loss, or any other mechanical problems. • All fluid levels should again be checked and any losses noted. (Continued) Pumping Apparatus Driver/Operator 16–47 Reviewing Test Results • All calculations and figures determined during the tests should be recorded so that they may be filed according to departmental recordkeeping procedures. (Continued) Pumping Apparatus Driver/Operator 16–48 Reviewing Test Results • If the fire pump tests to less than 90 percent of its capabilities when it was new and underwent certification testing, two options are available: – Take the pump out of service and restore it to its designed capabilities (preferred option). – Give the pump a lower rating based on the test results of its actual performance. Pumping Apparatus Driver/Operator 16–49 Causes of Problems that May Occur During Service Testing • Transmission in wrong gear • High gear lockup not functioning (automatic transmission) • Clutch slipping • Engine overheating Pumping Apparatus Driver/Operator (Continued) 16–50 Causes of Problems that May Occur During Service Testing • Muffler clogged • Tachometer inaccurate • Engine governor malfunctioning • Intake hose too small (Continued) Pumping Apparatus Driver/Operator 16–51 Causes of Problems that May Occur During Service Testing • Intake strainer submerged incorrectly • Intake screens clogged • Wrong strainer is being used for that type of hose • Lift is higher than 10 feet (3 m) Pumping Apparatus Driver/Operator (Continued) 16–52 Causes of Problems that May Occur During Service Testing • Intake hose clogged or inner lining collapsed • Excessive air leaks at intake side of pump • Pump impellers are clogged • Pump or intake hose not fully primed (Continued) Pumping Apparatus Driver/Operator 16–53 Causes of Problems that May Occur During Service Testing • Relief valve or pressure governor malfunctioning • Transfer valve in wrong position • Inaccurate gauges (Continued) Pumping Apparatus Driver/Operator 16–54 Causes of Problems that May Occur During Service Testing • Pitot tube partially clogged • Nozzle too large • Seized turbocharger • Excessive wear on impeller clearance rings Pumping Apparatus Driver/Operator 16–55 Summary • Preservice tests are conducted prior to the apparatus being delivered, and usually do not involve fire department personnel. • Once delivered, fire department pumpers are tested again before being placed into service, and driver/operators may or may not be involved in this testing. (Continued) Pumping Apparatus Driver/Operator 16–56 Summary • Once in service, pumping apparatus are tested at least annually to ensure continued acceptable performance. Fire department driver/operators are often directly involved in these annual service tests. (Continued) Pumping Apparatus Driver/Operator 16–57 Summary • Fire department driver/operators must be familiar with the preservice testing procedures, and be capable of conducting or assisting with annual service tests. (Continued) Pumping Apparatus Driver/Operator 16–58 Summary • To perform these duties adequately, driver/operators must be familiar with correcting net pump discharge pressure for tests, the sequence of tests, equipment needed, safety precautions, and possible causes of trouble during the tests. Pumping Apparatus Driver/Operator 16–59