Barrier Management Strategies

advertisement

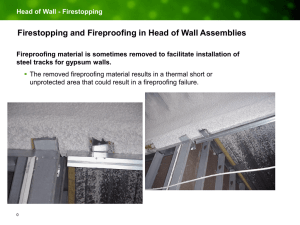

10/22/2015 BARRIER MANAGEMENT STRATEGIES Learning Objectives Understand the basics of Firestopping and why it’s required by code Understand the healthcare specific challenges and common failures / deficiencies found during an inspection Understand how to identify a qualified contractor and get the quality, compliant product you’re paying for What is Firestopping A specific tested & listed fire protection system made of various components used to seal openings and joints in fireresistance rated wall and/or floor assemblies. Why is Firestopping required by code? Why are rated barriers important… Allow safe egress from a facility Allow for defend in place where required Compartmentalizes a facility to limit exposure Decreases cross-contamination / infection rates Why is Firestopping required by code? Current Construction Methods & Materials Textiles – Furniture, drapes, sheets, particle / mdf cores, etc Sprinkler systems Notification systems directing people to egress paths Why is Firestopping required by code? 20 x 20 x 20 Room Experiment A single dime sized hole in a rated barrier The 8,000 sq ft room will fill with smoke in under 4 minutes So that you cannot see your hand 18 inches in front of you Source: International Firestop Council 2004 Why is Firestopping required by code? IFC Video: Demonstration of Proper vs Improper Firestopping https://www.youtube.com/watch?v=J4bw-2ME4uc Current Problem Current Problem Current Problem Current Problem: This is What We Should See… Firestopping in Healthcare How does it affect you… Barrier issues are consistently being cited by the Deeming Authorities (Joint Commission/ DNV / HFAP) Several of the top 10 cited items are related to the rated barriers within a healthcare facility Funding – budgets are continually being reallocated Multiple building codes & construction types all under one roof SOC / PFI – we’re chasing our tales Firestopping in Healthcare How did we get here… Design Construction / Installation Inspections Maintenance Firestopping in Healthcare Design Designing to multiple codes – IBC / IFC / NFPA / etc Requirements have changed drastically over the years relating to rated barriers and education has lagged behind Increasingly shifting responsibility to the construction team through performance oriented documents and “reviewing” submittals Often include details to get through city review without understanding ramifications of non-compliant designs Firestopping in Healthcare Construction / Installation Historically there has been little education around firestopping Scope is typically left to the individual trade contractors whose core competency is something else…electric / plumb / mech The average trade contractor provides their apprentice with a caulk gun and the “red stuff.” Design details are often incomplete or even non-compliant leaving an uneducated installer to decide what to do Firestopping in Healthcare Inspection / Enforcement “If it’s red, it’s good.” - Historically firestopping has been relatively ignored by the inspection community Massive changes in code editions and adoption rates Decreasing budgets = less manpower / less education Often generalists in code Firestopping in Healthcare Maintenance Decreasing budgets = less manpower / less education Budgets are always changing within a healthcare facility Planning is part 1, but the urgent need gets the funding A healthcare facility is always being renovated Little communication within departments (facility & system) Success looks different to each of you and is often conflicting No incentive to expose how bad it might be Firestopping in Healthcare Specific Failures Through Penetration Firestopping Fire-Resistive Joint Systems Data Cabling / Sprinkler Lines Wall Construction Life Safety Plans Quality and Compliance SET YOURSELF UP TO SUCCEED Quality and Compliance Qualified Contractors Company Certifications FM 4991 / UL QFCP Company specific Requires annual audits Requires ongoing CEU’s & recertification Educates companies on all aspects of Firestopping Financial investment and Firestop specific work history Manufacturer Certifications Hilti / STI / 3M / Rector Seal / Etc FIT Trained Specific to manufacturers products & tested systems Multiples levels from general firestop awareness to specific training Quality and Compliance Design Develop a consistent specification to provide your design teams with YOUR firestopping requirements… Material Manufacturer Installer Qualifications Consistency will help with long term maintenance / education Manufacturer certified / FM 4991 / UL QFCP Documentation Tag & label Software Quality and Compliance New Construction Pre-approve contractors who install firestopping on new construction Educate yourself to know what to look for Establish the importance of the rated barriers as a regular agenda item during construction Tag & Label / Documentation Quality and Compliance Inspection / Enforcement Get to know your local code officials and let them know this matters to you IBC 1705.16 (2012) requires 3rd Party Special Inspections for firestopping High rise construction Risk category 3 & 4 (I-2 / I-3 classifications) Quality and Compliance Maintenance Train your staff on basic installations Train your staff on how to identify non-compliant firestopping Communicate internally Know what you’re buying with your SOC inspections Above ceiling permitting / tracking – COMMUNICATION Engage experts when it’s simply too much to handle Quality and Compliance Randomly field check a hand full of installations that system requirements are being met Follow each system sheet from top to bottom. Takes 1-2 minutes Ratings Quick Reference Can often tell application, single or multiple thru pens, point of contact or annular space Substrate(s) Assembly Penetrating Item(s) The average trade contractor does not use mineral wool where required Material Installation Specifics ● Not Shown: Acceptable Installation Methods Quality and Compliance Quality and Compliance Randomly field check a hand full of installations that system requirements are being met Follow each system sheet from top to bottom. Takes 1-2 minutes The average trade contractor does not use mineral wool where required Ratings Quick Reference Can often tell application, single or multiple thru pens, point of contact or annular space Floor Assembly Wall Assembly Material Installation Specifics ● Not Shown: Acceptable Installation Methods 10 Common Failures 1. Wrong system selection (or no selection at all) 10 Common Failures 2. Maximum annular space exceeded (system expected to fail) 10 Common Failures 3. Depth of sealant (systems are tested with MINIMUM amounts) 10 Common Failures 4. Improper installation methods (#1 not tooled) 10 Common Failures 5. Installed as point of contact (must meet annular space requirements) 10 Common Failures 6. Not free of dust / foreign material (adhesion failure) 10 Common Failures 7. Mineral wool has not been used 10 Common Failures 8. Incorrect material used for installation 10 Common Failures 9. Installation outside of system parameters (Engineering Judgment) 10 Common Failures 10. Installation of drywall tape or other sealants Summary Education is key Hospital Staff / Contractors / Designers / Inspectors Follow the tested system details Know what to look for Communication Create incentives for communication within the hospital & with contractors Set yourself up to succeed Tag & label firestopping Document your progress Make it manageable QUESTIONS This is What We See…