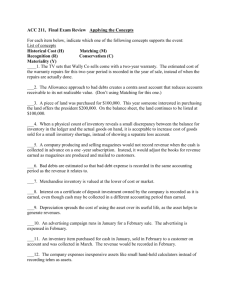

Transportation Policies

advertisement

Supply Chain Guru Quick Reference Sheet Transportation Policies Parcel: Quantity of product ships to the destination site immediately LTL (Less than Truckload): Quantity of product has to be transported from one site to another, it is transported immediately, without regard to any other product bundles that are going to the same site. Transportation asset can be selected. The asset will be required to be available in order for the shipment to move Full TL (Full Truckload): Transportation Asset required for Full Truckload policies. Product bundles are consolidated together based on aggregate weight and/or cubic, then dispatched as a single shipment to one destination when the asset is full Air, Rail and Ship: When a transportation asset is selected, the policy will behave similar to the Full TL policy. If no asset, then it behaves the same as the parcel policy Daily or Weekly Shipment: Product bundles shipped daily (every 24 hours) or weekly (every 7 days). When shipment time arrives, if an asset is specified, product bundles will be shipped when an asset becomes available Periodic Shipment: Product bundles ship on a repeating schedule Pooled Outbound/ Pooled Inbound: Similar to Full TL Policy, except that all products to/ from a single site are consolidated on a single asset Pooled Periodic Outbound/ Pooled Periodic Inbound: Similar to Periodic Shipment Policy, except that all products to/ from a single site are consolidated on a single asset Flow (Optimization Only): Designed for transportation through pipelines Link To Lane: Used for virtual lanes that make use of the Ship To field Sourcing Policies Single Source : Orders can only be filled by one source Single Source (Select Closest): Chooses the one source closest in distance to the site that is requesting product Sets up a sourcing policy in which multiple sources are possible but SC Guru does the work of determining which source, based on distance, will fill the site’s request Multiple Sources (Most Inventory):Orders will be filled by the source with the most inventory of the requested product on hand Multiple Sources (Order of Preference):Sets an order of preference for filling orders by defining preference Each site is checked to see if it has the inventory on-hand to fill the request. If it does, it is selected as the source. If not, the next preferred site is checked for inventory. If none of the sources have the inventory on-hand to fill the request, the first site is then selected. Multiple Sources (Probability): Randomly selects a source to fill orders based on probability. Source is selected based on the probability in the Policy Parameter field. In optimization, if this policy is selected fractional sourcing constraints are imposed. Source by Transfer: The site will rely on other model elements to push inventory to it. The site’s model variables continue to function, registering inventory and back order changes, but it will never order replenishment. It is usually used in conjunction with scripting logics. Make: Replenishments of this product are filled internally, or at the site. Can be used with the Bill of Materials (BOM). Can use the Guru submodel- defined work centers, work resources, and processes. Make by Schedule: Similar to the Source by Transfer policy: production will not be scheduled automatically when this rule is selected. Relies on external elements like the Productions Table and Scripting to schedule production. Make (Single Process), Make (Order of Preference), Make (Probability):These policies are used when a particular product can be made at the site by multiple processes or workcenters. Inventory Policies R,Q: Fixed replenishment point/fixed replenishment quantity inventory policy. When the inventory level onhand falls below a certain replenishment point, R, the site will generate a replenishment order for a certain quantity, Q, of this product. When using this policy, the Reorder Point field is set as the trigger level. The Reorder/Order Up To Qty field will be the exact number of units reordered. s,S: minimum/maximum inventory policy. When the inventory level on-hand falls below a minimum, s, the site will generate a request for a replenishment order that will restore the on-hand inventory to a target, or maximum, number, S. When using this policy, the Reorder Point field is the minimum, or trigger level. The Reorder/Order Up To Qty field is the maximum, or the number to which the inventory level is restored Demand Flow: No strict inventory control. Instead, every order that arrives at this site for this product will generate a request for a replenishment order for the exact same quantity. All requests are driven by the actual demand quantities received at this site for this product. Therefore, the Reorder Point and Reorder/Order Up To Qty fields are not used. Days of Supply (DOS) - Demand is similar to an s,S inventory policy except that the parameters for minimum and maximum levels are specified in number of days rather than product quantities. This policy computes the daily average of product by looking back at the actual demand. How far back to look is given by the DOS window field. DOS – Forecast: Similar to an s,S inventory policy except that the parameters for minimum and maximum levels are specified in number of days rather than product quantities. This policy computes the daily average of product by looking forward and using forecasted demand. How far forward to look is given by the DOS window field. Forecast quantities must be entered into the forecast R,Q Targets: Allows the user to change the Reorder Point (R) and Reorder Quantity (Q) based on a period of time designated by the user (year, quarter, month, day, etc.) When using the R,Q Targets inventory policy, the quantities and period are specified in the Forecasts input table. s,S Targets: Just like the regular s,S policy except that you can specify Reorder Point (s) and Order up to Quantity (S) for certain periods. You can define the period as days, weeks, months, years, quarters etc. When using the s,S Targets inventory policy, the quantities and period are specified in the Forecasts input table. Supply Chain Guru Quick Reference Sheet Mode Selection Rules Mode Rule Example First The mode with the lowest Mode number will be used. First Available Asset By Probability On Due Date On Qty The mode for which an asset becomes available first will be used. The mode will be picked based on the probability. Here the mode number reflects this probability. In the simulation engine, the modes are sorted in descending order from Longest to shortest. The first mode that can fulfill the order on time (before or on the Due Date) will be used. The mode will be picked based on the size of the order (in units). One mode with mode# 0 needs to be specified, and other modes where the mode# is used as the unit-break points. If there are 2 modes, one with mode# 0 and one with mode# 200, orders that have a size between 0 and 200 units, will take mode 0 and orders =>200 units, will take mode 200. On Weight The mode will be picked based on the size of the order (in weight). Similar to On Qty. On Cubic The mode will be picked based on the size of the order (in cubic). Similar to On Qty. Queue Only Shipments will only be placed in a queue, but never dispatched. Queue Only assumes a customer written script takes care of scheduling shipments. A custom script defined in the scripts table. Custom Parameter The mode with the lowest Mode number will be used. Enter 30, if chances are 30% that this mode will be used. The probabilities for the lane need to add up to 100. The mode will be picked based on the size of the order (in units). Each mode should have a range in which to send it (ie 0-200 = Mode_1, 200-500 = Mode 2, 500 And above = Mode 3). Take the first number in the range for that mode, and place that in the mode parameter. Each mode should have a range in which to send it (ie 0-200 = Mode_1, 200-500 = Mode 2, 500 And above = Mode 3). Take the first number in the range for that mode, and place that in the mode parameter. Each mode should have a range in which to send it (ie 0-200 = Mode_1, 200-500 = Mode 2, 500 And above = Mode 3). Take the first number in the range for that mode, and place that in the mode parameter. Shipments will only be placed in a queue, but never dispatched. Queue Only assumes a customer written script takes care of scheduling shipments. A custom script defined in the scripts table. LLamasoft Support Email: Support@llamasoft.com Website: www.llamasoft.com