Periodic Review System

advertisement

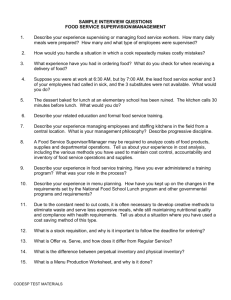

5-1 PERSEDIAAN PROBABILISTIK: PERIODIC REVIEW Replenishment Policies When and how much to order Continuous review with (Q,R) policy: Inv. is continuously monitored and when it drops to R, an order of size Q is placed Periodic review with (R,S) policy: Inv. is reviewed at regular periodic intervals (R), and an order is placed to raise the inv. to a specified level (order-up-to level, S) Periodic Review System: Order-Up-To-Level (R, S) System Periodic Review Systems Continuous Review Systems Often, we are constrained by WHEN we can order -and it may be periodically Always knew level of on-hand inventory Could place an order at any time Train dispatched once a week Delivery truck arrives each morning Thus, we do not need to continuously review inventory, just check periodically Periodic Review Systems If demand were known and constant, we would just resort to our EOQ solution, possibly modifying it to meet shipping date Now: demand is random variable Setting: Place an order every T periods Policy: Order up to S The value of Q (order quantity) will now change periodically Previous concern: demand exceeding supply during the lead time Now: demand exceeding supply during the period and lead time, or T + Periodic Review Order up to S every T periods of time. I(t) S Order arrives. Cycle continues. Demand Q Lead Time passes… T Time Expected cost function Include expected holding, setup, penalty and ordering (per unit) costs Average Inventory Level: S At level R*,on average, order Q = S-R* units. τ periods later, units arrive. Inventory level? R* τ T Expected cost function Include expected: holding, setup, penalty and ordering (per unit) costs Average Inventory Level: S S-l units present when Q arrive (expected) as l units consumed over leading time. T Expected cost function Include expected: holding, setup, penalty and ordering (per unit) costs Average Inventory Level: S - l lT units removed (expected) from inventory over time T. S T Expected cost function Include expected: holding, setup, penalty and ordering (per unit) costs Average Inventory Level: S S-l lT T Average Inventory Level = S l lT S-l-lT lT 2 S l lT 2 Expected cost function Include expected: holding, setup, penalty and ordering (per unit) costs Average Holding Cost: lT h S l 2 K Average Set-up Cost: T Expected cost function Expected Shortage per Cycle: f(x)dx = P(demand in T + is between x and x + dx) E (max(l (T ) S ,0)) ( x S ) f ( x ) dx n( S ) S Expected Penalty Cost : n(S) p T Cost Minimization Expected Cost Function: lT K pn(S) G(S,T) h(S l ) lc 2 T T Derivative: Recall that T and are given: dG p h n(S ) dS T Cost Minimization Derivative: dG p h n( S ) 0 dS T Note : n( S ) ( x S ) f ( x)dx S n( S ) (1 F ( S )) hT 1 F (S ) p or: p hT F(S) p Example A special control board is used in a version of a product on the production line The board cost is $122.50 The holding cost rate is 30% per year Reorders are placed at the start of each week, and the supplier delivers these parts in one week The shortage cost is $100 per board due to worker downtime Weekly demand is N (μ=125, δ2=104.17) Set up cost (K) is $120 Find S Solution Holding cost is: h = Ic = .30 (122.50) = 36.75 / 52 = $.7067 per week Compute: p hT 100 (.7067)1 F(S) 0.993 p 100 Demand Distribution is Normal mean = 125 variance = 104.17 Z = 2.455 from Normal table S z S = 125+(2.455)(104.17)1/2 = 150.06 Solution If penalty cost drops to $10 per unit: Compute: p hT 10 (.7067)1 F(S) 0.929 p 10 S = 125+(1.47)(104.17)1/2 = 140 p = 1? S = 125+(-.54)(104.17)1/2 = 119.49 References “Production & Operations Analysis” by S.Nahmias “Factory Physics” by W.J.Hopp, M.L.Spearman “Inventory Management and Production Planning and Scheduling” by E.A. Silver, D.F. Pyke, R. Peterson