INDUSTRIAL VENTILATION DESIGN PROCEDURE

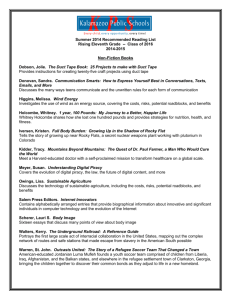

advertisement

Industrial Ventilation Design Procedure Industrial Ventilation Design Procedure 1. 2. 3. 4. 5. 6. 7. 8. Find Q Determine d Calculate actual V Calculate VP Find VP loss coefficients Calculate Fan SP Calculate Fan TP Choose Fan rpm from Fan Table Design Procedure 2 Losses Inches of water Percent of velocity pressure Friction losses Elbow losses Other losses Hood entry losses Orifice losses Expansion and Contraction losses Air cleaner losses Stack losses Design Procedure 3 Review Of Design Tables Refer to FIGURE 5-15 to find hood entry loss coefficients. Refer to FIGURE 5-16 to find elbow losses. Refer to TABLE 5-5 and TABLE 5-6 to find friction loss for the given diameter and velocity. Refer to TABLE 5-7A and TABLE 5-7B to find velocity for a given VP. Refer to TABLE 5-8 to find area for a given diameter. Refer to TABLE 5-10 to find Air Density Correction Factor for a given temperature and barometric pressure. Review rest of the tables given in chapter 5. Design Procedure 4 Review Of Design Tables For solving various problems given in chapter # 5 the corresponding figures are given in chapter # 10. For solving design problem 4, tables 10.70.1 to 10.70.4 will be useful. Before solving the design problems go through the figure and data given in chapter 10. Design Procedure 5 Review Of Design Tables Refer to TABLE 3-1 to find the various ranges of capture velocities. Refer to TABLE 3-2 to find the range of minimum duct velocities for various contaminants. Go through all the figures in chapter # 3 representing various hoods. Design Procedure 6 Design Procedure GIVEN DATA: Ventilation system: Laboratory Hood Volumetric Flow Rate, Q = 1500 CFM Minimum Transport Velocity, V = 4000 FPM Stamped elbow with R / D = 2 Design Procedure 7 Design Procedure Download DESIGN PROBLEM-1 Line 1: Inlet Section Line 2: Target Volume Flow Rate, Q = 1500 CFM (Given). Line 3: Minimum Transport Velocity, V = 4000 FPM (Given). Line 4: Maximum Duct Diameter, D = 8.29” We know Q = V * A Hence Duct Area = Q / A = 1500 / 4000 = 0.375 Sq. Ft. We know A = (Pi * D2) / 4 Hence, D = 8.29” Design Procedure 8 Design Procedure Line 5: Selected duct diameter = 8” We got Maximum Duct Diameter D = 8.29” We have to choose a diameter that is less than maximum selected diameter so that minimum transport velocity is not maintained in the duct. So, let’s choose 8” diameter. Note: Your choice is limited by the sizes given in the table. Line 6: Duct Area = 0.349 Sq. ft. Duct Area (from TABLE 5-8 at D = 8”) = 0.349 Sq. ft. Line 7: Actual Duct Velocity = 4298 FPM Velocity = Q / Area = 1500 / 0.349 = 4928 fpm Design Procedure 9 Design Procedure Line 8: Duct Velocity Pressure = 1.15” WG Duct VP (from TABLE 5-7A at V = 4298 FPM) = 1.15” WG Line 9-16 = N/A (since there are no slots) Line 17: Duct Entry Loss Coefficient = 0.49 Given, hood has a flanged duct end From TABLE 5-15 for a hood that has a flanged duct end, entry loss coefficient is 0.49 Design Procedure 10 Design Procedure Line 18: Acceleration Factor ( 1 or 0) = 1 Since acceleration factor is 1 for hoods. Line 19: Duct Entry Loss per VP (17 + 18) = 1.49” WG Line 20: Duct Entry Loss (8 * 19) = 1.714 Line 21: Other Losses = 0 Line 22: Hood Static Pressure, SPh (16+20+21) = 1.714” WG Line 23: Straight Duct Length = 35 ft (Given) Line 24: Friction Factor (Hf) = 0.0304 From TABLE 5-5 at D = 8” and V = 4000 FPM Hf = 0.0304 Line 25: Friction Loss per VP (23 * 24) = 1.064 Line 26: No. of 900 degree Elbows = 1 Design Procedure 11 Design Procedure Line 27: Elbow Loss Coefficient = 0.13 From TABLE 5-16 for a stamped elbow and R/D = 2 Line 28: Elbow Loss Factor (26 * Loss Factor(27)) = 0.13 Line 28-32 = N/A Since there are no branch entries Line 33: Duct Loss per VP (25 + 28 + 31+ 32) = 1.1940 Line 34: Duct Loss (8 * 33) = 1.3731 Line 35: Duct Segment SP Loss (22 + 34) = 3.087” WG Line 36: Other Losses = N / A Line 37: Cumulative Static Pressure = 3.087” WG Line 38: Governing Static Pressure = -3.087” WG Design Procedure 12 Design Procedure Line 39-42 = N / A Line 1: Outlet Section Line 2-8 same as for inlet section Line 9-22 = N / A as outlet is exhaust that is it will not have suction part Line 23: Straight Duct Length = 10 ft (Given) Line 24: Friction Factor (Hf) = 0.0304 From TABLE 5-5 at D = 8” and V = 4000 FPM Hf = 0.0304 Line 25: Friction Loss per VP (23 * 24) = 0.3019 Line 26: No. of 900 degree Elbows = 1 Design Procedure 13 Design Procedure Line 27: Elbow Loss Coefficient = 0.13 From TABLE 5-16 for a stamped elbow and R/D = 2 Line 28: Elbow Loss Factor (26 * Loss Factor(27)) = 0.13 Line 28-32 = N/A Since there are no branch entries Line 33: Duct Loss per VP (25 + 28 + 31+ 32) = 0.4319 Line 34: Duct Loss (8 * 33) = 0.4990 Line 35: Duct Segment SP Loss (22 + 34) = 0.499” WG Line 36: Other Losses = N / A Line 37: Cumulative Static Pressure = 0.499” WG Line 38: Governing Static Pressure = -0.499” WG Design Procedure 14 Design Procedure Final Calculations: The Fan SP = Spo – SPin - VPin = 0.499 – (-3.087) – 1.15 = 2.436 FPM The Fan TP = VPo + SPo – SPin - VPin = 1.15 + 0.499 – (-3.087) – 1.15 = 3.586 FPM BHP = (Fan TP * Q) / 6362 * η = (3.586 * 1500) / (6362 * 0.9) = 0.94 hp Where: η = Mechanical Efficiency (here taken as 0.9) You have completed the design of laboratory hood. Design Procedure 15 Design Problems Download DESIGN PROBLEM –2, 3, 4 and start doing the problems All are of the same procedure with minor changes. For fan pressure calculations refer 5.8 in the text book. Refer 5.9 to know the corrections for velocity changes. Refer 5.13 in the text book to get an idea of corrections for non-standard density. Go through various problems given in the text book. Design Procedure 16 CALCULATION OF Vpr For design problems 3 and 4 you need to calculate corrected volumetric flow rate and VPr. For calculating corrected volumetric flow rate and VPr formulae are given in the design spread sheets. Refer to the spread sheet solution and word solution given carefully. Design Procedure 17