WHMIS GENERIC TRAINING

advertisement

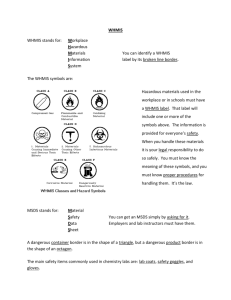

Occupational Health and Safety, Human Resources Services INTRODUCTION - RATIONAL Why do we do WHMIS training? Legal Obligations Required by the Occupational Health and Safety Act Advise workers of hazards Protect staff and students Protect the environment Protect our own families Generic WHMIS Training September 2005 1 Occupational Health and Safety, Human Resources Services INTRODUCTION What is WHMIS? WHMIS stands for Workplace Hazardous Material Information System Generic WHMIS Training September 2005 2 Occupational Health and Safety, Human Resources Services INTRODUCTION – LEGISLATION Federal Legislation Ontario Legislation The Hazardous Products Act The Occupational Health and Safety Act The WHMIS Regulation The Controlled Products Reg. The Ingredient Disclosure List The Hazardous Materials Information Review Act The Hazardous Materials Information Review Reg. Generic WHMIS Training September 2005 3 Occupational Health and Safety, Human Resources Services INTRODUCTION – LEGISLATION WHMIS CLASSIFICATION LABELS MSDS Generic WHMIS Training September 2005 TRAINING 4 Occupational Health and Safety, Human Resources Services INTRODUCTION – LEGISLATION Training will include: Generic WHMIS training • Taken by all employees once or more frequently as determined by Administration Annual WHMIS review training • Taken by all employees every year Secondary Module training • Taken by Secondary Science, Technology, Visual Arts and Cooperative Education teachers once or more frequently as determined by Administration Annual Secondary Module review training • Taken by all Secondary Science, Technology, Visual Arts and Cooperative Education teachers every year Generic WHMIS Training September 2005 5 Occupational Health and Safety, Human Resources Services INTRODUCTION – LEGISLATION What does WHMIS regulate? WHMIS does not regulate: » » » » » » » » » Explosives Food & Drugs Pesticides Hazardous Wastes Consumer Products Wood & Wood Products Tobacco & Tobacco Products Manufactured Goods Radioactive Materials Generic WHMIS Training September 2005 6 Occupational Health and Safety, Human Resources Services INTRODUCTION- RESPONSIBILITIES Manufacturer/Supplier Employer • Classification • Label all controlled products as a condition of sale • Provide a MSDS as a condition of sale • Review and update MSDS every three years • Ensure that controlled products are labeled or identified • Obtain an up to date MSDS for all controlled products used in the workplace • Educate workers Generic WHMIS Training September 2005 7 Occupational Health and Safety, Human Resources Services INTRODUCTION- RESPONSIBILITIES Workers • The right to know about hazardous materials you may be exposed to on the job including the right to review labels and MSDS and to receive training • The right to be consulted in the content and delivery of the training • Responsible to report missing or illegible labels, missing or out of date MSDS, and • Responsible to work in a safe manner and follow all work procedures required by the employer Generic WHMIS Training September 2005 8 Occupational Health and Safety, Human Resources Services TOXICITY - INTRODUCTION What is toxicity? Toxicity is an inherent physical property of a substance to cause harm. In order to be at risk, there must be exposure of an individual to the toxic substance. The degree to which the exposure may result in harm is a determined by the dose. Dose is a function of concentration over a period of time. Generic WHMIS Training September 2005 9 Occupational Health and Safety, Human Resources Services ROUTES OF ENTRY - INHALATION Generic WHMIS Training September 2005 10 Occupational Health and Safety, Human Resources Services ROUTES OF ENTRY – SKIN CONTACT Generic WHMIS Training September 2005 11 Occupational Health and Safety, Human Resources Services ROUTES OF ENTRY – EYE CONTACT Generic WHMIS Training September 2005 12 Occupational Health and Safety, Human Resources Services ROUTES OF ENTRY - INGESTION Ingestion of a hazardous material can occur while eating or smoking after handling hazardous materials if hands are not properly washed. Generic WHMIS Training September 2005 13 Occupational Health and Safety, Human Resources Services TOXICITY – ACUTE VS CHRONIC Acute: • Single large dose • Effects felt immediately or shortly after • Mild effects usually reversible Chronic • Multiple, smaller doses over a long period of time • Effects have long on-set period • Effects usually not reversible Generic WHMIS Training September 2005 14 Occupational Health and Safety, Human Resources Services TOXICITY – CONTROLS At the Source • Substitution • Isolation Along the Path • Ventilation • Barriers At the Worker • Personal Protective Equipment (ppe) • Administrative Controls Generic WHMIS Training September 2005 15 Occupational Health and Safety, Human Resources Services CLASSIFICATION WHMIS requires the manufacturer of a hazardous material to classify the material according to its inherent physical properties into one or more of 6 hazard classes. Generic WHMIS Training September 2005 16 Occupational Health and Safety, Human Resources Services CLASS A: COMPRESSED GAS A compressed gas is a material that is normally in the gaseous form at room temperatures. Hazards: • Explosion, Projectile • Frost Bite Precautions: • Store securely, upright and away from sources of heat • Do not puncture • Protect valves Generic WHMIS Training September 2005 17 Occupational Health and Safety, Human Resources Services CLASS B: FLAMMABLE & COMBUSTIBLE Class B is sub-divided into 6 divisions: 1. 2. 3. 4. 5. 6. Flammable Gases Flammable Liquids Combustible Liquids Flammable Solids Flammable Aerosols Reactive Flammable Materials Generic WHMIS Training September 2005 18 Occupational Health and Safety, Human Resources Services CLASS C: OXIDIZING MATERIALS Oxidizing materials cause/contribute to the combustion of other materials. Hazards: • Fire • Fire burns more vigorously Precautions: • Keep away from incompatible materials and flammable or combustible materials Generic WHMIS Training September 2005 19 Occupational Health and Safety, Human Resources Services CLASS D: POISONOUS & INFECTIOUS Division D1: Toxic Immediate and Severe Example: Carbon Monoxide Generic WHMIS Training September 2005 20 Occupational Health and Safety, Human Resources Services CLASS D: POISONOUS & INFECTIOUS Division D3: Biohazardous and Infectious Example: blood-contaminated materials (Hepatitis A, B, C, HIV) Generic WHMIS Training September 2005 21 Occupational Health and Safety, Human Resources Services CLASS D: POISONOUS & INFECTIOUS Division D2: Other Toxic Effects Examples: Latex Paint Solvents (e.g varsol) Asbestos Generic WHMIS Training September 2005 22 Occupational Health and Safety, Human Resources Services CLASS E: CORROSIVE Corrosives are materials that can attack and destroy on contact human tissues, clothes, and other materials, even metals. Hazards: • Burns to skin and eyes • Respiratory irritation or damage Precautions: • Use appropriate ppe • Avoid splashing • Avoid mist generation Generic WHMIS Training September 2005 23 Occupational Health and Safety, Human Resources Services CLASS F: DANGEROUSLY REACTIVE These materials can undergo vigorous reactions when heated, pressurized or agitated. They may also react with water to evolve a poisonous gas. Hazards: • Thermal burns Respiratory irritation or damage Precautions: • Use appropriate ppe • Avoid incompatible materials or conditions Generic WHMIS Training September 2005 24 Occupational Health and Safety, Human Resources Services LABELS There are two types of labels: 1. Supplier Labels: Suppliers are required to ensure that all containers of WHMIS Controlled products they offer for sale are labeled with a supplier label that meet the requirements of WHMIS. 2. Workplace Labels:When a WHMIS Controlled product is decanted from its original container or if the Supplier label becomes illegible or lost, a workplace label is required. Generic WHMIS Training September 2005 25 Occupational Health and Safety, Human Resources Services LABELS – SUPPLIER LABELS 1. 2. 3. 4. 5. 6. 7. Product Identifier Supplier Identifier Statement referring to the MSDS Hazard Symbol(s) Risk Phrase Precautionary Measures First Aid Measures Should you require a workplace label, or have any difficulty interpreting information on a label, contact your supervisor. Generic WHMIS Training September 2005 26 Occupational Health and Safety, Human Resources Services LABELS - WORKPLACE 1. 2. 3. Product Identifier Safe handling instructions Statement referring to the MSDS Should you require a workplace label, or have any difficulty interpreting information on a label, contact your supervisor. Generic WHMIS Training September 2005 27 Occupational Health and Safety, Human Resources Services MATERIAL SAFETY DATA SHEET Material Safety Data Sheets (MSDS) contain product-specific information including hazardous ingredients, first aid measures, health, fire and reactivity data, safe handling instructions, and special instructions for spills and waste disposal. MSDS must be updated every 3 years. You should always read the MSDS BEFORE using a new product. Generic WHMIS Training September 2005 28 Occupational Health and Safety, Human Resources Services MATERIAL SAFETY DATA SHEET MSDS are kept in a binder located at the front of the room. Should you notice that an MSDS is missing or is dated from more than 3 years ago, it is your responsibility to tell your supervisor immediately. Generic WHMIS Training September 2005 29 Occupational Health and Safety, Human Resources Services CONCLUSION • • • • • Before using a new product, always read the label and material safety data sheet! If you have any questions about how to use the product safely, ask your supervisor! Make sure that you have the appropriate personal protective equipment, that it is in good repair and you know how to use it! Always follow the instructions! Work safe! Generic WHMIS Training September 2005 30