A5_4_1_Structure_Nelson

advertisement

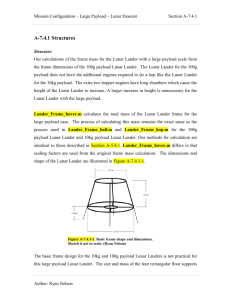

Mission Configuration – 100g Payload – Lunar Descent Section A-5.4.1 A-5.4.1 Structures Structure Our most important consideration in designing the structure of the Lunar Lander for the 100g payload is the mass of the frame. Two key drivers have a large impact on the mass of this frame. The total volume of the Lunar Lander and the mass of the Lunar Lander at lunar touchdown effect frame mass. The frame design for the Lunar Lander with the 100g payload is a conic frustum. We use this design to keep the analysis simple and easily recalculate the frame mass as various changes occur with the subsystems of the Lunar Lander. The size of the H202 tank, main engine chamber, and payload are the three main components driving the size of the Lunar Lander frame. A small increase in any one of these components results in an increase in frame mass and overall Lunar Lander mass. The size of the ball carrying the payload primarily dictates the lower diameter of the Lunar Lander frame. A majority of the frame mass comes from the floor components, so the size of the ball has a large effect on frame mass for this small payload case. Figure A-5.4.1 depicts the general make up of the Lunar Lander frame. Fig A-5.4.1. Schematic of basic frame shape and dimensions. (Ryan Nelson) Author: Ryan Nelson Mission Configuration – 100g Payload – Lunar Descent Section A-5.4.1 A large aluminum circular ring with a diameter of 1.3 meters determines the base of the Lunar Lander. The floor consists of four rectangular beams all equally spaced that feed into an inner circular ring which supports the main engine. The top of the Lunar Lander consists of a single aluminum circular ring with a diameter of 1 meter that the solar panel rests on. The center of this top ring is located 1 meter from the center of the floor. There are also four hollow side supports that run from the top ring to the floor outer ring at an angle of 8.53°. The Lunar Lander legs are hollow rods as well but have a smaller outer diameter than the side supports so that they can be stored within these side supports during Earth launch and lunar transit. A 0.5mm layer of magnesium skin placed around the entire Lunar Lander protects against micrometeoroids and provides thermal protection. We can refer to Figure 1 in Section 5.4.1 for a listing of each frame component. The total Volume of the Lunar Lander structure is 1.05m3 as calculated: V R 2 H 3 r 2 h 3 (A5.4.1-1) R and H correspond to the radius and height of the bottom of the frame assuming a conical frame shape. r and h correspond to the radius and height of the top of the frame again assuming a conical frame shape. The second key driver in the Lunar Lander frame mass is the mass of the entire Lunar Lander at touchdown on the lunar surface. It is determined that the Lunar Lander experiences a soft landing of under 10 Earth g’s for the 100g payload size. Looking at Lander_Frame_Ball.m, it can be seen that the total mass of the frame along with the mass of all the Lunar Lander subsystems multiplied by the forces at landing as well as a safety factor of 1.5 to get the forces that the Lunar Lander frame can withstand. A Lunar Lander frame mass of 11.44kg can withstand the loads at lunar touchdown. Lander_Frame_Ball.m also uses 30% of the calculated mass added to the total frame mass in order to account for connections between the different frame components. This Author: Ryan Nelson Mission Configuration – 100g Payload – Lunar Descent Section A-5.4.1 value of 30% is an approximation based on the percentage of total OTV structure mass used to connect major frame components. A break up of the frame into separate components allows for the easy calculation of each component mass. Summation of these component masses yields the total Lunar Lander frame mass. The four rectangular floor support beams account for the largest mass of any individual frame component. These beams support all the components within the Lunar Lander during lunar touchdown. The first mode of failure for the rectangular floor beams is from bending stress: My I (A5.4.1-2) the bending moment is strictly a factor of the landing force and the length of the floor beams. In order to decrease the bending stress subjected to the beams they are hollow. Hollow rectangular beams provide a larger moment of inertia than solid beams so that the beams can take larger loads. The only cross sectional shapes used to make up the frame components are rectangular (all four of the floor beams) and circular (every other frame component). Representation of the moment of inertia calculation for the rectangular beams: I bh 3 (b 2t )( h 2t ) 3 12 (A5.4.1-3) and representation of the moment of inertia calculation for the circular beams: I (r 22 r12 ) (A5.4.1-4) are used. The rectangular floor beams for this Lunar Lander have a base (b) value of 6cm and a height (h) value of 10 cm. The thickness (t) value recalculates from a step down process until a suitable a moment of inertia is found to support the landing loads. Author: Ryan Nelson Mission Configuration – 100g Payload – Lunar Descent Section A-5.4.1 In this calculation for moment of inertia, r2 represents the outer cross sectional radius of the give frame component and r1 represents the inner cross sectional radius of the same frame component. Shear forces acting on the rectangular floor beams becomes a concern as well. Figure A5.4.1-2 along with Equation 2 and shear calculation combine to demonstrate just one example of the effects between the rectangular floor beam bending moments and the shear forces on the outer ring. Fig A-5.4.1-2: Bending Moment and Shear force illustration on Rectangular Floor Beams. (Ryan Nelson) This bending moment calculation is the same reason that the outer support ring and engine support ring for the Lunar Lander floor are hollow. These rings do not see the same large bending moments as the floor supports so the cross sectional shape (rectangular or circular) is not as critical to the design. The top ring and the side supports have the same outer diameter as the floor rings. The inner diameters based on the first mode of failure vary based on the frame component being examined. Lander_Frame_ball.m shows a step down process in which the inner diameter of these rings gradually lowers until the component has a moment of inertia which allows it to withstand landing loads (See Equation 4). The method of failure analyzed for the four side supports: EI F= (kl) 2 Author: Ryan Nelson (A5.4.1-5) Mission Configuration – 100g Payload – Lunar Descent Section A-5.4.1 is buckling. For the side supports, both ends are fixed. One end to the top ring and the other end to the outer bottom ring. For this reason a k value of 0.5 is used. Making the side supports hollow results in a higher moment of inertia and therefore a higher maximum force before buckling. In addition to this, the mass of the four side supports reduces in hollowing out the rods. Buckling failure and compression failure: are both analyzed for the Lunar Lander legs. F A (A5.4.1-6) are both analyzed for the Lunar Lander legs. A buckling failure occurs much sooner than a compression failure as with the side supports on the Lunar Lander frame. A major difference in the buckling analysis for the legs is that one end is free to move where as both ends are fixed for the side supports. k in Equation 5 is four times as large for the legs. This k change cuts down the maximum force before buckling by a factor of 16 (assuming the length of the leg and side support are the same). The legs have a smaller outer diameter (6.0 cm) than the inner diameter of the side supports (9.2 cm) because the legs need to fit inside these side supports during Earth Launch. Although the k factor tends to increase the thickness of the legs, the legs are not as thick as the side supports because the length of each leg is about 0.405 m less than the length of a side support. Length is also a large contributor to the critical buckling force according to Equation 5. The legs contribute a small portion of mass to the overall frame mass for this reason. Shear failure at the connections between the different frame components: V A (5.4.1-7) becomes a concern. All of the frame beams are connected to either the outer ring on the Lunar Lander floor or the top ring. For all of these connections the area of each of the Author: Ryan Nelson Mission Configuration – 100g Payload – Lunar Descent Section A-5.4.1 beams previously calculated is checked to make sure that shear failure does not occur. Thickness increases by small increments until shear failure does not occur if shear failure occurs first in a frame component. All of the frame components have a 1.5 factor of safety. Table A-5.4.1-1 lists a breakdown of the shape and dimensions of each frame component for this Lunar Lander. Table A-5.4.1-1. Cross Sectional Shape and Dimensions for each frame component Structural Component Outer Ring Engine Support Ring Rectangular Floor Supports Side Supports Top Ring Legs Author: Ryan Nelson Cross sectional shape Circular Circular Rectangular Circular Circular Circular Outer Dimensions 10 cm Diameter 10 cm Diameter 10 cm Height, 6 cm Width 10 cm Diameter 10 cm Diameter 6 cm Diameter Thickness of cross section 4mm 4mm 6mm 2mm 4mm 3mm