Vacuum Measurement

advertisement

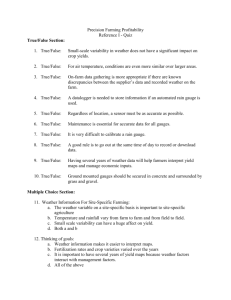

Vacuum Measurement Amir Danak AUT Winter 2004 Vacuum Measurement – Units / Ranges: Vacuum Applications: Industry: Rough-vacuum range near atmospheric to about 1 mbar: Mechanical handling Vacuum packing & forming Gas sampling Filtration Degassing ( Removing gases ) of oils Impregnation of electrical components Semiconductor devices fabrication 6 At lower pressure down to about 10 mbar: Refrigeration dehydration Metallurgical processes : i.e. Melting, Casting, Sintering, Brazing Chemical processes: vacuum distillation ( as a means of purification ) and freeze drying Semiconductor device fabrication 6 Pressure down to about 10 mbar: Cryogenic ( low-temperature ) & electrical insulation Lamps, television tubes, X-ray tubes, etc. Decorative, optical & electrical thin-film coating Mass spectrometer leak detectors Research: Pressure down to about 10 9 mbar: Electron microscopes Analytical mass spectrometers Particle accelerators Large-space simulation equipment Pressure region down to & bellow 10 9 mbar: Thermonuclear experiments Field ion & field emission microscopes Storage rings for particle accelerators Clean surface studies Specialized space simulator experiments Applications in industry: Electrical engineering industry: Manufacturing of electric light bulbs ( First usage : about 1900 ) Manufacturing power transformers & cables : ( Rem. large quantities of water from the core & windings, using a combination of heating & vacuum ) ( Also Removing air trapped in the windings / Finally being impregnated by oil ) Manufacturing of certain types of HV or HCC switches : Improvement in electrical insulation ( By Reducing their arcing or flashover in a LP env. ) Semiconductor Industry Chemical & allied industries: Lowering the boiling point ( to enable compounds to be separated into their ind. chem. compounds ) Purging Pipelines Production of reactive metals ( such as titanium ) Freeze drying: Dehydration by sublimation ( Changing the state without becoming water ) from the frozen surface Advantages : Minimal product spoilage ( ruin ) due to elim. of liquid & processing at sub-0 temp.s Using in : Reactive powders, Museum specimens, Tissue for microscopy, Preparation of blood plasma Product treatment : Coffee, Fruit juices, Vegetables, meat, Blood Plas., Antibiotics ( penicillin ) even Bone & Arteries have been preserved for long periods Vacuum coating: Vaporizing metals & salts under high vacuum , Condensing on any solid surface Producing : Mirrors, Ophthalmic lenses, Antiglare & antistatic glasses, Tel. tubes, Decorative Pls. Architectural glass ( multiple layers deposited, both transparent & heat reflecting ) Blooming of lens surfaces ( to increase light transmission ) Vacuum leak testing: Finding holes of app. one-millionth of cent. in diameter in a comp. having a wall thickness of 2mm. Aerospace, Electronics, Atomic energy, Cryogenics & Refrigeration industries, Missile const. Checking sealed devices ( such as transistors, crystals & relays ), U-Enrichment Vacuum Measurement: Total Pressure Measurement: No distinction is made between the permanent gases ( hydrogen, nitrogen, etc. ) and vapors ( oil vapor, water vapor, etc. ) Coming on the next page Partial Pressure Measurement: Also known as: Vacuum Analyzers Residual gas analyzers Mass spectrometers Vapors contained in the gases may be partially condensed, depending upon the comparison ratio & the degree to which the vapors are saturated Measurement: Determining the partial pressure of separate atomic & molecular species in the vacuum. Objective: Measuring the number of density of a particular species of molecule Results: Information more detailed than a rough estimate of total pressure Difficulty: The absorption rate & the desorption signal are dependant on the magnitude & location of the pumps Mass-Spectrometers: Identification of molecules by separating ions according to their charge to mass ratio Spectrometers: Detecting the release of chemisorbed & physisorbed gases upon heating the absorbent Using field emission or work function changes: Estimating the adsorbed gas coverage ( extent ) on surfaces Vacuum Total Pressure Measurement – Gauges: Direct: Mechanical phenomena gauges: Depend on the actual force exerted by the gas Measurement: The displacement of an elastic material The force required to compensate its disp. U-tube manometer Capsule dial gauge Strain gauge Capacitance manometers McLeod gauge Indirect: A particular physical property of the gas is measured Transport phenomena gauges: Measurement: The gaseous drag on a moving body Thermal conductivity of the gas Spinning rotor gauge Pirani, Thermistor & Thermocouple gauges Ionization phenomena gauges: Ionize the gas Measurement: Total ion current Cold cathode ionization gauge Hot cathode ionization gauge Mechanical phenomena gauges: U-tube manometer: Range: atmospheric pressure to 1 mbar Theory: System pressure = atmospheric pressure - pressure due to height of liquid ( h ) Problem: Dependent on atmospheric pressure, which varies from day to day Reason: Modifying by sealing one end More precision: Inclining the U-tube, thereby increasing the scale length Capsule dial gauge: Range: 1000 to 1 mbar Theory: Bordon Problem: Becoming contaminated, dirt or oil in the vacuum system Rapid rise in pressure caused by the system vacuum Not suitable for long distance measurement, due to the pressure drop along the line Mechanical phenomena gauges: ( Continued ) Strain gauges: Range: 1000 to 1 mbar Theory: Chg. in the Pressure causing a force, chg. the form of gauge, causing a change in R Advantage: Fast response time, Remote reading is available Capacitance manometers: Range: atmospheric pressure to 10-6 mbar Theory: Changing the capacitance between an electrode ( or electrodes ) & the diaphragm Problem: Sensitive to the temperature, oil … Advantage: Excellent zero stability, High signal-to-noise ratio Fast response, High precision Transport phenomena gauges: Spinning rotor gauge: Range: 0.1 to 10-7 mbar Theory: Slowing down of a levitated ball-bearing caused by molecular drag effects between the ball surface & the gas depends on: pressure, gas molecular weight & temperature of the gas & the surface state of the ball Advantage: Very accurate gauge Problem: Expensive Pirani, Thermistor & thermocouple gauges: Range: 1013 to 10-4 mbar ( Bellow that, the thermal conductivity principle is insensitive ) Theory: Pressure dependency of the ability of a gas to conduct heat Transport phenomena gauges: ( Continued ) Pirani: Filament = Sensor + Bridge Constant-voltage Pirani: Voltage exerted to the filament is constant, temperature is variable Range: 10 to 10-3 mbar Constant-temperature Pirani: Range: 1000 to 10-3 mbar Problem: Contamination ( by oil, etc. ) Thermocouple: Change of temperature of the filament is monitored by a thermocouple Range: 5 to 10-3 mbar ( Above 5, the filament temperature changes very little ) Advantage: Using very low power Ionization phenomena gauges: Only the ionization gauges, have proved really practical for UHV pressure measurement. Hot cathode ionization ( ion ) gauges: ( HCG ) Range: 10-3 to 10-10 mbar Bayard-Alpert gauge ( BAG ) Suppressor gauge Extractor gauge Orbitron gauge Gauges with magnetic fields Crossed-Field, Cold cathode gauges: ( CCG ) Range: 0.01 to 10-7 mbar Penning gauge Magnetron gauge Inverted magnetron Double inverted magnetron Ionization: Bombardment of a gas with electrons, remaining a positive ion Residual ( Remainder ) Currents: Establish a lower limit to the pressure measurable Soft x-ray ( Low-energy = No danger to health ) photo-emission: As electrons from the filament strike the grid, some of their energy is converted into X-rays. Many of these X-rays strike the collector & cause further electrons to be released from it. So some positive charge produced. Thus even if the pressure is below 10-10 mbar, the X-ray limit due to bombardment causes the gauge to register a steady 10-10 mbar. Hot cathode ionization gauges – Bayard-Alpert Type: ( BAG ) Theory: Thermionic emission Range: Boils electrons form a hot filament & accelerates them toward a cylindrical grid cage Electrons collide with gas molecules ionizing some of them A fine wire located at the center of the ionization volume collects ions, producing current Power requirement of a typical filament for 1mA emission is 10-15 W gas dependent ( Varying ionization efficiencies ) ( Normally nitrogen, argon ) 0.001 to 10-10 Torr. Lower limit: X-ray emission from the grid Upper limit: The response is non-linear & the danger of filament burning out Hot cathode ionization gauges – Bayard-Alpert gauge: ( Continued ) Advantages: Strict linear dependence of collector current on pressure More accurate, stable & reproducible than CCGs Problems: Reactions of the gas mols with hot filament, seriously affects the composition of the gas, reliability ( Typical operating temperature is 1700 ºC, hot enough to break down many mols into smaller fragments ) Filament lifetime ( ion bombardment, high pressure operation or chemical effects ) Delay ( Thermal equilibrium ) ( minutes to weeks! ) More complicated, require more power, bigger size than CCGs Current leakage through conducting layers, deposited on the inside of the gauge head Factors affecting the accuracy: Vacuum pumps resulting: water vapor, oil vapors, etc. changing the composition of gases. Depending on the past history of operation & the precise atmosphere in the vacuum system Acting either a source ( out gassing ) or sink ( pumping ) of gas: Whenever the gauge is exposed to atmosphere, gases are sorbed on all the interior surfaces. Releasing slowly when under vacuum, causing the gauge to read falsely high pressure. Reason: Degassing facility, causing the metal electrodes to be heated to 900 ºC. Immediately after degassing, the gauge acts like a pump, trapping gases to very clean surfaces. Reason: Using ‘Nude’ type of gauge head: a gauge head mounted on a flange, rather than in a body Cold cathode ionization gauges – Penning: Cold: Means No filament Theory: Discharge tubes: Two ways for indication of pressure a vacuum discharge tube is a glass vessel into which metal electrodes have been sealed and from which the air has been removed by a vacuum system. The probability of collision is proportional to gas density Range: 0.01 to 10-9 Torr. Lower limit: MFP of the electrons = very great, they travel straight to the electrodes, No colliding Upper limit: Current becomes so large, heating & sputtering from the electrodes becomes a problem Cold cathode ionization gauges – Penning: ( Continued ) Advantages: Faster than HCGs ( Respond very quickly to pumpdowns ) There is no filament to burn out Making outgassing much less of a problem Free of X-ray effect Degassing is not necessary Problems: The ion-induced current is not linearly related to the pressure, rather, the relationship is exponential Less accurate than HCGs Cleaning is necessary ( Oil vapors ) Starting of the CCGs can be delayed ( LP ), can be turned on at higher pressure during a pumpdown Uncertainty surrounding the accuracy of measurement: ( Price Comparison ) Lack of knowledge of the mixture of gases existing in the gauge head at any particular time Capsule dial ±5% of full-scale deflection Capacitance manometer ±1% of reading or better McLeod ±10% between 10-4 & 0.05 mbar Spinning Rotor ±1 – 2½% Pirani ±6% between 0.01 & 10 mbar Thermocouple ±10% between 0.01 & 1 mbar Penning +100% to –50 % e.g. at 10-4 it can be 2*10-4 or 5*10-5 mbar Bayard-Alpert ±10% between 10-7 & 10-4 mbar ±20% at 0.001 & 10-9 mbar ±100% at 10-10 mbar Vacuum Gauges – Companies: 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 2 3 3 3 3 3 3 3 3 3 3 4 4 4 4 4 4 4 4 4 4 5 5 5 5 5 5 5 5 5 5 6 6 6 6 6 6 6 6 6 6 7 7 7 7 7 7 7 7 7 7 8 8 8 8 8 8 8 8 8 8 9 9 9 9 9 9 9 9 9 9 10 10 10 10 10 10 10 10 10 10 Other companies: USG, Pascal technologies, VRC, JC Controls, … Vacuum Measurement – Active gauges – Inficon: Vacuum Measurement – Active gauges – Boc Edwards: Vacuum Intelligent ( Smart ) gauges: These electronic vacuum and pressure sensors are the way of the future Refrences: Books: ‘Modern vacuum practice’ by ‘Nigel Harris’ , McGraw-Hill ‘Scientific foundation of vacuum technique’ by ‘Saul Dushman’ , John Wiley & Sons ‘The physical basis of ultra-high vacuum’ by ‘P.A. Redhead, J.P. Hobson, E.V. Kornelsen’ , Chapman & Hall LTD Web: www.modernvacuumpractice.com www.lesman.com/index.html www.vacuumlab.com www.aip.org/tip www.activac-technology.com/index.html www.bocedwards.com www.inficon.com www.lacotech.com/index.html www.thinksrs.com www.helixtechnology.com/index.html www.mksinst.com/hpshome.html www.myers-vacuum.com www.jccontrols.net Intelligent: www.meriam.com www.festo.com www.hotektech.com/index.html www.sunx-ramco.com/index.htm www.vaccon.com www.fipa-online.com/language.asp www.ifm-electronic.com