NASA Wireless Smart Plug

advertisement

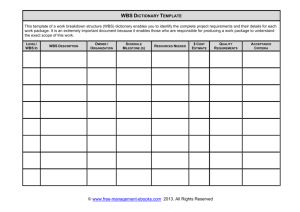

System Definition Review NASA Wireless Smart Plug Experimental Control Logic Labs September 19th, 2012 SDR Agenda 1.Team Members 2.Vision, Mission, Goal and Objectives of Project 3.Concept of Operations 4.System Architecture (includes system definition, concept and layout) 5.Level 1 Requirements 6.Traceability of requirements “flow down” 7.Work Breakdown Structure (WBS) 8.Technical Assessment 9.Preferred system solution definition 10.Preliminary functional baseline 11.Preliminary system software functional requirements 12. Risk assessment and mitigations approach 13. Design & Analysis tools to be used 14. Cost and schedule data 15. Hardware & Software Test Matrix 2 Team Members Paul Delaune NASA Technical Subject Matter Expert 3 Dr. Joseph Morgan MISL Director Matthew Leonard NASA Liaison Capstone Team Dr. Jay Porter Capstone Advisor Akeem Whitehead Project Manager Derek Garsee Software Engineer Jeffrey Jordan Hardware Engineer MISL Team Christian Carmichael Systems Integration Engineer Mission Goals and Objectives Create a control/monitoring system for DC power distribution on NASA Deep Space Habitat (DSH) Remotely configurable from Master Control Software (MCS) Automated monitoring and control of current draw 4 Concept of Operations • NASA Wireless Smart Plug (NWSP) is a proof-of-concept prototype • Installed in the Deep Space Habitat (DSH) mock-up for testing and evaluation purposes only (not space qualified) • Used to monitor and control power usage of DSH and its installed equipment • Monitor current draw from targeted device, and define actions based on measurement (i.e. wireless communication, emergency disconnect, load shedding). 5 6 System Architecture 120V-DC and/or 28V-DC NASA Wireless Smart Plug 1 sample/second ISA100.11a IEEE 802.15.4 120V-DC or 28V-DC Typical Device Windows OS LabVIEW GUI DSH Network Nivis VersaRouter 900 Master Control 7 System Architecture 120V-DC and/or 28V-DC NASA Wireless Smart Plug 1 sample/second ISA100.11a IEEE 802.15.4 120V-DC or 28V-DC Typical Device Windows OS LabVIEW GUI DSH Network Nivis VersaRouter 900 Master Control System Breakdown 8 NWSP Sensing & Control MSP430F5438 Wireless Communications VersaNode 210 VersaRouter 900 Client Software LabVIEW GUI Configuration & Display Level 1 System Requirements Power Control Support for 120V/28V DC Near real-time monitoring/control Fail safe Windows based master control client Communications Wireless configuration, control, monitoring and reporting Data rate: 1 sample/second Use a Nivis VN210 radio Support a Nivis VR900 router Standards: UART, ISA 100.11a Form Factor & Fit Small form factor Cannon-type connector Integration with DSH Deliver five NWSP units for evaluation 9 Requirements Flow Down 1/3 10 Power Control Voltages Monitor Fail Safe Threshold GUI 28VDC 0 to 5A 0 to 5A Standalone Executable 120VDC 3% Full Scale 0.1A Inc. Windows OS Trips Requirements Flow Down 2/3 Communications Data Rate Equipment Protocol 1 sample/s Nivis VN210 ISA100.11a IEEE 802.15.4 Trip Within 3s Nivis VR900 UART 11 Requirements Flow Down 3/3 Form Factor & Fit Size Integration 3” x 3” x 3” 5 NWSP Cannon-type Connector DSH Install 12 Project Work Breakdown Structure Overview 1/9 Total # of Boxes: 147 Project = 1 Phases = 7 Activities = 21 Tasks = 51 Sub-Tasks (Terminal Element) = 67 Total # of Work Packages: 106 13 WBS Phase Level 2/9 14 WBS 1.0 Research 3/9 15 WBS 2.0 Design 4/9 16 WBS 3.0 Simulation 5/9 17 WBS 4.0 Implementation 6/9 18 WBS 5.0 Testing 7/9 19 WBS 6.0 Documentation 8/9 20 WBS 7.0 Close-out 9/9 • All documents, development tools, and code will be transferred to MISL for final systems integration and deployment with NASA DSH 21 22 Technical Assessment: Current Sensor Device Pros Cons Cost ACS714 • • • • • 100 mV/A output $3.89 ACS754 • Low power loss • 1.2% full scale error • Higher load capacity • 50 A range • 10 mV/A output • Relatively expensive $7.00 ACS759 • Low power loss • Quick response time • Higher load capacity • Relatively low accuracy • 56 mV/A output • 12.5 A range $7.00 Hall Effect Small packaging 5 v input voltage 5A range Preferred System Solution Processor MSP430F5438 Wireless Communication VersaNode 210 VersaRouter 900 Current Sensing ACS714 Power Switching: G9EA-1 DC Power Relays Regulation: TI TL783 Linear Regulator Client Software LabVIEW 23 Preliminary Functional Baseline Functional Block Diagram 24 Power Budget Device VersaNode210 MSP430F5438 ACS714 Current Sensor IC Voltage Regulator 120V-DC Enable Circuit Selection Circuit Voltage Measurement Circuit 25 Max Current Draw 60 mA 312 uA 13 mA Preliminary System Software Functional Requirements • Master Control Unit • Communicate wirelessly with NWSP • Add/Configure NWSP units • Receive and display NWSP information • NWSP • Receive parameters from MCS • Perform auto disconnect • Control and monitor power usage • Report current draw to MCS 26 MCS Example GUI 27 PMI Risk Management Process • Identify • Evaluate • Develop Response • Control 28 Risk Prioritization Matrix Priority Total Overall 3 3 High 5 1 Low 6 0 Low 1 5 High 2 4 High 4 2 Medium Risk 1. Project goes overschedule 2. Injury or damage from 120V source 3. Funding delayed 4. Delay in parts procurement. 5. Solving 120V/28V available power problem 6. Limited financial resources 29 Comparison 1 2 12 33 123 444 1234 5555 12345 66666 Risk Evaluation 30 HIGH 5 4 PROBABILITY OF OCCURRENCE 6 1 LOW 1. 2. 3. 4. 5. 6. Legend Project over-schedule Injury/damage from 120V Funding delayed Delay in parts Solving 120V step-down Limited financial resources 3 2 HIGH LOW SEVERITY OF IMPACT Design & Analysis Tools to be Used NI Multisim Simulation OpNet Simulation NI Ultiboard PCB design LabVIEW GUI Inventor Enclosure Code Composer Studio MSP430 Programming Capstone Design Tools 31 Preliminary Cost Budget NASA $40,915 $3,000 Cost Sharing • Labor • Travel • Equipment $5,000 (TI) • ODCs $5,000 • Overhead/Indirect $22,501 (TAMU) _____________________________________________ Total Cost to Sponsor $48,915 $27,501 32 Schedule 33 NWSP Gantt Chart 28-Aug-12 Research Phase Design 17-Oct-12 6-Dec-12 Duration 25-Jan-13 16-Mar-13 5-May-13 11/1/12 11/25/12 Simulation 4/17/13 Implementation 4/18/13 Testing Documentation Close-out 4/29/13 5/6/13 5/10/13 Test Matrix 34 NASA Deliverables Date 1/8/12 19/9/12 Activity Kickoff Meeting SDR 24/10/12 PDR 5/12/12 CDR 10/12/12 Weekly 13/2/13 Project Status Meetings Progress Checkpoint #1 5/3/13 3/4/13 Final Design Review Progress Checkpoint #2 15/5/13 20/5/13 Progress Checkpoint #3 Final Presentation 15/6/13 15/8/13 15/9/13 Integration with DSH DSH Integrated Testing Final Acceptance Deliverable Draft System Design Process (SDP) Presentation Power Point Slides Video Presentation Power Point Slides Video Presentation Power Point Slides Video Final SDP Report Presentation and PPT Slides Alpha Schematic Alpha Board Layout Software Hierarchical Charts Test Matrix Presentation and PPT Slides Final Schematics Final Board Layout Software Flow Charts Test Plan Final Demonstration Final Report Five Smart Plugs Field Test Plan Field Test Report 35 Questions/Comments 36 Clarifications How many measurements per observation i.e. multiple array of values versus a single value) How long is the measurement process to remain active considering 1 sample/second Multiple measurement analysis i.e. averaging, sliding windows, statistical, etc. How will the limits be defined i.e. 2.9A is devices actual limit, 3.0A is the ideal limit, trip occurs at 3.1A threshold Trip response? i.e. circuit breaker, fast-blow fuse, slow-blow fuse, etc. How many NSWP devices will be used in actual implementation of DSH? 8-bits of addressing versus 64-bits of addressing 37