Junio 4, 2014. Flavonoides Totales C/tiempo de espera Sin/tiempo

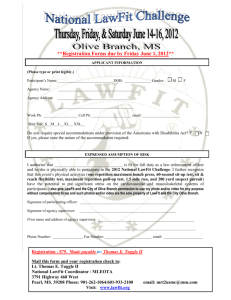

advertisement

Junio 4, 2014. C/tiempo de espera Catequina Flavonoides Totales Aceituna Nevadillo Extracción (I) 1a y 2a. Ext. Metanol (100%) 3a. Ext. Metanol (80%) 4a. Ext. Acetona (70%) mg/g p.seco Reacción según Annegowda y col. (2011) 2/06.2014 124.81 104.62 11.91 0.1502 2.01 -1.0765 138.73 Total Extracción (II) 3 veces Metanol (100%) Extracción (III) 3 veces Metanol (100%)+ Hexano (s/aceite) Reacción según Kim et al (2003) 28/05/2014 29/05/2014 30/05/2014 Sin/tiempo de espera Catequina mg/g p.seco 7.25 mg EC/ g peso 103.6937 fresco - 103.7 - 82.04 93.02 94.12 84.94 5.08 mg EC/ g peso 72.60 fresco . La extracción I y II dan resultados similares y son un mayores que los de la extracción III donde se elimina el aceite con hexano. La determinación se realizó varias veces y con diferente metodología. Los valores de flavonoides totales (extracción I) son similares a los de Martinelli y Tonutti (2012) y Souza y col (2014), expresados como mg Equivalentes de catequina/ g peso fresco. 1 Fenoles Totales Aceituna Nevadillo mg EAG mg EAG/g /Kg peso peso seco seco Extracción (I) 1a y 2a. Ext. Metanol (100%) 3a. Ext. Metanol (80%) 4a. Ext. Acetona (70%) Total Extracción (II) 3 veces Metanol (100%) Extracción (III) 3 veces Metanol (100%)+ Hexano (s/aceite) 15.26 6.26 3.28 24.8 24800 g EAG/Kg peso fresco 1.73 43.82 43820 6.02 86.08 86080 NOTA: Extracción (I) da valores similares a Issaoui y col (2011), (aunque los de este autor están reportados como equivalentes de hidroxitirosol y mg ET/ kg de peso seco), así como a los de Sousa y col (2014) quienes reportan como mg de EAG/ g peso seco, y superiores a otros estudios. Los valores de la extracción I y II se encuentran en el rango reportado por Tsantili (2014) como mg de EAG/ g peso seco de aceitunas maduras (negras) Se observa un mayor contenido de fenoles totales en la extracción III usando metanol al 100% y lavando el extracto con hexano para eliminar aceite. EAG: Equivalentes de ácido gálico. Estos valores son similares a los reportados como mg de eq. de ácido caféico/ kg de peso seco por Tovar y col (2002). Los valores de la extracción I y II están en el rango de valores reportado por Machado y col (2013), mientras que los de la extracción III son superiores. Procedimiento. Extracción I. Se tomaron 0.6 g de muestra liofilizada y se les adicionó 10 ml de metanol (100%), se homogenizaron en un Ultra Turrax por 1 min (12000 rpm). Posteriormente, se sonicó por 1 h en un Sonicador Branson. Se decantó la muestra, y se volvió a repetir este procedimiento por 3 veces más (1 h Metanol 100%, 30 min Metanol 80%, 30 min. Acetona 2 70%). Se combinaron todos los extractos y se centrifugaron. Se filtraron para su posterior análisis. Se usó el método de Aktas et al., (2014) sin extracción con hexano. Extracción II. Se tomaron 0.3 g de muestra liofilizada y se les adicionó 5 ml de metanol (100%), se homogenizaron en un Ultra Turrax por 2 min (12000 rpm). Se decantó la muestra, y se volvió a repetir este procedimiento por 2 veces más (5 ml Metanol 100% en cada extracción). Se combinaron todos los extractos y se centrifugaron. Se filtraron para su posterior análisis. Se usó el método de Aktas et al., (2013) sin extracción con hexano. Extracción III. Se tomaron 0.3 g de muestra liofilizada y se le adicionó 5 ml de metanol (100%) y se homogenizaron en un Ultra Turrax por 2 min (12 000 rpm). Se decantó la muestra, y se volvió a repetir este procedimiento por 2 veces más (5 ml metanol 100% en cada extracción). Se combinaron todos los extractos y se rotoevaporaron hasta un volumen final de 5 ml. Posteriormente se le adicionaron 10 ml de hexano para eliminar el aceite. Se separó el hexano en un embudo de separación, para su posterior eliminación del hexano. El exceso de hexano se eliminó con un flujo de nitrógeno por 2 min. Se filtró el extracto metanólico para su posterior análisis. Aktas et al., (2013) con extracción con hexano. 3 Fenoles y Flavonoides Totales en Aceitunas Referencia Muestra Cantidad muestra/Solvente 0.3 g + 5 ml MeOH 5X* Método Extracción Homogenización a 15000 rpm ( 5 X) concentración en rotavapor Aktas et al. (2014) Liofilizada Issaoui et al. (2011) Liofilizada 3 g + 50 ml MeOH (80%) Homogenizado (2X) Brahmi et al. (2014) Aceituna secadas a 25°C/ 8 días 5 g + 100ml MeOH Orbital Shaker 200 rpm (15 min) Sousa et al. (2014) Congelada (20°C) 5g + 50 ml MeOH (50%) Incubación (30 min) 3X (lavado con hexano) Tsantili (2014) Liofilizado 500 mg + Acetona (80%) Sonicación (15 min) 3X Brahmi et al. (2013) Secado al Horno (40°C)/3 días Congeladas c/N2 liquido 5 g + 100 ml MeOH Shaker (15 min) 1 g + 40 ml hexano (lavado) + 80 ml MeOH (80%) (extracción) 100 g + 250 ml MeOH (80%) Agitación (5 min) 3X Martinelli y Tonutti (2012) Jemai et al. (2009) Congeladas N2 liquido Bouaziz et al. (2010) Congeladas N2 liq a 80°C 100 g + 250 ml MeOH (80%) Agitación (24 h) Machado et al. (2013) Congelada a -80°C 5 g + 50 ml MeOH (50 %) Kiai y Hafidi (2014) Congelada Incubado (30 min) 3X lavado c/ hexano Incubación (15 min) 3X, lavado con hexano 10 g + 20 ml metanol 80% Agitación (24 h) Lavado c/hexano Fenoles Totales 29.21 a 1230.44 mg EAG/100g peso seco 25000 mg ET/kg peso seco 536.96 y 622.38 mg ET/100g peso seco 16.95 a 33.96 mg EAG/g peso fresco 30.09 a 36.91 mg EAG/g peso seco 139.26 a 802.62 mg EHT/100 g peso seco No analizado Flavonoides Totales No Analizado ~4 a 12 g EAG/kg peso fresco 3.46 a 4.3 g EAG/Kg peso fresco 8.7 a 61.3 mg EAG/ g peso seco 2 a 2.8 g ET/100 g peso seco ~ 60 a 200 mg EC/Kg peso fresco No analizado 222.89 y 174.32 mg EC/100 g peso seco 5.08 a 26.15 mg EC/g peso fresco No analizado 95.84 a 454.70 mg EC/100 g peso seco ~7 mg EC/g peso fresco 0.14 a 0.19 g EC/Kg peso fresco No analizado 0.8 a ~1.4 g EC/100 g peso seco *5X= 5 veces. EHT: Equivalentes de Hidroxitirosol EAG: Equivalentes de Ácido gálico ET: Equivalentes de tirosol EC: Equivalentes de catequina 4 J. Sci Food Agric 2014; 94: 691–698 Phenolics profile of a naturally debittering olive in comparison to regular olive varieties† A Burcu Aktas, Banu Ozen,∗ Figen Tokatli and Ilknur Sen Olive samples Three different types of olive were used in the analysis: Gemlik (G), Erkence (E) and Hurma (H) (naturally debittering Erkence) olives. For the two harvest years (2011 and 2012) all olives were picked up during 8 weeks of the maturation period from the end of October until the beginning of December. Every week approximately half a kilogram of olives was picked up from the all sides of three trees for each type. After harvesting, the kernels of olives were separated from the fruit immediately. For the storage, olives were first immersed in liquid nitrogen, then dried with a freeze dryer (Labconco, Kansas City, MO, USA). Total phenol content measurement The concentrations of total phenolic compounds of olives were determined with the Folin– Ciocalteu assay.12 Lyophilised olive pulp (0.3 g) was weighed and extracted with 5 mL methanol five times. The methanol in the extract was evaporated at 45 °C with a rotary evaporator (Laborato 4000; Heidolph,Schwabach,Germany) in 20 min. The remaining extract was dissolved in 5 mL methanol again. Resultados Total phenol content Values for the TPC of all three types of olive are listed in Table 1. The TPC of the Erkence variety changed between 504.7 and 1230.4 mg GAE 100 g−1 in 2011–2012, and between 335.9 and 664.8 mg GAE 100 g−1 in the 2012–2013 harvest years, respectively. Dhokar, the Tunisian sweet olive variety, also had a lower TPC (508–768mg GAE 100 g−1 DW) when compared with another olive variety, Chemlali (698–1300mg GAE 100 g−1 DW) and researchers also attributed the lower TPC of this variety to its sweet character. During the ripening period the TPC of all olive types increase and decrease. Mostly, there is a decreasing trend after the second week until the firth week, and an increase in TPC follows this decreasing phase. This trend of increase and decrease was also observed in other studies. 5 Eur Food Res Technol (2011) 232:867–876 Fatty acid profile, sugar composition, and antioxidant compounds of table olives as affected by different treatments Manel Issaoui • Samia Dabbou • Beligh Mechri • Amel Nakbi • Hechmi Chehab • Mohamed Hammami Olive samples (Olea europaea L. cv. ‘Meski’ (Tunisia), ‘Picholine’ (France), and ‘Manzanella’ (Spain)) were handpicked randomly of one tree each and transported. All cultivars were hand harvested and transported to the laboratory on the same day. Preparation of olive samples Olives were de-stoned and immediately placed in liquid nitrogen and then freeze-dried (-47 C) according to the moisture content of the fruit. Freeze-dried samples were placed in a freezer until ready for use. Each sample of freezedried pulp was then blended in a general-purpose electric blender to a fine powder. The powder was stored under nitrogen in plastic screw top jars, in a freezer at -20C. Total phenols content The amount of total phenolics in the fruit extracts was determined colorimetrically as described previously by Montedoro et al. [25]. In fact, 50 mL of methanol 80% was added to 3 g of the freeze-dried olive pulp. The mixture was homogenised then centrifuged at 5,000 rpm for 10 min. This step was done twice, and supernatants were mixed together and concentrated with a rotavapor until a final volume of 10 mL. Then, 10 mL of Folin Ciocalteu’s reagent (previously diluted 10-fold with distilled water) and 8 mL of Na2CO3 (75 g/L) were added to a suitable aliquot of the combined extracts, and the absorbance of the solution at 765 nm was measured after 2 h. Values were given as mg of hydroxytyrosol per kg of dry weight. Results obtained showed that fruit with a higher maturation index correlated with having lowest phenols content. This is in accordance with the results of Morello et al. [34] who also reported that varieties with smaller drupes had a higher level of oleuropein. 6 7 Variation in antioxidant activity and phenolic content in different organs of two Tunisian cultivars of Olea europaea L. Faten Brahmi • Beligh Mechri • Madiha Dhibi • Mohamed Hammami Acta Physiol Plant (2014) 36:169–178 Sample preparation Olea europaea L. aerial parts of the two Tunisian cultivars (‘chetoui’ and ‘chemchali’) were collected from the north (Beja) and the south (Gafsa) of Tunisia. Olive leaves and fruits were isolated manually from the aerial parts in our laboratory to obtain a weight of 500– 700 g of each part. The stems were separated from the other parts. Part of the leaves, fruits and stems has been dried in the shadow at room temperature (25 C), for 8 days. Voucher specimens have been deposited in the Herbarium of the Laboratory of Biochemistry, Faculty of Medicine of Monastir, Tunisia. Methanol extract Fresh leaves and fruits were pulverized to 0.2–0.4 mm particle in a cutting mill. The fresh leaves and fruits samples (5 g) were extracted with 100 ml of methanol solvent in an orbital shaker (Eyela Model MMS-300, Tokyo Rikakikai Co., Ltd., Japan) at 200 rpm, at room temperature and after centrifugation at 1,000g for 15 min, supernatant was decanted and the pellets were extracted under identical conditions. Supernatants were combined and used for analysis. The stems of each herb were manually ground to a powder and then extracted with absolute methanol, in a 1:10 (w/v) ratio of herb to solvent, for 4 h under a continuous reflux set up in a Soxhlet extractor. After the extraction, the methanol extracts were clarified by filtering through Whatman # 1 filter paper, followed by centrifugation at 14,000g for 5 min (Peter and Wong David 2006). All clarified methanol extracts were stored at -20 C prior to experimentation. Total phenols and o-diphenols Total phenolic and o-diphenols contents of fractions were determined according to the method of Montedoro et al. (1992) with minor modifications. For total phenols, 0.4 ml of each fraction and 10 ml of diluted Folin–Ciocalteu reagent were mixed. After 1-min incubation, 8 ml of sodium carbonate (75 g/l) was added and the mixture was incubated for 1 h. The absorbance was measured at 765 nm. The same extract was used to determine total odiphenols. Then, 1 ml of a solution of HCl (0.5 N), 1 ml of a solution of a mixture of NaNO2 (10 g) and Na- MoO4_2H2O (10 g) in 100 ml H2O and finally 1 ml of a solution of NaOH (1 N) were added to 100 ll of the extract. After 30 min, o-diphenols were read at 500 nm. The total phenols and o-diphenols were expressed on a dry weight basis as mg hydroxytyrosol equivalents/100 g of sample. Determination of total flavonoids Total flavonoid contents (TF) of the extracts were determined according to the colorimetric assay developed by Zhishen et al. (1999). One milliliter of properly diluted fruit extract was mixed with 4 ml of distilled water. At zero time, 0.3 ml of (5 % w/v) NaNO2 was added. After 5 min, 0.3 ml of (10 % w/v) AlCl3 was added. At 6 min, 2 ml of 1 M solution of NaOH was added. After that, the volume was made up to 10 ml, immediately by the addition of 2.4 ml of distilled water. The mixture was shaken vigorously and the absorbance of the mixture was read at 510 nm. The results were also expressed on a dry weight basis as mg catechin equivalents (CEQ)/100 g of sample. 8 ‘Cobrancosa’ Olive Oil and Drupe: Chemical Composition at Two Ripening Stages Claudia Sousa • Irene Gouvinhas • Diana Barreira • Maria Teresa Carvalho • Alice Vilela • Joao Lopes • Paula Martins-Lopes • Ana I. Barros J Am Oil Chem Soc (2014) 91:599–611 Only healthy olive drupes, without any kind of infection or physical damage were selected. Olive fruit samples were collected in two maturity stages: semi-ripe and ripe. At each sampling date, the maturity index according to their skin and pulp color was determined [11]. The ripeness index (RI) values range from 0 (100 % intense green skin) to 7 (100 % purple flesh and black skin). The olives were handpicked in the crop year 2011 on two different days. The semi-ripe samples (RI = 2.5—skin green with reddish spots) were collected in October (Oct 14, 2011) and the ripe samples (RI = 6—skin black with [50 % purple flesh) were harvested in November (Nov 8, 2011). After harvesting, the olive fruits were immediately transported to the laboratory and stored at -20 C until analysis. Preparation of Olive Fruit Extracts Olive samples (5 g) were macerated with 50 mL of a mixture of MeOH/H2O (50:50) and incubated at room temperature for 30 min. After, the supernatant was decanted and extractions were repeated three times. The liquid phase was filtered and subsequently centrifuged at 9,000 rpm for 10 min. To remove the fat phase the mixture was washed twice with hexane (50 mL) using a separating funnel and the organic phase was discarded. Three replicates per sample were performed. Each was introduced into a 200mL round-bottom flask, completing the volume of solution to capacity with MeOH/H2O (50:50) [14]. Total Phenolic Content The content of total phenolic compounds in the olive samples was determined using FolinCiocalteu reagent, with gallic acid as standard [17]. This method is based on the reduction of a phosphowolframate-phosphomolybdate complex by phenolics to blue reaction products. First, 1 mL of a diluted sample was mixed with 500 lL of Folin- Ciocalteu reagent, 2 mL of 7.5 % sodium carbonate solution and 6.5 mL of water. The mixture was shaken and the absorbance of the standards and samples was measured at 750 nm after 30 min reaction at 70 _C in relation to a gallic acid standard curve. All measurements were performed in triplicate. The results of olive drupes were expressed as milligrams of gallic acid equivalents per gram of sample (mg GAE g-1). 9 Flavonoids Content Total flavonoids were measured by the colorimetric assay developed by Zhishen et al. [19]. In a test tube, 0.5 mL of the sample-working solution and 150 lL of 5 % NaNO2 aq were introduced. After 5 min, 150 lL of 10 % AlCl3 aq were added and 6 min after 1 mL of 1 M NaOH was added. The mixture was shaken and the absorbance of the standards and samples was measured at 510 nm in relation to a catechin standard curve. All measurements were performed in triplicate. The results were expressed as milligrams of catechin per gram of sample (mg catechin g-1). Quality attributes and their relations in fresh black ripe ‘Kalamon’ olives (Olea europaea L.) for table use – phenolic compounds and total antioxidant capacity Eleni Tsantili International Journal of Food Science and Technology 2014, 49, 657–665 Extraction for measurements of total phenolic concentration and total antioxidant capacity The extraction was carried out according to Tsantili et al. (2012). Freeze-dried slices stored at _80 °C were powdered with a mortar and pestle in liquid nitrogen before phenolic extraction. For antioxidants, 500 mg of powdered tissue was extracted thrice with 80% v/v acetone in an ultrasonic ice bath for 15 min. The samples were then centrifuged at 4000 g for 5 min. The combined supernatants were divided into 2 parts, A and B. Phenolic compounds were extracted from part A thrice with same volume of ethyl acetate each time. The organic solvent was removed by a rotary evaporator at 37 °C, and the residue was dissolved in 0.5 mL methanol, filtered through a nylon syringe filter (0.2 lm pore size) and analysed by high-performance liquid chromatography (HPLC). Part B was used for total phenolic concentration (TP) and total antioxidant capacity (TAC) determinations. 10 Determination of total phenolic concentration and total antioxidant capacity The TP concentration was measured by a modified Folin–Ciocalteu colorimetric method (Singleton et al., 1999). Briefly, 0.2 mL of diluted extract was added into a tube containing 2.6 mL of water and 0.2 mL of Folin–Ciocalteu reagent. After 6 min at room temperature, 2 mL of Na2CO3 (7%, w/v) was added to the mixture. After incubation for 90 min at room temperature, absorbance was measured at 750 nm against a blank using a spectrophotometer (Hekios Gamma & Delta; Spectronic Unicam, Cambridge, UK). Results were expressed as gallic acid (mg GAE) equivalents per g of freeze-dried weight. Variations in phenolic compounds and antiradical scavenging activityof Olea europaea leaves and fruits extracts collected in two differentseasons Faten Brahmi∗, Beligh Mechri, Madiha Dhibi, Mohamed Hammami Industrial Crops and Products 49 (2013) 256– 264 2.3. Preparation of extracts Fresh leaves and fruits were air-dried in an oven at 40◦C for three days and then were pulverized to 0.2–0.4 mm particle in a cutting mill. For extraction, the fresh leaves and fruits samples (5 g) were extracted with 100 ml of the solvent methanol in a shaker (EyelaModel MMS-300, Tokyo Rikakikai Co., Ltd., Japan), at room temperature. After filtration, all extracts obtained were then transferred to vials and kept in the dark at −20◦C prior to use. 2.5. Total phenols and o-diphenols Total phenolic contents and o-diphenols of fractions were deter-mined according to the method of Montedoro et al. (1992) with minor modifications. For total phenols, 0.4 ml of each fraction and10 ml of diluted Folin–Ciocalteu reagent were mixed. After 1minincubation, 8 ml of sodium carbonate (75 g/l) was added and the mixture was incubated for 1 h. The absorbance was measured at765 nm. The same extract was used to determine total o-diphenols. Then, 1 ml of a solution of HCl (0.5 N), 1 ml of a solution of a mixture of NaNO2(10 g) and NaMoO4·2H2O (10 g) in 100 ml·H2O and finally 1 ml of a solution of NaOH (1 N) were added to 100 _l of the extract. After 30 min, o-diphenols were read at 500 nm. The total phenols and o-diphenols were expressed on a dry weight basis as mg hydroxytyrosol equivalents/100 g of sample 11 2.6. Determination of total flavonoids Total flavonoid contents (TF) of the extracts were determined according to the colorimetric assay developed by Zhishen et al.(1999). One ml of properly diluted extract was mixed with 4 ml of distilled water. At zero time, 0.3 ml of (5% w/v) NaNO2was added. After 5 min, 0.3 ml of (10% w/v) AlCl3 was added. At 6 min, 2 ml of1 M solution of NaOH were added. Finally, the volume was made up to 10 ml, immediately by the addition of 2.4 ml of distilled water. The mixture was shaken vigorously and the absorbance was read at 510 nm. The results were also expressed on a dry weight basis as mg catechin equivalents (CEQ)/100 g of sample. Chemical composition changes in four green olive cultivars during spontaneous fermentation Hajar Kiai, Abdellatif Hafidi LWT - Food Science and Technology 57 (2014) 663-670 2.3. Extraction The olive fruit pulp was crushed with hammer crusher in bath of ice (4 _C). A quantity (l0 g) of the obtained paste was extracted for 15 min with 20 ml of methanol/water 80:20 (v/v) at room temperature. The mixture was centrifuged at 4000 g for 10 min and the supernatant was recovered. The residues were re-extracted under identical conditions for further two times. The supernatants were combined, filtered and washed with hexane to remove oil. This extract was used for sugars; total phenolic and flavonoids content determination in olive flesh. Sugars, total phenolic and flavonoids contents were determined directly from brine samples. A volume of 50 ml of brine samples was extracted three times with ethyl acetate (v/v) at room temperature. The extracts was concentrated to dryness in a rotary evaporator and dissolved in 5 ml methanol for antioxidant activity determination and HPLC analysis.. 2.6 Total phenolic content Total phenolic content were determined colorimetrically using Folin Ciocalteu reagents according to the method of Catalano, Franco, De Nobili, and Leita (1999) using tyrosol as a standard, with slight modifications. The extract (100 ml) was mixed with 3.9 ml of distilled water and 100 ml of Folin-Ciocalteau reagent and allowed to stand at ambient temperature, for 3 min. 1 ml sodium carbonate solution (200 g/l) was added to the mixture. The tubes were left for 60 min in the dark at room temperature; absorbance was measured 12 at 725 nm using a visible spectrophotometer. The concentrations were expressed as g of tyrosol equivalent (TYE) per liter of brine and as g of TYE per 100 g of flesh dry weight (dw). The total phenolic content of olive flesh and brines were measured in triplicate. 2.7. Total flavonoids content Total flavonoids were measured by a colorimetric assay developed by Zhishen, Mengcheng, and Jianming (1999). 200 ml of diluted sample was added to 0.8 ml of distillate water. First 0.06 ml of sodium nitrite (50 g/l) was added to the flask. After 5 min, 0.04 ml of aluminum chloride (100 g/l) was added. At 6 min, 0.4 ml of 1 mol/l sodium carbonate was added to the mixture. Immediately, the flask content was diluted with the addition of 0.5 ml of distillate water and thoroughly mixed. Absorbance of the mixture was determined at 510 nm against prepared water blank. The concentrations were expressed as g of (þ)-catechin equivalent (CAE) per liter of brine and as g of CAE per 100 g of flesh dry weight (dw). The total flavonoids content of olive flesh was analyzed in triplicate. Phenolic profile and antioxidant activities of olive mill wastewater Abdelilah El-Abbassi, Hajar Kiai, Abdellatif Hafidi Food Chemistry 132 (2012) 406–412 2.4. OMW extracts The phenolic extract was obtained by a liquid–liquid extraction of the OMW. First, the pH of OMW samples (5 ml) was adjusted to pH 2 using HCl (2 M). After defatting with nhexane, extractions with ethyl acetate were performed thrice, and the three extracts were brought to dryness by vacuum evaporation at 40 _C, and then recuperated in 5 ml methanol. The resulting extract is called ‘phenolic extract’. 2.5. Total phenolic content, flavonoids, flavanols, and proanthocyanidins determinations - Total phenolic content (TPC) was determined following the Folin–Ciocalteu spectrophotometeric using tyrosol as a standard. The phenolic extract (0.1 ml) in a volumetric flask was diluted with distilled water (3.4 ml). Folin–Ciocalteu reagent (0.5 ml) was added and the contents of flask were mixed thoroughly. After 3 min 1 ml of a 20% anhydrous sodium carbonate solution (w/v) was added, and then the mixture was allowed to stand for 1 h in the dark. The optical density of the blue-coloured samples was measured at 765 nm. The total phenolic content was determined as tyrosol 13 equivalents (TYE) and values are expressed as g of tyrosol/l of olive oil mill wastewaters. - For the total flavonoids, a modified method from Kim, Chun, Kim, Moon, and Lee (2003) was used. A 0.2 ml aliquot of extract appropriately diluted was mixed with 0.8 ml distilled water in a 5 ml assays tube, 0.06 ml 5% NaNO2 was added, and allowed to react for 5 min. Afterwards, 0.04 ml 10% AlCl3 was added and the mixture stood for further 5 min. Finally, 0.4 ml 1 M Na2CO3 and 0.5 ml distilled water were added to the reaction mixture, and the absorbance at 510 nm was obtained against a similarly prepared blank, by replacing the extract with distilled water. Total flavonoid content was calculated from a calibration curve using catechin as a standard, and expressed as mg catechin equivalents (CTE) per litre of the extract F. Martinelli & P. Tonutti (2012) Flavonoid metabolism and gene expression in developing olive (Olea europaea L.) fruit, Plant Biosystems -146:sup1, 164-170 Plant material Fruit was sampled in 2008 from Olea europaea (L.) (cv Leccino) trees cultivated near Lucca (Italy) at 4 weeks after flowering (WAF) (before pit hardening), 9 WAF (after pit hardening), 12 WAF (mature fruit, green epicarp pigmentation), and 16 WAF (ripe fruit, about 50% epicarp pigmentation change). At 4 and 9 WAF, the entire pericarp was collected, whereas epicarp and mesocarp were collected separately at 12 and 16 WAF. All samples were frozen with liquid nitrogen and stored at -80C until use. All analyses were performed using three replicates consisting of a pool of 10 homogeneous fruits. Total flavonoid quantification One gram of ground olive tissues was mixed with 40 ml of hexane and agitated for 4 min; the upper phase was recovered and the extraction was repeated twice successively with the lower phase. Flavonoid compounds were extracted with 80 ml of 80% (v/v) methanol containing 0.04% (w/v) sodium metabisulphite. The mixture was agitated for 5 min, and then centrifuged for 5 min at 3000 RCF to separate the hydromethanolic phase. This 14 procedure was repeated three times using the same tissue; the hydromethanolic phases were then combined and filtered. Flavonoid content was measured using different dilutions of catechins as a standard. The test was performed in a 5-ml final solution containing: 500 ml MilliQ water, 150 ml NaNO2 5%. After 5 min, AlCl3 10% was added. The reaction was ended with 1 ml of 1M NaOH after 6 min of incubation, and absorbance measured at 510 nm. The analysis was repeated three times for each developmental stage. Phenolic Composition, Sugar Contents and Antioxidant Activity of Tunisian Sweet Olive Cultivar with Regard to Fruit Ripening HEDYA JEMAI, MOHAMED BOUAZIZ, AND SAMI SAYADI J. Agric. Food Chem. 2009, 57, 2961–2968 Olive Samples. Olive fruits harvested from a Dhokar cultivar olive tree growing in Tataouine (Southern Tunisia) were picked by hand at five different ripening times from July to October in 2006. The samples analyzed are shown in Table 1. Olives (250 g in each harvest) were immediately frozen in liquid N2 to block the enzymatic activities, and stored at -80 °C 15 before analysis. In order to minimize the effect of the sun exposure, the collection was accomplished from different parts of the tree. Extraction. The olive fruits were washed and crushed with a hammer crusher at 4 C (using a bath of ice to avoid phenol oxidation). The obtained paste (100 g) was extracted according to the method reported earlier (4). A mixture of methanol and water (250 mL, 4:1 v/v) was added to the olive paste, and the mixture was left to stand under agitation for 24 h. Subsequently, the solution was filtered using GF/F filter paper and washed with hexane (100 mL) to remove oil. The extract was concentrated by Rotavapor to dryness at 40 C, and the residue obtained was stored in glass vials, at 0 C in the dark for HPLC analyses. Determination of Total Phenols. Total phenols were determined by using the FolinCiocalteu reagent according to the method of Singleton and Rossi (13). Appropriate dilutions are used for each extract sample. Briefly, a 50 μL aliquot of the extracts was assayed with 250 μL of Folin reagent and 500 μL of sodium carbonate (20%, w/v). The mixture was vortexed and diluted with water to a final volume of 5 mL. After incubation for 30 min at room temperature, the absorbance was read at 765 nm. Total phenols were expressed on a dry weight basis as gallic acid equivalents (GAE), using a calibration curve of a freshly prepared gallic acid solution. For the gallic acid, the curve absorbance versus concentration is described by the equation y ) 0.0012x - 0.0345 (R2 ) 0.9997). The analyses were done in triplicate. Determination of Total Flavonoids. Total flavonoids were measured by a colorimetric assay developed by Zhishen and al (14). A 1 mL aliquot of appropriately diluted sample (reconstituted in methanol/water 4:1 v/v) or standard solution of catechin (20, 40, 60, 80 and 100 mg/ L) was added to a 10 mL volumetric flask containing 4 mL of double distillate H2O. At zero time, 0.3 mL of 5% NaNO2 was added to the flask. After 5 min, 0.3 mL 10% AlCl3 was added. At 6 min, 2 mL of 1 M NaOH was added to the mixture. Immediately, the flask content was diluted filling to the mark with the addition of 2.4 mL of ddH2O and thoroughly mixed. Absorbance of the mixture, pink in color, was determined at 510 nm versus prepared water blank. Total flavonoids of fruits were expressed on a fresh weight basis as mg of catechin equivalents (CE)/100 g of fruit. Samples were analyzed in triplicate. 16 Oil content, phenolic profiling and antioxidant potential of Tunisian olive drupes Bouaziz, Jemai, Khabou and Sayadi J Sci Food Agric 2010; 90: 1750–1758 Olive samples Sufficient amounts of olives were hand-picked from all sides of different olive trees growing under rain-fed conditions from October 2005 to February 2006. The samples analysed are shown in Table 1. The samples were immersed in liquid nitrogen, and stored at −80 ◦C prior to analysis. The olive fruits (2 kg) were collected from olive tree plantations located in several localities in the north, south and centre of Tunisia. To obtain uniform amounts of fruits, collection was accomplished from different parts of each tree, so as to minimise the effect of watering and sun exposure. Phenolic extraction The olive fruits were washed and crushed with a hammer crusher. The paste obtained (100 g) was extracted according to the method of Bouaziz and Sayadi. A mixture of methanol and water (250 mL, 4 : 1 v/v) was added to the olive paste and the mixture was left to stand under agitation for 24 h. Subsequently, the solution was filtered using GF/F filter paper and washed with hexane (100 mL) to remove oil. The extract was concentrated by evaporation to dryness at 40 ◦C and the residue obtained was stored in glass vials at 0 ◦C in the dark until HPLC analysis. Determination of total phenols Total phenol content of different olive extracts was determined using the Folin–Ciocalteu technique.21 Briefly, a 50 µL aliquot of the extracts was assayed with 250 µL Folin reagent and 500 µL sodium carbonate (20%, w/v). The mixture was vortexed and diluted with water to a final volume of 5 mL. After incubation for 30 min at room temperature, the absorbance was read at 765 nm. Total phenols were expressed as gallic acid equivalents 17 (GAE), using a calibration curve of a freshly prepared gallic acid solution. For the gallic acid, the curve absorbance versus concentration is described by the equation y = 0.0012x − 0.0345 (R2 = 0.9997). Total flavonoids Total flavonoids were measured by a colorimetric assay developed by Zhishen et al.22 A 1 mL aliquot of appropriately diluted sample or standard solutions of catechin (20, 40, 60, 80 and 100 mg L−1) were added to a 10 mL volumetric flask containing 4 mL double distillate H2O. At zero time, 0.30 mL 5% NaNO2 was added to the flask. After 5 min, 0.30mL 10% AlCl3 were added. At 6 min, 2 mL (1 mol L−1) NaOH were added to the mixture. Immediately, the reaction flask was diluted to volume with the addition of 2.40 mL of double distillate H2O and thoroughly mixed. Absorbance of the mixture, pink in colour,was determined at 510 nm versus prepared water blank. Total flavonoids of fruits were expressed on a fresh weight basis as mg 100 g−1 catechin equivalents (CE). Samples were analysed in triplicate. 18 Tunisian Table Olive Phenolic Compounds and Their Antioxidant Capacity BEN OTHMAN, D. ROBLAIN, P. THONART, AND M. HAMDI Vol. 73, Nr. 4, 2008—JOURNAL OF FOOD SCIENCE Extraction of phenolic compound The procedure for the extraction of polyphenols was the same for kernel and flesh. A quantity (0.5 g) of sample was extracted 5 times with 5 mL methanol. The extracts were combined, methanol was evaporated in vacuum, keeping the bath temperature under 45 ◦C, and the residue was dissolved in 5 mL methanol (Boskou and others 2006). The extract obtained was used for total phenol, antioxidant activity determination, and HPLC analysis. Analysis of total phenolic compounds in extracts The concentration of total phenolic compounds in extracts was determined with the Folin– Ciocalteu assay. To 0.5 mL of diluted extract, 2.5 mL of Folin–Ciocalteu reagent (diluted 10 times with water) were added and, after that (within time interval from 0.5 to 8 min), 2 mL of Na2CO3 (75 g/L) were added. The sample was incubated for 5 min at 50 ◦C and then cooled. For the control sample, 0.5 mL of distilled water was used. The absorbance was measured at 760nm (Skerget and others 2005). The results were expressed in milligram of gallic acid per 100 g of dry matter (mg GA/100 g Dwt) or in milligram of gallic acid per 100 g of fresh weight (mg GA/100 g Fwt). Polyphenolic compounds, antioxidant activity and L-phenylalanine ammonia-lyase activity during ripening of olive cv. “Cobrançosa” under different irrigation regimes Machado, Felizardo, Fernandes-Silva, Nunes , Barros Food Research International 51 (2013) 412–421 2.2. Sampling The olives are from three different water regimes: i) rainfed (T0), ii) deficit irrigation (T1), applying a dose of irrigation equivalent to 30% of evapotranspiration (ET) and well watered 19 (T2), and iii) providing a dose of irrigation in order tomeet the actual needs of evapotranspiration (100% ET). This study was conducted in the year 2006. The fruit samples were collected once every two weeks from early September until harvest (mid-December) and 40 olives per tree were collected, at breast height and the circumference of the tree, 2 trees per treatment and were placed in a deep-freezer until further analysis. At each sampling date was determined the rate of maturation of the olive (IM) according to the method proposed by the National Institute of Agronomic Research of Spain (Hermoso et al., 1991), relying primarily on subjective assessment of the extent of the of color the epidermis and mesocarp of the olive. The collected fruits were preserved at −80 °C for chemical determination. All measurements were performed in triplicate 2.5. Extraction of polyphenolic compounds from olive fruits Fresh olive flesh from 10 olive fruits (5 g) were macerated with 50 mL of a mixture of MeOH/H2O (50:50) and incubated at room temperature for 30 min. After, the supernatant was decanted and extractions were repeated three times. The liquid phase was centrifuged at 10,000 g for about 10 min. To remove the fat phase the mixture was washed twice with hexane (50 mL) using a separatory funnel and the organic phase was discarded. Three replicates per sample were performed. Each extract was introduced into a 200 mL round bottom flask, which was filled up to the mark with MeOH/H2O (50:50). 2.6. Quantification of total polyphenolic compounds and ortho-diphenols The content of total phenolic compounds in the olive flesh methanolic extracts was determined using a Folin–Ciocalteu reagent (Shahidi & Naczk, 1995), with gallic acid as standard. This method is based on the reduction of a phosphowolframate– phosphomolybdate complex by phenolics to blue reaction products. 1 mL of properly diluted methanolic extracts was mixed with 500 μL of the Folin–Ciocalteu reagent, 2 mL of 7.5% sodium carbonate solution and 6.5 mL of water. The mixture was shaken and the absorbance of the standard (gallic acid) and samples was measured at λ=750 nm after 30 min reaction at 70 °C. All measurements were performed in triplicate. The results were expressed as milligrams of gallic acid equivalents per gram of olive flesh (dry weight). The concentration of ortho-diphenolic compounds in themethanolic extract was determined by the method of Mateos et al., 2001. One milliliter of 5% (w/v) sodium molybdate in 50% ethanol was added to the aliquots of the methanolic extract (5 mL). The contents were mixed for 1 min and the absorbance was measured after 15 min at 370 nm against a blank reagent prepared by adding 1 mL of 50% ethanol to the aliquot of the extract instead of sodium molybdate solution. Gallic acid served as a standard to prepare a calibration curve with 0, 5, 10, 25, 50, 75 and 100 mg L−1 of gallic acid. The ortho-diphenolic content was expressed as mg of gallic acid equivalents /g olive flesh (dry weight). 20 L-Phenylalanine ammonia-lyase activity and concentration of phenolics in developing olive (L cv Arbequina) fruit grown under different irrigation regimes M Jesus Tovar, M Paz Romero, Joan Girona and M Jose Motilva JSFA (2002), 82:892-898 Lectura de absorbancia a 725 nm. Resultados expresados como g de eq. De ácido caféico /kg peso seco 21 Resultados: 22