Insect Rearing Quality Control - IPM Florida

advertisement

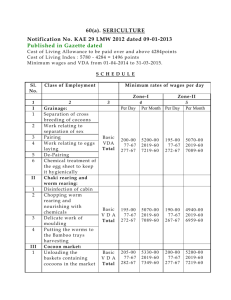

The Basics of Quality Control for Insect Rearing 2015 Norm Leppla University of Florida Entomology and Nematology Department I. Introduction Norm’s Career in Insect Rearing • University of Arizona- Insect rearing research, 2 years • USDA, ARS- Insectary management, Florida and Texas, 17 years • USDA, APHIS- Methods development, Washington DC and international, 7 years • University of Florida- Integrated pest management and biological control, 18 years • Rearing and quality of Tamarixia radiata (Chris Kerr) • Extension IPM (http://ipm.ifas.ufl.edu) Countries of Workshop Students Quality Control Topics I. II. III. IV. V. VI. Introduction- Learning how to rear quality insects Colony Establishment and Maintenance Monitoring Quality Evaluation and Management Guidelines for Quality Systems Total Quality Management Learning How to Rear High Quality Insects •Apprentice in an insectary •Network with other professionals •Literature plus trial-and-error •Visit other insectaries •Reviews by experts •Education and training programs MSU Insect Rearing Center Frank Davis John Schneider •Online courses •Classroom courses •Webinars •Mentoring http://insectdiets.com/ 2004 Insectary Manager Network Anyone associated with the mass rearing of insects 65 Members http://www.entsoc.org/ Insect Rearing Professionals Google Group Subscribe: (leonwesterd@gmail.com) Léon Westerd Group moderator Head of insect rearing Wageningen UR, Netherlands VI. Total Quality Management Generic Guidelines for Quality Systems •Policy, Planning and Administration •Design Assurance and Change Control •Control of Purchased Materials •Production Quality Control •User Contact and Field Performance •Corrective Action •Employees- Select, Train and Motivate Quality Control Programs •Individual Companies Customers •International Standards ISO 9000 ASTM •The Marketplace Quality Products Specifications- Requirements for a product or service Standards- The level of quality at which a specification is written Parts of an Insect Rearing System A Complete QA System II. Colony Establishment and Maintenance II. A. Purposes for Rearing Insects II. B. Types of Insect Rearing Systems II. C. Options for Colonizing Insects II. D. Maintaining the Quality of Colonized Insects II. A. Purposes for Rearing Insects White witch, Thysania agrippina (Lepidoptera: Noctuidae II. B. Types of Insect Rearing Systems Painted Lady Monarch Small-Scale Rearing: Butterflies Annie Lorie “Insect rearing is never a boring task; insects are always doing something interesting and pose new challenges all the time” Punky Rogers Medium-Scale Rearing Mass Rearing- Medfly El Pino, Guatemala Capacity- 3.5 billion sterile male pupae per week Metapa, Mexico II. C. Options for Colonizing Insects Peter Ebling Insect Producer Database Mgr. Great Lakes Forestry Centre 1219 Queen St. East Sault Ste. Marie, ON P6A 2E5 peter.ebling@nrcan.gc.ca (705) 541-5517 •World-wide listing, 35 insect & 21 nematode orders •Data submitted by sources •Searchable database •Expand clients •Adopt-a-colony http://www.insect.glfc.cfs.nrcan.gc.ca Field Collecting Cabbage Loopers Trichoplusia ni Continuous Improvement of Insect Rearing II. D. Maintaining the Quality of Colonized Insects •Collection of appropriate biotypes •Colonization and strain development •Rearing proficiency •Colony management (SOPs) •Select, infuse, hybridize •Strain replacement Sam 2005 Soybean Looper vs. Cabbage Looper Tritrophic Rearing System Tamarixia radiata SOPs Colony Management • Maintain- Low productivity, variability, expensive • Select- High productivity, uniformity, consistency • Infuse- Short term recovery, hybridize? • Hybridize- New strain, crosses • Replace- New strain, adaptation III. Monitoring Quality III. A. Quality Control Criteria and Standardized Tests III. B. Sampling for Consistent Quality III. C. Production, Process and Product Control III. A. Quality Control Criteria and Standardized Tests •Quantity- Number of required stage •Rate of Development-Synchronization •Viability- Emergence, sex ratio •Size- Weight or measurements •Fecundity- Oviposition and egg hatch •Adult Behavior-Flight, longevity •Field Performance- Achieve purpose Standardized QC Tests • Joop van Lenteren (2003), IOBCGuidelines for quality control of commercially produced natural enemies, 30 species • Rose Buitenhuis (2014), Grower guide to quality assurance of biocontrol products, 22 species • Custom, develop your own, sitespecific Number of Cabbage Looper Pupae Per Rearing Container Shelf Container 1 2 3 4 5 6 1 175 157.6 17.4 302.76 190 190 191 180 142 2 167 157.6 9.4 88.36 191 191 190 180 176 3 144 157.6 -13.6 184.96 191 190 192 189 156 4 166 157.6 8.4 70.56 191 192 190 176 138 5 136 157.6 -21.6 466.56 190 191 190 174 181 Average 157.6 190.6 190.8 190.6 179.8 158.6 0.5 0.8 0.9 5.8 19.4 Sum of Squares 1,113.2 Variance 278.3 Standard Deviation 16.7 Shelf 1 is lowest III. B. Sampling for Consistent Quality Count = Measurement = N Mean = Sum/Number of Counts = X Variance = Sum of (N – X)2 / n-1 = 2 Standard Deviation = Square Root of 2= SD Quality Control Charts Tamarixia radiata Parasitism on 3rd, 4th and 5th Instar Diphorina citri Nymphs Anonymous, UF Level of T. radiata Parasitism on D. citri Level of T. radiata Parasitism on D. citri T. Radiata Sex Ratio T. radiata Hind Tibia Length Minimum, maximum and mean hind tibia length of T. radiata that were developing on different Asian citrus psyllid host nymph instars 1, 2 Females Males Host instar Min Max x̄±SD (n) Min Max x̄±SD (n) Third -------------0.16 0.21 0.20±0.02 (13) c Fourth 0.23 0.27 0.25±0.02 (6) b 0.21 0.27 0.24±0.02 (55) b Fifth 0.34 0.31±0.02 (75) a 0.27 0.33 0.29±0.02 (40) a 0.27 1 Comparison of means within a given instar were not significantly different between sexes (Tukey’s HSD, α =0.05). III. C. Production, Process and Product Control Quality Assurance Actions Production and Process Control Frequency of Actions Routinely Have up-to-date standard operating procedures Periodically X Use check sheets to monitor rearing processes X Record daily production data X Track changes in production X Review production with staff X Improve product quality based on staff feedback X Product Control Conduct product quality control assessments X Have established minimum thresholds of quality X Use standard shipping and handling procedures X Customer Service Add customer feedback forms to shipments X Add product use instructions to shipments X Have an established customer service program X Improve product quality based on customer feedback X IV. Evaluation and Management IV. A. Structured Diagnostic Procedures IV. B. Quality Control Versus Methods Improvement IV. C. Periodic Review IV. A. Structured Diagnostic Procedures IV. B. Quality Control Versus Methods Improvement Quality Control • Monitor indicator variables • Evaluate multiple variables • Troubleshoot using QC data • Conduct evaluations rapidly • Goal is to maintain stable production Methods Improvement • Conduct evaluations methodically • Test one variable at a time • Use controlled experiments • Test results in the production system • Goal is to optimize production IV. C. Periodic Review W. G. Eden E. F. Knipling V. Guidelines for Quality Systems IOBC International Organization for Biological Control Mission: to facilitate and advance cost-effective rearing of high quality insects and other arthropods in support of biological control and integrated pest management http://www.amrqc.org Workshops of the IOBC, WGQC (AMRQC, MRQA) 1982 1984 1986 1988 1991 1992 1993 1995 1998 2003 2007 2010 2013 Gainesville, Florida Wadenswil, Switzerland Guatemala City, Guatemala Vancouver, Canada Wageningen, Netherlands Horsholm, Denmark Rimini, Italy Santa Barbara, California Cali, Colombia Montpellier, France Montreal, Canada Vienna, Austria Bangalore, India E. F. Boller and D. L. Chambers E. F. Boller and D. L. Chambers C. 0. Calkins C. 0. Calkins F. Bigler and J. C. van Lenteren F. Bigler M. Benuzzi and N. C. Leppla R. F. Luck and N. C. Leppla N. C. Leppla and T. R. Ashley P. De Clercq, S. Grenier and NCL S. Grenier and C. S. Glenister P. De Clercq and T. A. Coudron P. De Clercq and T. A. Coudron Insect Pest Control (IPC) http://www-naweb.iaea.org/nafa/ipc/public/ipc-model-plansterile-insect-technique.html Insect Rearing Quality Control References • Leppla, N. C. 2013. Quality Assurance for Mass-Reared Parasitoids and Predators. In Mass Production of Beneficial Organisms. Elsevier. Morales-Ramos, Rojas, and Shapiro-Ilan • Leppla, N. C. 2009. The basics of quality control for insect rearing. In Principles and Procedures for Rearing Quality Insects. Miss. State Univ. Schneider • Leppla, N. C. 2004, 2008. Rearing of Insects. Encyclopedia of Entomology. Kluwer. Capinera • Leppla, N. C. 2003. Guidelines for quality control of commercially produced natural enemies. In Quality Control and Production of Biological Control Agents, Theory and Testing Procedures. CABI. Van Lenteren For more information or a copy of this presentation please visit: http://ipm.ifas.ufl.edu