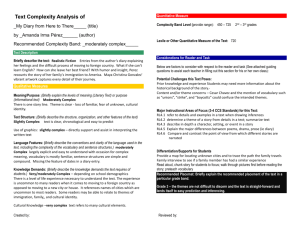

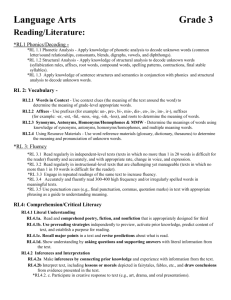

Selling an Idea or a Product

advertisement

RJR Polymers, Inc. The Complete Process Solution RJR Polymers, Inc. • • • • Specializes in the manufacture of Injection Molded Plastic Packages, Pre-applied Adhesives, Equipment and Processes that provide additional service to our customers in the Electronics Industry. Provide engineered solutions to our customers demanding product and process applications Allow our customers to focus on their core competencies. Can manage your product from design through to high volume offshore manufacturing through our licensed partners Market Mix • • • • • • • • RF/ Wireless Imaging Medical Military WAN/ LAN/ Broadband Telecom Automotive MEM’s, MOEM’s, sensors, etc. Technology Driven Pre-applied Adhesives Prototype Design And Assembly Injection Molded Plastic Packages RJR Technologies Sealing Equip. ITS De-reelers AITS Products/ Core Competencies • Plastic Air Cavity Packages • Thermally Enhanced SOIC, Power RF, High Freq RF (UHF, SHF), LDMOS, etc. • Plastic backed SOIC, MEM’s, MOEMS, Sensors • Vision, CCD, • Other • Epoxy coated Lids – Metal, Composites, Ceramic, Plastic and Glass • Flip Chip - Thermal Interface Adhesives • Heat Sink - Thermal Interface Adhesives • Windows - Vision Packages Materials • • Full staff of polymer chemists have formulated a complete line of B-staged adhesives. Our view of the entire process has allowed us to design functional materials you require today and the future. The common goals of all our materials are: • • • • Ionic purity Near ‘Zero” outgassing Fuse or cure in minutes (pushing the boundaries of today’s competitive materials) No Mess (it’s pre-applied)!! RJR’s pre-applied Materials Air Cavity Package Lids Plastic Composites Glass Ceramic Metal Glass Windows For CCD, CMOS and other Vision Devices Flip Chip Devices Adhesive Options * * * * Thermo-Set Thermo-Plastic Electrically Conductive Thermally Conductive Thermout™ Pulls heat away from the device through the lid RJR’S Optical Products • Glass • Standard Products • Borosilicate glass • Schott D263, Corning 1737F, Corning D211 • Supplied in standard thicknesses of 0.54mm and 0.71mm • Material supplied cut on tape on rings (plastic or metal) • Typical epoxy dispense pattern: • 0.76/1.40mm wide • 0.05/0.2mm height • 0.25mm typical pullback from edge • Standard Coatings available • Can be supplied beveled • Wafer Cleaning • Glass capacity to millions of units per month Microwave Application Low Chloride Quick Bond 1. RJR Supplied lids pre-applied Quick Bond 2. Place Packages and lids into the ITS or AITS 3. Start the cycle 4. Time from Start to cured ~ 4 minutes 5. Material is then fully cured! Flip Chip Application Thermout™ • Resilient material built to maintain thermal contact between a die and a lid or cover • B-stage material that is pre-applied • Can be applied to ceramic or metals • • Exhibits elastomer type behavior at elevated temperatures to maintain thermal performance Retains elongation and resiliency at low temperatures Flip Chip Application Thermout™ • Typical Properties of Thermouttm • Thermal conductivity 1 – 3.5 W/mK • Shear Modulus 360,000 psi • Tensile Elongation 3% • Water absorption 0.2% • Shear strength 2,000 psi Flip Chip Application Thermout™ • • • • • Will withstand Mil-Std thermal cycling requirements For PBGA Applications – Materials available that will pass MSL Level III For CBGA (HTCC or LTCC) Applications – Materials available that will pass MSL Level I 168 hr. Autoclave Can be manufactured with a variety of thermally enhanced fillers – Aln, BN, Ag Sealing Equipment • • Our staff of Expert Engineers have designed Semiautomatic AND Fully Automatic solutions for your Packaging sealing needs OUR Focus: • Increase throughput • Functioning today and with future applications • Increase yields • Eliminate “Blowouts” • Accurate lid placement • Decrease required floor space (REAL ESTATE) Equipment - ITS (Isothermal Packaging System) • • • Semiautomatic Custom Design & Built Plates Controls: • • • • • ** Run Rates are Dependant on Package Size and Configuration Time Pressure Temperature UPH: 600 - 700* 99% + Yield Air Cavity Package Technologies Plastic Backed For Low Energy Cavity Package Applications like Sensors, etc. CCD / CMOS (Thermo-Plastic) For Vision and Optical Sensor applications. Thermally Enhanced Metal Backed Eutectic & Non-eutectic applications with high thermal transfer Eutectic Die Attach in a Plastic Air Cavity Package ! This technology represents a breakthrough in polymer based air cavity electronic packaging. This new low cost injection molded packaging process allows the user to combine the thermal advantages gained by using a eutectic die attach material between die and backplane, with a moisture resistant plastic sidewall specifically designed to manage the higher power and frequency output values previously found only in ceramic packaging systems/ technology. Features: • Eutectic Die attach • Moisture resistant • Low CTE • CTE matched package • Low Dielectric • Low Parasitics • High Power • High Frequency • Low Cost ! Package Applications: • RF/ Microwave • WLAN/ LAN • Short Range Wireless • MEMS/ MOEMS • LDMOS • CCD/ CMOS RJR’s Injection Molded Packages • Package Buildup • Essentially 3 layers • Thermal Base (Cu, WCu, CuMoCu, AlSiC, etc) • Sidewall with leads • Lids with epoxy (pre-applied) • RJR formulated epoxy as interstitial layers • Plastic alloy formulated to match the CTE of Copper or Copper alloys (WCu, CuMo, etc.) • Leads are coated with moisture resistant polymer, then injection molded • The 3 layers are fused together using RJR ITS equipment RJR’s Injection Molded Packages • Thermal Package Performance • Moisture Resistant • Eutectic Die attachable • Thermal Dissipation >10 watts • Handle Frequency > 2.5 GHz Have parts in service at 5.8 GHz • Pass JEDEC Level I Moisture Pre-Conditioning • Pass Mil-Std 883 Section 1010 Condition C temp cycle • Anticipated improvement in electrical performance compared to ceramic RJR Air Cavity Package Technologies Benefits of RJR Packages vs Competition Equal or superior performance compared to ceramic packages. Fast turnaround time (two weeks) for prototype assembly. Lower tooling costs. Substantially less expensive !! All Packages Available in Leadframe Format Benefits of Thermally Enhanced Plastic Packages: Improved heat dissipation = lower die operating Temp. = longer life! Less Expensive !!! Thermally-Enhanced Package Build process procedure (eutectic die attach) Process Steps RJR Polymers 1) Package Base 2) Leadframe with moisture barrier applied 3) Injection mold sidewall over leadframe 4) Nickel and Gold plate leadframe 5) Epoxy coat molded sidewall Customer location –or- RJR Location 6) Perform Die attach to base leadframe 7) Using RJR’s ITS system – attach assembled base leadframe to coated injection molded sidewall 8) Wire Bond device to package 9) Using RJR’s ITS system – seal package lid to molded sidewall 10) Trim, Form and singulate Thermally-Enhanced Package Exploded View Package lid with pre-applied adhesive Lid Material: Plastic, Ceramic, Metal, Glass, etc. Injection molded sidewall Shown with moisture resistant seal encapsulating the leads and pre-applied adhesive on bottom surface Wire Bonds Device Solder Preform or Epoxy, etc. Package Base Base Material: Cu, Cu/Mo, Cu/Mo/Cu, WCu, etc. Completed Package RJR’S Optical Packaging • Packaging • 28, 32, 40, 48 and 52 lead count packages standard tooled • Packages are capable of JEDEC level 1 for moisture preconditioning • From design to prototypes in 6 weeks. • Customers experience Low Cost/ Low barriers to entry for product mechanical testing/ sampling • RJR’s offers product solutions for drop in replacements as well as new/ custom packaging. • RJR solution includes the use of RJR assembly technology RJR Polymers RF Power Products • LDMOS, MMIC, FET, pHEMT, Wide Bandgap • Power levels to +150 watt • Frequency Management to +5.8 GHz • Eutectic Die attachable (like all RJR Packages) • Enabling Technology • Internally matched elements transform impedence to manageable levels • • Flat sealing surface – reduces gross leak failure • Leadframe processing/ assembly Low cost – approx. 60% of ceramic equivalents RJR Air Cavity Package Costs/ Deliverables Benefits of R-Pak vs Competition • Rapid turnaround time (~6 weeks) for prototype/ custom packages • Fast turnaround time (two weeks) for prototype assembly. • Substantially lower tooling costs. • Substantially less expensive packages !! Typically half the cost of ceramic. • Low barriers to entry • Low Cost tooling • Low cost packages • Budget friendly RJR’s Injection Molded Package Program Rewards • • • • • • Equal or superior performance compared to ceramic packages. Moisture Resistant Eutectic, epoxy, RTV, etc. Die attachable Thermal Dissipation >10 watts Handle Frequency >= 5.8 GHz Can Pass JEDEC Level I Pre-Conditioning Pass Mil-Std 883 Section 1010 Condition C temp cycle RJR Plastic Alloy – HTP-1000 R-Pak Plastic Body Compound This custom thermoplastic compound is used in RJR R-Pak plastic body package technology. The following properties are typical for the bulk material molded into standard test configurations defined by the applicable test method. These property values are intended for general engineering purposes and are not intended for establishing product specifications. Physical: Density: 1.67 gm/cc ASTM D792 Water Absorption 0.02% ASTM D570 Mechanical @ 23C: Tensile Strength 21,000 PSI ASTM D638 Tensile Modulus 2.5 X 106 PSI ASTM D638 Elongation @ Break 1.2% ASTM D638 Flexural Strength 31,000 PSI ASTM D790 Flexural Modulus 2.4 X 106 PSI ASTM D790 IZOD Impact Strength Notched 1.6 ftlb/in ASTM D256 Thermal: Melting Point 280C (536F) ASTM D3418 DTUL @ 1.8 Mpa (264 PSI) 270C (518F) ASTM D648 Electrical: Volume Resistivity 1012 ohm-cm ASTM D257 Surface Resistivity 1017 ohm IEC 93 Dielectric Strength 766 V/mil ASTM D149 Dielectric Constant 3.8 @ 1 kHz ASTM D150 3.7 @ 100 kHz 3.7 @ 10 MHz Dissipation Factor 0.007 @ 100 kHz ASTM D150 0.003 @ 10 MHz ASTM D150 Arc Resistance 165 Sec. ASTM D495 Comparative Tracking Index 175 volts ASTM D3638 Chemical Resistance: Not affected by: Water, Acetone, MEK, Methyl celusolve, Hexanes, (Sulfuric Acid, Nitric Acid, and HCl) as used in electroplating baths. RJR Polymers Quality System • • • • • Roadmap to ISO Certification - Scheduled for Q3 2003 Supplier to Global OEM’s • Motorola • Ericsson/ Infineon Microelectronics • Agere Systems • Philips Semiconductors • Etc. ASQC Plan (Incoming and Outgoing) Provide QA on all components of product manufacture • Raw materials for epoxy, plastics • Lids • Packaging products Lot to Lot traceability back to Raw Material Components RJR Summary • • • • RJR has the technology background Integrated manufacturer Provide Solutions Manage the manufacturing cycle in-house • • • • • • • • • • Design Product Development Materials Injection Molding Coating products with epoxies Light/ Prototype assembly Offshore Partners Equipment manufacturer – ITS, AITS Innovative thinking The Total Electronic Package Solution South Korea Ken Park Far East Representative 201-104 Byuk-San BLDG Jookjeon-ri, Su-ji-Up Yong-in Si Kyunggi-Do, Korea Mobile: 011-82-11-839-7929 Fax 031-683-8182 E-mail:kpark@rjrkorea.co.kr Europe Renaud de Langlade European Representative Managing Director NovaPack Technologies Parc d’Activities de Pissaloup 4 rue Edouard Branly 78190 Trappes France Ph 33 1 64 48 76 67 Fax 33 1 30 68 10 86 Mobile: 33 6 20 42 91 63 E-mail: rdl@novapacktech.com Eastern USA Scott Mellen Eastern Regional Sales Manager/ Sales Engineer Ph (315) 676-4134 Fax (315) 676-5319 Mobile: (315)415-9401 E-mail: smellen@rjrpolymers.com Western USA David Pasfield Western Regional Sales Manager/ Sales Engineer Ph (707) 782-9257 Fax (707) 782-9268 Mobile: (707) 484-9669 e-mail: dpasfield@rjrpolymers.com Midwestern USA Dave DeWire Director Sales and Marketing Ph (303) 543-2223 Fax (303) 543-7123 Mobile: (303) 921-2222 E-mail: ddewire@rjrpolymers.com Taiwan/Pacific Rim Region Michael Leong Pacific Rim Regional Sales Manager/ Sales Engineer 8-15-06, Jalan Gangsa Greenlane Heights Penang 11600 Malaysia Ph 011-604-655-2468 Fax 011-604-658-2468 Mobile: 011-6012-486-5468 E-mail:mleong@maxis.net.my RJR Polymers Inc. Contact Information