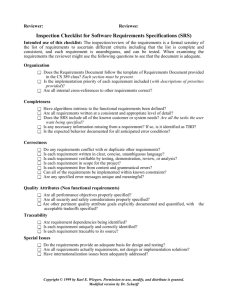

educational qualification - PRS Permacel Private Limited

advertisement

House No. F-20,Essar Nand Niketan Township, Near Bed Village, Okha Highway, Jamnagar. (Gujarat). . Mobile no: 07567870835 /9099418781. E-mail: arvindgdhadake@rediffmail.com Arvind G. Dhadake OBJECTIVES To seek challenging career with reputed organization this involves technical, analytical, communication & presentation skills at the same time being innovating and resourceful. Zero accident though out my service. EDUCATIONAL QUALIFICATION: Advance diploma in industrial safety from Central Labour Institute (CLI), (Sion), Mumbai. Government Of India (D.G.F.A.S.L.I). Aggregate percentage: 65.82%. Appearing Bachelor Engineering in Mechanical, from Karnataka State Open University. Certificate course completed in Operation and maintenance in chemical plant, From Advance Technical Institute Sion Mumbai in 2003. Aggregate percentage: 70.26% first Class. Bachelors in Science from University of Mumbai, in 1999,Guru Nanak College of Arts, Science and Commerce College, G.T.B.Nagar,Sion (E), Mumbai, Maharashtra. Aggregate Percentage: 53.62 %. H S C from Mumbai Board, in 1995, Patuck Technical Inst., Santacruze (East), Mumbai. Aggregate Percentage: 41.50 %. S S C from Mumbai Board, in 1993, Shivam Vidya Mandir, Kurla (West), Mumbai. Aggregate Percentage: 65.00 %. COMPUTER PROFICIENCY: MS-OFFICE course completed in 1999 conducted by state government Operating System : MS Windows 98., Word, Excel, Power-Point , Access Office : Office 2000, 2003, 2007. ENGLISH TYPING course completed in Nov, 1998 conducted by state Government Speed 40 w.p.m. TRAINING PARTICIPATED: 1. Participated in the programmed of Modern Risk Assessment by HP Management Development Institute, Pune. (2 days only) 2. Participated in the Indian Environment, Occupational Health & Safety Legislation by EQMS India (I), Ltd. New Delhi. (2 days only). 3. Participated in the International Marine Organization, at Kandla Port Trust, Vadinar, Gujrat. 4. Participated in the OSHAS training by EOL, Vadinar, Gujrat. WORK EXPERIENCE: 1. COMPANY NAME VADINAR OIL TERMINAL LTD ( ESSAR GROUP) DURATION 05th August, 2013 to till date DESIGNATION ASST. MANAGER OF SAFETY & FIRE ABOUT PLANT Handling and dispatch of Petroleum, Diesel, VGO, Naptha SKO & Black Oil Product by Jetty. PRODUCT JOB RESPONSIBILITIES MS (Motor Sprit-Petrol), HSD (High Speed Diesel), SKO (Sweet Kerosene Oil). (Naptha, VGO, B. Oil Product). As per HSE plan, storage of Petroleum product system with OISD-156 parameters. Preparation and handling documents of Accident investigations, first aid records, Tool & Tackles, near miss reports, suggesting preventive measures and Safety inspections, Job Safety Analysis, all work permits system, Compliance to statutory requirements, Monthly EHS performance report & Preparation of HSE Manual, HSE training, monitoring of hazards, QHSE Plan, Safety and their follow up. Conducting and participate in safety meeting and Safety training to all level of Employees. Fire fighting system (fire protection, fire water system, Portable fire fighting equipments, fire siren codes, Emergency response).Inspection fire fighting as per OISD-1O5, 117 &115). Safe Operation of Floating Roof Tank and Cone type Floating Roof Tank as per checklist. Inspection and maintained as per OISD Standards. Inspection of all fire fighting system. Review of all OISD Reports. Training as per OISD-154 Std. Compliance of OISD Recommendations.. Implementing safety norms As per Safety Rules. Monitoring the site performance. Identifying and eliminating all hazards. Ensuring follow-up of PPE’S use. Inspection of firefighting Equipments by checklist. Safety Checklist for various Process Parameters & Constructional. Maintains records of First Aid, Incident, Accident, Near-miss with details. Maintaining high standards in House Keeping. Monthly report on Safety performance. Maintaining the safety processes within the Jetty Terminal. Safety education, awareness & culture building. Documentation and records management for safety operations procedures. Preparation of Safety guidelines of different activities for workers and supervisors . Observe unsafe act and unsafe condition at the time of round. Monthly safety meeting with employees & construction Supervisor. Conducting mock drill. 2. COMPANY NAME INDIAN OIL TANKING INFRASTRUCTURE & ENERGY SERVICES LTD, Bahadurgarh-Haryana.(Joint Venture of IOCL) (POL TERMINAL-HINDUSTAN PETROLEUM CORP LTD.) DURATION 20th August, 2012 to 3rd August 2013. DESIGNATION ASST. MANAGER OF SAFETY & FIRE ABOUT PLANT Biggest Terminal of Petroleum product storage at North Zone in India. POL Terminal (Deals with Receipt, Storage and Dispatch of Petroleum Product). Storage Capacity-300000KL Which is 6th International Safety Rating System By DET NORSME VERITAS AS. PRODUCT MS (Motor Sprit-Petrol), HSD (High Speed Diesel), SKO (Sweet Kerosene Oil). (EURO-III & IV Product). JOB RESPONSIBILITIES As per HSE plan, storage of Petroleum product system with OISD parameters. Storage and Transportation in Tank Truck and Tank Wagon (Rail Gantry- Bogie Type Pneumatic). Knowing about, Transportation safety in Tank Truck and Rail Gantry. Preparation and handling documents of Accident investigations, first aid records, Tool & Tackles, near miss reports, suggesting preventive measures and Safety inspections, Job Safety Analysis, all work permits system, Compliance to statutory requirements, Monthly EHS performance report & Preparation of HSE Manual, HSE training, monitoring of hazards, QHSE Plan, Safety and their follow up. Conducting and participate in safety meeting and Safety training to all level of Employees. At HPCL Terminal–Bahadurgarh (Haryana State). I was actively & independently involved in OISD Audit, ISO-9001, Internal & External Audits and Factory Inspection Audit. Personally involved in Emergency Response Plan, Mock drill, On-site, Off-site emergency plan& firefighting instruments by checklist of facility in POL Terminal area. Monitoring of Stacks & hazardous waste also. Knowing about ISO-9001,14001, OHSAS-18001 Requirements of OISD. I have worked in various industries like chemical and Pharmaceutical company as production, R&D departments, and Refineries, as a process and project safety professional. Fire fighting system (fire protection, fire water system, Portable fire fighting equipments, fire siren codes, Emergency response).Inspection fire fighting as per OISD-1O5, 117 &115). Safe Operation of Floating Roof Tank and Cone type Floating Roof Tank as per checklist. Rake-up meeting. Training as per OISD-154 Std. Inspection of Petroleum Storage Tanks. Inspection of Tank Truck loading as per OISD-167 checklist. Inspection and maintained as per OISD Standards. Inspection of Tank Wagon loading. Inspection of all fire fighting system. Review of all OISD Reports. Compliance of OISD Recommendations. Pre-commissioning of Petroleum Storage Tanks. Implementing safety norms As per Safety Rules. Monitoring the site performance. Identifying and eliminating all hazards. Ensuring follow-up of PPE’S use. Inspection of firefighting Equipments by checklist. Safety Checklist for various Constructional and process parameters. Maintaining first aid record describing the nature of accident and details of near misses. Maintaining high standards in House Keeping. Monthly report on Safety performance. Maintaining the safety processes within the POL Terminal. Safety education, awareness & culture building. Documentation and records management for safety operations procedures. Preparation of Safety guidelines of different activities for workers and supervisors . Observe unsafe act and unsafe condition at the time of round. Conducting mock drill. 3. COMPANY NAME GURU GOBIND SINGH REFINERY (HPCL- MITTAL ENERGY LIMITED) DURATION 10th August, 2010 to 11th August 2012. DESIGNATION FIRE & SAFETY OFFICER ABOUT PLANT 9 MMTPA, EURO – IVRefineries. PRODUCT Petroleum Product - LPG, Aviation Turbine Fuel, MTO, Motor Sprit, VGO, Hexane, High Speed Diesel, Kerosene, Naphtha, Polypropylene, Sulphur, Coke. JOB RESPONSIBILITIES As per P & ID and HSE plan,Projects and Process system with parameters in Precommissioning & commissioning activity in CDU/VDU, HGU, MS Block, DHDT, SRU, LPG mounded bullets units.Handling and Bulk storage of hazardous chemicals like LPG, LDO, HDO &HSDO. Knowing about, Preparation and handling documents of Accident investigations, first aid records, Tool & Tackles near miss reports, suggesting preventive measures and Safety inspections, Job Safety Analysis, Job Risk Assessment, all work permits system, Compliance to statutory requirements, Monthly EHS performance report & Preparation of HSE Manual, HSE training, monitoring of hazards, QHSE Plan,Safety Audits with third party and their follow up.Conducting and participate in safety meeting and Safety training to all level of Employees. Independently involved in Emergency Response Plan, Mock drill, On-site, Off-site emergency plan& firefighting instruments by checklist facility in refinery area. Monitoring of Stacks & hazardous waste also. Knowing about ISO-9001, 14001, OHSAS-18001 Requirements of OISD & preparation SOPs. I have worked in various industries like chemical and Pharmaceutical company as production, R&D departments, and Refineries, as a process and project safety professional. At Guru Gobind Singh Refinery –( Joint Venture of Hindustan Mittal Energy Limited refinery). I was actively & independently involved in Pre-commissioning of Sulphur recovery unit,Hydrogen Generation Unit & CDU/VDU.I have done the system mark up,box-up, check listing as per P&ID,leak test,chemical cleaning,heater dry out etc.I have also done in safety studies like HAZOP, Initiative programs, Safety & fire auditsetc. Implementing safety norms As per Safety Rules. Monitoring the site performance. Identifying and eliminating all hazards. Inspection of firefighting Equipments by checklist. Safety Checklist for various Constructional and process parameters. Maintaining first aid record describing the nature of accident and details of near misses. Ensuring follow-up of PPE’S use. Prepare document for OHSAS – 18001 Providing lifeline and safety net as per requirement. Maintaining high standards in House Keeping. Making walk down in site & Checking Tools & Tackles. Monthly report on Safety performance. Maintaining the safety processes within the plant. Safety education, awareness & culture building. Documentation and records management for safety operations procedures. Follow up risk analysis and assessment for different types of job activities. Preparation of Safety guidelines of different activities for workers and supervisors . Monitoring the Radiography requirements. Observe unsafe act and unsafe condition at the time of round. Participate in mock drill as an observer. 4. COMPANY NAME ELIXIR CHEMICALS PVT. LTD. (DOMBIVALI, MAH.) DURATION 15ThNovember, 2004 to 8ThJuly, 2009. DESIGNATION Asst. Of Safety Officer (HSSE) ABOUT PLANT This is small chemical & pharmaceutical industry located in Dombivali. Now it merges with scientific laboratory. PRODUCT Intermediate of Veterinary Medicine and pharmacy Product (human). 5. COMPANY NAME:- NATIONAL ORGANIC CHEMICAL INDUSTRY LIMITED(NOCIL), (Turbhe, New Mumbai). DURATION Since June 2003 TO MAY 2004 DESIGNATION Lab Assistant ABOUT PLANT This is a big chemical industry located in Turbhe New Mumbai. Which is no.1 company to make acceleration powder of rubber manufacture. PRODUCT Acceleration Powder of Various RubberTyres CUSTOMER 6. COMPANY NAME:- CEAT Tyres, Madras Rubber Factory (MRF) Tyres , JK Tyres, Modistone Tyres. And rubber manufacture Company etc. JAI AMBIKA ENGINEERING WORKS Under Reliance Silicon India Limited Project (Khopoli). DURATION Since July 1999 TO June 2002. DESIGNATION ABOUT COMPANY This company specialist in all kinds of fabrication & Erection of Structural and Sand Grit shot Blasting and painting works etc. Safety Supervisor ( Sand Blasting and painting). JOB RESPONSIBILITY Working in three shifts with punctual responsible of Achieving daily target. Some time for managing shifts independently with the overall responsible For handling a shift of all packing line and record to the Supervisor & Me Also.Working with Shutdown Area. Working without rejected material. Sometime done an argent work with supervisor and plant operator. Working with hazardous chemical like to handle chlorine cylinder and to fill a drum of hot sulphur chemical. KNOWLEDGE OF HIRA Accident investigation and analysis, accident reporting Work permit system OSHAS 18001 HAZOP Risk Assessment PROJECT: Completed in plants training of safety in Bharat Petroleum Corporation Limited, Mahul, Mumbai in Evaluation of Safety in Refinery and its Personal Protective Equipments, from 27thOctomber 2009 to 04thDecember 2009. OBJECTIVE OF PROJECT To acquire the knowledge about hazards in refinery. To study the function of safety management system. To collect accident data and analysis data as per is-3786(1983). RESPONSIBILITY HANDLED DURING PROJECT Daily safety round in plant with safety officer. Observe unsafe act and unsafe condition at the time of round. Do job safety analysis in plant at every process. Participate in mock drill as an observer. Participate in shutdown work as an observer with safety officer. To communicate with the worker as well as contractworker and come to know about their views about safety and health and ppe`s LANGUAGE KNOWN : Marathi, Hindi, English, Kannada. PERSONAL DETAILS: Permanent Add. : Deepa General Store, Ashok Nagar, Behind Homeguard Compound, Kamani, Kurla (west), Mumbai – 400 070. Date of birth : 1st JUNE 1978. Sex : Male Nationality : Indian Height : 165 CM Weight : 65 Kgs. Marital Status : Married Hobbies : Listening music, Traveling, Reading books, playing. Self assessment : Ambitious and eager to learn, result oriented, Leadership skills. Current CTC. : 6.75 lacks /year. Date: Place: (Arvind G. Dhadake).