TIPS Presentation

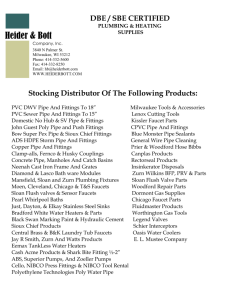

advertisement

Thermoplastic Industrial Piping Systems Presentation Prepared and Presented by TIPS Product Line Committee of the PPFA ©2003, 2004, 2005 - Plastics Pipe and Fittings Association All text, charts, and photos prepared and edited by Chasis Consulting, Inc. Disclaimer The material in this presentation/handbook has been prepared for the general information of the reader/user. The information presented is believed to be technically correct, however, the author, PPFA, PPEF, and their directors, officers, staff, and agents do not warrant the presentation/handbook or any of its contents suitable for any specific application. The presented material is published as an information guideline only. It shall be the responsibility of the reader/user to incorporate prudent and generally accepted engineering practices and meet the requirements of all involved regulatory agencies and their codes and standards. ©2003, 2004, 2005 - Plastics Pipe and Fittings Association PPFA Educational Materials • PPFA offers a wide range of educational materials, developed to help you become more proficient in the design, installation, and use of the ultimate piping system – thermoplastics! • Now available: – – – – Facilitated, on-site seminars (full-day, half-day, 90-minute) CD-based seminars (full-day, half-day, 90-minute) Workbooks Online tutorials • For more information on these products, visit us at http://www.ppfahome.org/tips 3 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association What is the PPFA? • The Plastic Pipe and Fittings Association (PPFA) is composed of more than 50 companies involved in the manufacturing of products for plastic piping systems. PPFA has been a major force in educating the American market for over two decades in thermoplastic residential, commercial and industrial piping products and installations. For further information, log on to www.ppfahome.org. 4 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association What is TIPS? • TIPS is the acronym for Thermoplastic Industrial Piping Systems; it also is the name of a product line committee (plc) of the PPFA. TIPS/plc is made up of several prestigious manufacturers in the industry whose goals are to educate and promote to the market place the many benefits of thermoplastic industrial piping systems. For further information log on to www.ppfahome.org/tips. 5 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association What does TIPS exclude? • For purposes of this presentation, TIPS is all piping excluding the following applications and product groups: – – – – – – – – – 6 - Introduction Irrigation Above-ground Fire Sprinkler Systems Residential Swimming Pools Gas Distribution and Transmission Municipal, Commercial, and Residential Potable Water, Sewer, Drain and Vent Plastic-lined Metal Piping Flexible Tubing Composite Piping Thermosets (Glass Reinforced Resins) ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Presentation Objectives • This presentation is to provide knowledge, proficiency and a comfort level in designing, specifying, and installing TIPS. For maximum educational benefit, the joint use of the one-day PowerPoint CD and workbook is recommended. 7 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Definitions and History ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Plastic • A material that contains organic, polymeric substances of large molecular weight, is solid in its finished state, and at some stage in its manufacture or processing into a finished article, can be shaped by flow 9 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Thermoplastic • A plastic that can be repeatedly softened by heating and hardened by cooling through a temperature range characteristic of the plastic, and that in the softened state, can be shaped by flow into an article by molding or extrusion Water analogy: Thermoplastics, similar to water, can be heated and cooled repeatedly without any change in the material’s basic properties. (i.e., recyclable) 10 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Thermoset • A plastic that, when cured by application of heat or by chemical means, changes into a substantially infusible and product Egg analogy: Thermosets, similar to eggs, can be processed only once with changes occurring in the material’s basic properties. 11 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Monomer • A relatively simple compound that can react to form a polymer Polymer • A substance consisting of molecules characterized by the repetition of one or more types of monomeric units Copolymer • A polymer formed by the polymerization of two chemically different monomers 12 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Resin • Broadly stated, the term designates any polymer or copolymer that is the basic material for a plastic Plastic resin 13 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Additives • Chemical ingredients incorporated in the resin or added during the manufacturing process to give desired product performance characteristics. These can include the following: – – – – – – – – 14 - Introduction Heat Stabilizers - Protect against thermal degradation Antioxidants - Protect against oxidation Ultraviolet Stabilizers - Protect against ultraviolet degradation Lubricants - Improve manufacturing processing Pigments - Add a distinctive color & aid in UV protection Fillers - Reduce cost and may also increase stiffness Property Modifiers - Enhance a particular material property Processing Aids - Assist material mixing/fusion during processing ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Compound • A mixture of a thermoplastic resin with other additives or ingredients Plastic pellet and powder compound 15 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Extrusion Extrusion Diagram • All thermoplastic pipe is extruded. Extrusion is a process whereby heated plastic forced throughExtruder a shaping orifice becomes one continuously formed piece. 16 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Injection Molding • Most voluminous thermoplastic non-pipe products are injection molded. Injection molding is the Injection Molding Machine process of forming a material by forcing it, under pressure, from a heated cylinder through a sprue (runner) into the cavity of a closed mold. Injection Molding Diagram 17 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Injection Molding Mold Sprue Bushing Injection Nozzle Press Clamp Unit Reciprocating Screw Reciprocating Hydraulic Injection Unit 18 - Introduction Screw Rotation Transmission ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Injection Molding “Hopper” Loading System Screw Movement Material Plasticized In Barrel 19 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Injection Molding Stationary Platen Moving Platen Screw Movement 20 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Injection Molding Mold Halves Platen Movement 21 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Injection Molding Molded Part 22 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Injection Molding Ejector Pins 23 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Injection Molding Platen Movement 24 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Injection Molding Screw Movement 25 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association History of Thermoplastic Piping Materials Estimated Year Plastic Discovered Plastic Material* Estimated Year of Piping Usage 1868 Cellulose Nitrate (Celluloid) First semi-synthetic plastic 1909 Phenol Formaldehyde (Bakelite) First all synthetic plastic 1927 Polyvinyl Chloride (PVC) 1940 1933 Polyethylene (PE) 1948 1938 Cellulose Acetate Butyrate (CAB) 1940 1938 Polytetrafluoroethylene (PTFE) 1960 1943 Chlorinated Polyvinyl Chloride (CPVC) 1960 1948 Acrylonitrile Butadiene Styrene (ABS) 1952 1955 Ethylene Chlorotrifluoroethylene (ECTFE) 1966 1956 Fluorinated Ethylenepropylene (FEP) 1965 1957 Polypropylene (PP) 1958 1960 Cross-Linked Polyethylene (PEX)** 1965 1962 Polybutylene (PB) 1971 1963 Polyvinylidene Fluoride (PVDF) 1964 1968 Perfluoroalkoxy (PFA) 1972 * Items in bold print are plastic materials included in this presentation. 26 - Introduction **A thermoset material ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Plastic Piping Materials • Thermoplastics accounted for over 95% of an estimated 11 billion pounds of plastic that went into all pipe, conduit and fittings in 2002. The estimated TIPS Market ($) share by pipe/valves/fitting materials for Year 2002 is shown in the pie chart. 27 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Material Characteristics ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Plastic Material Designations • ASTM is the standards development organization that classifies plastic piping materials by common physical characteristics categories. Over the past decade, there has been a movement to refine the classifications in a more meaningful way; however, the old designations are still in use. 29 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Plastic Material Designations • Old ASTM Designations: Material Designation – First Digit = Type – Second Digit = Grade – Third / Fourth Digit = Hydrostatic design stress divided by 100 • Example: PVC 1120 30 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Plastic Material Designations • New ASTM Designation Called Cell Classification – – – – – First Digit = Material Second Digit = Impact Strength Third Digit = Tensile Strength Fourth Digit = Modulus of Elasticity Fifth Digit = Heat Deflection Temperature • Example: PVC 12454 (Similar to PVC 1120) 31 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Plastic Material Designations • This seminar will include the following materials:* CPVC ASTM D1784-03 Cell Classification 23447/24448 HDPE ASTM D3350-02a Cell Classification 345464C PP ASTM D4101 Type I PVC ASTM D1784-03 Cell Classification 12454 PVDF ASTM D3222 Type I Grade 2 * Thermoplastic compounds can be reformulated to accentuate certain properties. Check with product manufacturers for latest compound usage. ABS material is not included in the Engineering and Physical Characteristics sections, because most ABS applications in the USA are for residential drain waste and vent, rather than industrial uses. 32 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Physical Characteristics* * The physical values listed may differ slightly due to variations of manufacturer’s resins and compounds. ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Specific Gravity • The ratio of the density of a material to the density of water at standard temperature (ASTM D-792 Test Method). The lower the number, the lighter the weight. Note: Water= 1.0 34 - Introduction PP 0.91 PE 0.92 PVC 1.38 CPVC 1.55 PVDF 1.76 PE Piping Lighter than Water ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Tensile Strength • The pulling force necessary to break a specimen, divided by the crosssection area at the point of failure. (ASTM D-638 Test Method) (psi @ 73°F) 35 - Introduction PVDF 8000 CPVC 7500 PVC 7300 PP 4600 PE 3500 Tensile TensileTesting Plastic Specimen Test Machine ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Modulus of Elasticity • The ratio of the stress to the elongation per inch due to this stress, in a material that deforms elastically. (ASTM D-638 Test Method) (psi @ 73°F x 105) 36 - Introduction PVC 4.2 CPVC 3.6 PVDF 2.1 PP 2.0 PE 1.2 ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Flexural Strength • The strength of a plastic material in bending as expressed by the tensile stress of the outermost fibers of a bent test sample at the instant of failure. (ASTM D-790 Test Method) (psi) 37 - Introduction PVC 14500 CPVC 13400 PVDF 9700 PP 7000 PE 3000 Flexural Plastic Specimen Test Flexural Testing Machine ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Izod Impact Strength • The resistance of a notched test specimen has to a sharp blow from a pendulum hammer. (ASTM Test D-256) (ft-lb/in) The lower the number, the lower the impact strength. 38 - Introduction PE 7.0 PVDF 3.8 CPVC 2.0 PVC 1.1 PP 0.8 Izod Testing Izod Testing MachineMachine ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Coefficient of Thermal Expansion • The fractional change in a length of a specimen due to a unit change in temperature. (ASTM D-6960 Test Method) (in./in./°F x 10-5) The lower the number, the lower the expansion rate. 39 - Introduction PVC 3.0 CPVC 3.8 PP 5.0 PVDF 7.3 PE 7.8 ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Thermal Conductivity • The time rate of transferring heat by conduction through a material of a given thickness and area for a given temperature difference. (ASTM C-177 Test Method)(Btu in./hr/ft2/°F) The lower the number, the less conductive. 40 - Introduction CPVC 0.95 PVDF 1.18 PVC 1.20 PP 1.20 PE 2.60 Thermal Conductivity via Modulated DSC ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Heat Resistance • The general maximum allowable temperature of a piping system in which 20-psi working pressure or less may be used (°F) Heat Deflection Testing Machine 41 - Introduction PVC 140 PE 160 PP 180 CPVC 210 PVDF 285 ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Abrasion Resistance • Using the Taber Abrasion Test, the weight loss of a material is measured after being exposed to an abrasive wheel for 1000 cycles. (mg) The lower the number, the more abrasion resistant. Note:Stainless Steel is 50. 42 - Introduction PE 5 PVDF 5-10 PP 15-20 PVC 12-20 CPVC 20 Taber Machine ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Flash Ignition Temperature • The lowest temperature of a substance at which sufficient combustible gas is evolved to be ignited by a small external flame. (°F) Note: Wood products ignite at 500°F and lower. 43 - Introduction CPVC 900 PVDF 790 PVC 730 PE 660 PP N/A Instrument to Test Flash Points of Materials ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Flammability Rating • An Underwriter Laboratories test to measure a material’s resistance to burning, dripping, glow emission and burn-through. The 94V-0 designation is the most resistant to burning; 94HB is the least resistant to burning. PVDF 94V-0 CPVC 94V-0 PVC 94V-0 PP* 94HB PE 94V-2 * Fire retardant grades can increase value to 94V-2. 44 - Introduction Flammability Testing by Underwriter Laboratories ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Limiting Oxygen Index • The percentage of oxygen needed in an atmosphere to support combustion (ASTM D2863 Test Method). The higher the number, the greater the resistance to burning. (%) 45 - Introduction CPVC 60 PVDF 44-75 PVC 43 PP 18 PE 17 ©2003, 2004, 2005 - Plastics Pipe and Fittings Association Flame Spread / Smoke Development Indices • These material are determined by Flame Spreadcharacteristics Index* Smoke Development Index* testing the surface0 flame spread of and5-50 smoke PVDF PVDF developed by plastic piping asPVC compared to fixed >300 PVC 15-20 index elements of15mineral fiber cement>350 board and CPVC CPVC red oak flooring. (ASTM E-84, NFPA 255, UL 723 PP N/A PP >400 and UBC 8-1) (42-1 Test Method). PE N/A PE >400 Note: MajorPP building andare mechanical require that combustible *CPVC, and PVC available codes in specially formulated product piping installedthat within animproved air plenumflame mustspread have aand/or maximum flame compounds have smoke spread index of characteristics. 25 and a maximum smoke development index of 50. development 46 - Introduction ©2003, 2004, 2005 - Plastics Pipe and Fittings Association TIPS are... • • • • • 47 - Introduction Environmentally sound Easy and safe to install Reliable Long-lasting Cost-effective ©2003, 2004, 2005 - Plastics Pipe and Fittings Association