chapter one transparency

advertisement

Chapter 10

HCS12 Serial Peripheral Interface

What is Serial Peripheral Interface (SPI)?

•

•

•

SPI is a synchronous serial protocol proposed by Motorola to be used as

standard for interfacing peripheral chips to a microcontroller.

Devices are classified into the master or slaves.

The SPI protocol uses four wires to carry out the task of data

communication:

–

–

–

–

•

•

MOSI: master out slave in

MISO: master in slave out

SCK: serial clock

SS: slave select

An SPI data transfer is initiated by the master device. A master is

responsible for generating the SCK signal to synchronize the data transfer.

The SPI protocol is mainly used to interface with shift registers, LED/LCD

drivers, phase locked loop chips, memory components with SPI interface, or

A/D or D/A converter chips.

The HCS12 SPI Modules

•

•

•

An HCS12 device may have from one to three SPI modules.

The MC9S12DP256 has three SPI modules: SPI0, SPI1, and SPI2.

By default, the SPI0 share the use of the upper 4 Port S pins:

–

–

–

–

•

By default, the SPI1 shares the use of the lower 4 Port P pins:

–

–

–

–

•

PP3 SS1 (can be rerouted to PH3)

PP2 SCK1

(can be rerouted to PH2)

PP1 MOSI1

(can be rerouted to PH1)

PP0 MISO1

(can be rerouted to PH0)

By default, the SPI2 shares the use of the upper 4 Port P pins:

–

–

–

–

•

PS7 SS0 (can be rerouted to PM3)

PS6 SCK0

(can be rerouted to PM5)

PS5 MOSI0

(can be rerouted to PM4)

PS4 MISO0

(can be rerouted to PM2)

PP6 SS2 (can be rerouted to PH7)

PP7 SCK2

(can be rerouted to PH6)

PP5 MOSI2

(can be rerouted to PH5)

PP4 MISO2

(can be rerouted to PH4)

It is important to make sure that there is no conflict in the use of signal pins when

making rerouting decision.

SPI Related Registers (1 of 6)

•

The operating parameters of each SPI module are controlled via two control

registers:

– SPIxCR1: (x = 0, 1, or 2)

– SPIxCR2

•

•

•

•

•

•

The baud rate of SPI transfer is controlled by the SPIxBR register.

The operation status of the SPI operation is recorded in the SPIxSR

register.

The contents of the SPIxCR1, SPIxCR2, SPIxBR, and SPIxSR registers are

illustrated in Figure 10.1 to 10.4, respectively.

The SS pin may be disconnected from SPI by clearing the SSOE bit in the

SPIxCR1 register. After that, it can be used as a general I/O pin.

If the SSOE bit in the SPIxCR1 register is set to 1, then the SS signal will be

asserted to enable the slave device whenever a new SPI transfer is started.

The equation for setting the SPI baud rate is given in Figure 10.3.

SPI Related Registers (2 of 6)

reset:

7

6

5

4

3

2

1

0

SPIE

SPE

SPTIE

MSTR

CPOL

CPHA

SSOE

LSBFE

0

0

0

0

0

1

0

0

SPIE: SPI interrupt enable bit

0 = SPI interrupts are disabled

1 = SPI interrupts are enabled

SPE: SPI system enable bit

0 = SPI disabled

1 = SPI enabled and pins PS4-PS7 are dedicated to SPI function

SPTIE: SPI transmit interrupt enable

0 = SPTEF interrupt disabled

1 = SPTEF interrupt enabled

MSTR: SPI master/slave mode select bit

0 = slave mode

1 = master mode

CPOL: SPI clock polarity bit

0 = active high clocks selected; SCK idle low

1 = active low clocks selected, SCK idle high

CPHA: SPI clock phase bit

0 = The first SCK edge is issued one-half cycle into the 8-cycle transfer operation.

1 = The SCK edge is issued at the beginning of the 8-cycle transfer operation.

SSOE: slave select output enable bit

The SS output feature is enabled only in master mode by asserting the

SSOE bit and the MODFEN bit of the SPIxCR2 register.

LSBF: SPI least-significant-bit first enable bit

0 = data is transferred most-significant bit first

1 = data is transferred least-significant bit first

Figure 10.1 SPI control register 1 (SPIxCR1, x = 0, 1, or 2)

SPI Related Registers (3 of 6)

reset:

7

6

5

0

0

0

0

0

0

4

3

MODFEN BIDIROE

0

1

2

1

0

0

SPSWAI

SPC0

0

0

0

MODFEN: Mode fault enable bit

0 = Disable the MODF error

1 = Enable settinig the MODF error

BIDIROE: Output enable in the bidirectional mode of operation

0 = Output buffer disabled

1 = Output buffer enabled

SPSWAI: SPI stop in wait mode

0 = SPI clock operates normally in stop mode

1 = Stop SPI clock generation in Wait mode

SPC0: Serial pin control bit 0

With the MSTR bit in the SPIxCR1 register, this bit enables bidirectional pin

configuration as shown in Table 10.1.

Figure 10.2 SPI control register 2 (SPIxCR2, x = 0, 1, or 2)

SPI Related Registers (4 of 6)

Table 10.1 SS input/output selection

MODFEN

SSOE

0

0

1

1

0

1

0

1

Master Mode

SS not used by SPI

SS not used by SPI

SS input with MODF feature

SS output

Slave mode

SS input

SS input

SS input

SS input

SPI Related Registers (5 of 6)

reset:

7

6

5

4

3

2

1

0

0

SPPR2

SPPR1

SPPR0

0

SPR2

SPR1

SPR0

0

0

0

0

0

0

0

0

SPPR2~SPPR0: SPI baud rate preselection bits

SPR2~SPR0: SPI baud rate selection bits

BaudRateDivisor = (SPPR + 1) 2(SPR + 1)

Baud Rate = Bus Clock BaudRateDivisor

Figure 10.3 SPI baud rate register (SPIxBR, x = 0, 1, or 2)

reset:

7

6

SPIF

0

0

0

5

4

SPTEF MODF

1

0

3

2

1

0

0

0

0

0

0

0

0

0

SPIF: SPI interrupt request bit

SPIF is set after the eight SCK cycles in a data transfer, and it is

cleared by reading the SP0SR register (with SPIF set) followed by

a read access to the SPI data register.

0 = transfer not yet complete

1 = new data copied to SPIxDR

SPTEF: SPI data register empty interrupt flag

0 = SPI data register not empty

1 = SPI data register empty

MODF: mode error interrupt status flag

0 = mode fault has not occurred

1 = mode fault has occurred

Figure 10.4 SPI status register (SPIxSR)

SPI Related Registers (6 of 6)

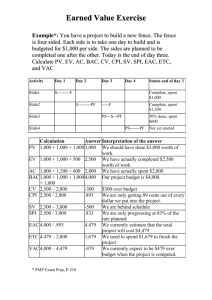

• Example 10.1 Give a value to be loaded to the SPIxBR

register to set the baud rate to 2 MHz for a 24 MHz bus

clock.

• Solution: 24 MHz 2 MHz = 12. One possibility is to set

SPPR2-SPPR0 and SPR2-SPR0 to 010 and 001,

respectively. The value to be loaded into the SPIxBR

register is $21.

• Example 10.2 What is the highest possible baud rate for

the SPI with 24 MHz bus clock?

• Solution: The highest SPI baud rate occurs when both

the SPPR2-SPPR0 and SPR2-SPR0 are 000. In this

case the baud rate is 24 MH 2 = 12 MHz.

SPI Transmission Format (1 of 3)

• The data bits can be shifted on the rising or the falling

edge of the SCK clock.

• Since the SCK can be idle high or idle low, there are four

possible combinations as shown in Figure 10.5 and 10.6.

• To shift data bits on the rising edge, set CPOL-CPHA to

00 or 11.

• To shift data bits on the falling edge, set CPOL-CPHA to

01 or 10.

• Data byte can be shifted in and out most significant bit

first or least significant bit first.

SPI Transmission Format (2 of 3)

Transfer

SS (O)

master only

Begin

End

SS (I)

SCK (CPOL = 0)

SCK (CPOL = 1)

Sample I

MOSI/MISO

Change O

MOSI Pin

Change O

MISO Pin

tL

MSB first (LSBF = 0)

LSB first (LSBF = 1)

MSB

LSB

tT

Bit 6

Bit 1

Bit 5

Bit 2

Bit 4

Bit 3

Bit 3

Bit 4

Bit 2

Bit 5

Bit 1

Bit 6

Figure 10.5 SPI Clock format 0 (CPHA = 0)

tI

tL

LSB Minimum 1/2 SCK

for tT, tI, tL

MSB

SPI Transmission Format (3 of 3)

Transfer

SS (O)

master only

Begin

End

SS (I)

SCK (CPOL = 0)

SCK (CPOL = 1)

Sample I

MOSI/MISO

Change O

MOSI Pin

Change O

MISO Pin

tL

MSB first (LSBF = 0)

LSB first (LSBF = 1)

tT

MSB

LSB

Bit 6

Bit 1

Bit 5

Bit 2

Bit 4

Bit 3

Bit 3

Bit 4

Bit 2

Bit 5

Figure 10.6 SPI Clock format 1 (CPHA = 1)

Bit 1

Bit 6

tI

tL

LSB Minimum 1/2

MSB SCK for tT, tI, tL

Bidirectional Mode (MOMI or SISO)

•

•

•

•

•

•

•

•

•

•

A mode that uses only one data pin to shift data in and out.

This mode is provided to deal with peripheral devices with only one data pin.

Either the MOSI pin or the MISO pin can be used as the bidirectional pin.

When the SPI is configured to the master mode (MSTR bit = 1), the MOSI pin is used

in data transmission and becomes the MOMI pin.

When the SPI is configured to the slave mode (MSTR bit = 0), the MISO pin is used

in data transmission and becomes the SISO pin.

The direction of each serial pin depends on the BIDIROE bit of the SPIxCR2 register.

The pin configuration for MOSI and MISO are illustrated in Figure 10.7.

If one wants to read data from the peripheral device, clear the BIDIROE bit to 0.

If one wants to output data to the peripheral device, set the BIDIROE bit to 1.

The use of the this mode is illustrated in exercise problem 10.8.

When SPE = 1

Serial Out

Normal

Mode

SPC0 = 0

Slave Mode

MSTR = 0

Master mode

MSTR = 1

MOSI

SPI

Serial In

MISO

Serial Out

SPI

Serial In

MOSI

SPI

SWOM enables open-drain output

Bi-directional

mode

SPC0 = 1

Serial In

MOMI

BIDIROE

MISO

Serial Out

SWOM enables open-drain output

Serial In

SPI

Serial Out

Figure 10.7 Normal mode and bidirectional mode

BIDIROE

SISO

Mode Fault Error

• If the SSx signal goes low while the SPIx is configured

as a master, it indicates a system error where more than

one master may be trying to drive the MOSIx and SCKx

pins simultaneously.

• The MODF bit in the SPIxSR register will be set to 1

when mode fault condition occurs.

• When mode fault occurs, the MSTR bit will be cleared to

0 and the output enable for the MOSIx and SCKx pins

will be deasserted.

SPI Circuit Connection

• In an SPI system, one device is configured as a master.

Other devices are configured as slaves.

• The circuit connection for a single-slave system is shown

in Figure 10.8.

• A multi-slave system may have two different connection

methods as illustrated in Figure 10.9 and 10.10.

• In Figure 10.9, the master can exchange data with each

individual slave without affecting other slaves.

• In Figure 10.10, all the slaves are configured into a

larger ring. A data transmission with certain slaves will go

through other slaves.

Master SPI

Shift register

MISO

MISO

MOSI

MOSI

SCK

Baud Rate

Generator

VDD

Slave SPI

Shift register

SCK

SS

SS

Figure 10.8 Master/slave transfer block diagram

+5V

Slave 0

Shift

register

SPI Master

(HCS12)

SS

MOSI SCK MISO SS

Slave 1

Shift

register

MOSI SCK MISO SS

Slave k

Shift

register

...

MOSI SCK MISO SS

SCKx

MOSIx

MISOx

PP0

PP1

.

.

.

.

.

.

PPk

Figure 10.9 Single-master and multiple-slave device connection (method 1)

Slave 0

SPI Master

(HCS12)

+5V

Shift

register

MOSI SCK MISO SS

SS

Slave 1

Slave k

Shift

register

Shift

register

...

MOSI SCK MISO SS

MOSI SCK MISO SS

...

SCKx

MOSIx

MISOx

Figure 10.10 Single-master and multiple-slave device connection (method 2)

• Example 10.3 Configure the SPI0 to operate with the following

setting assuming that E

• clock is 24 MHz:

–

–

–

–

–

–

–

6 MHz baud rate

Enable SPI0 to master mode

SCK0 pin idle low with data shifted on the rising edge of SCK

Transfer data most significant bit first and disable interrupt

Disable SS0 function

Stop SPI in Wait mode

Normal SPI operation (not bidirectional mode)

• Solution: fE / baud rate = 24 MHz/6 MHz = 4. We

need to set SPPR2-SPPR0 and SPR2-SPR0 to

001 and 000, respectively. Write the value $10

into the SPI0BR register.

– The following instruction sequence will configure the

SPI0 as desired:

movb #$10,SPI0BR

movb #$50,SPI0CR1

movb #$02,SPI0CR2

movb #0,WOMS

; set baud rate to 6 MHz

; disable interrupt, enable SPI, SCK idle low, data

; latched on rising edge, data transferred msb first

; disable bidirectional mode, stop SPI in wait mode

; enable Port S pull-up

SPI Utility Functions

• The following operations are common in many

applications and should be made into library functions to

be called by many SPI applications:

–

–

–

–

Send a character to SPI

Send a string to SPI

Read a character from SPI

Read a string from SPI

putcspix (x = 0, 1, or 2)

putsspix (x = 0, 1, or 2)

getcspix (x = 0, 1, or 2)

getsspix (x = 0, 1, or 2)

Function putcSPI0

putcspi0 brclr

staa

brclr

ldaa

rts

SPI0SR,SPTEF,*

SPI0DR

SPI0SR,SPIF,*

SPI0DR

void putcspi0 (char cx)

{

char temp;

while(!(SPI0SR & SPTEF));

SPI0DR = cx;

while(!(SPI0SR & SPIF));

temp = SPI0DR;

}

; wait until write operation is permissible

; output the character to SPI0

; wait until the byte is shifted out

; clear the SPIF flag

/* wait until write is permissible */

/* output the byte to the SPI */

/* wait until write operation is complete */

/* clear the SPIF flag */

Function putsSPI0

; the string to be output is pointed to by X

putsspi0 ldaa 1,x+

; get one byte to be output to SPI port

beq doneps0 ; reach the end of the string?

jsr

putcspi0 ; call subroutine to output the byte

bra putsspi0 ; continue to output

doneps0 rts

void putsspi0(char *ptr)

{

while(*ptr) {

/* continue until all characters have been output */

putcspi0(*ptr);

ptr++;

}

}

Function getcSPI0

; This function reads a character from SPI0 and returns it in accumulator A

getcspi0 brclr

staa

brclr

ldaa

rts

SPI0SR,SPTEF,* ; wait until write operation is permissible

SPI0DR

; trigger eight clock pulses for SPI transfer

SPI0SR,SPIF,* ; wait until a byte has been shifted in

SPI0DR

; return the byte in A and clear the SPIF flag

char getcspi0(void)

{

while(!(SPI0SR & SPTEF));

SPI0DR = 0x00;

while(!(SPI0SR & SPIF));

return SPI0DR;

}

/* wait until write is permissible */

/* trigger 8 SCK pulses to shift in data */

/* wait until a byte has been shifted in */

/* return the character */

Function getsSPI0

; This function reads a string from the SPI and store it in a buffer pointed to by X

; The number of bytes to be read in passed in accumulator B

getsspi0 tstb

beq

jsr

staa

decb

bra

donegs0 clr

rts

donegs0

getcspi0

1,x+

getsspi0

0,x

; check the byte count

; return when byte count is zero

; call subroutine to read a byte

; save the returned byte in the buffer

; decrement the byte count

; terminate the string with a NULL character

void getsspi0(char *ptr, char count)

{

while(count) {

/* continue while byte count is nonzero */

*ptr++ = getcspi0(); /* get a byte and save it in buffer */

count--;

}

*ptr = 0;

/* terminate the string with a NULL */

}

The HC595 Shift Register

• The HC595 consists of an 8-bit shift register and a D-type latch with

three-state parallel output.

• The shift register provides parallel data to the latch.

• The maximum data shift rate is 100 MHz (Philips part).

DS

15

14

Shift

register

SC

11

Reset 10

12

LC

13

OE

Latch

1

2

3

4

5

6

7

9

QA

QB

QC

QD

QE

QF

QG

QH

SQH

VCC = Pin 16

GND = Pin 8

Figure 10.11 The 74HC595 block diagram and pin assignment

Signal Pins of the HC595

• DS: serial data input

• SC: shift clock. A low-to-high transition on this pin causes the data at

the serial input pin to be shifted into the 8-bit shift register.

• Reset: A low on this pin resets the shift register portion of this

device.

• LC: latch clock. A low-to-high transition on this pin loads the contents

of the shift register into the output latch.

• OE: output enable. A low on this pin allows the data from the latches

to be presented at the outputs.

• QA to QH: tri-state latch output

• SQH: the output of the eight stage of the shift register

Applications of the HC595 (1 of 2)

• The HC595 is often used to add parallel ports to

the microcontroller.

• Both the connection methods shown in Figure

10.9 and 10.10 can be used to add parallel ports

to the MCU.

Applications of the HC595 (2 of 2)

•

Example 10.5 Describe how to use two 74HC595s to drive eight common

cathode seven-segment displays assuming that the E clock frequency of the

HCS12 is 24 MHz.

Solution: Use the circuit in figure 10.12 to connect two 74HC595s to the

HCS12.

5V

#7

300

reset

OE

74HC595

QG

QF

.

.

.

QA

DS

SC LC SQH

MOSI0

SCK0

PK7

HCS12

300

.

.

.

a

b

. . .

. . .

a

b

g

.

.

. g

. . .

g

common

cathode

common

cathode

common

cathode

R

2N2222

SC

Q. G

LC .

.

OE

QA

#0

a

b

5V

reset

DS QH

#6

R

.

.

.

2N2222

R

74HC595

Figure 10.12 Two 74HC595s together drive eight seven-segment displays

IMAX = 70 mA

•

2N2222

Program to display 87654321 on display #7 to #0

#include “c:\miniide\hcs12.inc"

org

$1000

icnt

ds.b

1

org

$1500

lds

#$1500

bset

DDRK,$80

jsr

openspi0

forever ldx

#dispTab

movb #8,icnt

loop

ldaa

1,x+

jsr

putcspi0

ldaa

1,x+

jsr

putcspi0

bclr

PTK,BIT7

bset

PTK,BIT7

ldy

#1

jsr

delayby1ms

dec

icnt

bne

loop

bra

forever

; loop count

; set up stack pointer

; configure the PK7 pin for output

; configure SPI0

; use X as a pointer to the table

; set loop count to 8

; send the digit select byte to the 74HC595

;

"

; send segment pattern to 74HC595

;

"

; transfer data from shift register to output

; latch

; display the digit for one ms

;

"

;

; if not reach digit 1, then next

; start from the start of the table

openspi0 movb #0,SPI0BR

; set baud rate to 12 MHz

movb #$50,SPI0CR1 ; disable interrupt, enable SPI, SCK idle low,

; latch data on rising edge, transfer data msb first

movb #$02,SPI0CR2 ; disable bidirectional mode, stop SPI in wait mode

movb #0,WOMS

; enable Port S pull-up

rts

#include "c:\miniide\delay.asm"

#include "c:\miniide\spi0util.asm"

; ********************************************************************

; Each digit consists of two bytes of data. The first byte is

; digit select, the second byte is the digit pattern.

; ********************************************************************

dispTab dc.b

$80,$7F,$40,$70,$20,$5F,$10,$5B

dc.b

$08,$33,$04,$79,$02,$6D,$01,$30

end

#include “c:\egnu091\include\hcs12.h”

#include “c:\egnu091\include\spi0util.c”

#include “c:\egnu091\include\delay.c”

void openspi0(void);

void main (void)

{

unsigned char disp_tab[8][2] = {{0x80,0x7F},{0x40,0x70},{0x20,0x5F},{0x10,0x5B},

{0x08,0x33},{0x04,0x79},{0x02,0x6D},{0x01,0x30}};

char i;

openspi0();

/* configure the SPI0 module */

DDRK |= BIT7; /* configure pin PK7 as output */

while(1) {

for (i = 0; i < 8; i++) {

putcspi0(disp_tab[i][0]); /* send out digit select value */

putcspi0(disp_tab[i][1]); /* send out segment pattern */

PTK &= ~BIT7;

/* transfer values to latches of 74HC595s */

PTK |= BIT7;

/* " */

delayby1ms(1);

/* display a digit for 1 ms */

}

}

}

The TC72 Digital Thermometer

•

•

•

•

•

10-bit resolution and SPI interface

Pin assignment and block diagram shown in Figure 10.13.

Capable of reading temperature from -55oC to 125oC.

Can be used in continuous temperature conversion or one-shot conversion mode.

Has internal clock generator to control the automatic temperature conversion

sequence

VDD

NC 1

CE

2

SCK 3

GND 4

8 VDD

TC72

7 NC

6 SDI

5 SDO

Internal

diode

temperature

sensor

10-bit

sigma Delta

A/D

converter

temperature

register

GND

TC72

Manufacturer

ID register

Serial

Port

Interface

Control

Register

Figure 10.13 TC72 pin assignment and functional block diagram

CE

SCK

SDO

SDI

Temperature Data Format

• Temperature is represented by a 10-bit two’s complement word with

a resolution of 0.25oC per least significant bit.

• The converter is scaled from -128oC to +127oC with 0oC

represented as 0x0000.

• The temperature value is stored in two 8-bit registers.

• Whenever the most significant bit is 1, the temperature is negative.

• A sample of temperature reading is shown.

Table 10.3 TC72 Temperature output data

Binary

high byte/low byte

0010

0100

0001

0000

0000

1111

1111

1110

1100

0001/0100

1010/1000

1010/1100

0001/1000

0000/0000

1111/1000

0010/1100

0111/0000

1001/0100

0000

0000

0000

0000

0000

0000

0000

0000

0000

Hex

Temperature

2140

4A80

1AC0

0180

0000

FF80

F2C0

E700

C900

33.25 oC

74.5oC

26.75 oC

1.5o C

0 oC

-0.5o C

-13.25oC

-24o C

-55o C

TC72’s Serial Interface

•

•

•

•

•

•

•

The CE input to the TC72 must be asserted (high) to enable SPI transfer.

Data can be shifted on the rising edge or the falling edge depending on the idle

polarity of the SCK source.

Data transfer to and from the TC72 consists of one address byte followed by one or

multiple data (2 to 4) bytes.

The TC72 registers and their addresses are shown in Table 10.4.

The most significant bit of the address byte determines whether a read (A7 = 0) or a

write (A7 = 1) operation will occur.

A multiple byte read operation will start from high address toward lower addresses.

The user can send in the temperature result high byte address and read the

temperature result high byte, low byte, and the control registers.

Table 10.4 Register for TC72

Register

Control

LSBtemperature

MSBtemperature

ManufacturerID

Read

Write

address address

0x00

0x01

0x02

0x03

Note. 1. OS is One-Shot

2. SHDN is Shutdown

0x80

N/A

N/A

N/A

Bit

7

Bit

6

Bit

5

Bit

4

Bit

3

Bit

2

Bit

1

Bit

0

0

T1

T9

0

0

T0

T8

1

0

0

T7

0

OS

0

T6

1

0

0

T5

0

0

0

T4

1

0 SHDN

0

0

T3 T2

0

0

Value on

POR/BOR

0x05

0x00

0x00

0x54

Procedure for Reading Temperature

•

(1 of 2)

Step 1

– Pull the CE pin high to enable SPI transfer.

•

Step 2

– Send the temperature result high byte read address (0x02) to the TC72. Wait

until the SPI transfer is complete.

•

Step 3

– Read the temperature result high byte. The user needs to write a dummy byte

into the SPI data register to trigger eight clock pulses.

•

Step 4

– Read the temperature result low byte. Again, the user needs to write a dummy

byte into the SPI data register to trigger eight clock pulses.

•

Step 5

– Pull CE pin to low so that a new transfer can be started.

•

Single-byte read and multiple-byte read timing diagrams are shown in

Figures 10.15b and 10.15c.

Procedure for Reading Temperature

(2 of 2)

CE

1

2

3

4

5

6

7

8

A

5

A

4

A

3

A

2

A

1

A

0

9

10

11

12

13

14

15

16

D

7

D

6

D

5

D

4

D

3

D

2

D

1

D

0

SCK

A7 = 0

SDI

A

7

A

6

High Z

SDO

high Z

Figure 10.15b Single data byte read operation

CE

Write operation

SCK

Read operation

Address byte = 0x02

SDI

SDO

A

7

A

0

D

7

D

0

D

7

Figure 10.15c SPI multiple data byte transfer

D

0

D

7

D

0

Control Register

•

•

•

•

•

•

The control register is used to select the shutdown, continuous, or one-shot

conversion operating mode.

The temperature conversion mode selection logic is shown in Table 10.5.

At power up, the SHDN bit is 1. Thus the TC72 is in the shutdown mode.

If the SHDN bit is 0, the TC72 will perform a temperature conversion

approximately every 150 ms.

A temperature conversion will be initiated by a write operation into the

control register to select the continuous mode or one-shot mode.

A typical circuit connection between the TC72 and the HCS12 is shown in

Figure 10.16.

Table 10.5 Control register temperature conversion mode selection

Operationmode

One-Shot bit

Shutdown bit

Continuoustemperatureconversion

Shutdown

Continuoustemperatureconversion

One-shot

0

0

1

1

0

1

0

1

TC72

VDD

HCS12 MCU

VDD

CE

0.1F

PK7

SCK

SCK0

SDO

MISO0

SDI

MOSI0

GND

Figure 10.16 Circuit connection between the TC72 and the HCS12

• Example 10.6 Write a C program to read the

temperature every 200 ms. Convert the temperature to a

string so that it can be displayed in an appropriate output

device. A pointer to hold the string will be passed to this

function. The bus clock is 24 MHz.

#include “c:\egnu091\include\hcs12.h”

#include “c:\egnu091\include\spi0util.c”

#include “c:\egnu091\include\delay.c”

#include “c:\egnu091\include\convert.c”

void read_temp (char *ptr);

void openspi0(void);

char buf[10];

void main (void)

{

DDRM

|= BIT1;

/* configure the PM1 pin for output */

openspi0();

/* configure SPI0 module */

read_temp(&buf[0]);

}

void openspi0(void)

{

SPI0BR = 0x10;

/* set baud rate to 6 MHz */

SPI0CR1 = 0x50;

/* enable SPI0 to master mode, select rising edge to

shift data in and out */

SPI0CR2 = 0x02;

/* select normal mode and stop SPI in wait mode */

WOMS

= 0x00;

/* enable Port S pull-up */

}

void read_temp (char *ptr)

{

char hi_byte, lo_byte, temp, *bptr;

unsigned int result;

bptr = ptr;

PTM |= BIT1;

/* enable TC72 data transfer */

putcspi0(0x80);

/* send out TC72 control register write address */

putcspi0(0x11);

/* perform one shot conversion */

PTM &= ~BIT1;

/* disable TC72 data transfer */

delayby100ms(2);

/* wait until temperature conversion is complete */

PTM |= BIT1;

/* enable TC72 data transfer */

putcspi0(0x02);

/* send MSB temperature read address */

hi_byte = getcspi0();

/* read the temperature high byte */

lo_byte = getcspi0();

/* save temperature low byte and clear SPIF */

PTM &= ~BIT1;

/* disable TC72 data transfer */

lo_byte &= 0xC0;

/* make sure the lower 6 bits are 0s */

result = (int) hi_byte * 256 + (int) lo_byte;

if (hi_byte & 0x80) {

/* temperature is negative */

result = ~result + 1; /* take the two' complement of result */

result >>= 6;

temp

= result & 0x0003; /* place the lowest two bits in temp */

result

>>= 2;

/* get rid of fractional part */

*ptr++ = 0x2D;

/* store the minus sign */

int2alpha(result, ptr);

}

else {

/* temperature is positive */

result >>= 6;

temp

= result & 0x0003; /* save fractional part */

result >>= 2;

/* get rid of fractional part */

int2alpha(result, ptr);

/* convert to ASCII string */

}

while(*bptr){

/* search the end of the string */

bptr++;

};

switch (temp){ /* add fractional digits to the temperature */

case 0:

break;

case 1:

/* fractional part is .25 */

*bptr++ = 0x2E; /* add decimal point */

*bptr++ = 0x32;

*bptr++ = 0x35;

*bptr = '\0';

break;

case 2:

/* fractional part is .5 */

*bptr++ = 0x2E; /* add decimal point */

*bptr++ = 0x35;

*bptr = '\0';

break;

case 3:

/* fractional part is .75 */

*bptr++ = 0x2E; /* add decimal point */

*bptr++ = 0x37;

*bptr++ = 0x35;

*bptr = '\0';

break;

default:

break;

}

}

The D/A Converter TLV5616

•

•

•

•

The TLV5616 is a 12-bit voltage output digital-to-analog converter (DAC)

with SPI interface.

The TLV5616 has an output settling time of 3 ms in fast mode and 9 ms in

slow mode.

A D/A conversion is started by writing a 16-bit serial string that contains 4

control bits and 12 data bits to the TLV5616.

TLV5616 can operate from 2.7V to 5.5V.

REFIN

DIN

+

Serial input

register

14

12

SCLK

DIN

1

8

VDD

SCLK

2

7

OUT

CS

3

6

REFIN

FS

4

5

AGND

(a) pin assignment

CS

16 cycle

timer

12-bit 12

data

latch

update

FS

2

Power-on

reset

Speed/

power-down

logic

(b) functional block diagram

Figure 10.17 The TLV5616 DAC pins and block diagram

x2

OUT

TLV5616 Signal Pins

•

•

•

•

•

•

•

•

AGND:

CS:

DIN:

FS:

OUT:

REFIN:

SCLK:

VDD:

analog ground

chip select (active low)

serial data input

frame sync

DAC analog output

reference analog input voltage

serial clock input

positive power supply

Date Format

- A 16-bit frame with 4 control bits and 12 data

bits.

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

x

SPD

PWR

x

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

SPD: speed control bit

0 = slow mode

1 = fast mode

PWR: power control bit

0 = normal operation

1 = power down

D11~D0: new DAC value

Figure 10.18 Input data format for the TLV5616 DAC

TLV5616 Output Voltage

• The output voltage is given by the following

expression:

– VOUT = 2 REF code 2n

• The reference voltage input cannot be higher

than VDD/2.

Data Shifting Timing

• The FS pulse must be generated before data

shifting can start.

• The highest data shift rate is 20 MHz.

twL

SCLK

DIN

tsu(D)

twH

th(D)

D15

D14

D13

D12

D1

tsu(FS-CK)

CS

D0

tsu(C16-CS)

tsu(CS-FS)

tsu(C16-FS)

twH(FS)

FS

Figure 10.19 TLV5616 data shifting timing diagam

CS and FS Trigger Sequence

•

•

•

•

Pull FS to high.

Pull CS to low.

Pull FS to low.

Send out control and data bits using the SPI

transfer.

• Wait until all 16 bits have been shifted out; pull

FS to high.

• Pull CS to high.

Circuit Connection between

the TLV5616 and HCS12

TLV5616

HCS12

MOSI0

SDIN

SCK0

SCLK

PM6

CS

PM7

FS

VDD

OUT

REFIN

AGND

Figure 10.20 TLV5616 to HCS12 interface

2V

• Example 10.9 Write a program to generate a waveform that is a repetition of the

waveform shown in Figure 10.21 using the circuit shown in Figure 10.20.

V OUT

3V

2V

1V

time

1ms 1ms 1ms 1ms 1ms 1ms 1ms 1ms

Figure 10.21 Waveform to be generated

• The values to be sent to the TLV5616 to generate 0V, 1V, 2V, and 3V outputs are:

val(0) = 0

val(1) = 212/4 = 1024

val(2) = 2 212/4 = 2048

val(3) = 3 212/4 = 3072

• The 16-bit values (in fast mode) to be written to the TLV5616 for this four voltages are

as follows:

code (0) = $4000

code (1) = $4400

code (2) = $4800

code (3) = $4C00

#include

PM7

PM6

prolog

epilog

forever

iloop

"c:\miniide\hcs12.inc"

equ

BIT7

equ

BIT6

macro

bset

PTM,PM7

bclr

PTM,PM6

bclr

PTM,PM7

endm

macro

bset

PTM,PM7

bset

PTM,PM6

endm

org

lds

bset

jsr

ldx

ldab

prolog

ldaa

$1500

#$1500

DDRM,$C0

openspi0

#D2ATab

#8

1,x+

; pull FS to high

; pull CS to low

; pull FS to low

; pull FS to high

; pull CS to high

; set up the stack pointer

; configure the PM6 and PM7 pins for output

; configure SPI0 properly

; Use X to point to the table

; entry count set to 8

; activate an FS pulse and pull CS to low

; output 0V from OUT pin

jsr

putcspi0

;

"

ldaa

1,x+

;

"

jsr

putcspi0

;

"

epilog

; pull PM7 and PM6 to high

ldy

#1

; wait for 1 ms

jsr

delayby1ms ;

"

dbne

b,iloop

; reach the end of the table?

bra

forever

; yes, start from the beginning

D2ATab dc.b

$40,$00,$44,$00,$48,$00,$44,$00

dc.b

$48,$00,$44,$00,$48,$00,$4C,$00

openspi0 movb #0,SPI0BR ; set baud rate to 12 MHz

movb #$54,SPI0CR1

movb #$02,SPI0CR2

movb #0,WOMS

; enable Port S pull-up

rts

#include "c:\miniide\delay.asm"

#include "c:\miniide\spi0util.asm"

end

Matrix LED Displays

• Many organizations have the need to display important information

at the entrance or some corners of their buildings.

• The information to be displayed can be rotated.

• Common matrix LED displays format are 5 7, 5 8, and 8 8.

• One can find color matrix LEDs with red, green, and red color.

• Matrix LED displays can be organized as cathode-row or anode-row.

• All LEDs in a cathode-row matrix LED display have a common

cathode whereas those in anode-row matrix LED display have a

common anode.

pin

column

13

3

4

10

6

1

2

3

4

5

row

9

1

14

2

8

3

12

4

1

5

7

6

2

7

Figure 10.22. Cathode row matrix LEDs (Fairchild GMC8X75C)

pin

column

13

3

4

10

6

1

2

3

4

5

row

9

1

14

2

8

3

12

4

1

5

7

6

2

7

Figure 10.23. Anode row matrix LEDs (Fairchild GMA8X75C)

The Driving Method of Matrix LED Displays

• Two parallel ports are needed to drive the matrix display.

• One port drives the column whereas the other port drives

the rows.

• One needs to scan the matrix LED displays one row at a

time, from top to bottom.

• For multiple matrix LED displays in the application, timemultiplexing technique needs to be used.

• Dedicated driver chips such as MAX6952 (SPI interface)

and MAX6953 (I2C interface) are available for cathoderow matrix LED displays to simplify the interfacing.

The MAX6952 Matrix Display Driver

• Designed to drive cathode-row matrix displays with 5 7

organization

• Can operate with power supply from 2.7 V to 5.5 V

• Can drive four monocolor or two bicolor cathode-row

matrix displays

• Has built-in 104-character Arial font and 24 user

definable characters

• Allows automatic blinking control for each segment and

provides 16-step digital brightness control

• Pin functions shown in Table 10.7

• Pin connections illustrated in Table 10.8 and 10.9

Table 10.7. MAX6952 4-digit matrix LED display driver pin functions

Name

Pin

SSOP

Function

PDIP

O0 to O13

1, 2, 3, 6-14,

23, 24

1, 2, 3, 7-15, LED cathode drivers. O0 to O13 outputs sink current

26, 27 from the displays's cathode rows.

GND

4, 5, 6

4, 5, 6, 18

ISET

15

17

Segment current setting. Connect ISET to GND

through series resistor RSET to set the peak current.

BLINK

17

19

Blink clock output. Output is open drain.

DIN

18

20

Serial data input. Data is loaded into the internal 16-bit

shift register on the rising edge of the CLK.

Ground

CLK

19

21

Serial-clock input. On the rising edge of CLK, data is

shifted into the internal shift register. On the falling

edge of CLK, data is clocked out of DOUT. CLK input

is active only when CS is low.

DOUT

20

22

Serial data output. Data clocked into DIN is output to

DOUT 15.5 clock cycles later. Data is clocked out on

the falling edge of CLK. Output is push-pull.

DOUT

21

23

Chip-select input. Serial data is loaded into the shift

register while CS is low. The last 16 bits of serial data

are latched on CS's rising edge.

24

Multiplex clock input. To use the internal oscillator,

connect capacitor CSET from OSC to GND. To use

external clock, drive OSC with a 1MHz to 8MHz

CMOS clock

OSC

O14 to O23

V+

22

25-31, 34,

35, 36

32, 33

28-34, 38, LED anode drivers. O14 to O23 output source current

39, 40 to the display's anode columns.

35, 36, 37

Positive supply voltage. Bypass V+ to GND with a 47

F bulk capacitor and a 0.1F ceramic capacitor.

Table 10.8 Connection scheme for four monocolor digits

Digit

1

O0~O6

O7~O13

digit 0 rows (cathodes) R1 to R7

digit 1 rows (cathodes) R1 to R7

digit 2 rows (cathodes) R1 to R7

2

digit 3 rows (cathodes) R1 to R7

O14~O18

O19~O23

digit 0 columns

(anodes) C1 to C5

digit 1 columns

(anodes) C6 to C10

digit 2 columns

(anodes) C1 to C5

digit 3 columns

(anodes) C6 to C10

O14~O18

O19~O23

Table 10.9 Connection scheme for two bicolor digits

Digit

O0~O6

1

digit 0 rows (cathodes) R1 to R14

2

O7~O13

digit 0 columns (anodes) C1 to C10

the 5 green anodes

digit 1 rows (cathodes) R1 to R14

the 5 red anodes

digit 1 columns (anodes) C1 to C10

the 5 green anodes

the 5 red anodes

One MAX6952 Drives Four Matrix Displays

V+

V+

0.1 F

47 F

GND

5V

4.7K

BLINK

interface

with

MCU

CLK

DIN

CS

DOUT

OSC

CSET

26pF

RSET

53.6K

ISET

O0

O1

O2

O3

O4

O5

O6

O7

O8

O9

O10

O11

O12

O13

O14

O15

O16

O17

O18

O19

O20

O21

O22

O23

O14

O15

O16

O17

O18

O0

O1

O2

O3

O4

O5

O6

C1 digit 0

C2

C3

C4 Cathode

row

C5

5x7

R1

Matrix

R2

LED

R3 display

R4

R5

R1

R2

O19

O20

O21

O22

O23

O0

O1

O2

O3

O4

O5

O6

C1 digit 1

C2

C3

C4 Cathode

row

C5

5x7

R1

Matrix

R2

LED

R3 display

R4

R5

R1

R2

O14

O15

O16

O17

O18

O7

O8

O9

O10

O11

O12

O13

C1 digit 2

C2

C3

C4 Cathode

row

C5

5x7

R1

Matrix

R2

LED

R3 display

R4

R5

R1

R2

O19

O20

O21

O22

O23

O7

O8

O9

O10

O11

O12

O13

C1 digit 3

C2

C3

C4 Cathode

row

C5

5x7

R1

Matrix

R2

LED

R3 display

R4

R5

R1

R2

Figure 10.24. MAX6952 driving four matrix LED displays

Concatenation of Multiple MAX6952s

• Multiple MAX6952s can be concatenated to

drive more than four matrix displays.

HCS12

MOSI0

SCK0

SS0

MAX6952

MAX6952

MAX6952

DIN DOUT

DIN DOUT

DIN DOUT

CLK

CLK

CLK

CS

CS

CS

MISO0

Figure 10.25 MAX6952 daisy-chain connection

MAX6952 Block Diagram

ISET

OSC

current

source

PWM

brightness

control

divider/

counter

network

row

multiplexer

character

generator

RAM

Blink

LED

drivers

character

generator

ROM

Blink

Speed

Select

Configuration

Register

RAM

CLK

CS

Serial Interface

DIN

DOUT

Figure 10.26. MAX6952 functional diagram

O0

to

O23

Procedure for Writing the MAX6952

• Step 1

– Pull the CLK signal to low.

• Step 2

– Pull the CS signal to low to enable the internal 16-bit shift register.

• Step 3

– Shift in 16 bits of data from the DIN pin with the most significant bit first.

The most significant bit (D15) must be low for a write operation.

• Step 4

– Pull the CS signal to high.

• Step 5

– Pull the CLK to low.

Procedure for Reading the MAX6952 Register

•

Step 1

– Pull the CLK signal to low.

•

Step 2

– Pull the CS signal to low to enable SPI transfer.

•

Step 3

– Clock 16 bits into the DIN pin with bit 15 first. Bit 15 must be a 1. Bits 14 to 8

contain the address of the register to be read. Bits 7 to 0 contain dummy data.

•

Step 4

– Pull the CS signal to high. Bits 7 to of the shift register will be loaded with the

data in the register addressed by bits 15 through 8.

•

Step 5

– Pull CLK to low.

•

Step 6

– Issue another read command and examine the bit stream at the DOUT pin. The

second 8 bits are the contents of the register addressed by bits 14 to 8 in Step 3.

MAX6952 Register Map

Table 10.10. MAX6952 register address map

Register

No op

Intensity10

Intensity32

Scan limit

Configuration

User defined fonts

Factory reserved (Do not write into)

Display test

Digit 0 Plane P0

Digit 1 Plane P0

Digit 2 Plane P0

Digit 3 Plane P0

Digit 0 Plane P1

Digit 1 Plane P1

Digit 2 Plane P1

Digit 3 Plane P1

Write digit 0 plane P0 and plane P1

with same data (reads as 0x00)

Write digit 1 plane P0 and plane P1

with same data (reads as 0x00)

Write digit 2 plane P0 and plane P1

with same data (reads as 0x00)

Write digit 3 plane P0 and plane P1

with same data (reads as 0x00)

Address (command byte)

D8

Hex

code

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

0x00

0x01

0x02

0x03

0x04

0x05

0x06

0x07

0x20

0x21

0x22

0x23

0x40

0x41

0x42

0x43

0x60

0

0

1

0x61

0

0

1

0

0x62

0

0

1

1

0x63

D15

D14

D13

D12

D11

D10 D9

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

1

0

0

0

0

0

0

0

0

0

R/W

1

1

0

0

R/W

1

1

0

R/W

1

1

0

Digit Registers (1 of 2)

• The MAX6952 uses eight digit registers to store the characters that

the user wishes to display on the four 5 7 digits.

• These digit registers are placed in two planes (P0 and P1) with each

plane having 4 bytes.

• Each LED digit is represented by 2 bytes of memory, one byte in

plane P0 and the other in plane P1.

• A digit data can be updated in P0, or P1, or both at the same time as

shown in Table 10.10.

• If the blink function is disabled, then the digit register data in plane

P0 is used to multiplex the display.

• If the blink function is enabled, then the digit register data in both

plane P0 and P1 are alternately used to multiplex the display.

• Blinking is achieved by multiplexing the LED display using data

planes P0 and P1 on alternate phases of the blink clock. The

multiplexing pattern in shown in Table 10.11.

Digit Registers (2 of 2)

• The data in the digit registers does not control the digit segments

directly.

• The register data is used to address a character generator, which

stores the data of a 128-character font.

• The lower 7 bits of he display data select the character font.

• The bit 7 of the register data selects whether the font data is used

directly (D7 = 0) or whether the font is inverted (D7 = 1).

Table 10.11 Digit register mapping with blink globally enabled

segment's bit

segment's bit

segment

setting

setting

behavior

in plane P1

in plane P0

0

0

Segment off

Segment on only during the

1

0

1st half of each blink period

Segment on only during the

1

0

2nd half of each blink period

segment on

1

1

Configuration Register

• The configuration register is used to enter and exit shutdown, select

the blink rate, enable and disable the blink function, clear the digit

data, and reset the blink timing.

7

6

5

4

3

2

1

0

P

x

R

T

E

B

x

S

P: Blink phase read back select (from the Blink pin)

0 = P1 blink phase

1 = P0 blink phase

R: Global clear digit data

0 = digit data on both plane P0 and P1 are not affected

1 = clear digit data on both planes P0 and P1

T: Global blink timing synchronization

0 = blink timing counter are unaffected

1 = blink timing counters are reset on the rising edge of CS

E: Global blink enable/disable

0 = blink function is disabled

1 = blink function is enabled

B: Blink rate selection

0 = select slow blinking (refreshed for 1s by plane P0, then 1s

by P1 at 4MHz)

1 = select fast blinking

S: Shutdown mode

0 = shutdown mode

1 = normal operation

Figure 10.27 The MAX6952 configuration register

Intensity Registers

• Display brightness is controlled by four pulse-width

modulators, one for each display digit.

• The upper four bits of the Intensity10 register control the

intensity of the matrix display 1, whereas the lower four

bits of the same register control the brightness of the

display 0.

• Matrix display digits 3 and 2 are controlled by the upper

four bits and lower four bits of the Intensity32 register,

respectively.

• The modulator scales the average segment current in 16

steps from a maximum of 15/16 down to 1/16 of the peak

current.

Scan Limit Register

• This register allows the user to choose between

displaying two or four matrix displays.

• The multiplexing scheme drives digits 0 and 1 at

the same time, then digits 2 and 3 at the same

time.

7

6

5

4

3

2

1

0

X

X

X

X

X

X

X

2or4

2or4: Scan two digits (0 and 1) or all four digits

0 = display digits 0 and 1 only

1 = display digits 0, 1, 2, and 3

Figure 20.28 The MAX6952 scan-limit register

Scan Test Register

• This register switches the drivers between two modes:

normal and test.

• Display test mode turns on all LEDs by overriding, but

not altering all control and digit registers.

• In display test mode, eight digits are scanned and the

duty cycle is 7/16 (half power).

7

6

5

4

3

2

1

0

X

X

X

X

X

X

X

test

test: test bit

0 = Normal operation

1 = Display test

Figure 10.29 The MAX6952 display test register

Character Generator Font Mapping

• The character generator comprises 104 characters in

ROM, and 24 user-definable characters.`

• The lower 7 bits of the digit register select the character

fonts.

• The character map follows the Arial font for 96

characters in the range from %0101000 to %1111111.

• The first 32 characters map the 24 user-defined

positions (RAM00 to RAM23), plus eight extra common

characters in ROM.

• When the msb is 0 the device will display the font

normally. Otherwise, the chip will display the font

inversely.

User-Defined Font Register

•

•

•

•

•

•

•

•

The 24 user-definable characters are represented by 120 entries of 7-bit data, five

entries per character in the SRAM.

The 120 user definable font data are written and read through a single register at the

address 0x05.

An auto-incrementing font address pointer indirectly accesses the font data.

The font data is written to and read from the MAX6952 indirectly, using the font

address pointer.

To define user fonts, the user first needs to set the font address pointer. This is done

by placing the address in the font address pointer register and set the bit 7 to 1. After

this, one can write the font data to the lower 7 bits and clear the bit 7.

The font address pointer autoincrements after a valid access to the user-defined font

data.

The memory mapping of user-defined font register 0x05 is detailed in Table 10.12.

The behavior of the font pointer address is illustrated in Table 10.13.

To display the user-defined fonts, one must send in the RAM address from 0x00 to

0x17, corresponding to the font address pointer value that is 5 RAM address.

Table 10.12. Memory mapping of user-defined font register 0x05

Addresscode

(hex)

Register

data

SPI read

or write

Function

0x85

0x00-0x7F

Read

Read 7-bit user-definable font data entry from

current font address. MSB of the register data is

clear. Font address pointer is incremented after

the read.

0x05

0x00-0x7F

Write

Write 7-bit user-definable font data entry to

current font address. Font address pointer is

incremented after the write.

0x05

0x80-0xFF

Write

Write font address pointer with the register data

Table 10.13. Font pointer address behavior

Font pointer address

Action

0x80-0xF6

Valid range to set the font address pointer. Pointer autoincrements after a

font data read or write, while pointer address remains in this range.

0xF7

0xF8 to 0xFF

Font address resets to 0x80 after a font data read or write to this pointer

address

Invalid range to set the font address pointer. Pointer is set to 0x80 .

Blinking Operation

• The blinking operation makes the LED drivers flip between

displaying the digit register data in planes P0 and P1.

• If the digit register data for any digit is different in two planes, then

that digit appears to flip between two characters.

• To make a character to appear to blink on and off, write the

character to one plane and use the blank character for the other

plane.

• Blinking is enabled by setting the E bit of the configuration register.

• The blink speed can be programmed to be fast or slow and is

determined by the frequency of the multiplex clock, OSC, and by

setting the B bit of the configuration register.

Choosing Values for RSET and CSET

• The MAX6952 uses an RC oscillator to generate clock

signals for display multiplexing.

• The recommended RSET and CSET values are 53.6K

and 26 pF, respectively.

• The recommended values for RSET and CSET will set the

slow and fast blinking frequencies to 0.5 Hz and 1 Hz.

• The recommended values for RSET and CSET will set the

peak current to 40 mA.

The Circuit that Daisy-Chains Two MAX6952 (1 of 2)

• Example 10.10 Connect eight matrix displays to these MAX6952

driver chips. Assume that the E clock frequency is 24 MHz. Write a

program to configure the SPI function to shift data at 12 MHz and

display the string “MSU ECET”.

HCS12

MOSI0

MAX6952

DIN

MAX6952

DOUT

DIN

OSC

DOUT

OSC

CSET

CSET

SCK0

PM5

CLK

CLK

CS

ISET

RSET

CS

MISO0

Figure 10.30 HCS12 driving two MAX6952s

ISET

RSET

The Circuit that Daisy-Chains Two MAX6952

(2 of 2)

•

•

Solution:

The SPI0 module should be

configured with the following

setting:

– 12 MHz baud rate

– Master mode with interrupts

disabled

– Shift data on the rising edge with

clock idle low

– Shift data out most significant bit

first

– Disable mode fault

– Stop SPI0 in wait mode

•

The setting of two MAX6952s are

as follows:

– Intensity10 registers

• Set to maximum intensity

• Send the values 0x01, 0xFF,

0x01, and 0xFF to these two

registers.

– Intensity32 registers

• Set to maximum intensity

• Send the values 0x02, 0xFF,

0x02, and 0xFF to these two

registers

– Scan limit registers

• Drive four monocolor matrix

displays

• Send the values 0x03, 0x01,

0x03, and 0x01 to these two

registers

Configuration Registers

•

•

•

•

•

•

•

Select P1 blink phase

Not to clear digit data on both plane P1 and P0

Reset blink counter on the rising edge of CS

Disable blink function

Select slow blinking (doesn’t matter)

Select normal mode

Send the values 0x04, 0x11, 0x04, and 0x11 to

these two registers

Display Test Registers

• Disable test.

• Send the values 0x07, 0x00, 0x07, and 0x00 to

these two registers.

Digit 0 Registers (Rightmost Digit) Plane P0

• Display space character and letter T on he

display 0 of the first and second MAX6952.

• Send the values 0x20, 0x54, 0x20, and 0x20 to

these two registers.

Digit 1 registers (second rightmost digit)

Plane P0

• Display letter U and E on the display 1 of the 1st

and 2nd MAX6952.

• Send the values 0x21, 0x45, 0x21, and 0x55 to

these two registers.

Digit 2 Registers (Second Leftmost Digit)

Plane 0

• Display letters S and C on the display 2 of the

1st and 2nd MAX6952.

• Send the values 0x22, 0x43, 0x22, and 0x53 to

these registers.

Digit 3 Registers (Leftmost Digit) Plane 0

• Display letters M and E on the display 3 of the 1st and 2nd

MAX6952.

• Send the values 0x23, 0x45, 0x23, and 0x4D to these registers.

– The program that perform the desired configuration is as follows:

#include “c:\egnu091\include\hcs12.h”

#include “c:\egnu091\include\spi0util.c”

void sendtomax(char x1, char x2, char x3, char x4);

void openspi0(void);

void main (void)

{

openspi0();

DDRM |= BIT5; // configure PM5 pin for output

sendtomax(0x01, 0xFF, 0x01, 0xFF); // set intensity for digits 0 & 1

sendtomax(0x02, 0xFF, 0x02, 0xFF); // set intensity for digits 2 & 3

sendtomax(0x03, 0x01, 0x03, 0x01); // set scan limit to drive 4 digits

sendtomax(0x04, 0x11, 0x04, 0x11); // set configuration register

sendtomax(0x07, 0x00, 0x07, 0x00); // disable test

sendtomax(0x20,

sendtomax(0x21,

sendtomax(0x22,

sendtomax(0x23,

0x54, 0x20, 0x20);

0x45, 0x21, 0x55);

0x43, 0x22, 0x53);

0x45, 0x23, 0x4D);

// value for digit 0

// value for digit 1

// value for digit 2

// value for digit 3

}

void sendtomax (char c1, char c2, char c3, char c4)

{

char temp;

PTM &= ~BIT5;

/* enable SPI transfer to MAX6952 */

putcspi0(c1);

/* send c1 to MAX6952 */

putcspi0(c2);

/* send c2 to MAX6952 */

putcspi0(c3);

/* send c3 to MAX6952 */

putcspi0(c4);

/* send c4 to MAX6952 */

PTM |= BIT5;

/* load data from shift register to latch */

}

void openspi0(void)

{

SPI0BR = 0x00; /* set baud rate to 12 MHz */

SPI0CR1 = 0x50; /* disable interrupt, set master mode, shift data on

rising edge, clock idle low */

SPI0CR2 = 0x02; /* disable mode fault, disable SPI in wait mode */

WOMS = 0;

/* enable Port S pull-up */

}

•

•

Example 10.11 Modify the previous example to blink the display at a slow rate.

Solution: The setting of the configuration needs to be changed and we need to

send the space character (0x20) to the plane P1. Send the values 0x04, 0x19,

0x03, and 0x19 to the configuration registers.

void main (void)

{

openspi0();

DDRM |= BIT5;

sendtomax(0x01, 0xFF, 0x01, 0xFF);

sendtomax(0x02, 0xFF, 0x02, 0xFF);

sendtomax(0x03, 0x01, 0x03, 0x01);

sendtomax(0x04, 0x19, 0x04, 0x19);

sendtomax(0x07, 0x00, 0x07, 0x00);

sendtomax(0x20, 0x54, 0x20, 0x20);

sendtomax(0x21, 0x45, 0x21, 0x55);

sendtomax(0x22, 0x43, 0x22, 0x53);

sendtomax(0x23, 0x45, 0x23, 0x4D);

sendtomax(0x40, 0x20, 0x40, 0x20);

sendtomax(0x41, 0x20, 0x41, 0x20);

sendtomax(0x42, 0x20, 0x42, 0x20);

sendtomax(0x43, 0x20, 0x43, 0x20);

}

// configure PM5 pin for output

// configuration register, blink at phase P1

// disable test

// value for digit 0 on plane P0

// value for digit 1

// value for digit 2

// value for digit 3

// value for digit 0 on plane P1 (space)

// value for digit 1

“

// value for digit 2

“

// value for digit 3

“

• Example 10.12 For the circuit shown in Figure 10.30, write a

program to display the following message and shift the information

from right-to-left every second and enable blinking:

08:30:40 Wednesday, 72oF, humidity: 60%

• Solution: One possible solution is as follows:

– Use the plane P0 to shift the message once every half a second.

– Use the message in plane P0 to multiplex the displays in half a second.

– Use the message sent to the plane P1 to multiplex the displays in the

next half of a second.

– Display space characters in plane P1 only to create blinking effect.

– Use a delay function to control the shifting of the message.

#include “c:\egnu091\include\hcs12.h”

#include “c:\egnu091\include\spi0util.c”

#include “c:\egnu091\include\delay.c”

void

send2max (char x1, char x2, char x3, char x4);

void

openspi0 (void);

char

msgP0[41] = "08:30:40 Wednesday, 72oF, humidity: 60% ";

void main (void)

{

char i1, i2, i3, i4;

char j1, j2, j3, j4;

char k;

openspi0();

DDRM |= BIT5;

// configure PM5 pin for output

send2max(0x01, 0xFF, 0x01, 0xFF);

send2max(0x02, 0xFF, 0x02, 0xFF);

send2max(0x03, 0x01, 0x03, 0x01);

send2max(0x04, 0x1D, 0x04, 0x1D); // configuration register

send2max(0x40, 0x20, 0x40, 0x20); // send space character to plane P1

send2max(0x41, 0x20, 0x41, 0x20);

send2max(0x42, 0x20, 0x42, 0x20);

send2max(0x43, 0x20, 0x43, 0x20);

k = 0;

while (1) {

i1 = k;

i2 = (k+1)%40;

i3 = (k+2)%40;

i4 = (k+3)%40;

j1 = (k+4)%40;

j2 = (k+5)%40;

j3 = (k+6)%40;

j4 = (k+7)%40;

sendtomax(0x20, msgP0[i1], 0x20, msgP0[j1]);

sendtomax(0x21, msgP0[i2], 0x21, msgP0[j2]);

sendtomax(0x22, msgP0[i3], 0x22, msgP0[j3]);

sendtomax(0x23, msgP0[i4], 0x23, msgP0[j4]);

delayby100ms(10); /* wait for 1 s */

k = (k+1)%40;

}

}

void sendtomax (char c1, char c2, char c3, char c4)

{

PTM &= ~BIT5;

/* enable SPI transfer to MAX6952 */

putcspi0(c1);

/* send c1 to MAX6952 */

putcspi0(c2);

/* send c2 to MAX6952 */

putcspi0(c3);

/* send c3 to MAX6952 */

putcspi0(c4);

/* send c4 to MAX6952 */

PTM |= BIT5;

/* load data from shift register to latch */

}

Figure 10.31 User-definable font example

0x49

0x49

0x7F

0x49

0x49

0x48

0x38

0x0F

0x38

0x48

0x70

0x40

0x7F

0x40

7

6

5

4

3

2

1

0

0x70

• Example 10.13 Write a program to define fonts

for three special characters as shown below.

Store these three special characters’ font at

locations from 0x00 to 0x0E of the MAX6952.

#include “c:\egnu091\include\hcs12.h”

#include “c:\egnu091\include\spi0util.c”

char fonts [15] = {0x70,0x40,0x7F,0x40,0x70,0x48,0x38,0x0F,0x38,0x48,0x49,

0x49,0x7F,0x49,0x49};

void send_font (char xc);

void openspi0 (void);

void main (void)

{

char i;

DDRM |= BIT5;

/* configure PM5 pin for output */

openspi0();

/* configure SPI module properly */

send_font(0x80);

/* set font address pointer address to 0x00 */

for (i = 0; i < 15; i++)

send_font(fonts[i]);

}

void send_font(char xx)

{

PTM &= ~BIT5;

/* enable SPI transfer */

putcspi0(0x05);

/* specify font address pointer */

putcspi0(xx);

/* send a font value */

PTM |= BIT5;

/* load data in shift register to destination */

}

void openspi0(void)

{

SPI0BR = 0x00;

SPI0CR1 = 0x50;

SPI0CR2 = 0x02;

WOMS = 0;

/* set baud rate to 12 MHz */

/* disable interrupt, set master mode, shift data on

rising edge, clock idle low */

/* disable mode fault, disable SPI in wait mode */

/* enable Port S pull-up */

}

The statements to display those three Chinese characters followed by letters A, B, C, D,

and E from left to right on the matrix LED displays shown in Figure 10.30 are as follows:

sendtomax(0x20, 0x42, 0x20, 0x00); // 0x00 is the address of the first character font

sendtomax(0x21, 0x43, 0x21, 0x01); // 0x01 is the address of the second character font

sendtomax(0x22, 0x44, 0x22, 0x02); // 0x02 is the address of the third character font

sendtomax(0x23, 0x45, 0x23, 0x41);