Assessing Attitudes and Behaviors for Safety Leadership Case Study 1

advertisement

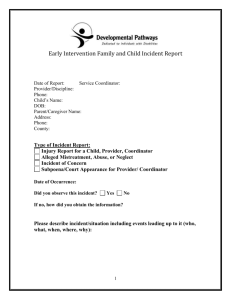

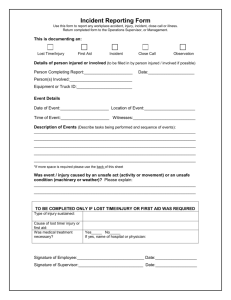

Assessing and Developing Your Safety Culture Steve Roberts, Ph.D. Senior Partner Safety Performance Solutions, Inc. Tel: 540.951.3993 / 7233 sroberts@safetyperformance.com www.safetyperformance.com © Safety Performance Solutions, Inc. 2012. The materials in this presentation are proprietary and contain limited reproduction rights. People-Based Safety: Assessing Attitudes and Behaviors for Safety Leadership Defining Safety Culture There Are Numerous Definitions of Organizational Culture. The assumptions, shared beliefs, and values people live by. Organizational climate, attitudes toward work, degree of personal responsibility for work. Patterns of interactions, values, and attitudes from traditions and past practices. The nature of interpersonal and intrapersonal conversations. The “rules of the game” for getting along in an organization. 3 ©Safety Performance Solutions, Inc. (1.08) Exercise: Define An Ideal Safety Culture. List characteristics of an ideal safety culture. Remember, a culture has to do with the shared beliefs, values, assumptions, or expectations that form the “acceptable” practices and attitudes within a work environment. Therefore, be sure to consider specific behaviors and attitudes of people, as well as the environment. 4 ©Safety Performance Solutions, Inc. (5.06) Common Themes in a Total Safety Culture. All employees comply with safety rules and regulations at all times. Employees continuously search for safety hazards. Employees take initiative themselves to correct safety hazards when they can. Employees are eager to participate in safety-related activities. Participation in safety-related activities is promoted and encouraged through respect and positive recognition. All safety-related issues are openly communicated. Fear of reprimand or discipline does not inhibit discussions. 5 ©Safety Performance Solutions, Inc. (5.06) Common Themes Continued... Safety incidents are viewed as an opportunity to identify system failures and therefore improve the system. Individuals are not assumed to be, and are rarely found to be, at fault. Training systems result in all employees having the needed knowledge, skills, and abilities to perform their jobs safely. All business activities are managed with a constant focus on accident prevention and occupational health. All employees fully understand and appreciate the potential hazards of the operations performed… 6 ©Safety Performance Solutions, Inc. (5.06) A Total Safety Culture Has Several Dimensions. LEADERSHIP CONDITIONS Are Senior Leaders committed to improving the culture and do they demonstrate safety as a value Does the physical environment (the interaction of equipment, facilities, procedures, and people) allow safe performance PEOPLE SYSTEMS Total Safety Culture Do people have positive perceptions of themselves, their coworkers, and the organization. Are they willing to go “above the call of duty” Do organizational systems support the “right” behaviors and are they consistent with organizational values. BEHAVIOR Do people perform the ‘right’ behaviors. EMPLOYEE ENGAGEMENT Are Employees Actively Involved in Making Valuable Contributions © Safety Performance Solutions, Inc. 2011 www.safetyperformance.com 7 People-Based Safety: Assessing Attitudes and Behaviors for Safety Leadership Perceptions, How We Feel, and How We Act Why Should We Measure Perceptions? - Behaviors are based on perceptions. - Therefore, whether correct or incorrect, perceptions are each person’s “reality”. © 2007 Safety Performance Solutions, Inc. 9 How We Feel, Influences How We Act. “Want-to” Self-Directed Excellent Engagement Good Discretionary Effort “Have-to” Other-Directed Average Participation Time 10 © Safety Performance Solutions, Inc. 2009 How We Feel, Influences How We Act. 11 © Safety Performance Solutions, Inc. 2009 Actively Caring Is Influenced by Several Person States. Self-Effectiveness “I can do it” Personal Control “I am in control” Optimism Actively Caring Belonging Self-Esteem “I care about myself” “I care about my team” 12 ©Safety Performance Solutions, Inc. (5.06) “I expect the best” Measuring Perceptions Can Be Difficult and Imprecise, But… It is Better to Have an Imprecise Measure of the Right Thing Than a Perfect Measure of the Wrong Thing. W. E. Deming © 2007 Safety Performance Solutions, Inc. 13 Optimal Performance Requires Certain Feelings and Expectations Feelings of personal control Appropriate knowledge of the job/situation Understanding of not just “what” works, but how & why Confidence in skills/abilities/training Feelings of support from co-workers/organization/others 14 ©Safety Performance Solutions, Inc. 2010 www.safetyperformance.com Video Optimal Performance Requires Certain Feelings and Expectations Feelings of personal control Appropriate knowledge of the job/situation Understanding of not just “what” works, but how & why Confidence in skills/abilities/training Feelings of support from co-workers/organization/others 16 ©Safety Performance Solutions, Inc. 2010 www.safetyperformance.com Take Home Exercise: Identifying and Improving Safety Expectations. List tasks or situations where you OR those you supervise lack control, knowledge, skills or support for safety. List actions you could take to increase control, knowledge, skills or support for yourself OR those you supervise. 17 ©Safety Performance Solutions, Inc. 2010 People-Based Safety: Assessing Attitudes and Behaviors for Safety Leadership Measuring Safety Culture Safety Culture Assessments Utilize Multiple Tools and Strategies. 1. Safety Culture Surveys 2. Structured Group Interviews 3. Safety Management Systems Assessment (e.g., Leadership Commitment, Incident Reporting & Analysis, Discipline Process, Environmental Audits/Inspections) 4. Leadership Behavior Evaluation © 2002 Safety Performance Solutions, Inc. (EVIT 8.00) 19 1) A Safety Culture Survey (SCS) Serves Several Purposes. Identifies strengths and weaknesses in current safety systems to help identify and prioritize areas of focus. Provides a means to compare performance against a benchmark. External (overall, industry) Internal (cross-department, cross-facilities, oneself over time) Provides a performance metric of improvement initiatives (through repeated administration). Opens lines of communication and build support for change. © 2007 Safety Performance Solutions, Inc. 20 A SCS Has Benefits Over Other Information Gathering Tools. Gathers information from all or a representative sample. Committees, suggestion systems, and even interviews favor the vocal minority Results in better information, as well as “empowered” workforce. Gathers sensitive information from employees in a confidential manner (thus encouraging more frank, candid responses). Relatively quick, easy, and cost-effective. © 2007 Safety Performance Solutions, Inc. 21 A SCS Should Measure A Wide Variety of Issues. Management Support for Safety Genuine interest in reducing injuries (v. “keeping the numbers low”) Willingness to invest resources (i.e., time, money, personnel) Ability to balance safety with other KPI’s (e.g., productivity, schedule) Peer Support for Safety Personal Responsibility for Safety © 2007 Safety Performance Solutions, Inc. 22 A SCS Should Measure A Wide Variety of Issues. Safety Management Systems, including: Incident Reporting & Investigation Discipline Rewards & Recognition Communication Safety Accountability Training Behavior-based Observation & Feedback process Employee Involvement Facilities Audits & Inspections © 2007 Safety Performance Solutions, Inc. 23 Care Should be Taken When Administering the Survey. What Demographic Information to Collect. Position or Level (line worker, supervisor, management) Business Unit / Location / Site Department Shift Tenure Who to Survey Everyone (eliminate sampling error) Random sample – who, how many, and how © 2007 Safety Performance Solutions, Inc. 24 Site S-SA 2000 46% 15% 38% When Interpreting the Data, Consider These 63% Interesting 25% Comparisons. 13% Particularly 60% Norm 21% 19% Plant Maint Plant Prod Mining Maint Mining Prod 54% 16% 30% X54%Survey Results:12% 2003 64% 13% 34% 23% "Supervisors sometimes encourage employees to Engineer Svcs 69% 6% 25% overlook hazards to get the job done." 71% 60% Repair Shop ‘11 2007 Site S-SA 2003 Loading Mgt ‘08 SiteMaterials S-SA 2001 2003 HR Accounting Site& S-SA 2000 ‘06 Unknown Norm Senior Mgt Wage Plant Maint LineProd Mgt Mgt. Plant Wage Mgt Norm Mining Maint Wage Norm Unknown Mining Prod 51% 74% 46%56% 53% 60% 50%63% 54% 71% 54% 69% 57% 64% Engineer Svcs Shift 1 © 2007 Safety Repair ShopPerformance Solutions, Inc. 69% 69% 71% 7% 20% 15% 17% 15% 21% 20% 25% 11% 33% 15% 21% 38% 23% 18% 21% 30%19% 17% 16% 25% 33% 13% 11% 30% 17% 18% 12% 34% 13% 15% 13% 29% 23% 6% 14% 7% 25% 18% 21% Organization vs. Time vs. Norm Wage vs. Salary vs. Wage Norm vs. Mgt. Norm 25 When Interpreting the Data, Consider These Particularly Interesting Comparisons. Look at the patterns shown by ‘sets’ of items: Employees should give feedback to peers for at-risk behavior… I’m willing to give feedback to peers… I do give feedback to peers… Should 80% 14% 6% Willing 78% 16% 6% Do 66% Favorable © 2007 Safety Performance Solutions, Inc. 24% Neutral 10% Unfavorable 26 When Interpreting the Data, Consider These Particularly Interesting Comparisons. Look at the patterns shown by ‘sets’ of items: Production demands don’t override Managers’ concern for safety. Organization Sunoco Chemicals Norm Petrochem Norm 57% 15% 45% 28% 25% 48% 31% 23% 29% Production demands don’t override concern for 48% 13% Supervisors’ 39% Maintenance safety. Plasticizer 42% Material Handling Organization Sunoco Chemicals 40% Laboratory Norm 50% 45% Plant Admin Petrochem Norm 51% Other Admin © 2007 Safety Performance Solutions, Inc. 5% 53% 27% 66% 14% 25% 27% 75% 87% 24% 33%21% 25% 28% 13%26% 13% 13% 27 Care Must Be Taken When Interpreting the Data. Look at “Favorable”, “Unfavorable”, and “Neutral” – don’t focus on just one! When comparing scores against the benchmark: Understand the benchmark – does it represent “average” or some other group? Remember the benchmark is a relative comparison, also consider the absolute measure © 2007 Safety Performance Solutions, Inc. 28 Relative vs. Absolute Comparisons. Management Support for Safety Overall Management Support for Safety O7 04 PeN EMN MT Op Lb 1st Ad Mgt TC Ct H 04H PHN S 74 70 53 64 61 52 73 94 95 100 83 83 63 62 42 9 Site management seems genuinely interested 86 83 75 in reducing injuries. 78 81 72 85 90 98 100 83 93 82 79 68 9 Site management is more concerned about keeping the injury statistics low than with truly 62 64 42 keeping people safe. 48 55 42 54 84 86 100 33 64 51 58 33 8 Work productivity and quality usually have a higher priority than work safety. 66 64 49 59 63 47 62 94 86 92 67 70 53 54 40 8 Production demands do not override supervisors' concern for safety. 68 67 51 59 64 51 64 90 84 92 67 67 57 60 42 8 Production demands do not override site management’s concern for safety. 71 62 48 58 56 54 54 97 93 100 83 83 60 54 38 9 © 2011 Safety Performance Solutions, Inc. 29 Understand the Potential Problems with Surveys. Perception surveys can be influenced by: Mood, recent events, ambience, history, perception of how valuable the results will be, literacy, language barriers, etc. Corrective actions include: Address language and literacy problems, provide appropriate ambience, communicate plan for using the results and connect the results to safety improvement It’s also important to conduct focus group interviews to add clarification to the survey results. Survey tells us “What;” interviews tell us “Why” Interview random sample of the population (e.g., 10%) © 2007 Safety Performance Solutions, Inc. 30 Compare Sites Across Corporations. 100 Corporation X Average (72) Norm (66) 95 90 85 80 75 70 65 60 © 2007 Safety Performance Solutions, Inc. CRDA OP Alumina Aratu OP Smelter ECL Lochaber Shawinigan Alucam IPSF ISAL SJdM Laterriere Arvida Lyne Power Vlissingen X Site EEQ Dunkerque Lyne Smelt Kitimat Tomago Sebree 50 Dubuc 60 62 65 67 68 68 68 69 69 70 70 71 71 72 73 73 75 75 76 77 77 78 80 81 OP Outros 55 31 Compare Site to Same Site From a Previous Time. CompanyXX ‘11 Company Company X ‘09 Company X ‘07 © 2007 Safety Performance Solutions, Inc. 32 Compare Sites to a Benchmark (Norm). Company X ‘11 Company X ‘09 Company X ‘07 © 2007 Safety Performance Solutions, Inc. 33 Also Consider Using A Customized Survey for Specific Issues. BBS Program Assessment – 18 question survey Incident Analysis Survey Demographics include “have” and “have not” been involved in an ‘investigation’ during past 5 years. Customizing / Adding to the Standard Survey Assessing Special Programs (e.g., “The new safety committee structure is an improvement over the old”.... “The 360 Walk Arounds Help Reduce Vehicle Crashes”) Expanding the focus of the standard survey (e.g., Including questions on Health and Environmental Protection in addition to Safety) Assessing the effects of organizational changes (e.g., “We feel we have come together with a unified corporate culture after the merger”) “Home” Safety Survey © 2007 Safety Performance Solutions, Inc. 34 The Results of the Survey Should be Used to Drive Change. Conduct focus group interviews to further explore problem areas. Assemble teams for problem solving Develop action plans and timelines Publicize survey results and next steps. Follow-up on completion of next steps, track progress using activity measures, and communicate results. Repeat survey every 18-24 months. Warning: A Safety Culture Survey should not be used unless management is committed to acting on the results. © 2007 Safety Performance Solutions, Inc. 35 Improper Uses for Culture/Perception/Personality Surveys. Hiring Firing Final Decisions © 2007 Safety Performance Solutions, Inc. 36 Why? There are Differences Between Knowledge/Skill Tests and Surveys. Right/Wrong Answers Ability to “Fake” Positive Answers Social Desirability Generalizing Results to Different Populations © 2007 Safety Performance Solutions, Inc. 37 Predictive vs. Concurrent Validity. Current Employees (Who is typically sampled) Target Population (Who we are actually interested in) Job Candidate Current Employee …Thinking: “I must score well to get this job”. …Thinking: “They Just want to know how I feel”. Findings Findings Scores = Performance Scores = Performance You Scored Like Our High Functioning Employees – We Should Hire You! So, We Should Hire People Like You! Flawed Logic Generalizing From Surrogate (current employees) to Target Population © 2012 Safety Performance Solutions, Inc. 38 Predictive vs. Concurrent Validity. Predictive Validity: The Way It Should Be Done Job Candidates (Not Hired Yet) …Thinking: I must score well to get this job Hire Based on Existing Criteria and Monitor Performance Scores = Performance Scores = Performance Now if There is a Significant Correlation Between Scores and Performance, You Have a Valid Measure. © 2007 Safety Performance Solutions, Inc. 39 2. Structured Interviews Are Excellent Tools Alone or Follow-Up to Surveys. The survey indicates “what” people feel. Structured interviews help indicate “why” people feel the way they do. Use the same demographic categories as the survey. Allow at lease 60-minute blocks. Interview a cross-section of organization. Keep the groups small (4-6 participants). © 2002 Safety Performance Solutions, Inc. (EVIT 8.00) 40 Structured Interviews May Result in Hundreds of Comments. But the Key is to Find Trends. © 2002 Safety Performance Solutions, Inc. (EVIT 8.00) 41 Sample Trends: North American Sites for Company X. Just-in-Time Inventory Process Creating a Bottleneck for Parts Incident Investigation Process Leads to Blame Confusing/Inconsistent SOPs Leads to Inconsistent Rule Compliance/Consistency Insufficient Staffing Leads to Short Cuts ©Safety Performance Solutions, Inc. (1.08) 42 Sample Trends: South American Sites for Company X. Production over safety attitude leads to risk taking Inconsistent Discipline/Favoritism Leads to Fear and Negative Attitudes Rosters/Schedules/Fatigue Creates Safety Hazards “Anything for the Company” Attitude Leads to Inappropriate Risk Taking Safety is Taken Home ©Safety Performance Solutions, Inc. (1.08) 43 3. Safety Management Systems Assessment. All safety management systems should accomplish their primary objectives in a way that fosters a Total Safety Culture. - Employee Involvement/Accountability - Safety (facilities) Audits - Incident Reporting & Analysis - Leaders’ Commitment - Safety Policies and Procedures © 2002 Safety Performance Solutions, Inc. (EVIT 8.00) - Safety Committees - Safety Communication - Discipline Process - Reward and Recognition - Behavior Observation & Feedback 44 Maturity Path Exercise Description of the Assessment Tool The assessment tool has four tiers (i.e., Beginning, Improving, Achieving, Leading), with each tier describing a stage in the evolution of that particular safety management system. A brief description of each tier is given below: 1) Beginning Safety management systems at the beginning level may involve several scenarios. The system doesn’t exist or if existing, the system is woefully inadequate. If the system does not exist, there may be little or no effort to implement the system, or even acknowledge the need for such a system. If the system exists, the organization has little or no procedures or documentation for the system at this level and adherence to the system itself is inconsistent or sporadic. Improvement opportunities are plentiful. 2) Improving Safety management systems exist at this level, but they are deemed inadequate by a majority of personnel affected by them. Procedures are in place and documented, but documentation is poor or adherence to documented procedures is sporadic and inconsistent. Additionally, the system is perceived by employees to generally lack effectiveness, thereby influencing poor support and participation. There is much room for improvement. 3) Achieving Safety management systems are well documented and generally used in an effective manner. System problems are identified and follow-up procedures exist that allow the organization to implement and evaluate improvements. Adherence to the system is generally consistent and employee perceptions of the system are generally positive. There is still room for improvement. 4) Leading Safety management systems are extremely effective in addressing and minimizing variance. Embraced by all, perception of system effectiveness, as well as participation and support, are quite high. The system is an exemplar to organizations benchmarking for improvement. © 2002 Safety Performance Solutions, Inc. (EVIT 8.00) 45 incidents. are performed on all incidents. Path: Incident and Analysis 5. Analyses are conducted by Maturity safety professionals 1 2 3Reporting 4 An incident analysis team is composed of members and/or supervisors only. representing a cross-section of the organization and Beginning (1) Leading (4) includes individuals involved in the event. 1. All but the most serious incidents go unreported. 1 2 3 4 All incidents (e.g., near misses, property damage, injuries) tools, are reported a timely 6. No structured processes or techniques are used 1 2 3 4 Analysis such asinevent andfashion. causal factor . during the analysis. charting and task analysis, are used as 2.. No formal incident analysis procedure exists or if 1 2 3 4 warranted. A formal incident analysis and reporting procedure one exists, it is vague. exists and clearly defines when, by whom, and how investigations are to be conducted. 7. No training is provided for incident reporting and 1 2 3 4 All employees receive training in the philosophy analysis. and overall process of investigating incidents. 3. The incident investigation procedure is not 1 2 3 4 Investigation The incident team investigation is consistently leaders procedure receive detailed training consistently followed. infollowed. investigation skills such as interviewing and root cause analysis. 4. Analyses are conducted only after sizable 1 2 3 4 Appropriate analyses (with varying level of detail) incidents. are performed all incidents.is on finding system8. The focus of the investigation is on documenting 1 2 3 4 The focus of theoninvestigation the event. level root causes. 5. Analyses are conducted by safety professionals 1 2 3 4 An incident analysis team is composed of members and/or supervisors only. representing a cross-section of the organization and 9. Analyses often result in identifying “who’s to 1 2 3 4 Incident analyses focus on determining system-level includes individuals involvedor eliminating them. blame.” Corrective measures such as discipline root causes and minimizing in the event. or “counseling” are common. Individuals are not assumed to be at fault. Appropriate behavior-based corrective actions are where warranted. 6. No structured processes or techniques are used 1 2 3 4 introduced Analysis tools, such as event and causal factor during the analysis. charting and task analysis, are used as warranted. 7. No training is provided for incident reporting and analysis. © 2002 Safety Performance Solutions, Inc. (EVIT 8.00) 1 2 3 4 All employees receive training in the philosophy and overall process of investigating incidents. 46 Investigation team leaders receive detailed training Here is a Sample SMS Summary Graph. 1 =B e g in n in g © 2002 Safety Performance Solutions, Inc. (EVIT 8.00) 2 =Im p r o v in g 3 =A c h ie v in g 4=L e a d in g 47 People-Based Safety: Assessing Attitudes and Behaviors for Safety Leadership Case Studies Case Study 1 Safety Management Systems Assessment: Incident Investigation Redesign The Management Team Questioned the Effectiveness of their Process. ? ? Root Causes ? 50 ©Safety Performance Solutions, Inc. (1.08) ? ? A Systematic Approach Was Used to Study and Revise the Existing System. Assess current system. review current process survey employees benchmark best practices Develop revised investigation processes. Train potential members of investigation teams. Develop incident investigation field manual. Train all employees. Implement new processes &51evaluate. ©Safety Performance Solutions, Inc. (1.08) We Assessed Numerous Elements of the Current Process. Nature of Typical Follow-up Degree of Employee Involvement Actions Recommended (Analysis, Follow-up) (“counsel employee or “discipline employee) Background of and/or Training Provided To Team Members Communication of the Incident Analysis Tools Used Communication of the Analysis Nature of Typical Root Causes Results Identified Completion of Follow-up Actions Communication of the Completion Generalization of Follow-up of the Follow-up Activities Actions 52 ©Safety Performance Solutions, Inc. (1.08) The Current Process Revealed Several Weaknesses. No Employee Involvement during Analysis or Follow-up No Expertise or Training Provided in Psychology or Human Factors No Behavior Analysis Tools Used Root Causes Identified Often Included “Employee Action” “Counsel Employee” or “Discipline Employee” were Common Follow-up Actions. Communication of the Incident was Haphazard Communication of the Analysis Results was Haphazard Completion of Follow-up Actions was Satisfactory Generalization of Follow-up Actions was Infrequent. Communication of the Completion of the Follow-up Activities was Haphazard 53 ©Safety Performance Solutions, Inc. (1.08) Survey Results Highlighted A Revealing Pattern. Blame... Non-Hourly who have been involved in incident investigations Hourly who have been involved in incident investigations Hourly who have NOT been involved in incident investigations 45 40 35 30 25 20 15 10 5 45 40 35 30 25 20 15 10 5 Very Somewhat Neither Somewhat Very Very Somewhat Neither Somewhat Very Very Somewhat Neither Somewhat Very 45 40 35 30 25 20 15 10 5 54 ©Safety Performance Solutions, Inc. (1.08) Problem Solving... Survey Results Highlighted A Revealing Pattern. Wrong Findings... Non-Hourly who have been involved in incident investigations Hourly who have been involved in incident investigations Hourly who have NOT been involved in incident investigations ©Safety Performance Solutions, Inc. (1.08) 50 45 40 35 30 25 20 15 10 5 45 40 35 30 25 20 15 10 5 45 40 35 30 25 20 15 10 5 Correct Findings... Very Somewhat Neither Somewhat Very Very Somewhat Neither Somewhat Very Very Somewhat Neither Somewhat Very 55 Employees Felt Like THEY Were Seen as the Root Causes of Incidents. 56 ©Safety Performance Solutions, Inc. (1.08) The Incident Analysis Process Was Redesigned to Meet Two Goals. 1. Better determine the immediate causes and root causes (including those influencing human behavior) which allowed the incident to occur so effective countermeasures can be taken to reduce future injury risk. 2. Encourage the full and open participation of all employees by eliminating any fault-finding, adversarial atmosphere. 57 ©Safety Performance Solutions, Inc. (1.08) A Systematic Approach Was Used to Study and Revise the Existing System. Assess current system and benchmark best practices. Survey employees. Develop revised investigation processes. Developed guidelines for team composition, roles and responsibilities, group norms and ground rules, etc. Introduced new analysis tools Revised the notification/communication system (pre-investigation and post-investigation) 58 ©Safety Performance Solutions, Inc. (1.08) Incident Analysis Team Training Course Outline Employee Survey Results Goals of the Revised System Steps of an Incident Investigation Interviewing Strategies and Techniques Factors Influencing Human Performance and Human Error Human Error Risky Behavior Analytical Investigation Techniques 59 ©Safety Performance Solutions, Inc. (1.08) Unsafe Behavior is Often the Result of System Influences. At-Risk Behavior Did operator purposefully perform a behavior which s/he knew to be unsafe? Human Error System-Induced Human Error Individual Variance No Yes System-Encouraged Behavior 60 ©Safety Performance Solutions, Inc. (1.08) Calculated Risk Willful Negligence Act of sabotage Incident Analyses Must Look For System-Level Root Causes. There are system influences on human error. Task structure Interface design Training systems Work structure and schedules Communication systems There are system influences on risky behavior. Formal and informal organizational reward systems Social reinforcement/social influence Work structure and schedules Employee empowerment 61 ©Safety Performance Solutions, Inc. (1.08) What Risky Behavior Does This System Reinforce? 62 ©Safety Performance Solutions, Inc. (1.08) 63 © Safety Performance Solutions, Inc. 2009 Case Study 2 Supervisor Accountability/Feedback System Employees Perceived Low Supervisor Support for Safety. Perceived Supervisor Support for Safety 100% 80% 60% 40% 20% 0% Balance Concerned Review safetyproductivity and about wellbeing related info safety vs. numbers regularly % Favorable % Neutral 65 ©Safety Performance Solutions, Inc. (1.08) % Unfavorable Privide feedback Supervisors Had Poorly-Defined Responsibilities for Safety. “Don’t have any injuries in your group”. “Give monthly safety meeting talk”. “Make sure everybody’s wearing their PPE”. “Stop an employee if you see them breaking a safety rule”. “Send people to training when required”. “Help new employees or transfers learn the safety rules”. 66 ©Safety Performance Solutions, Inc. (5.06) A Performance Feedback System Defines, Measures, and Reinforces Desired Performance. Define Measures (behaviors): Define the specific, measurable activities which will be measured and rewarded. Participation in the goal setting activity facilitates buy-in & commitment. Establish a Timeline: Identify the time period and/or frequency over which the activities are to be performed. Communicate/Train: Make sure everybody clearly understands what is expected and has the skills to succeed. Measure: Monitor and periodically review performance (formally and informally). Reinforce: Acknowledge and reinforce accomplishments and identify a plan for overcoming barriers67 impeding progress. ©Safety Performance Solutions, Inc. (5.06) People Should Be Held Accountable for Things Within Their Control. Plant safety statistics are a function of many variables: At-risk Behaviors and Conditions Uncontrollable Events Reporting Practices Record-Keeping Practices Medical Management and Return-to-Work Practices When individuals are held accountable for things outside their control: Motivation is decreased (Consequences are uncertain) (Dis)stress is increased 68 ©Safety Performance Solutions, Inc. (1.08) The Skill Set Contained Many Categories. 1) Support and reward employee participation in safety activities. 2) Set safety goals and expectations with employees. 3) Provide regular formal and informal safety performance feedback. 4) Model appropriate safety-related behaviors. 5) Solicit and encourage employee input on safety-related matters. 6) Demonstrate fact-finding rather than fault-finding for safety- related concerns. 69 ©Safety Performance Solutions, Inc. (1.08) The Skill Set Contained Many Categories (cont.). 7) Communicate safety-related information to employees regularly. 8) Show visible support for safety policies, rules, procedures, and regulations (regardless of personal opinion). 9) Demonstrate appropriate balance between safety and other performance measures. 10) Focus on safety processes 70 rather than outcomes. ©Safety Performance Solutions, Inc. (1.08) Each Category Contained Objective, Observable, Behaviors. A. Support and reward employee participation in safety activities Behavioral Observation and Feedback Process (BOFP) Work with BOFP committee member(s) to establish goals for your group. Schedule time for observations every week. Allow/encourage BOFP meetings. Participate in (or lead) ABC analyses. Request BOFP observations for specific operations or jobs and during outages or turnarounds. Request BOFP observations be performed on you. Review (or ask BOFP participant to review) BOFP progress reports at monthly safety meetings. Recognize individual contributions toward BOFP (privately and publicly). Recognize overall BOFP process accomplishments. Keep up-to-date on pertinent BOFP data, including: 71 Group members who trained observers. ©Safety Performance Solutions, Inc.are(1.08) Employees Complete the “Safety Leadership Feedback” Form. Safety Leadership Feedback Behavior 1 2 3 Comments 1. Encourage, support, and reinforce employee participation in safety activities. A. Safety Audits: - Regularly conduct audits yourself. - Allow / schedule time for employees to conduct audits. Help remove any barriers to conducting audits (e.g., time pressure). - Keep up-to-date on important audit data, including: ~ Group members who are trained as auditors (total number and their names). ~ Group members who are actively participating in conducting audits. ~ Results from audits in your area. ~ Status of follow-up items. 72 ©Safety Performance Solutions, Inc. (1.08) Individual and Collective Results Are Reviewed. Employees (Anonymously) Complete “Safety Leadership Feedback” Form Copies Are Forwarded to Safety Dept. for Compilation Originals Are Collected and Forwarded to Supervisor 73 ©Safety Performance Solutions, Inc. (1.08) The Summarized Information Leads to Group-level Improvements. Each Department’s Summarized Data Is Forwarded to and Reviewed by All Department Members. Department XYZ: Supervisor Feedback Results 10 0% 80 % % Un favorab le 60 % % Ne utral 40 % % Favorab le 20 % 0% Encoura ges em ployee pa rticipation Sets sa fety go als Provid es fe edba ck 74 ©Safety Performance Solutions, Inc. (1.08) Mode ls s afe be haviors 4. LEADS: Leadership Behavior Evaluations. Assessments of How Effectively Leaders Promote: 1. 2. 3. 4. 5. 6. Vision for Safety Engagement In Safety Rewards & Recognition for Safety Trust in Ability and Intent for Safety Communication for Safety Teamwork and Empowerment for Safety The assessment tool should target various levels of the organization (supervisors, plant-level leadership, executive leadership). © 2002 Safety Performance Solutions, Inc. (EVIT 8.00) 75 Case Study 3 LEADS: Executive Behavior Evaluation and Development Sample LEADS Results Engagement In Safety 1.00 2.00 3.00 Q8 Q9 Q10 Q11 Q12 Q13 Q14 VPs Directors 77 © Safety Performance Solutions, Inc. 2007 PMs 4.00 Sample LEADS Results Engagement In Safety 9. Leader actively participates in safety activities within the sites they oversee. - The role of the VP is not supposed to work at the plant level. VP’s may animate plant level plans but it is the plant managers’ role. - I (VP) participate in discussions, reward people, ask for examples and suggestions. I give best idea awards, and attend workshops focusing on safety. 12. Leader participates in HSE celebrations at the site level. -When plants win HSE awards they are extremely proud because of their commitment to the community and company. However, the VP is never present and rarely offers a letter of recognition. …there should be more attention given by the VP to safety celebrations and recognition. - He does recognize sites for safety – it is strong leadership behavior and very welcome from the people – Thus is a good/important thing he does. 78 © Safety Performance Solutions, Inc. 2007 Sample LEADS Results Accountability/Rewards/Recognition 1.00 2.00 3.00 Q46 Q47 Q48 Q49 Q50 Q51 Q52 VPs Directors 79 © Safety Performance Solutions, Inc. 2007 PMs 4.00 Sample LEADS Results Accountability/Rewards/Recognition 47. Always include a discussion of HS&E performance, praising good and challenging plant managers with poor performance in Operations Reviews. - We should start the operations review with HSE. Instead we are not seeing any discussion of HSE unless there is an incident. - We have sites with the goal of acting like a business unit; …. Now environmental issues and safety are much more emphasized. The downside is much higher when mistakes are made…Thus, HS&E should be higher on the agendas of operations. Leaders should “animate” safety with good processes beyond just one slide during the Operations Reviews. - I’m surprised this is even a question. I don’t do this and I don’t plan to do this. I should start with quality, safety should not be key unless there is a problem. My boss puts HSE at the end. Quality and production are our main issues now. I know some are trying to increase focus on safety and I appreciate this – But we all have goals and we all want our goals on top. 80 © Safety Performance Solutions, Inc. 2007 Exercise: Safety Leadership Mini Self-Assessment Evaluate your own safety leadership performance :. 1=Rarely 2= Occasionally 3= Of 4= Almost Always _ I maintain focus on safety even when safety performance is good. _ I actively participate in safety activities (e.g., safety meetings, safety training/hiring, safety committees, incident reviews, etc.). _ I include safety activities and efforts of employees in their performance reviews, thus letting employees know safety activities are a critical part of the job (as opposed to simply whether or not they’ve been injured). _ I routinely recognize employees for working safely. _ I ask employees what they need to do their jobs safely. _ I create opportunities for employees to discuss safety-related issues with each other. _ I ensure employees have adequate time to participate in safety activities (e.g., committees, safety suggestions, near miss reporting, safety training). 81 ©Safety Performance Solutions, Inc. (5.06) So What Would Others Think? Average LEADS Rating (on a scale from 1-4) Self-Evaluation x = 3.4 Evaluation by Others x = 2.1 Individuals Are Usually Poor At Assessing Their Own Leadership Skills. 82 ©Safety Performance Solutions, Inc. (5.06) LEADS (Leadership Evaluation & Development for Safety) o Usually Employs a 360 Format. 83 ©Safety Performance Solutions, Inc. (5.06) Case Study 3 Behavioral Observation Process Assessment An Observation and Feedback Process is More than Just Filling Out Checklists. Ge ne ric Obse rva tion Che c klist Depart: ____________ Observer's Name: ______________________ Month/Yr: ____ / ____ Safe At-Risk Comments: PPE: - Eyes / Face - Hearing - Hand - Foot - Protective Clothing Housekeeping: - Slip / Trip - Storage - Egress Body Position: - Cramped / Extended - Ergonomics - Lifting / Lowering - Line of Fire - Pinch Points Visual Focus: - Eyes on Task - Eyes on Path Other: 85 ©Safety Performance Solutions, Inc. 2010 www.safetyperformance.com An Observation and Feedback Process Reduces Injuries In Two Ways. Behavior Observation and Feedback Process Informal Process Formal Process Goal: Increase quality and quantity of interpersonal safety communication. Goal: Target, analyze, intervene to increase safe and decrease atrisk behaviors. Purpose: Injury Reduction 86 © SafetyPerformance ©Safety PerformanceSolutions, Solutions,Inc. Inc.2010 2010 www.safetyperformance.com An Observation and Feedback Process is More than Just Filling Out Checklists. Employees Observe Critical Behaviors Safety improvements are communicated to workforce providing motivation to continue collecting data. Checklists are completed and collected. The most critical behaviors are targeted for follow-up. Interventions developed (may include environmental or system changes) to increase safe and decrease at-risk behavior. Target behaviors are analyzed to determine why they are occurring. A breakdown at any step can STOP the cycle. 87 © SafetyPerformance ©Safety PerformanceSolutions, Solutions,Inc. Inc.2010 2009 www.safetyperformance.com Common Barriers to a Successful Observation Process. 1) Lack of Trust • People feel true observations will lead to disciplinary action. • People don’t trust co-worker reaction • Observations will primarily focus on conditions rather than behaviors • Reluctance to observe • “Pencil Whipping” is common 2) Poor Observation/Hazard Recognition Skills • People do not recognize hazardous behaviors and conditions • “Low Hanging Fruit” has already been picked • Little /insufficient training provided for workforce • Easy/Superficial observations are common “Lack of PPE” • Reluctance to observe – especially outside own work area • “Pencil Whipping” is common 88 © Safety Performance Solutions, Inc. 2010 www.safetyperformance.com Common Barriers to a Successful Observation Process. 3) Low Risk Perception • People don’t believe they are at-risk. • Low motivation to do anything “extra” for safety • Reluctance to observe • “Pencil Whipping” is common 4) Low Perceived Value in the Observation Process • People don’t believe the process targets the true hazards • People don’t believe the organization is willing to correct the true hazards once identified • Trending of data and appropriate follow-up intervention is rare • Employee input/ownership/control is typically low • Reluctance to observe • “Pencil Whipping” is common 89 © Safety Performance Solutions, Inc. 2010 www.safetyperformance.com A Total Safety Culture Has Several Dimensions. LEADERSHIP CONDITIONS Are Senior Leaders committed to improving the culture and do they demonstrate safety as a value Does the physical environment (the interaction of equipment, facilities, procedures, and people) allow safe performance PEOPLE SYSTEMS Total Safety Culture Do people have positive perceptions of themselves, their coworkers, and the organization. Are they willing to go “above the call of duty” Do organizational systems support the “right” behaviors and are they consistent with organizational values. BEHAVIOR Do people perform the ‘right’ behaviors. EMPLOYEE ENGAGEMENT Are Employees Actively Involved in Making Valuable Contributions © Safety Performance Solutions, Inc. 2011 www.safetyperformance.com 90