MIAMI Fire Lessons Learned

advertisement

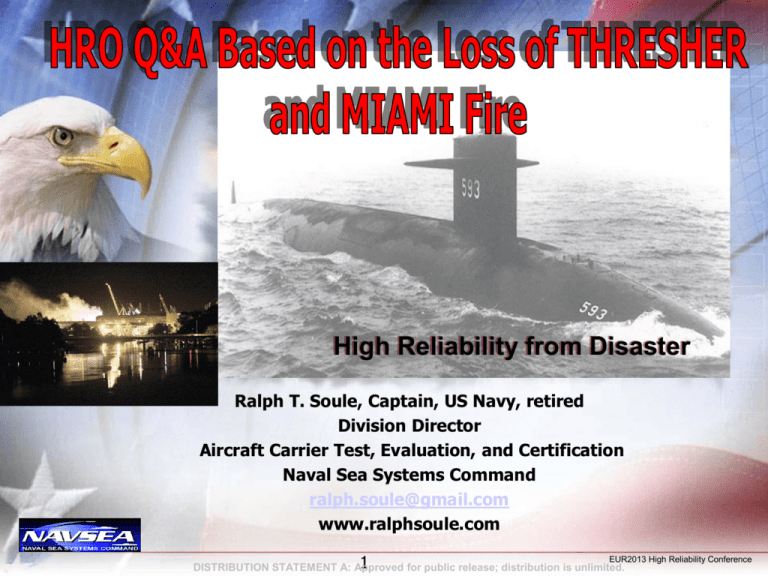

High Reliability from Disaster Ralph T. Soule, Captain, US Navy, retired Division Director Aircraft Carrier Test, Evaluation, and Certification Naval Sea Systems Command ralph.soule@gmail.com www.ralphsoule.com 1 EUR2013 High Reliability Conference DISTRIBUTION STATEMENT A: Approved for public release; distribution is unlimited. Risks of Submarine Operations Risks Designers Can/Cannot Control Case Study: THRESHER Risks to Ships of Industrial Operations Firefighting Aboard Ship is Complex Case Study: MIAMI 2Presentation Name 2 EUR2013 High Reliability Conference USS THRESHER (SSN-593) Laid down, 28 May 1958, at Portsmouth Naval Shipyard, Kittery, ME. Launched on 9 July 1960. 13th nuclear powered attack submarine. The first ship of its Class; leading edge of US submarine technology: USS THRESHER launching ceremonies at the Portsmouth Naval Shipyard, Kittery, Maine, 9 July 1960. combining nuclear power with modern hull design newly-designed equipment and components Ship was fast, quiet, and deep diving 3Presentation Name EUR2013 High Reliability Conference Question: What risks of normal operations can designers control? • Submerging and surfacing • Navigation under the water • Resistance to sea pressure • Fire and flooding 4Presentation Name 4 EUR2013 High Reliability Conference Question: What risks of normal operations are beyond the designers' control? • Crew training • Compliance with procedures • Worker attitudes and responsibility • Equipment maintenance performance • What problems are worthy of attention 5Presentation Name 5 EUR2013 High Reliability Conference Question: What risks of normal operations are beyond leaders' control? (or are they?) • How people respond to problems • How people communicate risks and problems • Supplier conformance to specifications • Shipyard conformance to specifications • Material performance under operations (does it behave the way you assumed?) 6Presentation Name 6 EUR2013 High Reliability Conference USS THRESHER Case Study • Background • Piping systems cannot be made of single pieces, connections (joints) must be leak free • Ship is in overhaul • Other ships in the same shipyard, all competing for the same resources • Much pressure to complete the overhaul on time • 145 critical piping joints being inspected (of more than 3000) 7Presentation Name 7 EUR2013 High Reliability Conference USS THRESHER Case Study • Problem – Some pipe joints do not meet standard • Inspections show that about 14 percent of the sea water piping joints checked require repair or replacement. 8Presentation Name 8 EUR2013 High Reliability Conference USS THRESHER Case Study • What to do? • Inspect more joints • Disassemble joints to understand failures • Analyze which assumptions of original design were wrong and why • Change/test fabrication procedures • Report failure/unexpected results to higher authority • Inspect other ships to gather more data • Document what went wrong and what you learned 9Presentation Name 9 EUR2013 High Reliability Conference On April 10, 1963, while engaged in a deep test dive, approximately 200 miles off the northeastern coast of the United States, the U.S.S. THRESHER (SSN-593), was lost at sea with all persons aboard - 112 naval personnel and 17 civilians. PNSY THRESHER wreckage: About 200 miles off Cape Cod in 8,400 ft of water Investigation Conclusions Flooding in the engine room Spray on electrical switchboards Presentation Name 11 Unable to secure from flooding Loss of propulsion power 11 Unable to blow ballast tanks EUR2013 High Reliability Conference Navy Response: SUBSAFE and Significant Culture Change LOSS of THRESHER Overhaul/Construction SUBSAFE PROGRAM Presentation Name 12 MAINTENANCE PROCESS CHANGES EUR2013 High Reliability Conference USS MIAMI Case Study Background • USS MIAMI (SSN 755) 2012 – US Navy Nuclear-powered Attack Submarine – In month 2 of a 20 month overhaul – Location: Portsmouth Naval Shipyard (PNSY), Maine • • • • • Ship was in dry dock Crew had moved off the ship All weapons removed Many spaces empty of personnel Reactor shut down www.ralphsoule.com 13 EUR2013 High Reliability Conference Question: Risks of Submarine Overhaul? • • • • Fire (sources?) Flooding, sinking Explosion Many personnel risks – Electric shock – Falls – Dropping heavy things – Lack of breathable air www.ralphsoule.com 14 EUR2013 High Reliability Conference If a Fire Occurred, What Makes Response Challenging? • Normal ship systems disabled • Firefighting equipment and crew removed from ship • Shipyard firefighters not familiar with ship • Many support hoses and cables complicate access • Ship compartments small • Hard to locate fire www.ralphsoule.com 15 EUR2013 High Reliability Conference Fire Location Fire Initiation Site www.ralphsoule.com 16 EUR2013 High Reliability Conference Fire Event • Major fire occurred in forward ship section – Date: 23 May 2012, ~1730 hrs – Duration of fire: over 10 hours – Cause: Arson – Initial Source: Combustible material – Damage: > $750M US estimate to repair, but submarine will be scrapped instead 17 Example of Damage www.ralphsoule.com 18 EUR2013 High Reliability Conference MIAMI Lessons Learned • Breathing air canister capacity insufficient • Too much combustible material present • Shipyard and ship’s crew had not rehearsed response sufficiently www.ralphsoule.com 19 EUR2013 High Reliability Conference MIAMI Lessons Learned • Industrial environment complicates fire and response. – Crew firefighting equipment removed – Hull cut provided air to feed the fire – Hatches and temporary services complicated access by emergency responders • Early detection and rapid response extremely important – Fire set in remote location – Heavy black smoke confused early reports of location • Command structure inadequate for complex, extended firefighting – 20 mutual aid fire departments augmented shipyard resources – Need integrated Command structure, interoperable radios, and coordinated fire fighting strategy www.ralphsoule.com 20 EUR2013 High Reliability Conference Questions www.ralphsoule.com 21 EUR2013 High Reliability Conference 22 23 24 25 26 27 28 29 Getting it Wrong