SECARB Phase III - Southern States Energy Board

Southeast Regional Carbon Sequestration Partnership

Project Number: DE-FC26-05NT42590

Presented to:

Regional Carbon Sequestration Partnerships 2011 Peer Review

Arlington, Virginia

March 17, 2011

Presented by:

Susan Hovorka

Research Scientist

Bureau of Economic Geology

The University of Texas at Austin

Vello A. Kuuskraa

President

Advanced Resources International, Inc.

Acknowledgements

This material is based upon work supported by the U.S.

Department of Energy National Energy Technology

Laboratory.

Cost share and research support provided by SECARB/SSEB

Carbon Management Partners.

2

Presentation Outline

1. Introduction (Hovorka)

2. Technical Discussion: Early Test (Hovorka)

3. Technical Discussion: Anthropogenic Test (Kuuskraa)

4. Wrap Up (Kuuskraa)

3

SECARB Phase III

SECARB Early Test was recognized by DOE for furthering CCS technology and meeting

G-8 goals for deployment of 20 similar projects by

2010. The Early Test is the fifth project worldwide to reach the

CO

2 injection volume of one million tonnes and the first in the U.S.

- (DOE Techline, 11/05/2009)

Early Test

Denbury Resources’ Cranfield Field

Near Natchez, Mississippi

Anthropogenic Test

Capture: Alabama Power ‘s Plant Barry,

Bucks, Alabama

Transportation: Denbury Onshore LLC

Geo Storage: Denbury’s Citronelle Field

,

Citronelle, Alabama

4

RCSP Program Goals – Early Test

Predict storage capacities within +/- 30%

Well known based upon production history; Early Test advanced the understanding of efficiency of pore-volume occupancy (E factor).

Success metrics: Measure saturation during multiphase plume evolution

(completed). Increase predictive capabilities (modeling underway).

Evaluate protocols to demonstrate that 99% of CO

2 is retained

Permanence of geologic system well understood prior to test because of retention of large volumes of methane.

Retention uncertainties lie in well performance. Early Test is evaluating methods to assess well performance.

Success metrics: Measure changes above the injection zone along well, above zone monitoring interval (AZMI), and at surface (P-site) over long times

(underway).

Contribute to development of Best Practices Manuals

Early Test researchers have contributed to Best Practices Manuals on MVA, characterization, risk and modeling. Assistance has been provided on related protocol development, including IOGCC (U.S.), Pew Center accounting study

(U.S.), IPAC-CO

2

(Canada), and CO

2

-Care (EU).

5

RCSP Project Goals – Early Test

Goal 1 - Adequate Injectivity and Capacity

Advanced the understanding of efficiency of pore-volume occupancy (E factor) by measuring the saturation during multiphase plume evolution. Anticipate increasing predictive capabilities through modeling.

Goal 2 - Storage Permanence

Although well understood prior to test, assessed methods for documenting well performance, which include:

– Measure changes above the injection zone along well, above zone monitoring interval

(AZMI), and at surface (P site) over long times (underway)

Goal 3 - Areal Extent of Plume and Potential Leakage Pathways

Measured down-dip extent of plume via VSP and 4-D seismic to improve the uncertainty regarding the radial flow (down dip/out of pattern) in the 4-way closure.

Increase predictive capabilities through modeling

Goal 4 -Risk Assessment

Saline storage site is located in EOR field with operator owning CO

2

.

Use Early Test to advance risk assessment techniques and share information.

Completed certification framework assessment of leakage risk.

Confirmed well performance as highest uncertainty and focus of monitoring research.

6

RCSP Project Goals – Early Test

Goal 5 - Develop Best Practices

Participated in developing BPMs for MVA, characterization, risk and reservoir modeling.

Goal 6 - Public Outreach and Education

On-site outreach handled by Landmen.

SSEB and Early Team focus on O&E in public and technical arenas.

Hosted site visits, responses to local and trade media, Fact Sheets, and website postings of project information.

Goal 7 - Improvement of Permitting Requirements

Permits obtained by site operator.

Project team focus is on development of regulatory framework for GHG.

Provided experience with monitoring instruments and well performance to decision makers.

7

SECARB Organizational Chart

DOE/NETL

Early Test

TX BEG /Gulf Coast Carbon Center

(Collaborators outlined in

Early Test section)

Environmental Information

Volumes

Steve Walden Consulting

Program Management

Project Management & Budget/Administrative Oversight

Southern States Energy Board (SSEB)

Anthropogenic Test

Electric Power

Research Institute

(Collaborators outlined in

Anthropogenic Test section)

Environmental Information

Volumes

Cardno ENTRIX, Steve Walden

Consulting

Regional Activities

Continued Characterization

TX BEG/GCCC, EPRI, ARI

Outreach

SSEB

Legal & Regulatory

SSEB

Offshore Study

(Collaborators: SSEB,

TX BEG/GCCC, Geological

Survey of Alabama, and

IOGCC)

8

Early Test Organization Chart

SSEB

Gulf Coast Carbon Center

Bureau of Economic Geology

Jackson School of Geosciences

The University of Texas at Austin

Denbury Resources

Field owner and injection system design, management, 4-D survey, HS&E

Vendors e.g. local landman

Sandia Technologies

Monitoring Systems

Design, Installation,

HS&E

50 Vendors e.g. Schlumberger

MSU Umiss

Hydro & hydrochem

Core Lab

UT DoG

Anchor QEA

Federal collaborators

Vis FWP

LBNL

Well-based geophysics,

U-tube and lab design and fabrication

LLNL

ERT

USGS

Geochemistry

Environmental

Information Volumes

Walden Consulting

Vendors e.g. equipment

Separately funded

ORNL

PFT, Stable isotopes

NRAP

VSP

NETL

Rock-water interaction

Stanford, Princeton, U Edinburgh, UT

PGE & ICES (CFSES), U. Tennessee, USGS

RITE, BP

9

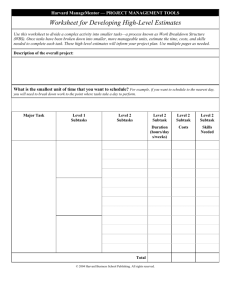

Project Overview: Scope of Work

Task 1.0: Continued Characterization of Regional Sequestration

Opportunities

– Assessment of regionally significant formations (saline); update of CO

2 sources; regional/national Atlas updates; participation in RCSP capacity work group.

Task 2.0: Public Outreach and Education

– Local (field test), regional , national, and international public outreach and education.

Task 3.0: Site Permitting

– Identification and submittal of required site permitting (EQs, EAs, drilling and injection permits from Miss. Oil and Gas Board).

Task 4.0: Site Characterization and Modeling

– Detailed site characterization (existing data and new data collection)

Task 5.0: Well Drilling and Completion

– Design and completion of observation and injection wells (Sandia

Tech/Denbury)

10

Project Overview: Scope of Work

Task 6.0: Infrastructure Development

– Mostly provided by Denbury. Enlarge well pad, electricity for MVA

Task 7.0: CO

2

Procurement

– Procure additional CO

2 to meet project metric.

Task 8.0: Transportation and Injection Operations

– Transportation and injection operations provided by Denbury

Task 9.0: Operational Monitoring and Modeling

– Early Test surface and subsurface monitoring, data collection, and modeling.

Task 10.0: Site Closure

– Early Test discontinuation plan: Denbury continue commercial injection for decades

Task 11.0: Post-Injection Monitoring and Modeling

– Time lapse monitoring and model updates to history match; RCSP MVA

Work Group participation.

11

Project Overview: Scope of Work

Task 12.0: Project Assessment

– Site-specific, regional and Partnership-wide findings.

Task 13.0: Project Management

– Local project management for field sites and overall project management and oversight.

Task 14.0: Does Not Exist

– A pipeline study was proposed for Phase III but was later added to the

Phase II program instead. Task 15.0, which was proposed at the same time, was added to the Phase III program. The task numbers were not changed, so there is no Task 14.0 in the Phase III SOW.

Task 15.0: Preliminary Evaluation of Offshore Transport and Storage of

CO

2

– Resource mapping offshore Gulf of Mexico (state and federal waters); infrastructure inventory; legal and regulatory analysis; outreach and education regarding findings.

12

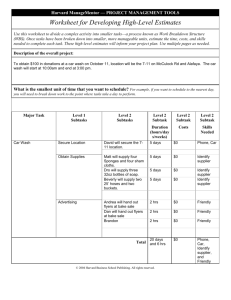

Project Overview: Schedule and Cost

Project Schedule

–

Early Test adjusted to match Denbury’s field development plan

Project Cost

Phase III Early Test

Dollars Percent

DOE Share $34,186,226 59.53%

Non-DOE Share $23,240,580 40.47%

Total Value

Expenditures as of

12/31/2010

$57,426,806*

$37,796,045

*Does not include the Anthropogenic Test, continued characterization (Task 1), offshore study

(Task 15), or regional activities (outreach, project assessment, project management). The total

SECARB Phase III Program budget is $111,413,431.

13

Project Overview: Milestones

14

Gantt Chart

All tasks are on schedule and budget.

15

Confining System

Regionally significant sequestration target:

Gulf Coast wedge

Repetitive depositional units

• Results transferable to:

• older and younger units

• other parts of region

Confining System

Early Test – large volumes of CO

2

Denbury Pipeline System

17

Update on Results of SECARB “ Early” Test of

Monitoring Large Volume Injection at Cranfield

Mississippi River

Natchez

Mississippi

3,000 m depth

Gas cap, oil ring, downdip water leg

Shut in since 1965

Strong water drive

Returned to near initial pressure

18

Illustration by Tip Meckel

Upper Cretaceous Tuscaloosa-Woodbine Trend – Cranfield in

Mississippi Salt Basin

Source of large volumes of

CO

2 via pipeline

Cranfield

Source: Dutton and others 1993

19

W

Stacked Reservoirs at Cranfield

Phase II

Oil-water contact

Phase III

E

Cross section from 3-D seismic survey

Tip Meckel

20

Cranfield Progress

2006 2007

First cored well, brine samples baseline seismic

2008 2009 2010

Drill Phase III

3 DAS wells

Monitoring

2011

Phase III injection

Phase II injection

2012

Phase II

Phase II + III

12/20/2009 1 million tons Phase III injection

10/2010

Repeat geophysical monitoring

10/2010

Project Workflow

Reservoir characterization;

3-D, Production history

Existing cores and logs

Existing aquifer data

GEM, TOUGH2

Geochemist workbench models for assessment

GEM and

TOUGH2 models for experiment design

Well drilling

Cross well seismic

Multi-well hydro tests

Logging, coring,

Petrography, petrophysics

Soil gas recon,

Groundwater surveillance

GEM, TOUGH2

Geochemist workbench models for Operations

Time-lapse Cross well, VSP, repeat 3-D

Groundwater

Surveillance

P-site measurements

GEM, TOUGH2

Geochemist workbench models for assessment

BHP BHT DTS

ERT, RST, U-tube geochemistry

Measurement

Groundwater

Surveillance

P-site measurements

22

MVA Design

Area tested Whole plume Focus study

Atmosphere

Soil gas

Groundwater

Not tested

Time-lapse surveys at active and P&A well pads

Monitoring well at each injector

Shallow production

Not tested

AZMI

Geo

Mechanical test

Injection zone

Not tested

Not tested

Geochemistry breakthrough

Not tested

“P site” methodology assessment

EGL-7 UM cored test well. Push-pull test

Not tested

DAS pressure and EGL

7 pressure + fluids

GMT-failed

DAS multi-well multi tool array

23

5km

EGL-7

High Volume

Injection Test

(HiVIT)

Psite

Five Study Areas

Phase II

Pipeline head&

Separation facility

GMT

Detail Area

Study DAS

Injector

Producer

(monitoring point)

Observation Well

GIS base Tip Meckel

24

Scientific and Technical Activities

Commercial Deployment

Subsurface perturbation predicted

Contingency plan

Parsimonious public assurance monitoring

CO

2 retained in-zonedocument no leakage to air-no damage to water

Surface monitoring: approach verification

Groundwater program

Gas variation over time

Above-zone acoustic monitoring (CASSM) & pressure monitoring

Sensitivity of tools; saturated-vadose modeling of flux and tracers

CO

2 saturation correctly predicted by flow modeling

CO

2 saturation measured through time – acoustic impedance + resistivity

Tomography and change through time, gravity

3- D time lapse surface/

VSP seismic

Dissolution and saturation measured via tracer breakthrough and chromatography

Lab-based core response to EM and acoustic under various saturations, tracer behavior

Pressure (flow plus deformation) correctly predicted by model

Microseismic test,

RITE pressure mapping

Acoustic response to pressure change over time

Advanced simulation of reservoir pressure field

25

E-W Stratigraphic Section

Above-Zone Pressure Monitoring –powerful tool for leakage detection

AZMI

Middle Tuscaloosa

Confining System

Tuscaloosa DE injection zone

CO2 Injection Zone

Fifteen Months of pressure data

Tip Meckel

26

High quality but complex injection zone

Channel erosion

Point bar

Channel erosion

Point bar

Channel erosion

Channel erosion

Galloway 1983

Stratal slicing of 3-D volume

Hongliu Zeng

Meander fluvial model

27

Injector

CFU 31F1

DAS Monitoring

Obs

CFU 31 F2

Obs

CFU 31 F3

Closely spaced well array to examine flow in complex reservoir

Petrel model Tip Meckel

10,500 feet BSL

F1 F2 F3

Above-zone monitoring

Above Zone Monitoring

Injection Zone

68m

112 m 28

Probabilistic realization of permeability

FI F2 F3

Jong-won Choi and JP Nicot BEG

29

Modeled breakthrough time at well F2 for each of the

10 permeability fields

Observed breakthrough

Jong-won Choi and JP Nicot BEG

30

Measuring distribution of CO

2

in the reservoir

Well-based methods

– Wireline logs in time lapse -RST

– Temperature

Cross well methods

–

–

Time- lapse ERT

Time – lapse acoustic (seismic)

Arial methods

– Azimuthal and walk away VSP

– Time-lapse 3-D seismic from surface

31

Baseline

Sep. 2009

F

3

F

2

Prelim. Cross-well Seismic F1

(Injection)

Change

Nov.

2010

0.0

140 Inter-well Distance

(ft)

367

Ajo-Franklin and Daley LBNL

Preliminary surface 3-D difference

2007 (pre injection)- 11/2010

Injector

Producer

Trevor Richards, Denbury

High frequency fluid sampling via U-tube yields data on flow processes

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

11/29/09 0:00

Originally brine methane saturated

CH4

CO2

12/4/09 0:00 12/9/09 0:00

Breakthrough of of CO

2

12/14/09 0:00 12/19/09 0:00

SAMPLING TIME

12/24/09 0:00 12/29/09 0:00 1/3/10 0:00

Double

Additional flow paths – more injection rate methane extracted

Small diameter sampler with N

2 intact drive brings fluids quickly to surface with tracers

CO

2 dissolution into brine liberates dissolved CH

4

BEG, LBNL, USGS, ORNL, UTDoG, data compiled by Changbing Yang BEG

35

P site Tests Effects of Vadose-Zone Carbon Cycling on

Leaked Gasses

Romanak and Yang, BEG

36

Modeling Underway

SIMSEQ – interpartnership model development test

GEM models – DAS and HiVIT

LBNL – TOUGH2

DOE BES EFRC program - CFSES

NRAP

TOUGH2

DAS

Doughty

LBNL

GEM modeled CO

2 plume evolution HiVIT

Nicot and Choi BEG

Dec 2009 March 2010

37

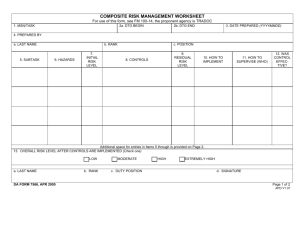

Risk Assessment – Certification Framework

Nicot, (BEG) Oldenburg (LBNL) and others,

2011

38

Risk Assessment – Certification Framework

Nicot, (BEG) Oldenburg

(LBNL) and others, 2011

2600

2800

3000

3200

0.0001

2000

2200

2400

0.001

Mass Flux (kg/m 2 /s)

0.01

0.1

Wilcox

Midway Claystones

1

Austin Chalk

Eagle Ford

Eutaw

Upper Tuscaloosa

Middle Tuscaloosa

Lower Tuscaloosa

Base Case

Sensitivity Case 1

Sensitivity Case 2

Lower Tuscaloosa

Middle Tuscaloosa

Upper Tuscaloosa

Eutaw

Eagle Ford

Austin Chalk

Midway Claystones

Examples

SECARB Early Knowledge Sharing

U.S. and International Programs

NRG CCPI BIG CCS

(Norway)

Sharing results with future projects

Univ. Oslo

(Norway)

SIM-

SEQ

Scottish

RITE

Microsesmic

Center CCS

Florida

USGS

IPAC-CO2

Florida

Polk Co

CFSES

AP/Leucadia

/Hastings

NRAP

Decatur

SECARB Anthro Test

Exchange with sister projects SECARB Early Test

Ketzin

Mountaineer

Building from past experiences

Otway

Nagaoka

GEO-SEQ Frio Test 1&2

In Salah

Plant Daniel

More commercial 40

Education and Outreach

• GCCC Outreach: press, conferences, publications, testimony www.gulfcoastcarbon.com

• ARRA Funded Projects

– STORE:

• sequestration training outreach research and education www.storeCO2now.com

– SECARB-Ed www.secarb-ed.org

(led by SSEB)

41

Interim Conclusions of Study at Cranfield

1 million metric ton/year rate achieved Dec 20, 2009,

2.6 Million metric tons monitored since July 2008

Injection maintained >30 months

Monitored with standard and novel approaches

–

–

–

–

–

History match pressure response

Above-Zone Monitoring Interval (AZMI)

Fluid flow measured/monitored with multiple tools in complex flow field

Quantification of dissolution

Knowledge sharing, outreach, risk assessment

Export to commercial EOR/sequestration projects

42

SECARB Early Test Future Plans

Extensive modeling

Continue monitoring Downhole,

P&T , AZMI P site , groundwater,

Mine existing Cranfield data and share with others to increase predictive capabilities (e.g., SIM-

SEQ inter-partnership model development program).

43

Attachment A

44

SECARB Phase II

Coal Seam Project

Host Company: El Paso E&P near Tuscaloosa, Alabama

Coal Seam Project

Host Company: CNX Gas

Russell County, Virginia

Stacked Storage Project

Cranfield Test Site

Host Company: Denbury Resources, Inc.

near Natchez, Mississippi

Mississippi Test Site

Mississippi Power’s Plant Daniel

Escatawpa, Mississippi

45

SECARB Phase III: Total Program Budget

46

Project Overview: Scope of Work Structure

Organization (Tasks 1, 15 are unique)

Organization (Tasks 2-13)

– Task Level (Activity)

Subtask Level (Field Test Site or Regional Effort)

–

–

–

Early Test is X.1

Anthropogenic Test is X.2

Regional Efforts are X.3

Example

– Task 2.0: Public Outreach and Education

Subtask 2.1: SECARB Early Test Public

Outreach and Education

Subtask 2.2: SECARB Anthropogenic Test

Public Outreach and Education

Subtask 2.3: Regional and Partnership Public

Outreach and Education

47

SECARB Phase III: Tasks & Schedule

All tasks are on schedule and budget.

Task

Continued Characterization of Regional Sequestration Options (TASK 1.0)

Subtask 1.1: Improved Geologic Characterization of Regionally Significant

Tuscaloosa/Woodbine Saline Formations

Subtask 1.2: Information for Use in the Update to the Regional Atlas

Subtask 1.3: Participation in Capacity Subgroup

Subtask 1.4: Further Geologic Characterization of Regionally Significant Large Capacity Saline

Formations

Subtask 1.5: Updated Assessment of the CO2 Storage Potential of the SECARB Coals and the

Organic Shales

Subtask 1.6: Reservoir Characteristic Data for Other SECARB Saline Reservoirs

Subtask 1.7: Update of CO2 Sources in the SECARB Region

Subtask 1.8: Provide Information for Use in the Updates to the Regional Atlas

Subtask 1.9: Provide Information on Subsequent Updates to Regional Atlas

Public Outreach and Education (TASK 2.0)

Subtask 2.1: SECARB Early Test Public Outreach and Education

Subtask 2.2: Anthropogenic Test Public Outreach and Education

Subtask 2.3: Regional and Partnership Public Outreach and Education

Start

10/1/07

1/1/08

10/1/07

10/1/07

1/1/09

1/1/09

10/1/09

10/1/09

10/1/12

10/1/15

10/1/07

10/1/07

1/1/09

10/1/07

End

3/31/17

12/14/09

9/25/08

9/25/08

12/31/12

12/17/10

9/30/12

9/30/12

9/30/15

3/31/17

9/30/17

9/30/17

9/30/15

9/30/17

48

SECARB Phase III: Tasks & Schedule

Task

Site Permitting (TASK 3.0)

Subtask 3.1: Permitting for the Early Test Site

Subtask 3.2: Permitting for the Anthropogenic Test Site

Site Characterization and Modeling (TASK 4.0)

Subtask 4.1: Site Characterization and Modeling for the Early Test Site

Subtask 4.2: Site Characterization and Modeling for the Anthropogenic Test Site

Well Drilling and Completion (TASK 5.0)

Subtask 5.1: Early Test Site Well Drilling and Completion

Subtask 5.2: Anthropogenic Test Well Drilling and Completion

Infrastructure Development (TASK 6.0)

Subtask 6.1: Early Test Site Infrastructure Development

Subtask 6.2: Anthropogenic Test Site Infrastructure Development

CO2 Procurement (TASK 7.0)

Subtask 7.1: Early Test CO2 Procurement

Subtask 7.2: Anthropogenic Test CO2 Procurement

Transportation and Injection Operations (TASK 8.0)

Subtask 8.1: Early Test CO2 Transportation and Injection Operations

Subtask 8.2: Anthropogenic Test CO2 Transportation and Injection Operations

Operational Monitoring and Modeling (TASK 9.0)

Subtask 9.1: Early Test Operational Monitoring and Modeling

Subtask 9.2: Anthropogenic Test Operational Monitoring and Modeling

All tasks are on schedule and budget.

Start

10/1/07

10/1/07

10/1/10

9/28/08

9/28/08

10/1/10

9/30/09

9/30/09

1/1/11

11/15/07

11/15/07

4/1/10

7/7/07

7/7/07

1/1/09

10/1/07

10/1/07

1/1/09

10/1/07

10/1/07

10/1/09

End

6/30/11

5/15/09

6/30/11

12/15/11

12/15/11

7/31/11

9/30/11

5/21/10

9/30/11

9/30/11

1/30/11

9/30/11

2/28/11

1/30/11

2/28/11

3/31/14

1/30/11

3/31/14

3/31/15

1/30/11

3/31/15

49

SECARB Phase III: Tasks & Schedule

All tasks are on schedule and budget.

Task

Site Closure (TASK 10.0)

Subtask 10.1: Cranfield Test Discontinuation

Subtask 10.2: Anthropogenic Test Site Closure

Post-Injection Monitoring and Modeling (TASK 11.0)

Subtask 11.1: Early Test Post-Injection Monitoring and Modeling

Subtask 11.2: Anthropogenic Test Post-Injection Monitoring and Modeling

Project Assessment (TASK 12.0)

Subtask 12.1: Early Test Project Assessment

Subtask 12.2: Anthropogenic Test Project Assessment

Subtask 12.3: Regional Project Assessment

Project Management (TASK 13.0)

Subtask 13.1: Project Management - GCCC

Subtask 13.2: Project Management - EPRI

Subtask 13.3: Project Management - SSEB

Preliminary Evaluation of Offshore Transport and Storage of CO2 (TASK 15.0)

Subtask 15.1: Offshore Gulf of Mexico Resource Mapping - Federal Waters

Subtask 15.2: Offshore Gulf of Mexico Resource Mapping - State Waters - Florida

Panhandle, Alabama, Mississippi, and Louisiana

Subtask 15.3: Legal and Regulatory Structures and Opportunities

Start

10/1/07

10/1/07

10/1/15

6/15/09

6/15/09

6/1/15

10/1/07

4/1/08

10/1/10

10/1/07

10/1/07

10/1/07

10/1/07

10/1/07

10/1/09

10/1/09

10/1/09

10/1/09

End

3/31/17

10/30/13

3/31/17

3/31/17

9/30/14

3/31/17

7/30/17

9/15/15

7/30/17

7/30/17

10/31/17

7/30/17

7/30/17

10/31/17

9/30/11

9/30/10

9/30/10

9/30/11

50