Chapter 11

advertisement

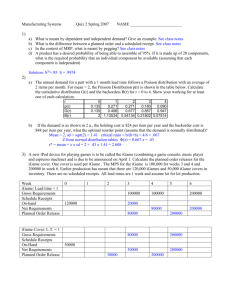

Example: MRP Schedule LocoMopeds is a manufacturer of off-road mopeds. The following product structure diagram represents the bill of materials for its dual-carburetor Model 442 moped. MOPED Level 0 Level 1 Level 2 ENGINE ASSEMBLY MOTOR GAS TANK CARBURETOR (2) WHEEL ASSEMBLY (2) HUB ASSEMBLY FRAME TIRE 1 Example: MRP Schedule Bill of Material Parent Code Component Code Level Code Compon. Req’d Description 442 0 #442 Moped 442 EA GT WA F 1 1 1 1 Engine Assem. Gas Tank Wheel Assem. Frame 1 1 2 1 EA M C 2 2 Motor Carburetor 1 2 WA HA T 2 2 Hub Assem. Tire 1 1 2 Example: MRP Schedule Inventory Status Report Item Code OnHand Safety Stock Lot Size Lead Time Sched. Receipts Qnty. Week 442 500 200 LFL 1 -- -- EA 300 100 500 1 1000 10 GT 600 200 LFL 2 900 10 WA 500 400 500 1 2000 10 F 600 0 2000 3 2000 10 M 250 0 LFL 1 -- -- C 150 100 2000+ 2 -- -- HA 100 0 LFL 1 2400 11 T 500 500 1000 3 3000,2000 11,12 3 Example: MRP Schedule The company is currently planning production for weeks 10 through 16. Based on existing orders and demand forecasts, the master production schedule is as follows: Master Production Schedule: #442 Moped WEEK 10 11 12 13 14 15 16 QUANTITY 0 1000 0 1300 800 1200 1400 Determine the MRP schedule required to support the master production schedule for the Model 442 moped in weeks 10-16. 4 Example: MRP Schedule MRP Schedule for #442 Mopeds for Weeks 10 - 16, considering that: Gross Requirements come from the moped MPS There is an On-Hand balance of 500 mopeds at the end of week 9 There are no Scheduled Receipts for mopeds A lot-for-lot rule is used for ordering mopeds Safety stock of 200 mopeds is desired Lead time for mopeds is one week 5 Example: MRP Schedule MRP Schedule for #442 Mopeds . . . Initially ITEM: 442 MOPED LOT SIZE: LFL LT: 1 SS: 200 GROSS REQUIREMENTS WEEK 10 11 12 0 1000 0 13 14 15 16 1300 800 1200 1400 SCHEDULED RECEIPTS AVAILABLE (ON-HAND = 500) NET REQUIREMENTS PLANNED ORDER RECEIPTS PLANNED ORDER RELEASES 6 Example: MRP Schedule MRP Schedule for #442 Mopeds . . . Completed ITEM: 442 MOPED LOT SIZE: LFL LT: 1 SS: 200 WEEK 10 11 12 0 1300 0 (ON-HAND = 500) 300 300 0 GROSS REQUIREMENTS 13 14 15 16 1300 800 1200 1400 SCHEDULED RECEIPTS AVAILABLE 0 0 0 0 NET REQUIREMENTS 1000 1300 800 1200 1400 PLANNED ORDER RECEIPTS 1000 1300 800 1200 1400 PLANNED ORDER RELEASES 1000 1300 800 1200 1400 7 Example: MRP Schedule MRP Schedule for Gas Tanks for Weeks 10 - 16, considering that: Gross Requirements come from moped PlannedOrder-Releases There is an On-Hand balance of 600 gas tanks at the end of week 9 There is a Scheduled Receipt for 900 tanks in week 10 A lot-for-lot rule is used for ordering gas tanks Safety stock of 200 gas tanks is desired Lead time for gas tanks is two weeks 8 Example: MRP Schedule MRP Schedule for Gas Tanks . . . Initially ITEM: GAS TANK LOT SIZE: LFL LT: 2 SS: 200 WEEK 10 11 GROSS REQUIREMENTS 1000 0 SCHEDULED RECEIPTS 900 AVAILABLE 12 13 14 15 1300 800 1200 1400 16 0 (ON-HAND = 600) NET REQUIREMENTS PLANNED ORDER RECEIPTS PLANNED ORDER RELEASES 9 Example: MRP Schedule MRP Schedule for Gas Tanks . . . Completed ITEM: GAS TANK LOT SIZE: LFL LT: 2 SS: 200 WEEK 10 11 GROSS REQUIREMENTS 1000 0 SCHEDULED RECEIPTS 900 AVAILABLE 12 13 14 15 1300 800 1200 1400 (ON-HAND = 600) 1300 300 300 0 0 0 NET REQUIREMENTS 1000 800 1200 1400 PLANNED ORDER RECEIPTS 1000 800 1200 1400 PLANNED ORDER RELEASES 16 0 0 1000 800 1200 1400 10 Example: MRP Schedule MRP Schedule for Frames for Weeks 10 - 16, considering that: Gross Requirements come from moped PlannedOrder-Releases There is an On-Hand balance of 600 frames at the end of week 9 There is a Scheduled Receipt for 2000 frames in week 10 The firm uses a Lot Size (multiple) of 2000 for ordering frames No safety stock of frames is desired Lead time for frames is 3 weeks 11 Example: MRP Schedule MRP Schedule for Frames . . . Initially ITEM: FRAME LOT SIZE: 2000 LT: 3 SS: 0 WEEK 10 11 GROSS REQUIREMENTS 1000 0 SCHEDULED RECEIPTS 2000 AVAILABLE 12 13 14 15 1300 800 1200 1400 16 0 600 NET REQUIREMENTS PLANNED ORDER RECEIPTS PLANNED ORDER RELEASES 12 Example: MRP Schedule MRP Schedule for Frames . . . Completed ITEM: FRAME LOT SIZE: 2000 LT: 3 SS: 0 WEEK 10 11 GROSS REQUIREMENTS 1000 0 SCHEDULED RECEIPTS 2000 AVAILABLE 12 13 14 15 1300 800 1200 1400 16 0 (ON-HAND = 600) 1600 1600 1600 300 1500 300 900 NET REQUIREMENTS 0 0 0 PLANNED ORDER RECEIPTS PLANNED ORDER RELEASES 500 2000 2000 0 1100 0 2000 2000 13 Example: MRP Schedule MRP Schedule for Engine Assemblies for Weeks 10 16, considering that: Gross Requirements come from moped PlannedOrder-Releases There is an On-Hand balance of 300 engine assemblies at the end of week 9 There is a Scheduled Receipt for 1000 engine assemblies in week 10 The firm uses a Lot Size (multiple) of 500 for ordering engine assemblies Safety Stock of 100 engine assemblies is desired Lead time for engine assemblies is 1 week 14 Example: MRP Schedule MRP Schedule for Engine Assemblies . . . Initially ITEM: ENGINE ASSEM. LT: 1 LOT SIZE: 500 SS: 100 WEEK 10 11 GROSS REQUIREMENTS 1000 0 SCHEDULED RECEIPTS 1000 AVAILABLE 12 13 14 15 1300 800 1200 1400 16 0 (ON-HAND = 300) NET REQUIREMENTS PLANNED ORDER RECEIPTS PLANNED ORDER RELEASES 15 Example: MRP Schedule MRP Schedule for Engine Assemblies . . . Completed ITEM: ENGINE ASSEM. LT: 1 LOT SIZE: 500 SS: 100 WEEK 10 11 GROSS REQUIREMENTS 1000 0 SCHEDULED RECEIPTS 1000 AVAILABLE (ON-HAND = 300) 200 200 12 13 14 15 1300 800 1200 1400 0 200 400 100 400 0 NET REQUIREMENTS 1100 400 1100 1000 PLANNED ORDER RECEIPTS 1500 500 1500 1000 PLANNED ORDER RELEASES 16 1500 500 1500 1000 16 Example: MRP Schedule MRP Schedule for Motors for Weeks 10 - 16, considering that: Gross Requirements come from engine assembly Planned-Order-Releases There is an On-Hand balance of 250 motors at the end of week 9 There are no Scheduled Receipts for motors A lot-for-lot rule is used for ordering motors No Safety Stock of motors is desired Lead time for motors is 1 week 17 Example: MRP Schedule MRP Schedule for Motors . . . Initially ITEM: MOTOR LOT SIZE: LFL LT: 1 SS: 0 GROSS REQUIREMENTS WEEK 10 11 12 13 14 15 16 1500 500 1500 1000 SCHEDULED RECEIPTS AVAILABLE (ON-HAND = 250) NET REQUIREMENTS PLANNED ORDER RECEIPTS PLANNED ORDER RELEASES 18 Example: MRP Schedule MRP Schedule for Motors . . . Completed ITEM: MOTOR LOT SIZE: LFL LT: 1 SS: 0 GROSS REQUIREMENTS WEEK 10 11 12 13 14 15 16 0 0 1500 500 1500 1000 SCHEDULED RECEIPTS AVAILABLE (ON-HAND = 250) 250 250 0 0 0 NET REQUIREMENTS 1250 500 1500 1000 PLANNED ORDER RECEIPTS 1250 500 1500 1000 PLANNED ORDER RELEASES 1250 500 1500 1000 19 Example: MRP Schedule MRP Schedule for Carburetors for Weeks 10 - 16, considering that: Gross Requirements come from engine assembly Planned-Order-Releases (times 2) There is an On-Hand balance of 150 carburetors at the end of week 9 There are no Scheduled Receipts for carburetors A Lot Size of 200+ is used for ordering carburetors Safety Stock of 100 carburetors is desired Lead time for carburetors is 2 weeks 20 Example: MRP Schedule MRP Schedule for Carburetors . . . Initially ITEM: CARBURETOR LOT SIZE: 2000+ LT: 2 SS: 100 GROSS REQUIREMENTS WEEK 10 11 12 13 14 15 16 3000 1000 3000 2000 SCHEDULED RECEIPTS AVAILABLE (ON-HAND = 150) NET REQUIREMENTS PLANNED ORDER RECEIPTS PLANNED ORDER RELEASES 21 Example: MRP Schedule MRP Schedule for Carburetors . . . Completed ITEM: CARBURETOR LOT SIZE: 2500+ LT: 2 SS: 100 WEEK 10 11 12 13 14 GROSS REQUIREMENTS 3000 1000 3000 2000 SCHEDULED RECEIPTS 3000 AVAILABLE (ON-HAND = 150) 16 50 3050 50 1550 1050 1550 1550 NET REQUIREMENTS 950 1450 950 PLANNED ORDER RECEIPTS 2500 2500 2500 PLANNED ORDER RELEASES 15 2500 2500 2500 22 Example: MRP Schedule MRP Schedule for Wheel Assemblies for Weeks 10 16, considering that: Gross Requirements come from moped PlannedOrder-Releases (times 2) There is an On-Hand balance of 500 wheel assemblies at the end of week 9 There is a Scheduled Receipt for 2000 wheel assemblies in week 10 A Lot Size (multiple) of 500 is used for ordering wheel assemblies Safety Stock of 400 wheel assemblies is desired Lead time for wheel assemblies is 1 week 23 Example: MRP Schedule MRP Schedule for Wheel Assemblies . . . Initially ITEM: WHEEL ASSEM. LT: 1 LOT SIZE: 500 SS: 400 WEEK 10 11 GROSS REQUIREMENTS 2000 0 SCHEDULED RECEIPTS 2000 AVAILABLE 12 13 14 15 2600 1600 2400 2800 16 0 (ON-HAND = 500) NET REQUIREMENTS PLANNED ORDER RECEIPTS PLANNED ORDER RELEASES 24 Example: MRP Schedule MRP Schedule for Wheel Assemblies . . . Completed ITEM: WHEEL ASSEM. LT: 1 LOT SIZE: 500 SS: 400 WEEK 10 11 GROSS REQUIREMENTS 2000 0 SCHEDULED RECEIPTS 2000 AVAILABLE 2100 100 100 (ON-HAND = 500) 12 13 14 15 2600 1600 2400 2800 0 400 0 NET REQUIREMENTS 2500 1600 2000 2800 PLANNED ORDER RECEIPTS 2500 2000 2000 3000 PLANNED ORDER RELEASES 16 0 200 2500 2000 2000 3000 25 Example: MRP Schedule MRP Schedule for Hub Assemblies for Weeks 10 - 16, considering that: Gross Requirements come from wheel assembly Planned-Order-Releases There is an On-Hand balance of 100 hub assemblies at the end of week 9 There is a Scheduled Receipt of 2400 hub assemblies in week 11 A lot-for-lot rule is used for ordering hub assemblies No Safety Stock of hub assemblies is desired Lead time for hub assemblies is 1 week 26 Example: MRP Schedule MRP Schedule for Hub Assemblies . . . Initially ITEM: HUB ASSEM. LOT SIZE: LFL LT: 1 SS: 0 GROSS REQUIREMENTS SCHEDULED RECEIPTS AVAILABLE WEEK 10 0 11 12 13 14 2500 2000 2000 3000 15 16 0 0 2400 (ON-HAND = 100) NET REQUIREMENTS PLANNED ORDER RECEIPTS PLANNED ORDER RELEASES 27 Example: MRP Schedule MRP Schedule for Hub Assemblies . . . Completed ITEM: HUB ASSEM. LOT SIZE: LFL LT: 1 SS: 0 GROSS REQUIREMENTS SCHEDULED RECEIPTS AVAILABLE (ON-HAND = 100) WEEK 10 0 11 12 13 14 2500 2000 2000 3000 16 0 0 0 0 2400 100 2500 0 0 0 NET REQUIREMENTS 2000 2000 3000 PLANNED ORDER RECEIPTS 2000 2000 3000 PLANNED ORDER RELEASES 15 2000 2000 3000 28 Example: MRP Schedule MRP Schedule for Tires for Weeks 10 - 16, considering that: Gross Requirements come from wheel assembly Planned-Order-Releases There is an On-Hand balance of 500 tires at the end of week 9 There are Scheduled Receipts for 3000 and 2000 tires weeks 11 and 12, respectively A Lot Size (multiple) of 1000 is used for ordering tires Safety Stock of 500 tires is desired Lead time for tires is 3 weeks 29 Example: MRP Schedule MRP Schedule for Tires . . . Initially ITEM: TIRE LOT SIZE: 1000 LT: 3 SS: 500 GROSS REQUIREMENTS SCHEDULED RECEIPTS AVAILABLE WEEK 10 0 11 12 13 14 2500 2000 2000 3000 15 16 0 0 3000 2000 (ON-HAND = 500) NET REQUIREMENTS PLANNED ORDER RECEIPTS PLANNED ORDER RELEASES 30 Example: MRP Schedule MRP Schedule for Tires . . . Completed ITEM: TIRE LOT SIZE: 1000 LT: 3 SS: 500 GROSS REQUIREMENTS WEEK 10 0 (ON-HAND = 500) 12 13 14 2500 2000 2000 3000 0 3000 2500 500 16 0 0 500 500 500 NET REQUIREMENTS 1500 2500 PLANNED ORDER RECEIPTS 2000 3000 PLANNED ORDER RELEASES 15 3000 2000 SCHEDULED RECEIPTS AVAILABLE 11 2000 3000 31 Issues in MRP Management Commitment User involvement Education and training Selection of S/W packages Data accuracy Realistic MPS Realistic lead times Maintaining accurate BOM files 32 Lot-Sizing in MRP Lot-size is the quantity ordered/produced at one time Large lots are preferred because: Changeovers cost less and capacity greater Annual cost of purchase orders less Price breaks and transportation breaks can be utilized Small lots are preferred because: Lower inventory carrying cost Reduced risk of obsolescence Shorter cycle time to produce customer order 33 Lot-Sizing Methods in MRP Economic Order Quantity (EOQ) does not consider quantity discounts does not always provide the most economical approach with lumpy demands Lot-for-Lot (LFL) accommodates lumpy demand Period Order Quantity (POQ) Many others 34 Lot-Sizing Methods in MRP The best lot-sizing method, resulting in least cost, depends on cost and demand patterns 35 Lot-Sizing in MRP Lot-size is the quantity ordered/produced at one time Large lots are preferred because: Changeovers cost less and capacity greater Annual cost of purchase orders less Price breaks and transportation breaks can be utilized Small lots are preferred because: Lower inventory carrying cost Reduced risk of obsolescence Shorter cycle time to produce customer order 36 Lot-Sizing Methods Economic Order Quantity (EOQ) does not consider quantity discounts does not always provide the most economical approach with lumpy demand Lot-for-Lot (LFL) accommodates lumpy demand Period Order Quantity (POQ) The best method, resulting in least cost, depends on cost and demand patterns. 37 Evaluation of MRP Most beneficial to process-focused systems that have long processing times and complex multistage production steps Lead times must be reliable Must freeze MPS for some time before actual production... certain demand Difficult to implement 38 Closed Loop MRP Production Planning Master Production Scheduling Material Requirements Planning Capacity Requirements Planning No Feedback Realistic? Feedback Yes Execute: Capacity Plans Material Plans 39 Closed Loop MRP Materials Management at Washburn Guitar, Inc. 40 Manufacturing Resource Planning (MRP II) Goal: Plan and monitor all resources of a manufacturing firm (closed loop): Manufacturing Marketing Finance Engineering Shop-floor control Simulation capability of the manufacturing system 41 Enterprise Resource Planning (ERP) ERP systems available today integrate manufacturing with other functional areas in an organization ERP systems make it easier for management to obtain local information about performance of specific processes, bottlenecks resources, and products (or product groups), etc. Class I ERP software packages (for large companies) include BAAN, SAP, and Oracle 42 MRP II System MRP II System 43 MRP I to MRP II MRP I simply exploded demand (MPS) into required materials MRP II became Manufacturing Resource Planning which provides a closed-loop business management system Financial management Shop floor control Operations management Simulation capability 44 Capacity Requirements Planning (CRP) 45 Capacity Requirements Planning (CRP) Tests MPS for feasibility Utilizes routings to determine labor/machine loads If schedule feasible, recommends freezing If schedule overloads resources, points out processes that are overscheduled 46 Load Schedules Compares actual labor and machine hours against available hours Offsets schedules between successive stages of production by lead times Provides feasible MPS and economically loaded work centers Promotes system operating efficiency ... lowers costs! 47 World-Class Practice Lead times respond to conditions Product development as levels of product structure tree Lead times that adjust to load MRP reports shared with customers and suppliers 48