ELiTES_2013_Hofmann

advertisement

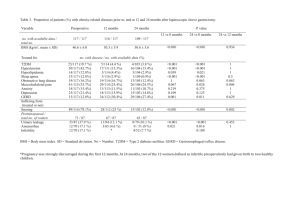

Mechanical Loss and Thermal Conductivity of Materials for KAGRA and ET Gerd Hofmann1, Julius Komma1, Christian Schwarz1, Daniel Heinert1, Paul Seidel1, Andreas Tünnermann2, and Ronny Nawrodt1 1Friedrich-Schiller-Universität Jena, Institute for Solid State Physics, Helmholtzweg 5, D-07743 Jena, Germany 2Friedrich-Schiller-Universität Jena, Institute of Applied Physics, Albert-Einstein-Strasse 15, D-07745 Jena, Germany April 19th 2013 ELiTES Workshop, Tokyo Friedrich-Schiller-Universität Jena Outline • Test mass materials for future GWDs – Fused silica – state of the art, certainly at RT (optics & suspension) – Silicon ET – Sapphire KAGRA • Bulk loss of silicon & sapphire vs. fused silica • Mechanical loss of sapphire fibers for suspension – Different lengths, single vs. double head • Thermal conductivity of sapphire fibers • Summary & Outlook Gerd Hofmann ELiTES Workshop, Tokyo, 19th April 2013 2 / XX MECHANICAL LOSS Friedrich-Schiller-Universität Jena Basic layout of an interferometric GWD • Extremely sensitive Michelson interferometer, several noise sources • Main topic: Brownian thermal noise arising from the mechanical loss of the materials (currently fused silica) for the optics, the test masses, and their suspensions. Gerd Hofmann ELiTES Workshop, Tokyo, 19th April 2013 4 / XX Friedrich-Schiller-Universität Jena The mechanical loss of fused silica strongly increases when being cooled down. Much more suitable are single crystalline materials like silicon or sapphire. For KAGRA, IMs and EMs will be made of sapphire. In ET-LF they will be made of silicon. Gerd Hofmann mechanical loss Mechanical loss of fused silica vs. silicon & sapphire 10 -2 10 -3 10 -4 10 -5 10 -6 10 -7 10 -8 10 -9 fused silica silicon sapphire 0 30 60 90 120 150 180 210 240 270 300 temperature in K [R. Nawrodt et al.: Cryogenic Setup for Q-factor measurements on bulk materials for future gravitational wave detectors, in Proceedings of ICEC22-ICMC2008 (2009)] ELiTES Workshop, Tokyo, 19th April 2013 5 / XX Friedrich-Schiller-Universität Jena mechanical loss Measured mechanical loss of sapphire Ø 3“ x 24mm 2x10 -7 10 -7 10 -8 10 32.3 kHz 36.2 kHz 50.8 kHz -9 0 30 60 90 120 150 180 210 240 270 300 330 temperature T in K At 20 K we achieved a loss of 10−8 . Our measurements reveal a loss peak at 35 K for all the measured modes. Gerd Hofmann ELiTES Workshop, Tokyo, 19th April 2013 6 / XX Friedrich-Schiller-Universität Jena Akhiezer damping in bulk sapphire Loss peak at 35 K is linked to Akhiezer loss (interaction of acoustic and thermal phonons) as follows: 10 𝜙= 𝜔𝜏𝑝 𝑇𝐶𝛾 2 𝜈2 1+ 𝜔𝜏𝑝 2 where 𝜏𝑝 = 3𝜅 . 𝐶𝜌𝜈2 [A. Akhieser: On the absorption of sound in solids. Journal of Physics (1939)] [V. B. Braginskyet al.: Systems with Small Dissipation.The University of Chicago Press, Chicago and London (1985)] 𝐶… heat capacity, 𝛾… Grüneisen‘s constant, 𝜈… solid‘s speed of sound, 𝜏𝑝 … lifetime of thermal phonons, mechanical loss -6 32.3 kHz 36.2 kHz 50.8 kHz 10 -7 10 -8 10 -9 0 30 𝜅… heat conductivity, and 𝜌… density of material. 60 90 120 150 temperature T in K Akhiezer loss can not be overcome thus it is an intrinsic limit. Gerd Hofmann ELiTES Workshop, Tokyo, 19th April 2013 7 / XX Friedrich-Schiller-Universität Jena Sapphire fibers measured in Jena • MolTech fibers (4 in total) – single nail head with flat Ø 10 mm x 5 mm – fiber Ø 1.8 mm – 1 unbroken (350 mm) – 1 broken (86 mm & 264 mm) • Impex fibers (5 in total) – double nail head Ø 10 mm x 5 mm – fiber Ø 1.6 mm – total lenght 100 mm Gerd Hofmann ELiTES Workshop, Tokyo, 19th April 2013 8 / XX Friedrich-Schiller-Universität Jena Measurement setup • Use of massive cooper supports and clamps: • Flat drill hole vs. Cone drill hole • Electrostatic driving plates for excitation • Optical readout by use of shaddow sensor • Ring down technique • Liquid helium cryostat 𝑇 = 5 … 300 K Gerd Hofmann ELiTES Workshop, Tokyo, 19th April 2013 9 / XX Friedrich-Schiller-Universität Jena mechanical loss MolTech fiber Ø 1.8 mm x 350 mm, clamped in cone 10 -4 10 -5 10 -6 10 -7 1217 Hz TED 10 -8 0 30 60 90 120 150 180 210 240 270 300 330 temperature T in K • Lowest obtained loss on sapphire fiber so far: 5 × 10−8 • Thermo elastic damping (TED) above 60 K Gerd Hofmann ELiTES Workshop, Tokyo, 19th April 2013 10 / XX Friedrich-Schiller-Universität Jena Thermo elastic damping in sapphire fibers Thermo elastic damping (TED) occurs from irreversible heat flow between compressed and strechted areas of the fiber. The loss is given by: 𝑌𝑇 𝜔𝜏 𝑇𝐸 𝜙= 𝜌𝐶 1 + 𝜔𝜏 𝜏 𝑇𝐸 2 1 𝜌𝐶𝑑 = 2.16 × 2𝜋 𝜅 [C. Zener : Internal Friction in Solids: I. Theory of Internal Friction in Reeds. Physical Review 52 (1937)] [C. Zener : Internal Friction of Solids: II.General Theory of Thermoelastic Internal Friction. Physical Review 53 (1938)] 𝑌… Young‘s Modulus, 𝜏 𝑇𝐸 …characteristic time, 𝑑… diamter of the fiber Gerd Hofmann ELiTES Workshop, Tokyo, 19th April 2013 11 / XX Friedrich-Schiller-Universität Jena Impex fiber No.3, attached head clamped in cone Mechanical loss 10 -3 10 -4 10 -5 10 -6 10 -7 87Hz 1240Hz 3676Hz 35132Hz 0 30 60 90 120 150 180 210 240 270 300 Temperature in K • Again: TED above 60 K seems to limit the loss • Low temperature behaviour is not cleared and under investigation Gerd Hofmann ELiTES Workshop, Tokyo, 19th April 2013 12 / XX THERMAL CONDUCTIVITY Friedrich-Schiller-Universität Jena Thermal conductivity measurement • Measured with the broken piece of MolTech fiber: – Ø 1.8 mm – 264 mm in length • Copper clamps to attach – the heater – the sensors – the heat sink Gerd Hofmann ELiTES Workshop, Tokyo, 19th April 2013 14 / XX Friedrich-Schiller-Universität Jena Setup and measurement procedure THeater Distance: 10…200 mm T1 T2 THeat Sink Gerd Hofmann 𝐴 𝑃 = 𝜅Δ𝑇 𝐿 𝜅 … therm. conductivity A … cross section P … electr. power 𝐿 𝑑𝑃 𝜅= 𝐴 𝑑𝑇 L … temp-sensor distance Δ𝑇 … temp. difference Measurement Procedure: #1 – Wait until all sensors are in thermal equilibrium #2 – Set a given Heater Power and wait until all sensors reach thermal equilibrium again #3 – Repeat #2 until a maximum given temperature difference between T1 and T2 is reached #4 – Plot T1-T2 vs. PHeater + linear fit of the data ELiTES Workshop, Tokyo, 19th April 2013 15 / XX Friedrich-Schiller-Universität Jena Thermal conductivity of sapphire 30000 Thermal Conductivity [W/mK] 10000 1000 100 1.8mm dia, 168mm length, MolTec-Fibre (Jena) 1.55mm dia, 60mm length, unpolished (Touloukian) 2.47mm dia, 60mm length, unpolished, annealed 2.52mm dia, 60mm length, polished, annealed recommended values for bulk sapphire 10 1 10 100 1000 Temperature [K] • Thermal conductivity of the fiber is clearly different to that of bulk sapphire • Surface and also heat treatment might change the thermal conductivity Gerd Hofmann ELiTES Workshop, Tokyo, 19th April 2013 16 / XX Friedrich-Schiller-Universität Jena Heat extraction from fibers • If we asume – – – – L = 30 cm, Ø 1.8 mm Test mass TM 20K Upper mass UM 16K Thermal conductivity of k 2 x 10^3 W/m/K • Heat extraction of one fiber: 𝐴𝑤 𝑄= 𝑘 𝑇𝑇𝑀 − 𝑇𝑈𝑀 ≈ 200𝑚𝑊 𝐿 • Around 1 W of extracted heat is desirable for KAGRA, but with fibers of Ø 1.6 mm • Futher investigations are needed! Gerd Hofmann ELiTES Workshop, Tokyo, 19th April 2013 17 / XX Friedrich-Schiller-Universität Jena Summary • Cooling of the test masses and suspensions will reduce brownian thermal noise in future GWDs using silicon or sapphire • Bulk sapphire is limited by phonon-phonon-interaction at the desired temperature of 20 K (𝜙𝑏𝑢𝑙𝑘 ≈ 10−8 ) • Above 60 K TED limits the loss of sapphire fibers Losses of better than 𝜙𝑓𝑖𝑏𝑒𝑟 ≈ 10−7 are achieved below 10 K • Heat extraction by suspension fibers needs to be slightly improved Nevertheless: Sapphire will fulfill the requirements for KAGRA Gerd Hofmann ELiTES Workshop, Tokyo, 19th April 2013 18 / XX