Présentation PowerPoint

advertisement

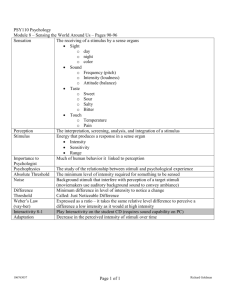

Interpretation of indicators in industry Reunión Técnica de Trabajo del Proyecto BIEE 24 – 26 de febrero, 2014, San José, Costa Rica Bruno Lapillonne, Vice President, Enerdata Outline 1. Overall trends 2. Analysis by branch 3. Effect of structural changes Contents 1. Overall trends a. Energy consumption, value added and production index , (2000-2010) selection of period of analysis b. Energy intensity of industry and manufacturing (annual variation by period) c. Breakdown of consumption by industrial branch (2000 - 2010) (for the 5 main branches) Trends in energy consumption and value added in industry: case of Chile industry= manufacturing + mining + construction Trends in energy consumption and value added (2000=100) 140 135 Indice 2000=100 130 125 120 115 110 105 100 2000 2001 2002 2003 Consumo Energía Industria 2004 2005 2006 2007 Valor agregado Industria Source: BIEE, Ministerio de Energía de Chile 2008 2009 2010 2011 Valor Agregado Manufactura Trends in energy intensity of industry: identification of homogeneous periods for analysis: case of Chile Energy intensities of industry, manufacturing and mining 1.20 1.00 koe/ k$2003 0.80 0.60 0.40 0.20 0.00 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 Intensidad Industria Intensidad Manufactura Source: BIEE, Ministerio de Energía de Chile Intensidad Minería Trends in energy intensity of industry: analysis by period : case of Chile Annual variation in energy intensities of industry, manufacturing and mining (%/year) 8.0% 6.0% 4.0% 2.0% 0.0% 2000-2005 2005-2010 2000-2011 -2.0% -4.0% -6.0% Intensidad Industria Intensidad Manufactura Source: BIEE, Ministerio de Energía de Chile Intensidad Minería Trends in energy intensity of manufacturing industry: analysis by period : case of Brazil 1990-1999: inflation control and economic development in Brazil 1999-2001: significant decrease (electricity crisis and rationing) 2001-2007: recovery period and new projects in industry 2007-2009: impacts of the global economic crisis) 2009-2012: large projects for steel, bauxite, alumina and pulp production Choice of period for analysis: case of Brazil 2.0% 1.5% 1.0% 0.5% 1.6% 1.4% 1.2% 0.9% 0.0% -0.5% 1990-1999 -1.0% 1999-2001 -0.8% 2001-2007 2007-2009 -1.7% -1.5% -2.0% Source: EPE Source: BIEE, Ministerio de Energía de Chile 2009-2012 1990-2012 Breakdown of the energy consumption by industrial branch: case of Brazil Increasing relative share of food industry: sugar, processed and frozen products; Decreasing share of primary metals and chemicals (less investments and more imports) Energy consumption of manufacturing by sub-sector in Brazil 2000 Food 2012 Textile 9% 21% 2% 35% 11% 5% 6% Paper 9% 11% 28% Cement 29% 6% 6% 9% Chemicals 1% 12% Ceramics Primary metals including iron-alloys Other manufacturing Source: BIEE EPE 8 Outline 1. Main trends 2. Analysis by branch 3. Effect of structural changes Content Objective: o Show trends in energy efficiency by focusing on main energy intensive products (cement, steel, paper, copper,etc..) o Show trends in energy intensities by sub-sector (textiles, chemicals, food,etc..). Content o Specific consumption of energy-intensive products (cement, steel, paper) o Energy intensity by branch (2000 and 2010); 10 Specific energy consumption of energy intensive products: case of Chile Copper is very intensive in Chile and its specific energy consumption is increasing due to less concentrated ores Using a double scale or showing each product separately enables to better see the trends by product Specific energy consumption (toe/ton) 0.700 0.600 Toe/ ton 0.500 0.400 0.300 0.200 0.100 0.000 2000 2001 2002 Intensidad Papel y celulosa 2003 2004 2005 Intensidad Acero Source: BIEE, Ministerio de Energía de Chile 2006 2007 Intensidad Cemento 2008 2009 2010 Intensidad Cobre Specific energy consumption of steel in Brazil Decreasing specific energy consumption of steel 0.700 0.600 toe/tonne 0.500 0.400 0.300 0.200 0.100 0.000 Steel 1990 Source: EPE 2000 Source: BIEE/EPE 2010 2012 Specific energy consumption of cement in Brazil toe/tonne Decreasing specific energy consumption of cement until 2010 0.100 0.090 0.080 0.070 0.060 0.050 0.040 0.030 0.020 0.010 0.000 Cement 1990 2000 Source: BIEE/EPE 2010 2012 13 Trends in the energy intensity by industrial branch : case of Uruguay Increases in the energy intensity of all branches in Uruguay Energy intensity by branch (unit koe per € 2000) (Uruguay) 0.07 0.06 2000 2010 0.05 0.04 0.03 0.02 0.01 0 Source: BIEE, MIEM/ DNE Medener 14 Outline 1. Main trends 2. Analysis by branch 3. Effect of structural changes Content Objectives: Analyze the effect of changes in industrial specialization on the energy intensity (role of structural effects), first at the manufacturing level and for industry as whole Content: o Change in industrial structure: breakdown of value added by branch (2000 and 2010); o Relative levels of energy intensity of the branches o Intensity at constant structure 16 Structural changes in manufacturing industry: case of Chile Value added structure by industrial branch in Chile 2000 2011 Alimentos, bebidas y tabaco Textil, prendas de vestir y cuero 13% 13% 29% 8% 32% 8% Maderas y muebles Papel e imprentas 6% 27% 7% 10% 25% 4% 6% 12% Source: BIEE, Ministerio de Energía de Chile Química, petróleo, caucho y plástico Minerales no metálicos y metálica básica Productos metálicos, maquinaria y equipos y otros Relative levels of energy intensity by branch Paper and non metallic minerals are 15 to 20 times more energy intensive than machinery in Uruguay Food, textile and chemicals very similar ~ 4 times more energy intensive than machinery 20 18 16 14 12 10 8 6 4 2 0 Energy intensity by branch (relative value: machinery=1) (Uruguay) 2010 Medener 18 Calculation of an intensity at constant structure to measure the impact of structural changes in industry or manufacturing To quantify the impact of structural changes on the energy intensity of manufacturing industry, the usual approach is to calculate a fictive energy intensity at constant structure, i.e. assuming that the structure did not change compared to a base year (e.g. 2000). This intensity at constant structure is calculated at year t with the sectoral intensities of year t and the value added structure of manufacturing (i.e. the share of each sub-sector i in the total value added of manufacturing of the base year 0): IEs = (VAi/VA)o * (Ei/VAi)t with : IEs : intensity at constant structure VAi: value added of sub-sector i; VA: total value added of manufacturing; Ei: energy consumption of sub-sector i; o :base year (e.g. 2000) and t: current year 19 Impact of structural changes on manufacturing energy intensity: case of Uruguay Until 2007, effects of structural changes in manufacturing is negligible; after 2007, strong impact Energy intensity of manufacturing: observed and at constant structure in Uruguay 0.0180 0.0160 effects of structural changes 0.0140 0.0120 0.0100 0.0080 0.0060 0.0040 Manufacturing Manufacturing at constant structure Source: MIEM/DNE Impact of structural changes on manufacturing energy intensity: case of Uruguay : summary by period Until 2007, effects of structural changes in manufacturing is negligible; after 2007, around 40% of the increase is due to structural changes (ie 6/16%) Energy intensity of manufacturing 16.0% 12.0% 8.0% 4.0% 40% 0.0% -4.0% 1997-2007 2007-2011 Manufacturing Manufacturing at constant structure Effect of structural changes Source: MIEM/DNE Change in industry value added structure : structural changes : case of Brazil Decreasing share of chemicals and paper but increasing share of food and to a lesser extent of non metallic minerals and basis metals Share of industry value added by branch 100% 80% 60% 40% 20% 9% 6% 8% 13% 12% 14% 33% 29% 27% 32% 2000 2012 0% Food products, beverages and tobacco Chemicals, Chemical products and man-made fibres Non-metallic mineral products Basic metals (steel+non ferrous) + ferroalloys Textile and textile products Pulp, Paper and Paper products; publishing and printing Source: EPE Energy intensity by industrial branch : case of Brazil The branch “primary metals” has the highest energy intensity; it is 13 times more intensive than textiles , followed by paper and pulp ( factor 9 compared to textiles), food and non metallic minerals (factor 4) Energy intensity by branch 2 1.8 2000 ktoe/€$ [2000] 1.6 1.4 1.2 1 0.8 0.6 0.4 0.2 0 Source: EPE 2010 Impact of structural changes on manufacturing energy intensity: case of Brazil Structural changes towards less intensive branches contributed to limit around 50% of the intensity increase 2000-2010 0.80% 0.60% Energy intensity (actual) 0.40% 0.20% Energy intensity at constant structure 0.00% -0.20% -0.40% Energy intensity (actual) Energy intensity at constant structure Structural effects Structural effects 24