Camelback Quarry Management Plan

advertisement

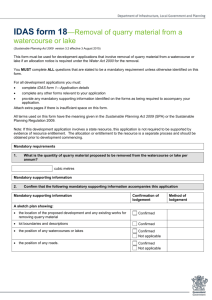

Camelback Quarry Management Plan June 2015 CONTENTS Summary ................................................................................................................................................ 3 Section 1: Introduction ........................................................................................................................ 4 Section 2: Background ......................................................................................................................... 4 Section 3: Financial .............................................................................................................................. 5 Section 4: Performance Measures...................................................................................................... 6 Section 5: Council and Contractor Responsibilities.......................................................................... 6 Section 6: Site Specific Methodology ................................................................................................. 7 Section 9: Quarry Permits and Consents ........................................................................................ 10 Camelback Quarry Management Plan 2015 2 Summary This plan sets out the history and future plans of Camelback so there is a record of any major decisions, expenditure, permits and consents. It identifies the objective of the quarry as well as the methods of monitoring the condition of the quarry and rock, and determines the annual funding and expenditure needed to retain the safest and most cost effective plan possible. Camelback Quarry Management Plan 2015 3 Section 1: Introduction 1.1 Purpose of a Quarry Management Plan This Quarry Management Plan defines the objective and performance standards of Camelback Quarry for which the West Coast Regional Council has the ultimate responsibility. This Quarry Management Plan: - Identifies the service level for the quarry Describes the background of the quarry Describes the methods used to maintain the service level of the quarry Complies with the regulatory requirements of the current Health and Safety in Employment Act/s Regulations thereon and all relevant Permits/Consents. Section 2: Background Camelback Quarry is situated in the north-eastern slope of Mt Camelback, approximately 1 km south-west of the Kowhitirangi Township at the junction of Ford Road and McArthur Road. Mt Camelback is situated in the middle of the Hokitika River flat rising from 100 metres to approximately 1900 metres above mean sea level. Camelback Quarry has been in operation for 45-50 years on a permit area of 10.749 hectares of which is jointly owned by the Regional Council (8.505Ha) and T & C Elcock (2.24Ha). The predominant rock type quarried at Camelback is heavily jointed Limestone and banded calcareous mudstone with well-defined bedding planes with a dip of 10 degrees. The quarry is operated for the exclusive production of Armour Grade Protection Rock (AGPR) ranging from .25 tonne through to rocks with an individual weight of 4.5 tonne plus. Camelback Quarry Management Plan 2015 4 Section 3: Financial 3.1 Direct and Overhead Costs The below costs do not include the “stock adjustment” which is applied when product is sold or quarried. That adjustment reflects the “cost of rock sold” and is not a cost of operating the quarries. The below costs include direct costs and allocated overhead costs. Year To Camelback Quarry Specific Cost 30/06/2006 30/06/2007 30/06/2008 30/06/2009 30/06/2010 30/06/2011 30/06/2012 30/06/2013 30/06/2014 Part Year 31/03/2015 $12,532 $8,665 $19,158 $6,345 $37,320 $203,660 $99,356 $58,123 $688,896 $44,251 Whataroa Quarry Management Plan 2015 5 Section 4: Performance Measures The overall performance measure is to operate Camelback Quarry in the safest and most cost effective manner possible. The following procedures will be adopted to ensure the adequacy of Safety and Efficiency. Annually Rock production meets specific target(s) Procedures meet Health and Safety requirements Performance Measure Waste to rock ratio – 20% waste 80% rock Lost time due to injuries/incidents Random Health and Safety Audits Section 5: Council and Contractor Responsibilities To achieve the primary aim of the Regional Council’s Camelback Quarry it is essential that both the Contractor and Council ensure that all responsibilities under existing Health and Safety in Employment Law and relevant amended acts and regulations are recognized and acted upon. 5.1 Contractor Responsibilities It is expected that the goal of a ‘Zero Harm’ working quarry environment is achievable, operation expediency over safe work practices in WCRC quarries will not be tolerated under any circumstances. It is expected that all contractors operating in WCRC quarries will follow industry accepted best quarry practices at all times. Whataroa Quarry Management Plan 2015 6 Section 6: Site Specific Methodology 6.1 Drill and Blast Methodology The West Coast Regional Council have recently invested a considerable sum in relocating previously inappropriately managed waste material to sites within the quarry where it will not impinge upon continuing quarry operation or cover potential AGPR reserves. The varying width and depth of the bedding planes along with associated jointing means that sections of the available resource may lead to unavoidable variations in waste product/AGPR ratios. The knowledge and experience of the Contractors Quarry Manager will be important in managing these variations. Due to the high Calcium Carbonate content “waste” material (i.e. any rock below .25 tonne) may have some residual value for crusher feed stock at the Limeworks Company currently operating some 300m through the ridge. There is also some limited demand for crushed product for use on dairy farm races and roading projects. These possibilities will be discussed with the directors of this company in the near future. 6.2 Faces and Benches Presently, main bench orientation is east-west with face retreat generally to the south, although at one point approximately midway along the face any further retreat will need to be restricted due to the proximity of the quarry boundary. There is still a very large reserve of rock available on the western aspect of the quarry and benching from the top down will be required to allow safe extraction of this resource. 6.3 Future Approximate Face Heights Face heights in Camelback Quarry will be limited to approximately 7-8m at all times except where the Contractor can clearly demonstrate long term safe and cost effective efficiencies by either increasing or reducing these heights. Camelback Quarry Management Plan 2015 7 6.4 Bunding Recent changes, both pending and actual to Health and Safety in Employment Laws and all acts and regulations thereon have made adequate bunding in Quarries mandatory. This requirement includes all roads, benches, faces and terminal drop-offs where there is a risk of vehicle rollover or falls. The construction of bench edge, tip head and access road bunding will utilize considerable volumes of blast generated waste as a priority over just transporting this material to designated waste dumps. WCRC have determined that the height of these bunds shall be a minimum of atleast 2/3 the height of the largest wheel operating in the quarry. 6.5 Waste Dump Management In the past indiscriminate dumping of waste product has led to benches and faces be covered by large volumes of waste which eventually required costly relocation within the quarry footprint. Waste product should only be handled once in the breakout/loadout cycle and designated dump sites will be marked out by the WCRC Quarry Manager prior to commencement of any quarry activity. At all times waste product should receive as a minimum a track roll as it is being placed and end dumping should also be avoided wherever possible particularly in the upper levels of the quarry. Some of the waste generated during the normal drill/blast cycle will be used to form bench edge, tip head and access road bunding as well as being utilized to improve haul road gradients etc. There may be a possibility to load out waste product directly from the working face for use by Kowhitirangi Lime Co. from time to time subject to reaching a mutually benefical arrangement between parties. 6.6 Rock Stockpile Areas At Camelback Quarry AGPR will generally be stockpiled on the main floor area in designated areas to be marked out by the WCRC Quarry Manager prior to commencement of quarry operations. Although all quarry product ex the face shall be weighed as it is broken out prior to loadout to stockpile the actual stockpiles shall also be constructed in such a manner that Camelback Quarry Management Plan 2015 8 facilitates physical measurement of rock volumes in the stockpile, (regular shape, straight sides, consistent height etc.) 6.7 Hazards and Issues specific to Camelback Quarry Fly rock potential Close proximity to occupied dwelling located opposite quarry gate Geological considerations Steep terrain Risk of rock falls Risk of rollover/falls Gradients and uneven floors Section 8: Quarry Restoration, Rehabilitation and Expenditure Plan The Restoration/Rehabilitation efforts of the last few years in the Council’s quarries mean that overall the future requirements have been somewhat reduced at all sites but in any case this Restore/Rehab expenditure must be viewed as a function of the ongoing quarries operation. It is therefore important to ensure that each quarry has a dedicated budget line to maintain a meaningful Restore/Rehab programme into the future. The level of annual expenditure should remain reasonably constant being more or less in lock step with annual production volumes unless a large flood event or similar occurs. In this situation Restoration/Rehabilitation costs will increase in line with any production surge but based on averages should equate to around $0.15 (15 cents) per tonne of armour grade rock produced to also provide an additional lump sum at closedown/decommissioning. This lump sum will be required to deal with: Roading issues Public access Long term safety issues Pit slope and face stabilization Drainage Contouring Landscaping Land ownership/transfers etc. Camelback Quarry Management Plan 2015 9 8.1 Expenditure Requirements for Camelback Quarry As at 1/09/2014 year one restore/rehab programme and expenditure requirements for Camelback Quarry are as follows: Seed collection/seedlings (endemic to location) Labour and nursery costs Planting including “clump” relocation within quarry, landscaping etc. Follow-up/release/replant as necessary Total first year expenditure $750 $800 $500 $2050 Thereafter: An annual expenditure of $1025 will be required to carry out the Restore/Rehab at Camelback Quarry. At the current rate of extraction the minimum life of Camelback Quarry is expected to be 20 years. Annual production (without extraordinary weather events) is presently 6000 tonne. Therefore assume 20 years at 6000t per annum will total = 120000t + 30% waste = 156000t all up. Using an average of $0.15 per tonne the provisional sum required for decommissioning at Camelback Quarry totals: 156000 X $0.15 = $23400 LS required at closedown. Section 9: Quarry Permits and Consents 9.1 Crown Minerals Permit 50370 Permit Number Permit Term Commencement Date Expiry Date Area 9.2 50370 40 years 2008 2048 10.749 hectares West Coast Regional Council Consents Held Resource consent Number 99/253 *RC080132/1 Date Granted 08.03.2000 31.03.2008 Term 9 Years 35 Years Expiry date 08.03.2009 31.03.2043 Purpose Discharge to air Land use *Not required due to compliance with Permitted Activity Rule. Camelback Quarry Management Plan 2015 10 Camelback Quarry Management Plan 2015 11