Team 10 Air Conditioning Experiment

advertisement

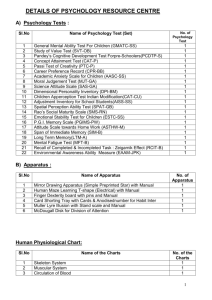

Team 10 Air Conditioning Experiment • Members – – – – Sean Gallagher Pamela McDowell Brian Davison Prathana Vanarath • Sponsors – Dr. Wexler – Dr. Advani • Advisor – Dr. Keefe Presentation Overview • Introduction • Method – Concept Generation – Concept Selection • Schedule & Budget • Questions Project Background New Curriculum for Mechanical Engineers “ME 2000 Curriculum” • Joint Laboratory Classes for Thermodynamics and Heat Transfer classes • We must investigate 2 aspects of this issue: – Single lab apparatus for multiple labs (Hardware) – Increased understanding of Thermodynamic and Heat Transfer fundamentals (Lab Experiments) Mission • Design a set of thermodynamic and heat transfer experiments for the University of Delaware Mechanical Engineering Undergraduate Laboratory, using a window air conditioner, that will be completed by April for approximately $4000. Approach 1 Identifying customer(s) – wants – needs – constraints. 2 Benchmark to identify – competitors – metrics – possible solutions. 3 Generate concepts 4 Compare, eliminate, expand and synthesize possible solutions based on the metrics. 5 Proceed to a Go/No-Go review of the concepts. Build and test a prototype. Customers ¶ Dr. Wexler Dr. Advani Undergraduate students Graduate students Judy Green: Educational Dr. Sun William Davison Manufacturers: Hampden, Armfield Ltd. Other Schools: Georgia Tech, Penn State Wants ¶ Effective learning tool Easy to Use Self Evident Easy to set up Cost Effectiveness Multiple Purposes LabView compatible data acquisition Forgiving of incompetence Quiet Quick Constraints (Prioritized) • Portable • Schedule dictated by NCDA • Budget set by Sponsor • Separation of Project set by Sponsor Concept Sub-Concept Category Sub-Concept Category Category Sub-Category Category Sub-Category Sub-Category Sub-Category Sub-Category Sub-Category Sub-Category Sub-Category Problem Description • Hardware – Develop a lab apparatus using a window air conditioner and sensors – Develop a Data Acquisition Program • Lab Experiments – Develop a set of experiments that include a variety of Thermodynamic and Heat Transfer Principles Systems Benchmarking (Major Competitors) • Hampden Basic Refrigeration Cycle Trainer • Hampden Basic Refrigeration Cycle and Heat Pump Trainer • Hampden Refrigeration Demonstrator • Hampden Heat Pump Trainer • Armfield Heat Exchanger Training Equipment Series • Armfield Heat Transfer Teaching Equipment Series • Armfield Temperature Measurement Bench • Others Functional Benchmarking • Omega Engineering - Sensors – Carries every type of sensor we will require – Catalogs are an excellent technical reference • Optrand - Sensors – Fiber-optic pressure transducer • Air Conditioning Manufacturers - AC units • University of Delaware HVAC - sample AC Metrics • Cost Effectiveness – Low initial price • Target value $4000 – Low operating cost • Target value $22. – Durable • Target value 10 years – Parts availability • Target value: 2 week lead time • Easy to Use – Visible Components • Physically look at chosen apparatus and rate 1 - 10, target value 10. – Accessible Components • same as above Metrics Cont’d • Effective Learning Tool – – – – Fun Number of Fundamentals Clear Lessons/Objectives Real World Connection to Students – Keeps Students’ Interests – Hands-on/Interactive • All are evaluated yes or no, the target value is yes. • Self Evident – Clear Lessons/Objectives • Survey scored 1 - 5: target value 5 – Logical Procedure • Survey scored 1 - 5: target value 5 • Quiet – Low noise level • Target value of 60 dB Metrics Cont’d • Forgiving of Incompetence – Years of experience • Target value 2 years engineering experience • Easy to set up – Time • Target value 15 minutes – Self Contained • Target value 1 • Quick – Time • Target Value within set lab time (2 hrs) • Easy Maintenance – Parts visibility • Physically look at chosen apparatus and rate 1 - 10, target value 10. – Parts availability • Target value: 2 week lead time Concept Generation and Selection Concept Lab Reports Number of Experiments Presentation of Lab Reports Overall Presentation of Experiments Hardware Apparatus Sensors Concept Generation and Selection Number of Experiments 1 Experiment 4-7 Experiments 13 Experiments Number of Experiments Generation and Selection ¶ One Experiment using different sensors 4 - 7 Experiments – Not an effective learning tool – Difficult to set up – Easy to set up – More effective learning tool than and Multiple Purposes 13 Experiments – Easy to set up – More effective learning tool than – Multiple Purposes Concept Generation and Selection Overall Presentation of Experiments By Component By Fundamental Overall Presentation of Experiments Generation and Selection ¶ By Fundamental – Self Evident: clear lessons – Quick: can be completed in lab time By Component – Self Evident: clear lessons – Quick: can be completed in lab time – More effective learning tool than Concept Generation and Selection Presentation of Lab Reports Standard Lab Reports Short Lab Reports + Technical Paper Presentation of Lab Reports Generation and Selection ¶ Standard Lab Reports – Self Evident: clear lessons Short Lab Reports & Technical Paper – Self Evident: clear lessons – More effective learning tool than Concept Generation and Selection Apparatus Air Conditioning Unit Other Apparatus Generation and Selection ¶ Other – Quick: can be completed in lab time – Easy to set up: can be set up in less than 15 min. Air Conditioning Unit – Quick: can be completed in lab time – Easy to set up: can be set up in less than 15 min. – More effective learning tool than – More self evident than – Easier to use than – More cost effective Sensors Generation and Selection ¶ Fully Instrumented with Redundancy – Most expensive Fully Instrumented without Redundancy – Most feasible Economically Instrumented – Least expensive but sacrifices functionality Updated Concept Flow-Chart Concept Lab Reports Hardware Overall Presentation of Presentation Lab Reports of Experiments Standard By Component Lab Report N umber of Experiment s 1 Experiment 4-7 Experiments 13 Experiments By Fundamental Apparatus Sensors AC unit Other Technical Paper Final Concept Selection • Number of Experiments – 4 - 7 Experiments • Overall Presentation of Experiments – By Components • Apparatus – Air Conditioning Unit • Presentation of Lab Reports – Short Lab Reports & Technical Paper • Sensors – Fully Instrumented without Redundancy Working Model • Lab Experiments – See Handout • Air Conditioner – See apparatus Actual Progress • Wanted to be here: • We are here: – Develop Heat Transfer Lab Fundamentals – Applied Heat Transfer fundamentals to labs – Develop Thermodynamic Lab Fundamentals – Applied Thermodynamic fundamentals to labs – Investigate Educational Values/Criteria – Researched and applied these values to labs – Evaluate Key Equations – Lab write-ups made – Obtain Sample Air Conditioner for Study – Sample Air Conditioner used in determining labs – Examine Possible Sensor Placements – Possible locations determined Not Too Detailed Schedule • January • February – Compile and finalize lab manuals – Select and purchase required equipment • March – Assemble lab apparatus – Test and evaluate labs • April – Complete project Estimated Budget Estimated Budget: Team 99.10, ME Air Conditioning Lab Fully Instrumented Unit Unit Price Quantity Total Price Air Conditioner $ 250.00 1 $ 250.00 Lab Cart $ 100.00 1 $ 100.00 Relative Humidity Sensor $ 225.00 4 $ 900.00 Mass Flow Sensor $ 1,000.00 2 $ 2,000.00 Thermocouples $ 25.00 12 Pressure Transducer $ 200.00 8 Various Pipe Fittings $ 10.00 $ 10.00 Wiring and Connectors $ 10.00 $ 10.00 Misc. Fabrication Costs $ 25.00 $ 25.00 Estimated Budget $ 300.00 $ 1,600.00 $ 5,195.00 Concluding Remarks