Chapter 1, Heizer/Render, 5th edition

advertisement

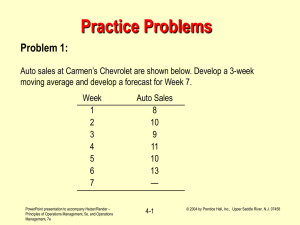

Operations Management Linear Programming Module B PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-1 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Outline Requirements of a Linear Programming Problem Formulating Linear Programming Problems Shader Electronics example Graphical Solution to a Linear Programming Problem Graphical representation of Constraints Iso-Profit Line Solution Method Corner-Point Solution Method PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-2 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Outline - continued Sensitivity Analysis Solving Minimization Problems Linear Programming Applications Production Mix Example Diet Problem Example Production Scheduling Example Labor Scheduling Example The Simplex Method of LP PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-3 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Learning Objectives When you complete this chapter, you should be able to : Identify or Define: Objective function Constraints Feasible region Iso-profit/iso-cost methods Corner-point solution Shadow price PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-4 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Learning Objectives - continued When you complete this chapter, you should be able to : Describe or Explain: How to formulate linear models Graphical method of linear programming How to interpret sensitivity analysis PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-5 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 What is Linear Programming? Mathematical technique Not computer programming Allocates scarce resources to achieve an objective Pioneered by George Dantzig in World War II Developed workable solution in 1947 Called Simplex Method PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-6 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Examples of Successful LP Applications Scheduling school busses to minimize total distance traveled when carrying students Allocating police patrol units to high crime areas in order to minimize response time to 911 calls Scheduling tellers at banks to that needs are met during each hour of the day while minimizing the total cost of labor PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-7 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Examples of Successful LP Applications - continued Picking blends of raw materials in feed mills to produce finished feed combinations at minimum costs Selecting the product mix in a factory to make best use of machine- and labor-hours available while maximizing the firm’s profit Allocating space for a tenant mix in a new shopping mall so as to maximize revenues to the leasing company PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-8 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Requirements of a Linear Programming Problem 1 Must seek to maximize or minimize some quantity (the objective function) 2 Presence of restrictions or constraints limits ability to achieve objective 3 Must be alternative courses of action from which to choose 4 Objectives and constraints must be expressible as linear equations or inequalities PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-9 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Formulating Linear Programming Problems Assume: You wish to produce two products (1) Walkman AM/FM/Cassette and (2) Watch-TV Walkman takes 4 hours of electronic work and 2 hours assembly Watch-TV takes 3 hours electronic work and 1 hour assembly There are 240 hours of electronic work time and 100 hours of assembly time available Profit on a Walkman is $7; profit on a Watch-TV $5 PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-10 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Formulating Linear Programming Problems - continued Let: X1 = number of Walkmans X2 = number of Watch-TVs Then: 4X1 + 3X2 240 2X1 + 1X2 100 7X1 + 5X2 = profit PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) electronics constraint assembly constraint maximize profit B-11 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Graphical Solution Method Draw graph with vertical & horizontal axes (1st quadrant only) Plot constraints as lines, then as planes Use (X1,0), (0,X2) for line Find feasible region Find optimal solution Corner point method Iso-profit line method PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-12 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Shader Electronic Company Problem Department Electronic Hours Required to Produce 1 Unit X1 X2 Walkmans Watch-TV’s 4 3 Assembly 2 1 Profit/unit $7 $5 Available Hours This Week 240 100 Constraints: 4x1 + 3x2 240 (Hours of Electronic Time) 2x1 + 1x2 100 (Hours of Assembly Time) Objective: Maximize: 7x1 + 5x2 PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-13 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Number of Watch-TVs (X2) Shader Electronic Company Constraints Electronics 120 (Constraint A) 100 Assembly (Constraint B) 80 60 40 20 0 0 10 20 30 40 50 60 70 80 Number of Walkmans (X1) PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-14 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Number of Watch-TVs (X2) Shader Electronic Company Feasible Region Electronics (Constraint A) 120 100 Assembly (Constraint B) 80 60 40 Feasible Region 20 0 0 10 20 30 40 50 60 70 80 Number of Walkmans (X1) PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-15 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Number of Watch-TVs (X2) Shader Electronic Company Iso-Profit Lines Electronics (Constraint A) Assembly (Constraint B) 120 100 80 60 40 20 0 0 10 20 30 40 50 60 70 80 Number of Walkmans (X1) PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-16 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Number of Watch-TVs (X2) Shader Electronic Company Solution Electronics (Constraint A) Assembly (Constraint B) 120 ISO-Profit Line 100 80 Solution Point (X1=30, X2=40) 60 40 20 0 0 10 20 30 40 50 60 70 80 Number of Walkmans (X1) PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-17 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Number of Watch-TVs (X2) Shader Electronic Company Solution Corner Point Solution Electronics (Constraint A) Assembly (Constraint B) 120 100 Possible Corner Point Solution 80 60 Optimal solution 40 20 0 0 10 20 30 40 50 60 70 80 Number of Walkmans (X1) PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-18 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Formulation of Solution Decision variables X1 = tons of BW chemical produced X2 = tons of color chemical produced Objective Minimize Z = 2500X1 + 3000X2 Constraints X1 30 (BW); X2 20 (Color) X1 + X2 60 (Total tonnage) X1 0; X2 0 (Non-negativity) PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-19 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Simplex Steps for Maximization 1 Choose the variable with the greatest positive Cj- Zj to enter the solution 2 Determine the row to be replaced by selecting that one with the smallest (non-negative) quantity-to-pivot column ratio 3 Calculate the new values for the pivot row 4 Calculate the new values for the other row(s) 5 Calculate the Cj and Cj-Zj values for this tableau. If there are any Cj-Zj numbers greater than zero, return to step 1. PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-20 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Sensitivity Analysis Projects how much a solution might change if there were changes in variables or input data. Shadow price (dual) - value of one additional unit of a resource PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-21 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Minimization Example BW: $2,500 You’re an analyst for a division of manufacturing cost Kodak, which makes BW & color per month chemicals. At least 30 tons of BW and at least 20 tons of color must be made each month. The total chemicals made must be at least 60 tons. How many tons of each chemical should be made to minimize costs? Color: $ 3,000 manufacturing © 1995 Corel Corp. cost per month PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-22 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Graphical Solution 80 Find values for X1 + X2 60. BW 60 X1 30, X2 20. Total Feasible Region Tons, Color Chemical 40 (X2) 20 Color 0 0 PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) 20 40 60 Tons, BW Chemical (X1) B-23 80 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Optimal Solution: Corner Point Method 80 Find corner points. BW 60 Total Tons, Color Chemical 40 Feasible Region B 20 Color A 0 0 PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) 20 40 60 Tons, BW Chemical B-24 80 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458 Simplex Steps for Minimization 1 Choose the variable with the greatest negative Cj- Zj to enter the solution 2 Determine the row to be replaced by selecting that one with the smallest (non-negative) quantity-topivot column ratio 3 Calculate the new values for the pivot row 4 Calculate the new values for the other row(s) 5 Calculate the Cj and Cj-Zj values for this tableau. If there are any Cj-Zj numbers less than zero, return to step 1. PowerPoint presentation to accompany Operations Management, 6E (Heizer & Render) B-25 © 2001 by Prentice Hall, Inc., Upper Saddle River, N.J. 07458