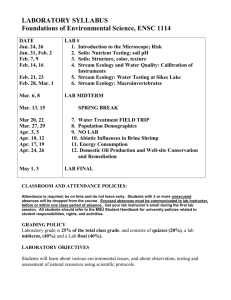

McGraw-Hill/Irwin

Copyright © 2009 by The McGraw-Hill Companies, Inc. All rights reserved.

Chapter 16

Aggregate Sales and

Operations Planning

16-3

OBJECTIVES

• Sales and Operations Planning

• The Aggregate Operations Plan

• Examples: Chase and Level

strategies

16-4

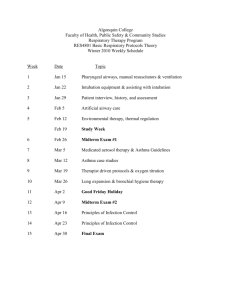

Process planning

Long

range

Supply network

planning

Strategic capacity

planning

Forecasting and

demand management

Sales and operations

(aggregate) planning

Sales

plan

Medium

range

Manufacturing

Master scheduling

Short

range

Aggregate

operations

plan

Logistics

Services

Vehicle capacity

planning

Material requirements

planning

Vehicle loading

Order scheduling

Vehicle dispatching

Warehouse

receipt

planning

Weekly

workforce

scheduling

Daily workforce

scheduling

1-4

16-5

Sales and Operations Planning Activities

• Long-range planning

–

–

Greater than one year planning horizon

Usually performed in annual increments

• Medium-range planning

–

–

Six to eighteen months

Usually with weekly, monthly or quarterly

increments

• Short-range planning

–

–

One day to less than six months

Usually with weekly or daily increments

16-6

The Aggregate Operations Plan

• Main purpose: Specify the

optimal combination of

– production rate (units

completed per unit of time)

– workforce level (number of

workers)

– inventory on hand (inventory

carried from previous period)

• Product group or broad

category (Aggregation)

• This planning is done over an

intermediate-range planning

period of 3 to18 months

16-7

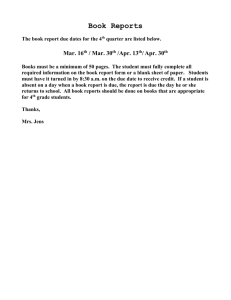

Balancing Aggregate Demand

and Aggregate Production Capacity

10000

Suppose the figure to

the right represents

forecast demand in

units

Now suppose this

lower figure represents

the aggregate capacity

of the company to

meet demand

10000

8000

8000

6000

7000

6000

5500

4500

4000

2000

0

Jan

Feb

Mar

Apr

May

Jun

9000

10000

8000

8000

What we want to do is

balance out the

production rate,

workforce levels, and

inventory to make

these figures match up

6000

6000

4500

4000

Jan

Feb

4000

4000

2000

0

Mar

Apr

May

Jun

16-8

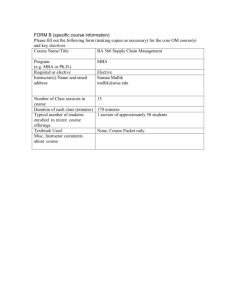

Required Inputs to the Production Planning System

Competitors’

behavior

External

capacity

Current

physical

capacity

Raw material

availability

Planning

for

production

Current

workforce

Inventory

levels

Market

demand

External

to firm

Economic

conditions

Activities

required

for

production

Internal

to firm

16-9

Key Strategies for Meeting Demand

• Chase

• Level

• Stable workforce

16-10

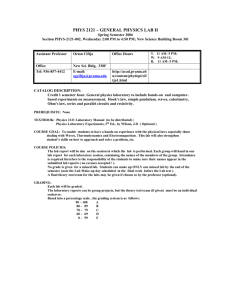

Aggregate Planning Examples: Unit Demand and Cost Data

Suppose we have the following unit

demand and cost information:

Demand/mo

Jan

Feb

Mar

Apr

May

Jun

4500

5500

7000

10000

8000

6000

Materials

Holding costs

Marginal cost of stockout

Hiring and training cost

Layoff costs

Labor hours required

Straight time labor cost

Beginning inventory

Productive hours/worker/day

Paid straight hrs/day

$5/unit

$1/unit per mo.

$1.25/unit per mo.

$200/worker

$250/worker

.15 hrs/unit

$8/hour

250 units

7.25

8

16-11

Cut-and-Try Example: Determining

Straight Labor Costs and Output

Given the demand and cost information below, what

are the aggregate hours/worker/month, units/worker, and

dollars/worker?

Demand/mo

Jun

Jan

4500

Feb

5500

Mar

7000

Apr

May

10000

7.25x2

2

8000

6000

Productive hours/worker/day

Paid straight hrs/day

22x8hrsx$8=$140

8

Days/mo

Hrs/worker/mo

Units/worker

$/worker

Jan

22

159.5

1063.33

$1,408

Feb

19

137.75

918.33

1,216

7.25

8

Mar

21

152.25

1015

1,344

7.25x0.15=48.33

&

84.33x22=1063.33

Apr

21

152.25

1015

1,344

May

22

159.5

1063.33

1,408

Jun

20

145

966.67

1,280

16-12

Chase Strategy

(Hiring & Firing to meet demand)

Days/m o

Hrs/wo rker/m o

Units/wo rker

$ /wo rker

Dem and

Beg. inv.

Net req.

Req. wo rkers

Hired

Fired

W o rkfo rce

Ending invento ry

Jan

22

1 5 9 .5

1 ,0 6 3 .3 3

$ 1 ,4 0 8

Jan

4 ,5 0 0

250

4 ,2 5 0

3 .9 9 7

3

4

0

Lets assume our current workforce is 7

workers.

First, calculate net requirements for

production, or 4500-250=4250 units

Then, calculate number of workers

needed to produce the net

requirements, or

4250/1063.33=3.997 or 4 workers

Finally, determine the number of

workers to hire/fire. In this case we

only need 4 workers, we have 7, so

3 can be fired.

16-13

Below are the complete calculations for the remaining

months in the six month planning horizon

Days/mo

Hrs/worker/mo

Units/worker

$/worker

Demand

Beg. inv.

Net req.

Req. workers

Hired

Fired

Workforce

Ending inventory

Jan

22

159.5

1,063

$1,408

Feb

19

137.75

918

1,216

Mar

21

152.25

1,015

1,344

Apr

21

152.25

1,015

1,344

May

22

159.5

1,063

1,408

Jun

20

145

967

1,280

Jan

4,500

250

4,250

3.997

Feb

5,500

Mar

7,000

Apr

10,000

May

8,000

Jun

6,000

5,500

5.989

2

7,000

6.897

1

10,000

9.852

3

8,000

7.524

6,000

6.207

2

8

0

1

7

0

3

4

0

6

0

7

0

10

0

16-14

Below are the complete calculations for the remaining months in

the six month planning horizon with the other costs included

Demand

Beg. inv.

Net req.

Req. workers

Hired

Fired

W orkforce

Ending inventory

Material

Labor

Hiring cost

Firing cost

Jan

4,500

250

4,250

3.997

3

4

0

Feb

5,500

Mar

7,000

Apr

10,000

May

8,000

Jun

6,000

5,500

5.989

2

7,000

6.897

1

10,000

9.852

3

8,000

7.524

6,000

6.207

2

8

0

1

7

0

6

0

7

0

10

0

Jan

Feb

Mar

Apr

May

Jun

$21,250.00 $27,500.00 $35,000.00 $50,000.00 $40,000.00 $30,000.00

5,627.59

7,282.76

9,268.97 13,241.38 10,593.10

7,944.83

400.00

200.00

600.00

750.00

500.00

250.00

Costs

203,750.00

53,958.62

1,200.00

1,500.00

$260,408.62

16-15

Level Workforce Strategy (Surplus and Shortage Allowed)

Lets take the same problem as

before but this time use the

Level Workforce strategy

This time we will seek to use

a workforce level of 6 workers

Demand

Beg. inv.

Net req.

W orkers

P roduction

Ending inventory

Surplus

Shortage

Jan

4,500

250

4,250

6

6,380

2,130

2,130

16-16

Below are the complete calculations for the remaining

months in the six month planning horizon

Demand

Beg. inv.

Net req.

Workers

Production

Ending inventory

Surplus

Shortage

Jan

4,500

250

4,250

6

6,380

2,130

2,130

Feb

5,500

2,130

3,370

6

5,510

2,140

2,140

Mar

7,000

2,140

4,860

6

6,090

1,230

1,230

Apr

10,000

1,230

8,770

6

6,090

-2,680

May

8,000

-2,680

10,680

6

6,380

-1,300

Jun

6,000

-1,300

7,300

6

5,800

-1,500

2,680

1,300

1,500

Note, if we recalculate this sheet with 7 workers

we would have a surplus

16-17

Below are the complete calculations for the

remaining months in the six month planning

horizon with the other costs included

Jan

4,500

250

4,250

6

6,380

2,130

2,130

Jan

$8,448

31,900

2,130

Feb

5,500

2,130

3,370

6

5,510

2,140

2,140

Feb

$7,296

27,550

2,140

Mar

7,000

10

4,860

6

6,090

1,230

1,230

Mar

$8,064

30,450

1,230

Apr

10,000

-910

8,770

6

6,090

-2,680

May

8,000

-3,910

10,680

6

6,380

-1,300

Jun

6,000

-1,620

7,300

6

5,800

-1,500

2,680

1,300

1,500

Apr

$8,064

30,450

May

$8,448

31,900

Jun

$7,680

29,000

3,350

1,625

1,875

Note, total

costs under

this strategy

are less than

Chase at

$260.408.62

$48,000.00

181,250.00

5,500.00

6,850.00

$241,600.00

Labor

Material

Storage

Stockout

16-18

Question Bowl

Sales and Operations Planning

activities are usually conducted

during which planning time

horizon?

a. Long-range

b. Intermediate-range

c. Short-range

d. Really short-range

e. None of the above

Answer: b. Intermediate-range (i.e., 6 to

18 months)

16-19

Question Bowl

Which of the following are

Production Planning Strategies

can involve trade-offs among the

workforce size, work hours,

inventory, and backlogs?

a. Chase strategy

b. Stable workforce-variable work

hours

c. Level strategy

d. All of the above

e. None of the above

Answer: d. All of the above

16-20

Question Bowl

Which of the following are considered

“relevant costs” in the Aggregate

Production Plan?

a. Costs associated with changes in

the production rate

b. Inventory holding costs

c. Backordering costs

d. Basic production costs

e. All of the above

Answer: e. All of the above

16-21

Question Bowl

Which of the following Aggregate

Planning Techniques can be

performed using simple

spreadsheets?

a. Cut-and-try

b. Linear programming

c. Transportation method

d. All of the above

e. None of the above

Answer: a. Cut-and-try (The other two involve more

complex computational effort than simple

spreadsheets.)

16-22

End of Chapter 16