SLIDES (5MB, Power Point file)

advertisement

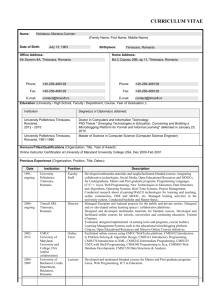

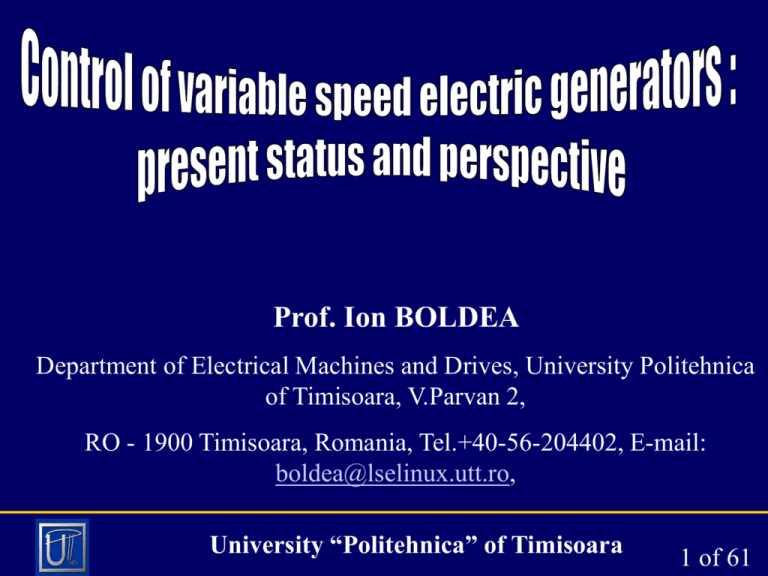

Prof. Ion BOLDEA Department of Electrical Machines and Drives, University Politehnica of Timisoara, V.Parvan 2, RO - 1900 Timisoara, Romania, Tel.+40-56-204402, E-mail: boldea@lselinux.utt.ro, University “Politehnica” of Timisoara 1 of 61 Contents • • • • • Introduction Variable speed wind-generator systems Variable speed hydro-generator systems Stand-alone variable speed generators Superhigh speed gas turbine PM generator systems • Automotive starter (torque-assist)/alternator systems • Home and space electric generator systems • Conclusion University “Politehnica” of Timisoara 2 of 61 Variable speed wind-generator systems • 13,932 MW by the end of 1999 • 2 – 2.5 MW units Wind turbine induction generator system with blade angle control and soft-starter [1] CR-IG University “Politehnica” of Timisoara 3 of 61 Connection circuit for fixed – speed wind turbine using external resistors CR-IG University “Politehnica” of Timisoara 4 of 61 Measured (gray) and calculated (black) current magnitude as the 15- kW machine is connected using external resistance [26] Measured (gray) and calculated (black) rotor speed magnitude as the 15- kW machine is connected using external resistance [26] Measured (gray) and calculated (black) machine voltage as 15- kW machine is connected using external resistance [26] University “Politehnica” of Timisoara CR-IG 5 of 61 Variable speed generator connected to the grid through bidirectional converter University “Politehnica” of Timisoara CR-IG 6 of 61 Grid side converter control University “Politehnica” of Timisoara CR-IG 7 of 61 Machine side converter control University “Politehnica” of Timisoara CR-IG 8 of 61 CR-IG Unity power factor Phase current and voltage.Speed 1500 rpm, generator, torque 100% Phase current and voltage per phase.Speed 1500 rpm, generator, torque 100%, reactive power 50% Results with inverter control at power grid University “Politehnica” of Timisoara 9 of 61 Stand alone SCIG control systems [3] University “Politehnica” of Timisoara CR-IG 10 of 61 a) Vdc versus time b) Vd versus time Full load application over 50% load application [3] CR-IG University “Politehnica” of Timisoara 11 of 61 Doubly-fed IG (DFIG) wind turbine system DFIG University “Politehnica” of Timisoara 12 of 61 a) b) Vector control of DFIG a) and step active power response b), without and with decoupled control [4] University “Politehnica” of Timisoara 13 of 61 Sensorless DFIG with operating modes I, II, III [8] University “Politehnica” of Timisoara 14 of 61 Rotor and stator current and their harmonics content at s = -0.27with controlled rectifier - current source inverter in the rotor DFIG University “Politehnica” of Timisoara 15 of 61 DFIG connected to the power grid University “Politehnica” of Timisoara 16 of 61 Power [pu / 2000 kW] Turbine speed referred to generator side [rpm] Implemented wind turbine characteristics – aerodynamics characteristics DFIG University “Politehnica” of Timisoara 17 of 61 DFIG The block diagram of the supply – side converter control [8] University “Politehnica” of Timisoara 18 of 61 The block diagram of the machine-side converter control in a DFIG doubly-fed wind turbine [8] University “Politehnica” of Timisoara 19 of 61 a) The active and b) reactive stator power control [8] DFIG University “Politehnica” of Timisoara 20 of 61 Three-phase short-circuit on the power grid : a) Stator voltage b) Stator currents c) Rotor currents d) Speed e) Turbine torque f) Electromagnetic torque g) Active power h) Reactive power [8] University “Politehnica” of Timisoara DFIG 21 of 61 Modified vector controller for unbalanced voltages in the power grid [6] DFIG University “Politehnica” of Timisoara 22 of 61 Stator currents in individual phases Stator currents in individual phases for 10% negative-sequence voltage for 10% negative-sequence voltage applied - conventional controller [6] applied - modified controller [6] DFIG University “Politehnica” of Timisoara 23 of 61 Stator currents in individual phases for two- phase operation-modified controller [6] DFIG University “Politehnica” of Timisoara 24 of 61 Sensorless control of DFIG Im s s Im s j Im s Ls s V s Rs i s dt Ls I ir jir i ms i s Lm s r cos 1 ir is cos 2 ir ? ir sin 1 ir ir sin 2 ir ? is sin er sin 1 2 d er r dt DFIG University “Politehnica” of Timisoara 25 of 61 Sensorless control of DFIG Experimental waveforms showing estimated and actual sin for step in ifrom 0 to 0.5 p.u. [2] rq DFIG University “Politehnica” of Timisoara 26 of 61 Sensorless control of DFIG DFIG a) Before filtering [2] b) After filtering Experimental waveforms showing estimated and actual at starting University “Politehnica” of Timisoara 27 of 61 Variable speed hydrogenerator systems Pump storage necessities prompted by nuclear power usage led to the design and application of two rather large (310MW) power DFIGs; one with a cycloconverter and the other with a GTO inverterconverter in the rotor circuit [10] University “Politehnica” of Timisoara 28 of 61 Ramp power response for motoring mode (Ohkawachi unit 4) [10] University “Politehnica” of Timisoara DFIG 29 of 61 Ramp power response for generating mode (Ohkawachi unit 4) [10] DFIG University “Politehnica” of Timisoara 30 of 61 Goldishtal pump-storage station 300 MW [27] University “Politehnica” of Timisoara DFIG 31 of 61 Power flow at constant torque in turbine and pump operation [27] DFIG University “Politehnica” of Timisoara 32 of 61 Stand-alone variable speed generators Stand-alone MG generator – converter with battery quick back up PMSG University “Politehnica” of Timisoara 33 of 61 PMSG PM generator advanced mobile genset [28] PMSG University “Politehnica” of Timisoara 34 of 61 PM generator advanced mobile genset [28] Peak torque, power and fuel consumption PMSG University “Politehnica” of Timisoara 35 of 61 PM alternator genset with Diesel engine [28] PMSG University “Politehnica” of Timisoara 36 of 61 Dual stator winding IG with reduced count inverter – battery system University “Politehnica” of Timisoara CRIG 37 of 61 Starter generators for vehicular technologies • Induction type • IPM brushless type • Transverse flux PM brushless type • Switched reluctance type • Claw pole rotor synchronous type Characteristics : * High starting torque * Large power speed range * Low volume and system costs * Low total system losses at 42 Vdc – battery – mild hybrids, 200 – 400 Vdc – battery – full hybrids and electric vehicles ISG University “Politehnica” of Timisoara 38 of 61 Starter-alternators (continued) So there is the low voltage (42 V d.c.) starter-alternator and the high voltage (150400 V d.c.) motor-generator for mild and respective heavy hybrids electric vehicles. Typical peak torque and voltage versus speed for a PM-RSM mild hybrid starting and, respectively, torque-assist mode are shown in next slide, with corresponding ISG efficiency. University “Politehnica” of Timisoara 39 of 61 Starter-alternators (continued) 42V battery voltage versus d.c. current load ISG University “Politehnica” of Timisoara 40 of 61 Starteralternators PM-RSM crosssection [12] ISG University “Politehnica” of Timisoara 41 of 61 a) Generating Rotor position b) Motoring er in relation to s and s ISG University “Politehnica” of Timisoara 42 of 61 Starter-alternators (continued) 150 1 60 0.9 125 50 100 40 0.8 30 50 20 25 10 Efficiency 75 Voltage (V) Torque (rpm) 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 0 1000 2000 3000 speed (rpm) a) 4000 5000 0 6000 0 0 1000 2000 3000 Speed [rpm] 4000 5000 6000 b) Peak torque, voltage a) and corresponding machine efficiency versus speed b) [12] University “Politehnica” of Timisoara ISG 43 of 61 a) b) Potential 42V d.c. automotive starter/alternator system with winding switch (a.c. machines) and passive (capacitor) voltage a) and with boost/buck converter b) ISG University “Politehnica” of Timisoara 44 of 61 H-bridge dc – dc boost bidirectional converter with transformer and inductance (T + L) [11] ISG University “Politehnica” of Timisoara 45 of 61 IGBT losses for the induction motor drive: base and max speed, with and without boost converter [11] Total power loss at 30 kW max. delivered power motor design of Table 2 with boost converter, Vb =180 V [11] Total power loss at 30 kW max. delivered power motor design of Table 1 with boost converter, Vb =180 V [11] University “Politehnica” of Timisoara 46 of 61 Fundamental rotor – position and speed tracking observer [14] ISG University “Politehnica” of Timisoara 47 of 61 Estimated initial electrical rotor position [14] University “Politehnica” of Timisoara ISG 48 of 61 Superhigh speed gas turbine PM generator systems Typical power – speed ranges : • to 150 kW at 70 – 80 000 rpm • to 1.4 – 5 MW at 18 000 – 15 000 rpm Applications : Stand alone, standby or cogeneration in distributed power systems. PMSG University “Politehnica” of Timisoara 49 of 61 The superhigh PM generator : rotors a) cylindrical b) disk – shape PMSG University “Politehnica” of Timisoara 50 of 61 Variable speed PMSG system with constant output voltage and frequency PMSG University “Politehnica” of Timisoara 51 of 61 3 – 5 MW medium voltage superhigh speed PMSG ( f1 0.6 1.2 kHz ) With dc voltage booster and three level PWM inverter University “Politehnica” of Timisoara 52 of 61 Home and space electric generator systems Stirling engine linear PM generator [25] University “Politehnica” of Timisoara 53 of 61 Various PM linear alternators [25] University “Politehnica” of Timisoara 54 of 61 Conclusion The present paper leads to conclusions such as: variable-speed generator technologies for power systems are already available up to 400 MW with doubly-fed induction generator motors. They bring more flexibility and better efficiency to power production and transportation for distributed/power systems wind and hydro electric generators are prime candidates for variable speed better system design optimisation and sensorless control methodologies are still desired University “Politehnica” of Timisoara 55 of 61 • automotive starter-alternator system for mild (42V d.c.) and heavy (150-600V d.c.) hybrid vehicles have been proposed in various configurations. The IM solution has been brought to markets by Toyota and Honda. Up to 35% fuel consumption reduction in town driving has been reported for Toyota Prius but the additional electrical equipment has been rated at 3000 USD. PM-RSM or transverse flux PM rotor configurations are currently proposed as they are credited with slightly less initial system costs for lower total system losses. University “Politehnica” of Timisoara 56 of 61 PM or induction generators with full (respectively fractionary) power electronics rating are proposed for dedicated stand alone or mobile gensets in the tens or hundreds of kW. Faster availability, lower volume and better energy conversion ratio with faster response for load transients are expected for such solutions. • Superhigh speed PM generators with powers up to 150kW and 75 krpm and for higher powers (up to 5 MW and 15 krpm ) are proposed for distributed power systems, aircraft and small vessel. University “Politehnica” of Timisoara 57 of 61 Home combined electricity and heat production through burning natural gas has been demonstrated with quiet, free piston Stirling engines and linear PM generators for efficiency above 85%, and at the power electric grid for tens of thousands of hours in the kW range. More compact configurations with still high efficiency and lower initial costs are required to make home electricity generation truly practical with all implicit advantages. University “Politehnica” of Timisoara 58 of 61 References 1. L. Mihet Popa, F. Blaabjerg, I. Boldea, “Simulation of wind generator systems for the power grid”, Record of OPTIM – 2002, vol 2, Nr. 423 – 428. 2. G. Podder, A. Joseph, A.K. Unnikshnan, “Sensorless variable – speed control for existing fixed speed wind power generator with unity power factor operation”, IEEE Transactions, Vol. ???, No. 5, 2003, pp. 1007 – 1015. 3. R. Teodorescu, F. Blaabjerg, F. Iov, “Control strategy for small stand – alone wind turbines ”, Record of PCIM – 2003, Nurnberg, pp. 201 – 206. 4. S. Muller, M. Deicke, R.W. De Doncker, “Adjustable speed generators for wind turbines based on doubly fed machines and 4 quadrant IGBT converter linked to the rotor”, Record of IEEE – IAS – 2000 Annual meeting, pp. 2249 – 2254. 5. E. Bogalecka, Z. Krzenmiski, “Sensorless control of doubly fed machine for wind power generators”, Record of EPE – PEMC – 2002, Dubrovnic – Cavtat . 6. I. Bendl, M. Chomat, L. Schreier, “Independent control of positive – negative sequence current components in doubly fed machine”, Record of EPE - 2001 7. L. Morel, H. Godfroid, A. Mirzoian, J.M. Kauffmann, “Doubly – fed induction machine: converter optimization and field orientation control without position sensor ”, Proc. IEE, Vol. EPA – 145, No. 4, 1998, pp. 360 – 368. 8. I. Serban, F. Blaabjerg, I. Boldea, Z. Chen, “A study of doubly-fed wind power generator under power systems faults ”, Record of EPE – 2003, Toulouse, France. University “Politehnica” of Timisoara 59 of 61 9. P. Pena, J.C. Clare, G.M. Asher, “A doubly fed induction generator using back to back PWM converter supplying an isolated load from a variable speed turbine ” , Proc. IEE, Vol. EPA – 143, No. 5, 1996, pp. 380 – 387. 10. T. Kuwabara, A. Shibuja, H. Furata, “Design and dynamic response characteristics of 400 MW adjustable speed pump storage unit at Ohkawachi power station”, IEEE Transactions, Vol. EC – 11, No. 2, 1996, pp. 376 – 384. 11. A. Vagati, A. Fratta, P. Gugliehni, G. Franchi, F. Villata, “Comparison of a.c. motor based drives for electric vehicle application”, Record of PCIM – 1999, Nurenberg, pp. 173 – 181. 12. I. Boldea, L. Tutelea, C.I. Pitic, “PM-assisted reluctance synchronous motor/generator (PM-RSM) for mild hybrid vehicles”, Record of OPTIM – 2002, Vol. 3, pp. 383 - 388. 13. W. L.. Soong, M. Ertugrul, E.C. Lovelace, T. M. Jahns, ”Investigation of interior permanent magnet offset coupled automotive integrated starter – alternator ”, Record of IEEE – IAS – 2001, Annual meeting. 14. H. Kim, K. K. Huh, M. Harke, J. Wai, R.D. Lorenz, T. Jahns, “Initial rotor position estimation for an integrated starter alternator IPM synchronous machine”, Record of EPE – 2003, Toulouse, France. 15. M. Linke, R. Kennel, J. Holtz, “Sensorless speed and position control of synchronous machines using alternating carrier injection”, Record IEEE – IEMDC – 2003, Vol. 2, pp. 1211 – 1217. 16. H. Bausch, A. Graif, K. Kanelis, A. Nickel, “Torque control of battery – supplied switched reluctance drives for electrical vehicles ”, Record of ICEM – 1998, Vol. 1, pp. 229 – 239. 17. O. Pyrhönen, “Analysis and control of excitation, field weakening and stability in direct torque controlled electrically excited synchronous motor driver ”, Ph. D. Dissertation , Lappenranta University of Technology, Finland, 1998. 18. M. P. Kazmierkowski, F. Blaabjerg, R. Krishnan, Editors , “Control in power electronics ” – special problems, book, chapter 9, “DTC of a.c. drives”, by I. Boldea, Academic Press, 2002. University “Politehnica” of Timisoara 60 of 61 19. H. Polinder, “On the losses in a high speed PM generator with rectifier with special attention to the effect of damper winding”, Ph. D. Thesis, Technical University Delft, Netherlands, 1998. 20. A. Castagnini, I. Leone, “Test results of a very high speed PM brushless motor”, Record of ICEM – 2002. 21. D. Ede, Z.Q. Zhu, D. Howe, “Rotor resonance of high speed PM brushless machines”, IEEE Transactions, Vol. IA – 38, No. 6, 2002, pp. 1542 – 1548 . 22. Z.J.J. Offringa, R.W. P Kerwnaer, J.L.F. Van der Veen, “A high speed 1400 kW PM generator with rectifier”, Record of ICEM – 2000, Vol. 1, pp. 301 – 313. 23. K.H. Kim, M.J. Youn, “DSP – based high – speed sensorless control for a brushless d.c. motor using a d.c. link voltage control”, ECPS Journal, Vol. 30, No. 9, 2002, pp. 889 – 906. 24. B-H Bae, S-K Sul, J-H Kvon, J-S Byeon, “Inplementation of sensorless vector control for superhigh speed PMSM of turbo – compressor”, IEEE Transactions, Vol. IA – 29, No. 3, 2003, pp. 811 – 818. 25. I. Boldea, “Linear electric actuators and their control”, Record of EPE – PEMC – 2002, Dubrovnik, Croatia. 26. T. Thiringer, “Grid-Friendly Connecting of Constant-Speed Wind Turbines using External Resistors”, IEEE Transactions on Energy Conversion, vol. 17, December, 2002 27. A. Bocquel, J. Janning, “4*300 MW Variable Speed Drive for Pump-Storage Plant Application”, EPE 2003 – Toulouse 28. L. M. Tolbert, W. A. Peterson, T. J. Theiss, M. B. Scudiere, “GEN-SETS”, Industry Application, IEEE, March, 2003 University “Politehnica” of Timisoara 61 of 61