1.0 Final Configuration

advertisement

FINAL PRELIMINARY DESIGN

Middle of Market Transport Team 2

Submitted By:

Ryan Burke, Michael Cleek, Paige Dumke, Brandon Goss,

Ryan McGill, Anthony Ragusa, Andrew Willard

The Pennsylvania State University

Aerospace 402A

Dr. James Coder

Contents

1.0 Final Configuration .................................................................................................................................. 2

1.1 Three-View Drawing ........................................................................................................................... 2

1.2 Wing Configuration ............................................................................................................................. 2

1.3 Fuselage Configuration ....................................................................................................................... 4

1.4 Empennage Configuration .................................................................................................................. 6

2.0 Aircraft Specifications ............................................................................................................................. 6

3.0 Weight Analysis ....................................................................................................................................... 9

3.1 Mission Sizing ...................................................................................................................................... 9

3.2 Comprehensive Weight Analysis....................................................................................................... 10

3.3 Composite Structures ....................................................................................................................... 12

4.0 Airfoil & Wing Aerodynamics ................................................................................................................ 14

4.1 Maximum Lift Coefficient and Lift Curve .......................................................................................... 14

4.2 High Lift Devices ................................................................................................................................ 17

5.0 Performance ......................................................................................................................................... 17

5.1 Drag Build-Up .................................................................................................................................... 17

5.2 Thrust Requirements ........................................................................................................................ 21

5.3 Propulsion System............................................................................................................................. 23

5.4 Climb Parameters.............................................................................................................................. 27

5.5 Takeoff and Landing Analysis ............................................................................................................ 28

6.0 Stability Analysis ................................................................................................................................... 31

6.1 Longitudinal Static Stability............................................................................................................... 31

6.2 Stability Requirements ...................................................................................................................... 33

7.0 Cost Estimates ....................................................................................................................................... 34

Concluding Statements ............................................................................................................................... 36

References .................................................................................................................................................. 37

Appendix ..................................................................................................................................................... 39

A.

Additional Figures and Tables ......................................................................................................... 39

B.

Advanced Composite Materials Trade Study .................................................................................. 40

C.

MATLAB Scripts ............................................................................................................................... 42

1

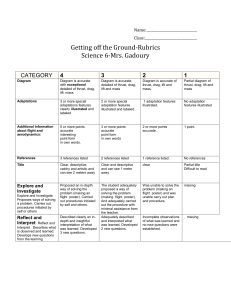

1.0 Final Configuration

1.1 Three-View Drawing

162 ft

142 ft

1.2 Wing Configuration

Wing Area

To size the wing, one looks to the takeoff constraints. In this case, takeoff dictates the minimum wing size.

To obtain a takeoff wing size a few assumptions were made. Assuming the maximum lift coefficient and

approach speed are the same as the 757-200 (giving the same airport reference code) and based on the

weight, wing area and approach speed of a 757-200, one can find its maximum lift coefficient to be 2.8.

Thus, with the two assumptions specified, one can obtain the takeoff wing sizing from Equation 1.1.

2WTO

2

stall cLmax

Slanding = ρV

2

(1.1)

It is important to note that the takeoff weight is used to define the landing wing area in case of emergency

landing immediately after takeoff. The constraint on the wing area for landing is a minimum of S landing =

2240 ft2.

With the landing constraint in mind looking to cruise coefficient can help to size the wing. For maximum

range,

𝐶𝐿 1/2

should be maximized. Differentiating, setting equal to zero, and assuming a drag polar as shown

𝐶𝐷

in Equation 1.2, obtains the optimum lift coefficient expression for cruise, shown in Equation 1.3.

CD = CD0 +

CLopt =

(CL −CL0 )2

(1.2)

πe0 AR

2kCL0 +√4k2 CL0 2 −(16k)(−kCL0 2 −CD0 )

6k

where k =

1

πe0 AR

(1.3)

From Equation 1.3, one can see that the optimum lift coefficient is a strong function of the lift coefficient

at zero angle of attack, 𝐶𝐿0 . Also, from the drag polar, one can see that the drag coefficient decreases with

increasing CL0 . By setting the landing wing area equal to the wing area at cruise, the optimum lift coefficient

in cruise can be obtained. With a cruise wing area of 2240 ft2 and 𝐶𝐿0 = 0.35 (See cruise lift curve) a CLopt

of 0.511 was obtained.

Wing Span

Once the wing area is specified, one can obtain other wing characteristics. By holding the aspect ratio

constant at AR = 9, a span of 142.0 ft can be obtained by applying Equation 1.4.

𝑏 = √𝐴𝑅 ∗ 𝑆

(1.4)

With span specified a mean aerodynamic chord (MAC) can be obtained by using the equation for chord as

a function of span for a wing with a single linear taper (Equation 1.5) and the definition of mean

aerodynamic chord (Equation 1.6). The MAC obtained is 18.11 ft.

2𝑆

𝑐(𝑦) = (1+𝜆)𝑏 [1 −

2

2(1−𝜆)

|𝑦|]

𝑏

𝑏/2 2

𝑀𝐴𝐶 = ∫0

𝑆

𝑐 𝑑𝑦

(1.5)

(1.6)

A typical mid-sized transport taper ratio of λ=0.2 and the MAC can then be used to determine the tip chord

(ct) and root chord (cr) via Equations 1.7 and 1.8, respectively.

𝑐𝑟 =

3𝑀𝐴𝐶

𝜆+1

(𝜆2 +𝜆+1)

2

(1.7)

𝑐𝑡 = 𝜆𝑐𝑟

(1.8)

The values of the obtained root and tip chord respectively are found to be 26.0 ft and 5.0 ft.

3

Aspect Ratio

Based on existing aircrafts, an aspect ratio can be chosen to best match the mission requirements. In this

case, an aspect ratio of 9 was chosen and held constant throughout the wing sizing process. This was based

on the aspect ratios of both Boeing 757-200 and 787. It was also chosen as 9 to reflect use of composites,

much like the Boeing 787.

Fuel Tanks

Since the fuselage has little room to spare after fitting the payload requirements, the fuel for the flight must

be held elsewhere, mainly inside the wing structure. From Nicolai and Carichner Chapter 8.6, they provide

fuel densities and packaging factors for several different fuels and tanks. This transport will presumably

have integrated tanks in the wings and wing box to contain the 103,000 lbs. of fuel. This translates to a fuel

tank volume of 2760 ft3. The fuel used for this calculation was JP-8, a common jet fuel. However, by 2025

and beyond, the use of natural gas and fuels may be limited, so it’s always a possibility a new fuel source

may be utilized. It can be concluded that tanks capable of holding 1380 gallons should be present in both

wings.

1.3 Fuselage Configuration

The final design fuselage configuration remained the same as in previous iterations. It will feature a singleaisle with three seats on each side. Primary reasons for choosing a narrow-bodied aircraft was a belief that

there would be less drag than a wide-body aircraft, which increases performance. Since this design is

carrying 220 passengers it falls within the range of multiple narrow-body passenger capacities.

The length of the fuselage was determined to be 162 Ft. This was the minimum length that will be able to

accommodate all 220 passengers in two classes (First and Economy) and other various necessities such as

lavatories (8), exit aisles (4), the cockpit, nose cone and finally the empennage (see Table 1.1 for fuselage

length build-up). Windows on the fuselage will be located at every 40 inches (Nicolai) down the fuselage

primarily in the seating sections of the aircraft. Figure 1.1 provides an inboard profile view of the fuselage

and demonstrates how the lengths in Table 1.1 were utilized.

Table 1.1 Fuselage Length Build-Up

Component

Length

Quantity

Radome

4 ft

1

Cockpit

8 ft

1

First Class Row (seat Pitch)

38 in.

6

Economy Class Row (seat pitch)

32 in.

33

Exit Areas

6 ft

4

Empennage

20 ft

1

Total Length

4

Total Length [ft]

4

8

19

88

24

20

162

Figure 1.1 Interior View of Fuselage

The cockpit would presumably feature a state-of-the-art avionics and flight control system. Aircraft systems

today are almost fully digital or “fly-by-wire” and the advances in this technology could possibly make the

cockpit smaller or make other aspects of the aircraft more efficient like weight, volume, etc. For now, this

is not a primary concern for the scope of this preliminary design.

Figure 1.2 depicts the designed cross section for the economy class. This is the critical design area because

the economy class is made to be the most volume efficient, and therefore drives cabin diameter for at least

the top of the fuselage. The first class seating arrangement will consist of a 2-2 per row configuration to

have a more comfortable seating option in the aircraft.

Figure 1.2 Aircraft Economy Class Cross Section (From Jetsizer-II Excel Workbook)

5

The cargo hold is located beneath the cabin floor, also seen in Figure 1.2 which must be able to contain

approximately 3520 ft3 for the specified passengers, (based on 225 passenger and cargo assumption, and

volume assumption from Nicolai text). The most volume efficient and lightest option for containers was

found to be (20) LD-3 size containers with a combined volume of 3520 ft3. These containers have overall

dimensions of 5.3 x 6.6 x 5 ft (searates.com) where the width falls within width of the lower fuselage.

1.4 Empennage Configuration

Once the wing design was also completed, the tail design began since the wing drives the tail design. The

tail functions as a counter mechanism to the wing, to create a downforce behind the aircraft’s neutral point

to eliminate the nose up pitching moment the lift of the wing creates. It also allows for control surfaces to

be implemented, elevators on the horizontal tail and a rudder the vertical tail provides aircraft stability and

control in both longitudinal and lateral/directional axes. This preliminary report does not include the

elevator and rudder sizing, but instead the surface areas for the vertical and horizontal tail.

As most passenger transports today, including the chosen parent aircraft use a “conventional”

configuration for the tail surfaces. This includes two horizontal fins on each side of the fuselage somewhere

mid-tail cone, and the vertical tail is located on the fuselage’s centerline on the top surface. This

configuration allows for larger horizontal tails sizes and best control authority because the engines are

mounted below the wings. There is no extra weight added to the current design because the fuselage

already exists for the tail to be mounted on. In addition, a conventional style tail reduces the stress on the

vertical tail as opposed to mounting the horizontal stabilizer onto the vertical stabilizer. In turn, the vertical

tail is smaller which keeps the weight of the aircraft lower.

In the interim design, it was assumed that the aerodynamic centers of both the horizontal and vertical tail

airfoils were located at the same distance in respect to the wing aerodynamic center. This was later dealt

with when performing C.G and neutral point calculations, and for stability it was determined the horizontal

moment arm would be equal to 80 ft and the vertical tail moment arm equal to 75 ft. This changed the

required tail areas and therefore multiple other parameters. See Section 2.0 for more information on the

tail sizing.

2.0 Aircraft Specifications

Below is a list of all relevant parameters for this design. Note that much of these values are subject to

change once the next phase of design is started, so values are given with little precision and are to be

treated as estimates.

Table 2.1 Aircraft Specifications

Variable

Value

Units

WTO

Wfuel

Wfixed

Wempty

lbs.

lbs.

lbs.

lbs.

Parameter

Weight

Gross Weight (Maximum Take-Off)

Fuel Weight

Fixed Weight

Empty Weight

6

281005

103480

51075

126451

Wing Sizing

Wing Area - Landing

Wing Area - Cruise

Wing Span

Root Chord

Tip Chord

Mean Aerodynamic Chord

Local Airfoil Aerodynamic

Center

Taper Ratio

Sweep Angle

Thickness Ratio

Effective Cruise Mach

Landing Max Clean Lift Coefficient

Cruise Max Clean Lift Coefficient

Landing Lift Curve Slope

Cruise Lift Curve Slope

Wing Sizing

Aspect Ratio

Efficiency

Cruise Wing Loading

Take-Off Wing Loading

Optimum Lift Coefficient

Average Cruise Weight

High Lift Devices

Double Slotted Fowler

c'/c

Sflapped/S

Sweep Angle, High Lift

Delta Max Lift Coefficient

Krueger

Sflapped/S

Delta Max Lift Coefficient

Slanding

Scruise

b

𝑐𝑟

𝑐𝑡

MAC

XAC

2240

2076

142

26

5

18.11

4.53

ft2

ft2

ft

ft

ft

ft

ft

Λ

t/c

Meff_cr

0.20

30

0.14

0.69

1.74

1.4

0.10

0.30

degrees

degrees-1

degrees-1

9

0.6

109.25

psf

CLmax, landing

CLmax, cruise

CLα, landing

CLα, cruise

AR

eo

𝑊

𝑆 𝑐𝑟𝑢𝑖𝑠𝑒

𝑊

𝑆 𝑇𝑂

𝐶𝐿𝑜𝑝𝑡

𝑊𝑐𝑟𝑢𝑖𝑠𝑒𝑎𝑣𝑔

135.38

psf

0.319

226758

lbs.

Λ HL

CLmax

1.3

0.5

20.3

0.878

degrees

-

CLmax

0.8

0.203

-

2

52,200

0.312

93.6

132.2

97

lbs.

(lbs._m/hr)/lbs._f

in

in

in

Engines

Number of Engines

Power (Thrust) Rating

Specific Fuel Consumption

Fan Diameter

Length

Width/Diameter

SFC

7

Horizontal Tail

Area

Span

Root Chord

Tip Chord

Mean Aerodynamic Chord

Taper Ratio

Aspect Ratio

SHT

bHT

𝑐𝑟𝐻𝑇

𝑐𝑡𝐻𝑇

MAC

AR

561

50.26

11.17

3.69

8.43

0.33

4.5

ft2

ft

ft

ft

ft

-

Vertical Tail

Area

Span

Root Chord

Tip Chord

Mean Aerodynamic Chord

Taper Ratio

Aspect Ratio

SVT

bVT

𝑐𝑟𝑉𝑇

𝑐𝑡𝑉𝑇

MAC

AR

385

24.02

16.01

5.28

12.55

0.33

1.5

ft2

ft

ft

ft

ft

-

29194

17.33

14.42

162.83

1

38

33

6

8.33

20

3.5

ft3

ft

ft

ft

ft

ft

ft

ft/s

Vstall, landing

Vstall, cruise

774.17

0.8

177.78

401.6

Vmin power, SL

Vmin power, cruise

366

717

ft/s

ft/s

593

5897

43627

45217

16

ft/s

nmi

ft

ft

min

Fuselage Sizing

Pressurized Volume

Fuselage Width

Fuselage Height

Fuselage Length

Number of Aisles

Total Number of Rows

Economy Rows

First Class Rows

Cockpit Length

Empennage

Radome

Performance

Cruise Speed

Cruise Mach Number

Stall Speed (Landing)

Stall Speed (Cruise)

Maximum Endurance

Velocity at Min. Power, Sea Level

Velocity at Min. Power, Cruise

Maximum Range

Max Velocity, Sea Level

Maximum Cruise Range

Service Ceiling

Absolute Ceiling

Time to Climb

Vcruise

Mcruise

8

ft/s

ft/s

3.0 Weight Analysis

3.1 Mission Sizing

As previously stated in the initial design report, maximum take-off weight, WTO, was determined by

summing the Wfixed, Wempty, and Wfuel. Fixed weight consists of the weight of the 7 crew members and 220

passengers, assuming a weight of 225 lbs. for each individual, which yields 51,075 lbs.. This weight is viewed

as constant through our calculations. For fuel weight, calculations can be seen below. Ultimately, fuel

weight was found to be a function of take-off weight, which was found through iterations to be

0.3498*WTO. Regarding empty weight, Equation 3.1 is also found to be a function of take-off weight. From

Table 5.1 in the Nicolai and Carichner text, constants a and b for a transport aircraft are 0.911 and 0.947,

respectively.

Wempty = aWTO b

(3.1)

Fuel weight is expressed as several ratios at each segment during the mission profile. This is because fuel

is burned consistently during flight and the ratios at take-off will not equal that of the ratios at descent or

landing. (Nicolai) For example, the ratio of the weight after take-off to the initial weight is equal to 0.975,

while the ratio of weight after ascending to 32,000 feet to the weight after the take-off is equivalent to

0.97. For a turbojet, the weight ratio for cruise can be found below in Equation 3.2.

R=C

V

TSFC

L

W

ln(Wi )

D

f

(3.2)

Figure 3.1 Designed Mission Profile

From the Mission Profile in Figure 3.1 above, the range is close to 5000 feet and each phase of the mission

requires different amounts of fuel. In Table 3.1 below, the fuel burn during segments can be seen using the

range equation to compare the initial weight with the final weight of each segment.

9

Table 3.1 Mission Profile

Mission Segment

Fuel Burn (W_n+1/W_n)

Segment

Weight (lbs..)

n=1

n=2

0.975

n=1

281005

n=2

n=3

0.97

n=2

273980

n=3

n=6

0.70649

n=3

265760

n=6

n=7

1

n=6

187756

n=7

n=8

0.98251

n=7

187756

n=8

n=9

1

n=8

184472

n=9

n=10

1

n=9

184472

n=10

184472

Final Weight

3.2 Comprehensive Weight Analysis

More Detailed weights include Landing Gear, Starting Systems, Surface Controls, Flight Instruments,

Furnishings, and AC and Icing instruments. These weight estimations came from the several following

empirical Equations (3.3-3.7) which were found in the Nicolai & Carichner text, Chapter 20.2.1.

WLanding Gear = 62.21 ∗ (. 01WTO )0.84

(3.3)

WStarting system = 38.93(2 ∗ WENG ∗ .01)0.918

(3.4)

WSurface Controls = 56.01(WTO ∗ qMAX ∗ .0001)0.576

(3.5)

WFlight Instruments = 2 ∗ (15 + .032 ∗ (. 01 ∗ WTO ) + 4.8 + .006 ∗ (. 01 ∗ WTO ) + .15 ∗ (. 01 ∗ WTO ))

WAC and Anti−Icing = 469.3(Volume ∗ 227 ∗ .001)0.419

(3.6)

(3.7)

The other detailed weights include the weight of the furnishing on the aircraft included the flight deck,

passenger seats, lavatories, buffet stations, oxygen system, windows, cargo holdings, and miscellaneous.

Structure weights included the planform weight, fuselage weight, and the tail weight, all adjusted for using

advanced composite materials (see section 3.3 for more details of how this was done). After calculating

these, Table 3.2 below shows the detailed weights of the furnishings and the sum of them all. Engine weight

is found from manufacturing data.

Table 3.2 Comprehensive Weight Analysis

Component

Weight (lbs.)

Systems

10

% TOGW

Starting System

719

0.26%

Integrated Fuel Tanks

3347

1.19%

C.G Control System

304

0.11%

Engine Controls

67

0.02%

6662

2.37%

Flight Instruments

51

0.02%

Engine Instruments

14

0.005%

Miscellaneous Instruments

49

0.02%

Electrical

2503

0.89%

Air Conditioning & Anti-Icing

7138

2.54%

Flight Deck

275

0.26%

Passenger Seats

7047

1.19%

Lavatories

1448

0.11%

Food Provisions

2387

0.02%

O2 System

316

2.37%

Windows

6954

0.02%

Cargo Provisions

813

0.005%

Cargo Containers

3748

0.02%

Miscellaneous Furnishings

254

0.89%

Fuselage

18552

6.6%

Landing Gear

8095

2.9%

Planform

20505

7.3%

Empennage

11250

4.0%

Control Surface Hydraulics &

Pneumatics

Furnishings

Structures

11

Engines & Nacelles

23954

8.5%

Crew & Attendants

1575

0.6%

Passengers

49500

17.6%

Mission

97271

34.6%

Reserve

5174

1.8%

Trapped

1035

0.4%

281005

100%

Payload

Fuel

TOTAL

3.3 Composite Structures

When designing an advanced mid-sized transport aircraft, it is important to examine the use of advanced

materials to reduce weight of the airplane structures. A trade study on the benefits and penalties of the

use of composites in the construction of a modern aircraft was conducted and found that there are three

main advantages to the use of composite structures. They are weight savings, maintenance savings, and

increased lifespan.

The conclusion of the trade study shows that using composite materials has more benefits than using

typical aluminum materials for the airplane structure. Continuing concerns over the current cost of

production for advanced materials have been raised, but the team feels as though cost will decrease as

production increases, so that composite materials will significantly benefit our airplane design. For

reference, the trade study can be found in Appendix B.

Previous calculations for the weight of the structure were adjusted for the implementation of composites

materials. The empty weight was reduced by 17% and the gross takeoff weight was reduced by 15%. Table

3.3 below shows in detail how the empty weight was adjusted for composites. The reduction percentages

in Table 3.3 were chosen directly from chapter 20 of Nicolai & Carichner’s text.

Components

Planform

Empennage

Fuselage

Landing Gear

Table 3.3 Weight Corrections for Advanced Composite Materials

%Reduction

Weight (lbs.)

Without Composites

0%

25631

With Composites

20%

20505

Without Composites

0%

15000

With Composites

25%

11250

Without Composites

0%

24736

With Composites

25%

18552

Without Composites

0%

8742

12

All Else Empty

Engines

With Composites

Without Composites

With Composites

Without Composites

8%

0%

2%

0%

Revised Empty Weight

Empty Weight Reduction

Takeoff Gross Weight Reduction

8095

44757

44095

23954

126450

17%

15%

Composites are a combination of materials mixed together to achieve specific structural properties, the

independent materials in composites do not dissolve or merge completely but rather act together as one.

These materials generally consist of a fibrous material embedded in a resin matrix that is laminated with

fibers oriented in alternating directions. This structure helps establish strength. Different strength for a

desired direction can be produced by changing the fiber orientations for layers in a laminate.

Carbon Fiber Reinforced Polymer is an extremely strong and light fiber-reinforced plastic. It is often

comprised of carbon fibers and a binding polymer. It can be made by heating the fibers, typically aramid

(Kevlar), to ~2000ºC in an oxygen-deprived oven. These fiber end up being approximately 6μm (six

micrometers) in diameter and spun into a thread. These threads are then woven into sheets and mixed

with hardening resins, such as epoxy or silica, to form the various material needs. The manufactured

composite laminate is known to have the high strength to weight ratio as well as rigidity, which lends itself

to be very applicable to the aerospace industry.

Looking at our parent aircraft, the Boeing 787, carbon fiber reinforced polymer is used in the fuselage,

wings, empennage, and other various parts of the aircraft as seen in Figure 3.2. The Boeing 787 uses

approximately 50% composite materials by weight. This percentage is the largest by far of any Boeing

commercial airplane use in composite materials. Compared to an all-aluminum approach, the Boeing 787

saves about 20% of weight while full.

The composite material usage does not only cut down on the weight saved, but also on the maintenance

required, both scheduled and nonscheduled. This can be seen in the more experiences Boeing 777, which

has approximately 12% composites. Compared to the 767 aluminum tail, the 777 composite tail is

approximately 25% larger, while requiring about 35% less maintenance. Apart from the tail, the 777

incorporates a composite floor beam in all 565 airplanes. In the 10 years of flying, none of the 777’s needed

a composite floor beam to be replaced. Even if there is repair needed on a composite component, the same

process is used – with bolted repairs. There is also the option to perform bonded composite repairs, which

keeps the airplane’s aerodynamic and aesthetic finish. This rapid composite repair technique will allow

these airplanes to get back into the air faster than an aluminum airplane. Another technique that Airbus is

implementing is the use of composite panels, instead of full composite bodies. This allows for a whole new

panel to be installed for the broken panel. This method is faster in many cases.

Issues with composite materials are that they do not have visible cracks unlike metals and often can be

missed by simple inspection. In addition, composite materials are very porous in nature and collect

moisture caused stresses and strains inside the material. The stresses can cause delamination, or composite

layer separation. Many non-destructive inspection are used to see if the material is close to failure. Such

procedures include ultrasonic, X-ray, moisture detector, and audible sonic testing.

13

Figure 3.2 Boeing 787 Material Composition [modernairliners.com]

4.0 Airfoil & Wing Aerodynamics

4.1 Maximum Lift Coefficient and Lift Curve

To obtain the maximum lift coefficients at cruise and landing conditions, two-dimensional lift curves were

obtained for each case. The cruise lift curve was obtained using Xfoil at landing conditions, which

correspond to an effective Mach number of 0.1747 (a landing speed of 137 knots) and a Reynold’s number

of 26,007,742. The resulting two-dimensional lift curve can be seen in Figure 4.1.

Figure 4.1 Lift curve of SC2-0714 at sea level conditions.

It can be noted that Xfoil likely overestimated the higher end of the lift curve. Estimating that the maximum

lift coefficient probably occurs somewhere around a Cd=0.0250, a corrected Clmax of 2.21 can be obtained. This

maximum lift coefficient occurs at α=15 degrees. From this value, a three-dimensional CLmax of 1.72 was

obtained using Equation (4.1).

14

𝐶𝐿𝑚𝑎𝑥 = 0.9𝐶𝑙𝑚𝑎𝑥 cos (𝛬𝑐 )

(4.1)

4

Likewise, the two-dimensional lift curve was able to be obtained for cruise conditions from figures of NASA

Technical Memorandum 4044. Noting that for small angles the airfoil lift coefficient, Cl, is approximately equal

to the normal force coefficient, Cn, the lift curve at cruise conditions (Meff=0.70 and Re=40 x 106) is given and

can be seen in Figure 4.2

Figure 4.2 Lift curve of SC2-0714 at cruise conditions.

To find CLmax at cruise altitude, a Mach number for CLmax was obtained from Equation (4.2), where the

subscript “cruise” indicates conditions at cruise speed.

MCLmax =

Mcruise √CLcruise

1.2

(4.2)

The Mach number for maximum lift coefficient is 0.417, which corresponds to a Reynold’s number of

18,048,022. This condition was then used in Xfoil to obtain a Clmax of 1.79. Again, using Equation (4.2), a

CLmax of 1.40 was obtained. To approximate the full wing lift curve, the wing lift curve slope was found by

Equation (4.3).

AR

CLα = Clα (AR+2)

(4.3)

The two dimensional lift curve slope was obtained from the linear region of the airfoil lift curve and was

0.118 deg-1 for sea level and 0.155 deg-1 in cruise. Also, by fitting a line to the linear region of the lift curve,

an angle of attack for zero lift can be obtained, which is the same for infinite aspect ratio as it is for a finite

aspect ratio. The angle of attack for zero lift, α0L, is approximated to be -4.95 degrees. Using this

15

information, three-dimensional lift curve slopes were obtained, their values being 0.096 deg-1 and 0.127

deg-1 respectively. The effect of aspect ratio on the wing lift curve slope can be seen in Figures 4.3 and 4.4.

Figure 4.3 Lift curve of SC2-0714 with Infinite AR vs. AR=9 at Sea Level.

Figure 4.4 Lift curve of SC2-0714 with Infinite AR vs. AR=9 in Cruise.

16

4.2 High Lift Devices

By adding double slotted Fowler flaps, ΔCLmax at sea level increases by 0.878, which was calculated using

Equation (4.4) and noting that Equation (4.5) gives the ΔCLmax for double slotted Fowler flaps. Here, c’ is

the new chord with flaps extended, which was chosen to be a 30 percent increase from the base chord

(c’/c=1.3).

c’

ΔCLmax = 1.6 ∗ c

ΔCLmax = 0.9ΔClmax

Sflapped

Splanform

(4.4)

cos(ΛHL )

(4.5)

The sweep angle of the fowler flaps was calculated to be 20.3 degrees by Equation (4.6) to satisfy the 30

percent increase in chord. Also, it was assumed that the flapped area was approximately 50 percent of the

planform area.

4

1−λ

tan(Λ HL ) = tan(Λ LE ) − [0.7

(4.6)

]

AR

1+λ

Likewise, by adding Kreuger flaps along 80 percent of the span and applying Equation (4.5) with Kreuger

flaps contributing a ΔClmax of 0.3, CLmax was increased by 0.203. With the high lift devices deployed the new

ΔCLmax at sea level is 2.82.

5.0 Performance

5.1 Drag Build-Up

Drag contributions were contributed to profile drag for the wing, fuselage, and tail, the induced drag cause

by the wing, and finally trim drag from the tail. Each component of drag was calculated individually across

the speed range at both sea level and cruise altitudes. Then, they were summed to find the total drag across

the aircraft, Figs. 5.1 and 5.2 are the resulting drag force curves with respect to velocity. For Figures of drag

contributions to the total drag, see Appendix A.

17

Figure 5.1 All Drag versus Velocity Curves across Sea Level Speed Range

Figure 5.2 All Drag versus Velocity Curves across Cruise Altitude Speed Range

18

Profile Drag

The profile drag at sea level conditions was obtain using Xfoil and varying Mach number and Reynold’s

number. These values were then run at the corresponding lift coefficient needed for that speed to obtain

the speed’s section drag coefficient. Using the drag Equation (5.1), the profile drag was obtained. The

results of this can be seen in Figures 5.1.

1

Dprofile = 2 ρV 2 SCdprofile

(5.1)

The profile drag at a cruise altitude of 35,000 feet was obtained from NASA Technical Paper 2890. Again,

speed was varied and matched with a given Cn (Cn ≈ Cl for small α) to obtain the section drag coefficients.

Equation (5.1) was applied to obtain the total profile drag. The results can be seen in Figure 5.2.

Fuselage Drag

The fuselage drag was one of the more complicated drags to calculate, considering changing Reynolds

number along the length of the fuselage and different equations for skin friction coefficients due to

changing Reynolds number. A MATLAB script was written to deal with the complexities of the fuselage drag,

but also for the other drags. See Appendix B for the complete drag build-up script. The total length and

correct cross section of the aircraft was inputted into the Jetsizer-II workbook and produced nine different

points along the fuselage, dividing it into ten sections. This was done to use surface areas between the ten

sections of the aircraft to calculate the drag.

Then the Reynolds number was calculated for every location of the fuselage at every velocity in the speed

range. The script was written to determine if either Equations (5.2) or (5.3) should be used for skin friction

coefficient. Finally, the drag at every velocity was found using Equation (5.4).

1

CfLaminar = 1.328Re−2

(5.2)

Cf Turbulent = 0.455Re−2.58

(5.3)

Where 𝑅e =

ρVx

μ

and transiton Re ≅ 500,000

DFuselage = ∑𝑖 0.5ρV 2 Swi Cfi

(5.4)

Tail Profile Drag

Difficult to determine without a tail airfoil selected, the profile drag of the horizontal and vertical stabilizers

was estimated by taking the ratio of surface area between the tail and wing. This served as a correction

factor to the wing profile drag coefficient and it was decided to use these to find the tail drag. Of course,

this is an extremely crude approximation, but comparing to the Jetsizer-II workbook, the tail drags were of

similar magnitude.

Induced Drag

Induced drag is a result of the wing creating the necessary pressure difference between upper and lower

surfaces in order to produce lift, hence the term ‘induced’ drag. Furthermore, it is directly related to the

lift coefficient of the aircraft as seen in Equation 5.5.

19

C2

L

CDi = πeAR

(5.5)

Since CL is already a function of velocity squared, it is squared again in the induced drag coefficient. Then,

CDi is multiplied by velocity squared when finding total induced drag, therefore, the total induced drag

should be inversely proportional to velocity squared and this is evident in Figures 5.1 and 5.2. The induced

drag is the largest contributor to the aircraft drag.

Trim Drag

Trim drag is the consequence of the tail providing a down force with a backwards component to cancel the

aircraft nose-up pitching moment. Although it is a necessary evil, it should only account for 1-10%) of the

total drag of the aircraft (Nicolai & Carichner). Using a free body diagram of the aircraft in trimmed flight,

the lift coefficient for the tail required to obtain trimmed flight can be find as seen in Equation 5.6.

S

CLt = S l (c̅Cmac + xCL )

(5.6)

t t

Where the reference areas of the wing and tail appear, along with tail moment arm, lt , mean aerodynamic

chord, c̅, and moment coefficient about the wing aerodynamic center, Cmac. Trim drag coefficients were

then calculated from the derived formula of Equation 5.7.

S CLt

CDtrim = S

t

[

CLt eAR

CL CL et ARt

− 2] CDi

(5.7)

It is clear the trim drag is dependent on wing and tail parameters, and more importantly the induced drag

coefficient which was found beforehand. The trim drag at both altitudes were 5% and 4% of the total drag

and therefore were considered to be within reasonable magnitude.

Total Drag

Each component of drag were combined and the result is shown in Figures 5.1 and 5.2. Critical information

L

from these figures include the D

max

L

at both altitudes as well as the D at cruise velocity. Lift to drag ratios

are at a maximum at minimum drag, therefore the lowest points on the drag curve are where the values in

Table 5.1 are derived from. The maximum lift to drag ratios were considered reasonable for an advanced

mid-size transport, but it is thought that these values still have potential to increase, especially the cruise

L/D which reflects the efficiency of the aircraft and should be optimized.

Table 5.1 Lift to Drag Ratios Taken From Drag Curve

Sea Level

L/D max=23.7

L/D max=20.4

Cruise (35,000 Ft.)

L/D cruise=15.9

There are still many other forms of drag that were not accounted for in this preliminary analysis. Base,

interference, and transonic wave drag are some of the other forms of drag that could have a significant

impact on the values in Table 5.1, and therefore the design. Although the drag force will most likely

increase, with further analysis and detail design the wings may be able to produce more lift than expected,

or be optimized to reduce induced drag, trim drag, or others.

20

5.2 Thrust Requirements

For a constant altitude, the thrust of the aircraft is limited by the thrust available while being required to

overcome the drag at certain velocities. The thrust required for the aircraft is dependent on the total drag

build up from Figure 5.1 and 5.2. The drag buildup for a third altitude was also calculated to show a better

analysis of altitude variation for thrust. The mid-cruise altitude of 10,000 feet was used to find a third drag

build up, which was expected to fall in between the sea level and cruise curves.

The thrust available for this aircraft is dependent on the constraint diagram and thrust needed to take off.

Therefore, the thrust available to ensure the mission can be executed was 52,200 lbs. per engine at sea

level. The static thrust available for a constant altitude is equal to the original thrust available multiplied

by the ratio of the air density at that altitude over the air density of sea level. So the original 104,000 lbs.

at takeoff and sea level decreases to 74% that value at 10,000 feet and 31% that value at 35,000 feet. The

actual thrust available would experience a slight decrease in this value as airspeeds increase, until it

approaches the maximum speed wherein it increases again.

From the calculated thrust required from the drag build up and the thrust available given by the engine and

air density, the thrust curves for each of the altitudes can be found in Figures 5.3, 5.4 and 5.5.

Figure 5.3 Thrust Requirement Curve for Sea Level

21

Figure 5.4 Thrust Requirement Curve for 10,000 ft

Figure 5.5 Thrust Requirement Curve for 35,000 ft

22

5.3 Propulsion System

To size the propulsion system many parameters must be taken into account. To start the thrust to weight

ratio for the take-off, cruise, landing stall speed and service ceiling need to be found and graph compared

to wing loading to find the ideal engine size. Stall speed is the first parameter found and the calculation is

relatively simply. To find the stall speed we took Equation (5.8) and manipulated it to solve for wing loading

at stall speed, which produced Equation (5.9).

1

2

L = W = 2 ρVmax

SCLmax

W

S VS

( )

(5.8)

1

2

2

= ρVmax

SCLmax

(5.9)

This value will set the right side limit of the constraint diagram. Everything to the left of this wing loading

value will be in the acceptable range and meet the requirements set forth by the limiting stall speed.

Next the thrust to weight ratio for cruise is calculated to and graphed against wing loading as wing loading

increases. Starting with Equation (5.10), where 𝑉𝑚𝑎𝑥 is the velocity during cruise, and breaking down 𝐶𝐷

into component form we can get the following Equation (5.11) which is a manipulated thrust to weight

equation for cruise.

1

TSL σ = 2 ρV2max SCD

1

2

(5.10)

2

𝑇𝑆𝐿 𝜎 = 𝜌𝑉𝑚𝑎𝑥

𝑆 (𝐶𝐷0 + 𝐾 ∗ [

2

2𝑊

)

]

2

𝜌𝑉𝑚𝑎𝑥 𝑆

(5.11)

Finally after rearranging Equation (5.12), the thrust to weight ratio during cruise can be compared to the

wing loading.

TSL

)

W Vmax

(

2

= ρ0 Vmax

CD0

1

W

S

2( )

+

2K

W

( )

ρσV2max S

(5.12)

Next, the thrust to weight ratio during take-off needs to be accounted for. This will most likely set the

lower limit of the thrust to weight ratio needed to properly size the engines. Starting with the modified

take-off distance Equation (5.13), found from Mohammad Sadraey's report "Preliminary Aircraft Design"

where 𝐶𝐷𝐺 = (𝐶𝐷𝑇𝑂 − 𝜇𝐶𝐿𝑇𝑂 ) and 𝐶𝐿𝑅 =

𝐶𝐷𝑇𝑂 = 𝐶𝐷0 + 𝐶𝐷0 𝑇𝑂 + 𝐶𝐷 0

𝑓𝑙𝑎𝑝𝑠

2𝑚𝑔

2

𝜌𝑆𝑉𝑐𝑟𝑢𝑖𝑠𝑒

, the T/W value for take-off can be found. Noting that

and keeping in mind the average values for 𝐶𝐷0 𝑇𝑂 and 𝐶𝐷 0

𝑓𝑙𝑎𝑝𝑠

are 0.008

and 0.005 respectively, also found in Sadraeys's report, the equation can be manipulated to solve for T/W

and we get Equation (5.14).

1.65W

STO = ρgSC

DG

23

T

−μ

W

CD

−μ− G

W

CL

R

ln[ T

]

(5.13)

T

(W)

STO

(μ−(μ+

=

CD

1

0 )[exp(0.6ρgC S

D0 TO W )])

CL

R

S

1

(5.14)

1−exp(0.6ρgCD0 STO W )

S

This gives us a close to linear line when graphed and becomes the lower limit for operational thrust to

weight limits allowed within the design constraints.

Finally the thrust to weight ratio for the service ceiling is calculated. Using the rate of climb, Equation

(5.15) and solving for 𝑇/𝑊 we get Equation (5.16).

ROC =

T

(W) =

Pavl −Preq

ROC

2

W

( )

√ √CD0 S

ρ

(5.15)

W

+

1

(5.16)

L

( )

D max

K

To relate this to the service ceiling we use a 𝑅𝑂𝐶 equal to 100 ft/min and alter the equation to include

the ratio or densities at the giving service ceiling altitude, 𝜎. This now gives us Equation (5.17). This is

another critical equation in deciding the thrust to weight ratio needed for engine size selection as the ratio

needs to be above this curve for the aircraft to meet the requirements.

T

(W)

sc

=

ROC

2

W

σ

( )

√ √CD0 S

ρ

+

1

L

σ( )

D max

(5.17)

K

Pulling all these equations together and using the known values we are able to plot these four equations,

via Matlab, all on the same graph and therefore find the ideal thrust to weight ratio needed, seen in Figure

5.6.

24

Figure 5.6 Propulsion Design Constraint Diagram

The region in Figure 5.6 that is in between the four different curves is the ideal thrust to weight ratio region

and the designated design space for our engine. We chose a value for 𝑇/𝑊 of 0.325, the upper limit above

where the service ceiling and take-off 𝑇/𝑊 intersect.

This 𝑇/𝑊 ratio of 0.325 gives us a needed thrust of 91,326 lbs. for our take-off weight of 281,005 lbs. Using

a two engine set up this means we need about 45,663 lbs. of thrust for each engine. This value now means

we are going to look for a lightweight fuel-efficient engine that can provide at least this amount of thrust

per engine.

After research, the Pratt & Whitney PW4152 is the engine that most fits our requirements. With 52,200

lbs. of thrust per engine this is plenty of power to fly our plane. Intentionally oversizing the engines slightly

leads to greater safety in case one were to fail and the SFC is actually lower for this engine than many other

engines with a thrust closer to our ideal value. Overall this engine will provide the thrust required for all

elements of flight and provides our team with a resourceful and cost effective efficient turbofan engine.

25

Engine Specs

The engine chosen for our aircraft design is the Pratt & Whitney PW4152. Two engines will be

implemented into our design, each with a thrust of 52,200 lbs. and specific fuel consumption (SFC) of

0.312. More specification of the PW4152 can be found in Table 5.2, as well as an image of the engine in

Figure 5.7.

Table 5.2 Engine Specifications

Manufacturer

Pratt & Whitney

Units

Model

PW4152

-

Applications

A310-324/-324ET/-324F

-

Weight

9,213

[lb]

Thrust

52,200

[lbf]

SFC

0.312

[lb/lbf hr]

Fan Diameter

93.6

[in]

Length

132.2

[in]

Width/Diameter

97

[in]

Figure 5.7 PW4152 Engine Image

26

5.4 Climb Parameters

From the thrust requirement curves for the three different altitudes, the rate of climb of the aircraft can

be found. The rate of climb is a function of excess power, which is found by the velocity multiplied by the

difference between the thrust available and the thrust required. The high available thrust available of sea

level allows for the most excess power at a speed above take off velocity. Therefore, at sea level the rate

of climb is around 2939 ft/min. As altitude increases, the rate of climb decreases to 708 ft/min at the

cruise altitude. This data is plotted in Figure 5.8, in order to find the service ceiling and absolute ceiling

limits.

Rate of Climb vs. Altitude

3500

Rate of Climb (ft/min)

3000

2500

2000

1500

1000

500

0

0

5

10

15

20

25

30

35

40

45

50

Altitude (1e10 ft)

Figure 5.8 Rate of Climb

From this data in Figure 5.8, the service ceiling can be found as the altitude at which the rate of climb is

100 ft/min. Thus, the service ceiling is defined at 43,627 feet. The absolute ceiling is similarly found as

the altitude for which the rate of climb is 0 ft/min. The absolute ceiling was found at 45,217 feet. Both

these ceilings are limits and consequently larger than the mission requirements of 43,000 feet ceiling. Yet,

these values being relatively close to the mission requirements ensures the aircraft is operating efficiently.

The time of climb to the cruise altitude from sea level uses the rate of climb and distance needed to be

climb. From Figure 5.8, the time to climb to cruise without any other maneuvers or restrictions would be

approximately 16 minutes. Although this is relatively short, the excess power granted from the engines at

the altitudes leading up to the desired 35,000 feet allows for the higher rate of climb. A shorter time of

climb value is optimal for decreasing profile drag, but is limited by the rate of climb to prevent excess fuel

consumption.

27

5.5 Takeoff and Landing Analysis

Take off distance is the sum of ground distance, rotation distance, transition distance, and climb distance.

These values all depend on various aircraft properties such as stall velocity, coefficient of lift, coefficient

of drag, etc. The following Equations (5.18-5.21) pertain to values used in the takeoff estimation for this

aircraft.

g

(T − D − μ(WTO − L))

WTO

acceleration =

VTO = 1.2Vstall = 1.2 ∗ √

2 ∗ WTO

ρSREF CLmax

∆CDG = ∆CDflaps + ∆CDgear + ∆CDi

VTO

SG = ∫

0

2

d(V 2 )

VTO

≈ 0.5

2a

a

(5.18)

(5.19)

(5.20)

(5.21)

There are several ways to estimate the takeoff ground distance for an airplane. This estimation procedure

assumes the acceleration is constant, and equal to the value at V = 0.707 V_TO. Using Equation (5.18), it

is possible to find the ground acceleration of the airplane, which is found to be 9.5 feet per second, when

the airplane is at 0.707 velocity take-off. The takeoff velocity is found using Equation (5.19), incorporating

the stall speed at sea level. For this aircraft, the maximum lift coefficient during takeoff is 2.6, then the

takeoff speed is calculated to be 240 feet per seconds. This speed is consistent with our parent aircrafts.

The lift and drag are changing as the velocity changes, so to calculate these values, these coefficients are

needed. The initial lift coefficient is 0.49 and incorporating double fowler flaps, we can increase this value

to 1.37 as a maximum lift coefficient. The drag coefficient is calculated using the initial drag coefficient

and changes due to flaps, gear, and induced drag. This is represented in Equation 5(5.20). These values

can be found in figure 9.25 and 10.5 in Nicolai for the flaps and gear respectively. The induced drag can

be calculated using the new value of coefficient of lift with the given flap setting. The coefficient of drag

is found to be 0.2 for this aircraft during takeoff at sea level. Equation (5.21) is then used to calculate the

ground roll distance which was found to be 5896 feet.

The next distance can be calculated using Equation (5.22) below. This is the rotation distance in which the

aircraft is (still on the ground) rotated to an angle of attack in such the coefficient of lift is now 0.8 ΔCLmax .

After this rotation, the coefficient of lift will have a value of 2.1 for this aircraft. This distance is estimated

to take 2 seconds and is calculated to be 482 feet.

SR = (2 seconds) ∗ VTO

(5.22)

STR = Rsin(θCL )

(5.23)

R=

2

VTO

0.152g

Rate of Climb

θCL = sin−1 (

)

VTO

28

(5.24)

(5.25)

SCL =

(hobsticle − hTR )

tan(θCL )

(5.26)

Equation (5.23) estimates the transition distance. This is the distance that the aircraft flies a constantvelocity arc with a radius R. The radius can be calculated in Equation (5.24) and was found to be almost

12000 feet. The angle of climb can be estimated from the rate of climb, which is 3400 feet per minute.

The angle of climb is calculated to be about 7 degrees, using Equation (5.25). Using Equation (5.23), the

distance for transition is calculated to be 1378 feet. At the end of this takeoff phase, the airplane is at a

height of 160 feet. This value is greater than the given FAA requirement for an obstacle, 35 feet. Figure

5.9 describes a takeoff trajectory.

Figure 5.9 Schematic for Takeoff Analysis (Nicolai)

Therefore, Equation (5.26) is not needed, as we are above the climb needed and the climbing distance is

zero feet. The takeoff distance can be seen in Table 5.3 below. The sum of the takeoff distances gives the

total distance to be 7756 feet. This value is just under the 7800 feet takeoff requirement.

Table 5.3 Take off Distance for different thrust amounts

Thrust Amount

Full

SG

5896 feet

SR

482 feet

STR

1378 feet

SCL

0 feet

STOTAL

7756 feet

The landing distance is defined as the horizontal distance required to clear a 50 foot obstacle, free roll,

and then break to complete stop. Figure 5.10 below show the schematic for landing. The velocity over the

50 foot obstacle is assumed to be 1.3 Vstall, or 228 feet per second. The touchdown velocity is assumed to

be 1.15 Vstall, or 202 feet per second. The weight of the aircraft is assumed to be when half the fuel is

burned, or 231,172 pounds. The coefficient of lift for landing is assumed to be the maximum value with

engaged flaps and slats in the landing configuration. The lift coefficient is 2.82 for the landing coefficient.

29

Figure 5.10 Schematic for Landing Analysis (Nicolai)

The sum of the air distance, free roll distance, and braking distance is the estimation of the total landing

distance. The air distance uses the relationship between kinetic and potential energy. It can be calculated

using Equation (5.27) below. This Equation utilizes the lift and drag of the airplane. The lift can be assumed

as the weight of the landing airplane. The drag can be calculated using Equation (5.28). The coefficient of

drag must be altered due to drag effects of the flaps, gears, and changing induced drag. The coefficient of

drag is calculated to be 0.346, and this is represented in Equation (5.29) below. The air distance can now

be calculated to be 774 feet.

2

2

L V50

− VTD

(5.27)

SA = (

− hobsticle )

D

g

D = q50 SREF CD

(5.28)

CD = CD0 + CDi + ∆CDflaps + ∆CDgear

(5.29)

The free roll distance is the distance covered while the pilot reduces the power to idle, retracts the flaps,

deploys the spoilers, and applies the brakes. These adjustments change the values of the thrust and the

drag coefficient. The thrust can then be assumes to be zero and the coefficient of drag is updated to be

about 0.353. Free roll is assumed to last 3 seconds and it is represented in Equation (5.30) below.

SFR = (3 seconds)VTD

(5.30)

The braking distance can be calculated using Equation (5.31) below. The acceleration can be calculated

using Equation (5.32), where R is the reverse thrust. For this estimation, thrust is assumed to be zero while

breaking, and the reverse thrust is neglected for now. The coefficient of drag is also calculated to be 0.353

for a landing configuration that does not retract the flaps during free roll. This is done using Equation

(5.33). The deceleration can then be calculated as 6 feet per second. If the pilot does retract the flaps

during free roll, the coefficient of drag is 0.17. The deceleration can be calculated to be 3 feet per second.

After substitution and manipulations, Equation (5.31) can be simplified to Equation (5.34) to find the

braking distance. The breaking distance without retracting the flaps is 8070 feet. The breaking distance

with retracting the flaps is 9274 feet.

d(V 2 )

2a

V2

TD

0

SB = ∫

30

(5.31)

1

a = ( ) (T − D − μ(L − WL ) − R)

m

(5.32)

CD = CD0 + CDi + ∆CDflaps + ∆CDgear + ∆CDmisc + CDspoilers

(5.33)

WL

SB =

gμρSREF ((

CD

) − CLG )

μ

ln (1 +

ρ SREF CD

2

( − CLG ) VTD

)

2 WL μ

(5.34)

The total landing distance is the sum of the air distance, free roll distance, and braking distance. During

the free roll the pilot has the option to retract the flaps and slats to decrease lift, so that the total landing

distance is calculated to be 10980. If the pilot does not, the coefficient of drag remains high and the total

braking distance is 9777 feet. While these both exceed the takeoff requirement, it is still a reasonable

value for various international airport runways worldwide. While these estimates can hold close to actual

values, there may be more drag available to slow the airplane down as the drag build up at sea level close

to stall speed has a coefficient of drag of 0.443. Other forms of deceleration could be from reverse thrust

or high energy absorption brakes. Table 5.4 below shows the landing distances below.

Flaps

SA

SFR

SB

STOTAL

Table 5.4 Landing Distance

Retracted

1102 feet

605 feet

9274 feet

10981 feet

Engaged

1102 Feet

605 Feet

8070 Feet

9777 Feet

6.0 Stability Analysis

6.1 Longitudinal Static Stability

For the design to be considered airworthy, it must be able to fly safely and adhere to stability requirements

set by the Federal Aviation Administration. In this preliminary design, only critical longitudinal static stability

requirements were considered. This analysis required calculating the center of gravity (C.G.) location, C.G.

limits, neutral point location, Static Margin, and pitch stiffness.

Center of Gravity

The C.G. location for this aircraft was determined from the different components' weights and moment

arms in relation to the location of the mean aerodynamic chord of the wing. The weights of the wing

planform, fuselage, engines, landing gears, empennage, and all else empty were found from the

comprehensive weight analysis summarized in Table 3.2.

31

The moment arms for each component were dependent on the location of the component to the leading

edge of the mean aerodynamic chord. The weight of the wing and engines, positioned at 55% the length

of the plane, were acting at a moment arm of 40% the mean aerodynamic chord aft the leading edge.

For the landing gear, the nose gear was positioned 15% the length aft the nose of the plane, with the main

gear acting at 85% the total length. The weights of the fuselage and all else were positioned at 50% the

length of the aircraft. For the empennage, the horizontal tail mean aerodynamic center was determined

to be 80.2 feet from the mean aerodynamic center of the wing, and the distance for the vertical tail was

75.3 feet.

Using these moment arms, the C.G. location was found by the ratio of each component's weight and

moment arm product over the total weight of the aircraft. Therefore, the C.G. location was 4.2 feet aft the

leading edge of the mean aerodynamic chord, or 23% the chord. To see the MATLAB script used to find the

C.G location, refer to Appendix C.

Neutral Point

𝑑𝐶

The neutral point is effectively the aerodynamic center of the entire aircraft or where 𝑚 = 0. Therefore,

𝑑𝛼

the neutral point is where the pitch moment of the entire aircraft does not change when the angle of attack

changes. For most aircraft, the neutral point location in respect to the center of gravity is critical for a design

𝑑𝐶

because it relates to a very important stability derivative which also happens to be 𝑚 or the “pitch

𝑑𝛼

stiffness”.

How the neutral point was found is by virtue of summing the longitudinal moments about the aircraft,

differentiating them with respect to 𝛼, setting the result equal to 0, and finally solve for the X-location of

the neutral point. This process gives the result found in Equation 6.1. For this design, Equation 6.1 yields a

neutral point location that is 6 Ft. aft of the leading of the mean aerodynamic chord, or 33% of the MAC.

Xnp =

S

1 d

Xacw CLα HT CLαHT +

[Mfuselage +Mnacelles ]

S

qSdα

S

CLα + HT ClαHT

S

(6.1)

The moments of the fuselage and nacelles derivatives with respect to the angle of attack were found using

two simple derived formulas that were provided. They are Equations 6.2 and 6.3, for the fuselage and

nacelle respectively.

Cmαfuselage =Kf

Cmα

W2fusemax Lfuse

Sc̅

2∀

nacelles = sc̅

(6.2)

(6.3)

The length and width and wing characteristics are variables of the fuselage pitch moment derivative. The

K f coefficient is a factor from NASA Technical Report TR711 Figure 8, and estimated to be 1.6 for this design.

For the nacelles the ∀ parameter is the enclosed volume of the nacelle assembly.

32

6.2 Stability Requirements

After finding the neutral point location, the next step is to calculate the static margin, which is defined as

the distance per percent chord of the center of gravity and the neutral point, see Equation 6.4. Usual values

of static margin for a transport aircraft are between 4% and 7% (Nicolai 616). This design’s calculated static

margin is equal to 9.8%, which is slightly higher than expected, and translates to a more stable, but less

maneuverable aircraft. In future iterations it will be desired to reduce the static margin to increase aircraft

maneuverability.

SM = (hn − h)

(6.4)

Cmα =CLα (h−hn)

(6.5)

The real problem with the C.G and neutral point locations are that they are believed to be too far forward

on the MAC. Typical values usually range between 25-35% of the MAC for the C.G. This is because the

aircraft wants to be almost balanced about the wing aerodynamic center so that when the C.G moves it

does so only slightly.

The pitch stiffness is proportional to negative static margin, and is shown in Equation 6.5. For stability, the

pitch stiffness must be negative along with a positive Cm0 to allow the aircraft to be stable and trim-able.

Thus a positive static margin is required for stability, and ultimately the C.G may not exceed the neutral

point along the MAC.

Center of Gravity Limits

The Limits for the center of gravity forward and aft of the aircraft can be determined by two criteria. The

simpler of the two is the aft C.G. limit, which is equal to the neutral point location of the aircraft, and does

not change. This is to retain a positive static margin for longitudinal stability requirements. Therefore h may

not exceed 33% of the mean aerodynamic chord. .

The forward limit was approximated by using a free-body diagram approach, where the C.G was moved

forward and the lift forces to trim were calculated. Once the lift force on the horizontal tail became

extremely large, so much that it obviously must be enlarged in order to produce such a force that was the

determined forward limit of the C.G . This was about -10% of the mean aerodynamic chord, where the

negative percentage means it in in fact forward of the wing. Figure 6.1 depicts these limits along with the

center of gravity and neutral point locations.

33

Figure 6.1 Center of Gravity, Neutral Point and C.G. Limits at Maximum Takeoff Weight

In the graphic above, 6.1, the red dashed lines indicated the forward and aft limits of the center of gravity.

These seem very close, in fact the C.G is within 2 Ft. of the aft limit, and 6 Ft. of the forward limit. However,

by keeping the C.G on top of the wing and almost centered on the entire aircraft, it should not move as

much as the fuel is depleted. Also, this aircraft would include a water pump system to control the C.G

movement as the fuel (almost a third of the weight) is removed.

7.0 Cost Estimates

Table 7.1 Cost Estimation Breakdown for 100 Aircraft Produced (2 Test Aircraft)

2015 Calculations

Values

Engineering ($/hr)

132

Engineering

2954762015

Development Support (With Inflation)

446147015

Flight Testing (With Inflation)

43396196

Tooling ($/hr)

143

Tooling

1856700398

Manufacturing ($/hr, 2015)

114

Manufacturing

4747049450

34

Quality Control

360775758

Material and Equipment

2108005139

Engine and Avionics

2574194

Total Cost

12519410166

Cost per Aircraft

122739315

Table 7.2 Production Cost with varying Aircraft Quantity

Number of Aircraft Produced

Production Cost ($)

Cost per Aircraft ($)

100

12,519,410,166

122,739,315

500

28,864,315,492

57,498,636

1000

43,343,200,034

43,256,686

The production cost estimation of the aircraft was calculated using the DAPCA IV Equations, taken from

Nicolai and Carichner chapter 24. Items such as engineering, tooling, manufacturing, and materials have all

experienced increases in “wrap rate” since 1998.

To estimate this increase, Figure 24.4 from Nicolai and Carichner was utilized. Taking the linear curve fits,

and entering the year 2015, the adjusted rates were able to be estimated reasonably. In doing so, it was

apparent that the most expensive item, in terms of rates, was tooling. Fortunately this is a nonrecurring

cost, and therefore does not drive the cost significantly higher in the long term. Factors such as

development support and flight testing have been adjusted using an inflation rate of 1.46%, taken from a

basic inflation calculator.

In evaluating the cost in the long term, for larger orders such as 1000 production aircraft, it became

apparent that the cost per aircraft largely decreases as compared to producing only 100 aircraft. This can

be attributed to the nonrecurring costs such as engineering and tooling, as previously stated. In the end,

the most significant factor which drives the cost of production for the aircraft is ultimately manufacturing

cost. Manufacturing cost consumes an increasingly large percent of production cost as the number of

orders increases. It is to be noted that “fudge factors” have not been included in this cost estimation, as it

is apparent that various different composites are used in highly specific locations on the aircraft, something

outside the scope of this preliminary design. With this said, the cost per aircraft will be inherently higher

than the given aluminum predictions seen above.

35

Concluding Statements

Team 2 started this design almost three months ago. It is fulfilling to have closed out the preliminary

design phase with this report. This preliminary design served as a learning experience for seven young

engineers pursuing undergraduate degrees in Aerospace Engineering. Much of the figures and values of

the design presented in this report went through several iterations until finalizing the design. The project

began with numerous assumptions, many which would need to be corrected and have been since, but for

the means of this project, they were the only possible direction to take to begin the calculations.

There is still, however, much more work to be done and a more detailed design is needed in order to

have a flyable aircraft. In this detailed design, some of the prominent aircraft parameters will change such

as the gross takeoff weight, length, width, and wing area of the aircraft. It is understood by Team 2 that

the aircraft in its current state is most likely not at its optimum design, and has potential to be more

efficient in several areas. One such area is the engine sizing; it is a general consensus among the group

that the engines are too large for the mission requirements, but were chosen because no others in the

market fit the design better.

Very important aspects of the design vehicle not taken into any consideration are the control surfaces:

elevators, rudder, and ailerons. These will be critical systems to incorporate into the aircraft and could

potentially require changes in the tail and wing design.

Despite these concerns, Team 2 believes strongly in this concept aircraft and has confidence that it can be

a very efficient aircraft after more design features are implemented. As for the overall experience itself, it

is safe to say Team 2 has obtained a great amount of knowledge about general aircraft design. If starting

the design over again from right now, the design could have taken a slightly different course, and be

overall better due to the newly gained experience of the team.

As it turns out, the most challenging aspect of this project was dealing with assumptions and choosing

parameters that were unknown for the design. Whether the values came from the parent aircraft, the

textbook, or some other source, it always became a question of if these assumptions were valid to use.

There was very limited test data, and much of aircraft parameters are proprietary data held by real

aircraft manufacturers. This was dealt with in any way possible, and usually included one of the sources

listed below. Another frequent concern was determining if calculated values were of reasonable

magnitude for this aircraft. The general design philosophy assumed that it is a mid-size transport,

therefore it should have roughly mid-sized values to other transport aircraft.

One last note on the project challenges, and the most important one, was how to make this design a

competitive solution for a 2025 entry date. As always, it is difficult to predict where the industry will head

towards in the next decade in terms of advances in technology and market demand. These considerations

are truly what drives an aircraft design and determines what makes it marketable.

Middle of Market Team 2 would like to thank Dr. James Coder and teaching assistant Nick Grasser for

their instruction, guidance, time, and consideration throughout the entirety of the development process.

36

References

"AERO - Boeing 787 from the Ground Up." AERO - Boeing 787 from the Ground Up. N.p., n.d.

Web. 20 Oct. 2015.

"Air Cargo ULD Containers: LD-3 Dimensions." SeaRates. N.p., n.d. Web. 12 Dec. 2015.

"Boeing Considers Single, Twin Aisle, Co-development 757/767 Style for next New Airplane –

Leeham News and Comment." Leeham News and Comment. N.p., 02 Nov. 2014. Web.

21 Oct. 2015.

"Boeing Sees Airlines Craving Longest-Ever Narrow-Body Plane." Bloomberg.com. Bloomberg,

n.d. Web. 21 Oct. 2015.

"Boeing 787 Dreamliner: Analysis." Lissys Ltd., 2006. Web. 20 Sept. 2015.

"Circular Economy Could save Billions of Dollars." New Scientist 213.2854 (2012): 5. Web.

"Civil Jet Aircraft Design - Boeing Aircraft." BookSite. Butterworth-Heinemann, 2001. Web. 22 Oct.

2015.

"Delta Seat Maps Boeing 757-200." SeatGuru. Tripadvisor.com, 2015. Web. 22 Oct. 2015.

Fuchte, Joerg, Bjoern Nagel, and Volker Gollnick. "Twin Aisle for Short Range Operations - An

Economically Attractive Alternative?" 12th AIAA Aviation Technology, Integration, and

Operations (ATIO) Conference and 14th AIAA/ISSMO Multidisciplinary Analysis and

Optimization Conference (2012): n. pag. Web.

Gilruth, R. R., and M. D. White. "Analysis and Prediction of Longitudinal Stability of Airplanes." NACA-TR711 (1941): 137-45. Web.

"How Do Winglets Work?" Flite Test. N.p., n.d. Web. 23 Oct. 2015.

"Innovative Materials | Airbus, a Leading Aircraft Manufacturer." Airbus. N.p., n.d. Web. 20

Oct. 2015.

Jenkinson, L., P. Simpkin, and D. Rhodes. "Butterworth-Heinemann - Civil Jet Aircraft Design - Aircraft Data

File - Boeing Aircraft."Butterworth-Heinemann - Civil Jet Aircraft Design - Aircraft Data File Boeing Aircraft. N.p., n.d. Web. 13 Dec. 2015.

Jenkins, Renaldo V., and Acquilla S. Hill. "Aerodynamic Force." Aerodynamic Performance and Pressure

Distributions for a NASA SC(2)-0714 Airfoil (1988): n. pag. Web.

Jenkins, Renaldo V. NASA SC(2)-07 14 Airfoil Data Corrected for Sidewall Boundary-Layer Effects.

Washington, D.C.?: National Aeronautics and Space Administration, 1989. Web.

Kroo, I. "Vki Lecture Series On Innovative Configurations And Advanced Concepts For Future Civil

37

Aircraft." NONPLANAR WING CONCEPTS FOR INCREASED AIRCRAFT EFFICIENCY (2005): n. pag.

Aero.stanford.edu. Stanford University. Web.

Liebeck, R.H. "Design of the Blended Wing Body Subsonic Transport." Journal of Aircraft 41.1 (2004): n.

pag. Vicomplex.hu. Web. 22 Oct. 2015.

"Longitudinal Static Stability." Longitudinal Static Stability. N.p., n.d. Web. 23 Nov. 2015.

Mizrahi, Joe. "Blended Wing Body - New Concept in Passenger Aircraft." Twitt.org. N.p., n.d. Web. 23

Oct. 2015.

Nicolai, Leland M., Grant Carichner, and Leland M. Nicolai. Fundamentals of Aircraft and

Airship Design. Reston, VA: American Institute of Aeronautics and Astronautics, 2010.

Print.

Robert Faye Robert Laprete Michael Winter. BLENDED WINGLETS (n.d.): n. pag. Web.

Sadraey, Mohammad. "Chapter 4. Preliminary Design." Dxc.edu. N.p., n.d. Web. 1 Dec. 2015.

"Supercritical Airfoil Design." Integral Equation Method in Transonic Flow Lecture Notes in Physics (1982):

135-49. Web.

"The Future of the Narrowbody Airplane Market." Seeking Alpha. N.p., n.d. Web. 21 Oct. 2015.

"Their New Materials." WSJ. N.p., n.d. Web. 20 Oct. 2015.

"The Spiroid Winglet." Tails Through Time: The Spiroid Winglet. N.p., 07 Aug. 2010. Web. 23 Oct. 2015.

"UIUC Airfoil Data Site." UIUC Applied Aerodynamics Group, 2015. Web. 22 Oct. 2015.

"US Airways Seat Maps Boeing 757-200 (752) V1." SeatGuru. N.p., 2015. Web. 22 Oct. 2015.

"Winglets - A Triumph of Marketing over Reality »." AirInsight. N.p., 10 Apr. 2012. Web. 22

Oct. 2015.

"Winglets: Making Their Presence Felt." (n.d.): n.

pag. Http://www.aviationpartnersboeing.com/pdf/news/at69winglets.pdf. Apr.-May 2004.

Web. Oct. 2015.

38

Appendix

A. Additional Figures and Tables

Detailed Weight Breakdown By Percentage

0.9%

1.3%

Structure

2.5%

2.4%

8.3%

Fuel

17.9%

0.3%

Payload

2.9%

Propulsion

8.5%

Landing Gear

Start System

18.2%

36.8%

Control Surface

Gear

Figure A.1 Comprehensive Weight Analysis

Empty Weight Reduction By Including Advanced Composite Materials

180000

160000

[Weight [lbs..]

140000

120000

100000

80000

Without Composites

60000

With Composites

40000

20000

0

Planform Empennage Fuselage

Landing

Gear

All Else

Empty

Total

Components

Figure A.2 Empty Weight Reductions

39

Sea Level Drag Contributions by Component

Profile

21.2%

25.1%

1.6%

Induced

Trim

5.5%

Tail Profile

Fuselage

46.5%

Figure A.1 Drag Contributions at Sea Level, values taken at L/Dmax.

Cruise Altitude Drag Contribution by Component

18.4%

28.8%

1.8%

Profile

Induced

4.41%

Trim

Tail Profile

Fuselage

46.6%

Figure A.1 Drag Contributions at 35,000 Ft., values taken at L/Dmax.

B. Advanced Composite Materials Trade Study

In researching the benefits and penalties of the use of composites in construction of modern aircraft, three

glaring advantages were recognized; weight savings, maintenance savings, and increased lifespan.

Both Airbus and Boeing discuss the implementation of advanced composites on their new aircraft. Boeing

states that, “The result is an airframe comprising nearly half carbon fiber reinforced plastic and other

composites. This approach offers weight savings on average of 20 percent compared to more conventional

aluminum designs”, when discussing the new 787 Dreamliner in their website magazine. Similarly, Airbus

40

claims to have seen a 20% weight reduction as a result of the new A350 XWB being constructed from 53%