Lecture 2 Part 1 - IQSoft Software Consultants

advertisement

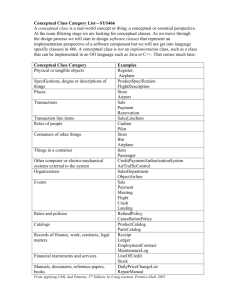

CPPT 9010: Facility Design & Operation D.I.T. DT275 Masters in Chemical and Pharmaceutical Process Technology 26th November 2009 Clement Farrar BA BAI MSc MIEI 1 Lecture Overview 1) Conceptual design 2) Site Master Plan 3) Tech Transfer 4) Assignment Workshop 2 Conceptual Design What is Conceptual design? 3 Result of many hours brainstorming, discussion….. Formal and structured document Fact not fiction Conceptual Design Definition/ Purpose 4 First and real quantified attempt to size, shape, program and cost an investment Provides a robust basis for investment decisions Key element in feasibility study Assists in facility location decisions Basis for assessing local infrastructure Basis for detailed design Conceptual Design Approach 5 The process is key - start with the process and provide optimal conditions Develop batch philosophy, sizing, frequency and throughput for all stages Size process elements and define space and servicing requirements Design outwards from process elements to other disciplines e.g. utilities, HVAC, E&I, Civil/ Structural/ Architectural Manage a coordinated design approach across all disciplines Collect/ collate disciplinary input for cost estimation Conceptual Design Manufacturing Logistics 6 Essential as a good basis for concept Full scale study begins with dose form and market projection based on annual patient dose and patient population Move backwards through doses, packs, lyo load, fill rate, formulation batch size, vessel size and number, innoculum, seeding etc to sees what’s required to meet the target (always allow a safety factor) Allow for qualification, cleaning, downtime, decontamination, shifts, maintenance etc. in study Move outwards from core process through CIP, Process Utilities, General Utilities etc Conceptual Design Deliverables from Conceptual Design 7 Process descriptions and PFD’s (Process flow Diagrams) (not P&ID’s) Equipment Lists, schedules and outline specs Layouts and sections with classifications Material and personnel flow studies cGMP review HVAC schematic and philosophy Schematic for clean and general utilities Electrical load calculations and SLD Controls philosophy Cost estimate +/- 25% (typical) Project Schedule Site Plan Conceptual Design Optional Deliverables 8 Planning Package Selected Equipment Specifications Long Delivery PO’s Negotiations with utilities providers Validation Master Plan Validation input on long delivery items Conceptual Design Develop Process Remember the core purpose of the facility is to accommodate a process or processes ‘Process’ can be fermentation, DSP, formulation, fill finish or even packaging A robust process with known output requirements is a basic prerequisite PFD’s are first Engineering Description of Process Good PFD’s will show: 9 Equipment with sizes/ duties Flows Material Balances Sequence/ Timings/ Durations Cleaning/ Process Utilities needs Conceptual Design Equipment 10 Process equipment list is a critical document – for planning, layout, costing etc Key equipment sized from manufacturing logistics and batch sizing (what is it required to do?) Early vendor input is beneficial Size and shape of equipment needed for concept stage Configuration of process areas is based on equipment sizing and access requirements Decisions on ‘state of the art’ technology or older proven technology Conceptual Design Critical Utilities 11 Start with process utilities and direct impact systems Includes RO, WFI & Clean Steam Can also include CIP (may be part of process) Size and shape of generation plant, storage and distribution Other than CIP, which is integrated, most critical utilities need to be close/ adjacent Conceptual Design HVAC & Classification 12 Critical in most areas of typical aseptic facility - more so in fill finish Have the classification discussions/ decisions early In essence, HVAC plant and distribution need to be adjoining to area served HVAC, classifications are major determinant of ultimate layout and indeed of most utilities Conceptual Design Layers 13 Apply layering concept Layers roughly correspond to classifications ‘Core’ is where critical process takes place In multi process facilities, there may be multiple cores Adjacent layers – reduced need for proximity Remote layers – not proximity dependent Conceptual Design Preliminary Layouts 14 Developed on ‘core outward’ basis Classifications are critical - classification drawings needed Protection of process core areas – airlocks and garbing Define pre and post inactivation Separate entry and exit may be needed Return corridors Decontamination areas Corridors critical – these can dictate classifications Conceptual Design Process Layouts Sensible spacing Common sense flow patterns Ordered configuration Access for Materials, Personnel, Maintenance Engineering Aesthetics Flow Priorities are: 15 Materials Personnel Fluids Cable systems Conceptual Design Buffer Make-up 16 Biggest material movements in bulk processing Should be adjacent to formulation Generally larger overall volumes than core process May require material handling, dust control etc Sterile filtered at this point Conceptual Design Clean Utilities & CIP 17 CIP/ SIP are integral parts of a process design WFI generation, storage and loop distribution Clean Steam generation & distribution Significant space required CIP circuits should be as short as possible/ integrated – design for gravity return where possible Conceptual Design Access & Communications Corridors 18 Keep material movements under cover Link corridor preferred – also favour straight spine with buildings either side Warehouse is focal here – more so for fill/ finish than bulk Personnel facilities are important – significant time losses in canteen or rest room trips (smoking areas?) Also truck access to be addressed Link corridor may be at 2 levels Conceptual Design Warehouse/ Material Movements 19 Calculate number of pallets - no shortcuts here as operations are specific Minimum level for large plant is narrow aisle with 7-8 pallets high - requires 0.5 m2 per pallet Traditional low profile needs 2.0m2 per pallet Decisions on receiving/ dispatch, sampling, dispensing etc Warehouse configuration drives site layout Conceptual Design Personnel Movements 20 Essential personnel only close to process (balance garbing and accommodation costs against proximity) Secondary/ tertiary garbing must be close Normal now to have separate in/ out flow passages Separate primary change/ lockers/ toilets/ showers Analyse movements – may justify multiple cafeterias, toilets, primary change areas Conceptual Design Decisions on Height 21 Fill/ Finish height – usually single process floor Bio facility ideally at least 3 floors: Process is sandwiched between HVAC and CIP (utilities) Process utilities can be above, below or alongside Two floor process drives us to 4 floor ideal (e.g. 12500L Vessel) Warehouse height – min 12m Admin & other heights based on footprint available Conceptual Design Air Handling 22 Layouts and classification drive HVAC sizing HVAC plant is a big space user – plant room footprint usually exceeds total process area (top floor) Early decisions needed for walk-on concept, interstitial spaces etc Care with intakes and exhausts – allow segregation Decision re: LPHW or steam as heating medium Don’t over specify humidity limits – costly Smart recirculation policy based on energy efficiency Separate once-through needed for ‘active’ spaces Conceptual Design Utilities – General 23 Biggest user is HVAC – next is Process Utilities Assess demands for these users Size primary generation equipment – use modular approach >3 units CUB (Central Utilities Building) concept now fairly universal CUB usually remote to avoid interference with expansion plans Smart planning for pipe racks and distribution Conceptual Design Electrical 24 Size from load list and utilities requirement Apply diversity factors based on experience Locate MCC’s adjacent to loads Decision on standby generation and scope Assess local reliability and capacity Policy on centralized versus distributed transformers Consider renewable/ sustainable energy Conceptual Design Controls & Automation 25 Early decisions on general principles: PLC vs. DCS Similarly for scope of communication and networking Avoid ‘nice to have’ items – can result in downstream complications Similarly avoid ‘state of the art’ – usually untested and may result in unknown complications Remember need for aseptic interfaces Conceptual Design Finishes 26 Policy decision re: proprietary partition vs. traditional stud Similar decisions for floors, ceilings, doors and windows Again, remember Baselines Guides for economical solutions Proprietary partitions cost significantly more – don’t be fooled They can however save significantly in time, use of wet trades, disruption They also look better (makes facility more impressive) Clean Room Wall Make-Up STICK BUILT Cold formed Metal stud frame system. Gypsum plaster board Plaster skim coat. Spray applied STERIDEX paint system. Wall protection. MODULAR High pressure laminate. (Or steel panel) . 27 Advantages: Theoretically more economical. Disadvantages: Coordination of trades. Wet & dusty construction. Schedule impact Advantages: Pre fabricated. Quality control Parallel work faces - Schedule advantage Disadvantages: More expensive (Depending on system) Integral wall protection. Demountable. Conceptual Design Structure/ Civil 28 Design develops from layouts, height decisions, size, shape etc Site structural capability needs to be assessed Special requirements for super flat floors in warehouses etc Integrate drainage requirements – all types Site development, roads, car parks, landscaping Remember special requirements e.g. Fire Protection, Earthquake etc Conceptual Design Cost Estimate 29 Amount of effort depends on accuracy required Process Equipment costs usually based on mix of vendor enquiries and engineers database Process utilities normally costed on similar basis Process piping based on estimated run length and composite unit costs can be factored HVAC can be based on actual sizing costs for core areas and factored per square meter or cubic meter for others Conceptual Design Cost Estimate (cont.) 30 Utilities costed on actual sizing and database costings Distribution costed on estimated length and composite costs, or can be factored Electrical costs based on points at various load sizes – derived from loads list Field Instruments based on count and category – add a premium for aseptic quality Automation costed based on I/O count Extra added for special cGMP requirements e.g. GAMP and Part 11 Conceptual Design Cost Estimate (cont.) Include for: Professional design – Basic & Detailed Validation – C&Q Construction Management Permitting Client Internal Costs Contingency 31 Conceptual Design Schedule Critical aspect – must minimise time to market Be realistic even though it’s years away! Allow for decisions, approvals, objections, contingencies Allow for disruption and include constructability study Beware of false assumptions on feasibility of existing site Consult all parties early on and get agreement on big decisions 32 Conceptual Design Summary 33 Apply serious front end loading at concept stage A poorly assembled concept can be a ‘milestone’ for later stages Remember even the best estimates will omit some items – allow for unforeseen On the other hand – don't kill it by being too conservative Formulation & Vial Fill/ Finish Process 10 CONJ. FORMULATION ROOM BUFFER PREP FORMULATION VESSEL MOBILE TRANSFER VESSEL MOBILE TRANSFER VESSEL Transfer Room MANIFOLD F F WASHER VIALS REGIONAL PACKAGING DEPYRO VIAL TUNNEL FILLER VIAL STOPPER WAREHOUSE SEMI AUTO VISION SYS COLD MANUAL TRAY STORE PALLETIZER LOADER AUTOVISION SYSTEM TRAYS 34 CAPPER Formulation and Syringe Fill/ Finish Typical Output Grade C Formulation 200,000 Syringes Buffer Make-Up Vessel Filter Buffer Hold Vessel Filter Conjugate Download Conjugate Pooling Vessel Filter 0.22 μm Filters Product Vessel AlPO4 Can Upload Filling & Inspection 1 day Grade C E-Beam Product Vessel Grade A Room/ Isolator Surge Tub Filling Vessel Sterilisation Recirculation Stoppering 2 days 35 Grade D Automated Inspection Product Ready Syringe Filling & Inspection 36 Syringe Filling Process 37 Syringe Filling Line Layout Elevation View INFEED ISOLATOR OUTFEED Plan View 38 E-Beam Process Plan GRADE C INFEED GRADE C SUPPLIED E-BEAM TUNNEL PRE+44Pa IRRADIATION GRADE A SUPPLIED E-BEAM TUNNEL POST+74Pa IRRADIATION +54Pa E-BEAM EXHAUST AIR FLOW MATERIAL FLOW POINT OF SURFACE DECONTAMINATION Plan View 39 Isolator and Outfeed Process Plan GRADE A DELID / DELINER GRADE A NESTED UDF FILL / STOPPERING GRADE A OUTFEED BUFFER GRADE C MOUSEHOLE UDF HIGH FLOW GRADE C BACKGROUND +84 Pa +84 Pa +84 Pa +54 Pa +54 Pa MATERIAL FLOW AIR FLOW WASTE FLOW Plan View 40 Vial Fill Finish Layout 41