UPC 2

advertisement

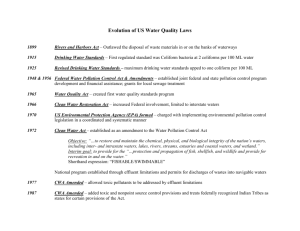

Let’s Get CRITICAL, Supercritical Fluid Extraction (SFE) Giorgis Isaac, PhD Principal Scientist Giorgis_isaac@waters.com ©2015 Waters Corporation 1 SFE Outline Sample Preparation Challenges & Extraction Techniques MV-10 ASFE System Introduction & Benefits SFE Applications ©2015 Waters Corporation 2 A Fully Supercritical Fluid Process No treatment between Extraction, Separation and Isolation SFE Extraction Extraction Analysis and scale-up prediction Final purity assessment ©2015 Waters Corporation Preparative SFC for Purification 3 Sample Preparation Challenges Sample Preparation Sample preparation: – Often overlooked – Least developed – Most time-intensive – Most error-prone ©2015 Waters Corporation 4 Classical Extraction Methods Evaporation Soxhlet Extraction Distillation ©2015 Waters Corporation 5 Traditional Extraction Methods Drawbacks Limited selectivity Thermal degradation of heat-labile compounds Oxidative degradation of highly unsaturated compounds Organic toxic solvents – Residual solvents – Government regulations on the use of organic solvent such as hexane ©2015 Waters Corporation 6 SFE Outline Sample Preparation Challenges & Extraction Techniques MV-10 ASFE System Introduction & Benefits SFE Applications ©2015 Waters Corporation 7 What is a Supercritical Fluid? Supercritical fluid has High Diffusivity, Low Viscosity and Low Surface Tension! 73.8 304.1 K ©2015 Waters Corporation 8 Advantages of SFE Low temperature extraction conditions – Minimal degradation of thermo-labile molecules Highly selective Solvent power can be varied by control of pressure and temperature Low viscosity aids rapid extraction Negligible surface tension Utilization of non-toxic solvent – No toxic residue Isolation of extracted analytes from extraction medium is readily accomplished by pressure reduction ©2015 Waters Corporation 9 MV-10 ASFE System Components Backpressure Regulator(BPR) Heat Exchanger Up to 6 Co-Solvents Available Fluid Delivery Module Column Oven -up to 10 Extraction Vessels ©2015 Waters Corporation Fraction Collection Moduleup to 12 collection bottles (5, 10 or 25 mL) 10 Extraction Modes Dynamic – (e.g. coffee maker) continuous supply of fresh fluid passes over/through the matrix/analyte – Fluid contamination builds up at the trap – Volatiles may be blown from the trap Static – (e.g. tea cup) fixed amount of fluid is exposed to the matrix/analyte – mixing by diffusion/re-circulation – Extraction may not be exhaustive Static / Dynamic Combination (Most Popular) – Pressurize analyte/matrix with fresh fluid for period of time followed by continuous flow of fresh fluid over analyte/matrix. ©2015 Waters Corporation 11 Extractability Based on Polarity Increasing Polarity Nonpolars Alkanes Ethers Esters Alcohols Amides Acids Amines Highly polar organics Inorganic ions SFE Neat CO2 CO2 + modifier CO2 + modifier + ternary additives CO2 + modifier + ternary additives + water Liquid – based extraction methods Small molecules Peptides Large proteins Increasing Molecular Weight One of the largest advantages of SFE: Selectivity ©2015 Waters Corporation 12 Supercritical Fluid Extraction: Effect of Increasing Density of CO2 100 Bar 200 Bar 3 extract’s CO2 & 1% MEOH @ 100, 200 & 350 bar Isolated compound of interest Isolated compound of interest 300 Bar Isolated compound of interest ©2015 Waters Corporation 13 Effect of extraction T and P on γ–tocopherol yeild ©2015 Waters Corporation 14 Control of Tunable Extraction Parameters Critical to Optimizing and Reproducibility CO2 tunable parameters and polarity for selectivity ©2015 Waters Corporation 15 SFE Outline Sample Preparation Challenges & Extraction Techniques MV-10 ASFE System Introduction & Benefits SFE Applications ©2015 Waters Corporation 16 Example 1: Omega-3 From Marine Origines SFE Step – 90 –150 bar, max 45 °C – Remove pesticides & heavy metals – Separate <C18 from >C18 (mainly saturated and mono-unsaturated FA) – Remove cholesterol Fish Oil EPA Saturated Monounsaturated Omega-6 DHA SFC Step – 90 –150 bar, max 45 °C – Selectivity according to C-chain length AND to number of double bonds – Highly purified concentrates up to over 99% per individual FA Omega-3 FA are handled under CO2 atmosphere at temperatures below 45 C. Concentrated Omega-3 Saturated Monounsaturated Omega-6 EPA DHA – No thermal stress – No oxidation ©2015 Waters Corporation Commercial process - Patented 17 Example 2: Stevia Extraction Stevioside isolated from Stevia rebaudiana has been proposed as a promising sweetener because of its low calorie content and relatively low toxicity – Stevioside and rebaudioside A have about 300 times the relative sweetness intensity of 0.4% (w/v) sucrose 2 major diterpene glycosides – stevioside (5–18%) – rebaudioside A (2–4%) ©2015 Waters Corporation 18 Stevioside Extraction Conventional extraction methods for stevioside involve – aqueous or alcohol extraction – precipitation and coagulation with filtration – clean-up step – crystallization and drying ©2015 Waters Corporation Choi, Y. H. et. al, Chromatographia, 55, 716-620, 2002. 19 Example 3: SFE Increases Specificity Using Super Critical Fluid as an extraction solvent provides a mechanism to increase specificity – By varying the extraction conditions, we can reduce the amount of unwanted interference compounds o Less compound interference, more column loading capacity (A) SFE % Target, m/z= 391, 1.61e7 SFE Extract 0 0.50 1.00 1.50 2.00 2.50 3.00 3.50 (B) Solvent Extraction Target m/z=391, 1.68e7 % Solvent Extract 0 0.50 ©2015 Waters Corporation 4.00 1.00 1.50 2.00 2.50 3.00 3.50 Time 4.00 20 Example 4: Selective Extraction of Ingenol from Euphorbia Plant Selectivity is key to efficient sample preparation % Residual Sample after SFE 0 2.00 4.00 6.00 8.00 10.00 12.00 14.00 % SFE Extract 0 2.00 4.00 6.00 8.00 10.00 12.00 14.00 % Solvent Extract 1 2.00 4.00 6.00 8.00 10.00 12.00 14.00 % Ingenol Standard 0 2.00 ©2015 Waters Corporation 4.00 6.00 8.00 10.00 12.00 Time 14.00 21 Summary SFE provides an appealing sample preparation technique which: – Improves extraction efficiency and reduces extraction time vs. other sample preparation techniques – Reduces costly and hazardous solvent consumption – Is environmentally compatible – Does not require pre-concentration prior to analysis – Automated – Can selectively extract specific fractions of a complex sample – Operates at lower temperatures than PFE, MAE and soxhlet – Wider selectivity range with use of co-solvents SFE simplified for the end user: MV10-ASFE ©2015 Waters Corporation 22 Let’s Get CRITICAL, Supercritical Fluid Chromatography (SFC) Introduction to ACQUITY UPC2 Giorgis Isaac, PhD Principal Scientist Giorgis_isaac@waters.com ©2015 Waters Corporation 23 A Fully Supercritical Fluid Process No treatment between Extraction, Separation and Isolation SFE Extraction Extraction Analysis and scale-up prediction Final purity assessment ©2015 Waters Corporation Preparative SFC for Purification 24 UltraPerformance Convergence Chromatography (UPC2)TM Convergence Chromatography is a category of separation science that provides orthogonal and increased separation power, compared to liquid or gas chromatography, to solve separation challenges. UltraPerformance Convergence Chromatography [UPC2]TM is a holistically designed chromatographic system that utilizes liquid CO2 as a mobile phase with one or more co-solvents to leverage the chromatographic principles and selectivity of normal phase chromatography. The ACQUITY UPC2 System is built utilizing proven UPLC Technology to enable scientists to address routine and complex separation challenges while delivering reliability, robustness, sensitivity and throughput. Accepted in the scientific community as: UHPSFC: UltraHigh Performance Supercritical Fluid Chromatography SFC: Supercritical Fluid Chromatography (NOT Science Fiction Chromatography) ©2015 Waters Corporation 25 What Does Supercritical Fluid Mean To The Chromatographer? Lower viscosity means higher optimal flow rates – About 4 times higher than LC Higher flow rates means – Faster equilibration times – Faster transit time on column – Lower operating pressures allows for the ability to work with multiple columns in series Adjusting pressure adjusts solvating strength – In LC, we adjust solvent composition and temperature – In SFC pressure adjustment provides an additional variable to work with ©2015 Waters Corporation 26 Evolution of Separation Technology Gas Chromatography Liquid Chromatography Convergence Chromatography GC HPLC SFC Capillary GC UPLC UPC2 Resolution, Sensitivity, Throughput ©2015 Waters Corporation 27 How the ACQUITY UPC2 System Works Splitter PDA detector Column Manager Make-up Pump Mass Spec Auxiliary Inject valve Back Pressure Regulator (Dynamic and Static) Inject valve mixer Thermo-electric heat exchanger Waste Modifier ©2015 Waters Corporation CO2 Supply CO2 Pump Modifier Pump 28 Example 1: Separating Polar Compounds (Catalpol/stachyose/sucrose/D-mannitol/yellow glucoside) RPLC UPC2 DH_Neg_20eV_RP1 1: TOF MS ESTIC 1.49e6 0.74 1.5x107 % Rehmannia extract (the polar compounds elute near solvent front) 0.68 3x106 5.25x107 0 -3.26 EIC, 181 -4.61 EIC, 361 -4.49 EIC, 341 Time 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 10.00 11.00 DH_Neg_20eV_RP1 80 (0.737) Cm (18:126) 1: TOF MS ES2.11e6 341.11 100 4.5x106 -6.45 EIC, 685 665.21 3x107 -6.64 EIC, 665 % 711.22 503.16 ES-, TIC 549.17 387.11 666.22 290.09 128.04 113.00 133.02 89.03 181.07 191.02 343.12 195.02 245.10 0 50 308.10 361.11 3.0x107 712.22 342.11 407.12 470.15 455.10 425.10 504.16 471.12 505.16 632.20 683.22 827.26 845.27 550.17 713.22 633.18 551.16 617.15 873.27 794.25 779.20 874.27 956.31 974.34 m/z 100 150 200 250 ©2015 Waters Corporation 300 350 400 450 500 550 600 650 700 750 800 850 900 950 0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.00 Minutes 29 Example 2: Fat Soluble Compounds Lycopene and -Carotene HPLC 0.008 UHPSFC 0.006 -carotene LogP=10.68 Lycopene LogP=11.11 60 min L. Zhang et al. / Food Chemistry 132 (2012) 2112–2117 AU 0.004 UPLC 0.002 0.000 -0.002 0.00 0.20 0.40 0.60 0.80 Minutes 1.00 1.20 1.40 1.5 min H. Li et al. / Food Chemistry 132 (2012) 508–517 ©2015 Waters Corporation 16 min 30 Example 3: Chiral Separations 2.47 4.25 4.0 2.90 3.75 3.5 3.25 3.0 2.75 2.5 2.25 2.0 AU 1.75 1.5 1.25 1.0 7.5e-1 5.0e-1 2.5e-1 0.85 -9.375e-8 -2.5e-1 -5.0e-1 -7.5e-1 -1.0 -1.25 0.00 0.50 1.00 1.50 60 min R, S-Goitrin from Isatis Indigotica Fort (板蓝根) (S) O (R) Goitrin (S-goitrin) 2.50 3.00 3.50 4.00 4.50 5.00 5.50 Time 6.00 6 min O S S N H 2.00 N H Epigoitrin (R-goitrin) “手性高效液相色谱法测定板蓝根中表告依春和告依春含量”, 林瑞超, 2010, Chinese Journal of Chromatography, 28 (10), 1001-04 ©2015 Waters Corporation 31 Taking Advantage of Low Viscosity (A) 150 mm 750.000 LSU Coupling columns in series is one of the benefits of working with low viscosity solvents 500.000 250.000 0.000 0.00 5.00 10.00 15.00 20.00 25.00 (B) 250 mm LSU 600.000 400.000 200.000 0.000 0.00 5.00 10.00 15.00 20.00 LSU 600.000 25.00 (B) 400 mm 400.000 200.000 0.000 0.00 5.00 10.00 15.00 20.00 Time 25.00 Table 1. Comparison of three SFC runs with different column lengths. Column Length t1 (min) t2 (min) w0.5,1 w0.5,2 150 7.14 7.95 0.34 0.39 250 11.21 12.54 0.44 400 18.20 20.33 0.55 (mm) Isomeric ratio Theor. *Rs Increase 0.62 1.31 0 0 0.48 0.64 1.71 31% 29% 0.58 0.64 2.23 70% 63% (peak1/peak2) Increase *, where t is the retention time and w0.5 is the peak width at half height ©2015 Waters Corporation 32 Example 4: Analysis of Volatile Compounds from TCM Target analytes are lipophilic α/β cis/trans isomers Currently separate by GC, 29 minutes – Difficult sample prep: need derivitization – can not be scaled up for purification ©2015 Waters Corporation 33 UPC2 Analysis of Volatile Compounds from TCM Overlay of 6 replicates UPC2 analysis for the isomers 组分1 – Analysis time 2.5 minutes 254nm RSD<1% – Direct analysis, easy sample prep 组分2 – Easy scale up to Prep 2.5min ©2015 Waters Corporation 34 Example 5: UPC2 Analysis of Cannabinoids UPC2 and UPLC chromatograms of a mixture of 10 cannabinoid standards UPLC UPC2 UPC2 ©2015 Waters Corporation CBDV CBDA CDG CBD THCV CBN THC CBC THCA CDBV CBD d8THC d9THC CBC CBN CBG THCA CBDA CBGA 35 Example 6: UPC2 Analysis of Lipid Liquid-liquid extraction using chloroform/MeOH – Folch method / Blight and Dyer method RPLC & HILIC – Phase transfer required to be able to inject onto RP and HILIC system UPC2 – Phase transfer process can be eliminated by injecting the organic extract directly onto the UPC2 system ©2015 Waters Corporation 36 Lipid Analysis Work Flow GC, LC and UPC2 Sample GC Sample UPC2 • Extraction • FAMEs Derivitization • Extraction • Ready for GC/MS analysis • Direct UPC2 analysis Free fatty acids are typically derivatized to form Fatty Acid Methyl Esters (FAMEs)~ 1hr Risk of rearrangement of the FA and contamination Low volatile very long chain fatty acids (>24 carbon atoms) are difficult to analyze Analysis time ~30 min ©2015 Waters Corporation Organic extract can be injected directly to the system Single methodology to separate complex inter and intra lipid class Faster baseline separation of lipids based on chain length and number of double bonds ~ 5min Sample UPLC • Extraction • Evaporate to dryness • Reconstitution • Ready for UPLC analysis Analyzed by both HILIC & RP HILIC separates lipid classes by polar head group Phase transfer required before injection RP separates based on acyl chain length and number of double bonds ~ 20min 37 Fast and Simple Free Fatty Acid Analysis Using UPC2 283.26 311.30 100 367.36 20 to 25 % B % 227.20 199.17 197.81 0 0.50 1.00 1.50 283.26 100 311.29 2.00 2.50 3.00 3.50 4.00 367.36 15 to 25 % B % 227.20 197.81 199.17 0 0.50 1.00 1.50 16:0 100 18:0 283.26 2.00 20:0 311.30 2.50 22:0 339.33 % 10:0 3.00 3.50 24:0 5 to 25 % B 14:0 227.20 12:0 197.81 199.17 0 0.50 1.00 1.50 2.00 2.50 3.00 3.50 311.29 100 283.26 227.20 0 0.50 ©2015 Waters Corporation 1.00 1.50 2.00 2.50 3.00 FA 1 143.10 C8:0 2 171.14 C10:0 3 199.17 C12:0 4 227.20 C14:0 5 255.53 C16:0 6 283.26 C18:0 7 311.30 C20:0 8 339.33 C22:0 9 367.36 C24:0 367.36 255.23 197.81 171.14 199.17 m/z 4.00 339.33 1 to 25 % B Peak 4.00 367.36 255.23 % UPC2 Conditions: A= CO2 B=MeOH in 0.1% FA Column= ACQUITY UPC2 HSS C18 SB 1.8µm (2.1 x 150 mm) Flow rate= 0.6 mL/min Column temp= 50 ºC P=1600 psi 3.50 Time 4.00 38 Separation of FFA C8-C36 from Algae Extract 16:0 255.23 100 FFA C8-C36 x16 465.47 32:0 479.48 % 283.27 23:0 395.39 227.20 423.42 367.36 299.20 479.45 451.45 311.30 0 -0.00 0.20 0.40 0.60 0.80 1.00 1.20 34:0 507.48 1.40 1.60 1.80 455.24 Time 2.00 2 min ©2015 Waters Corporation 39 UHPSFC/MS of Both Polar and Non-Polar Lipid Classes in 6 min Miroslav Lísa and Michal Holčapek ; Anal. Chem., 2015, 87 (14), pp 7187–7195 ©2015 Waters Corporation 40 A Fully Supercritical Fluid Process No treatment between Extraction, Separation and Isolation SFE Extraction Extraction Analysis and scale-up prediction Final purity assessment ©2015 Waters Corporation Preparative SFC for Purification 41 Example 7: Extraction, Separation and Isolation of Schisandra Berry Extracts Using SFE and SFC Berries of schisandra (Schisandra chinensis) have been used for medicinal purposes in TCM – Extraction: MV 10- ASFE – Separation: UPC2 – Scale up: Prep 100q SFC System ©2015 Waters Corporation 42 Extraction, Separation and Isolation of Schisandra Berry Extracts using SFE and SFC SFE UPC2 separation of crude SFE extract UPC2/PDA 220 UPC2/PDA 220 separation of collected fraction ©2015 Waters Corporation UPC2/QDa Prep SFC separation of crude SFE extract 43 Extraction, Separation and Purification Simplifies your Sample Complexity 1: Scan AP+ TIC 4.10e7 % G4_SolE_002 Extraction 0 Time 0.20 0.40 0.60 0.80 1.00 1.20 1.40 1.60 1.80 2.00 2.20 2.40 2.60 2.80 3.00 3.20 3.40 3.60 3.80 1: Scan AP+ TIC 6.65e7 % G4_MPLC_023 0.20 0.40 0.60 0.80 1.00 1.20 1.40 1.60 1.80 2.00 2.20 2.40 2.60 2.80 3.00 3.20 3.40 3.60 3.80 Time 4.00 1: Scan ES+ 391 1.23e8 % 100 Simpler 2 G4_2_25_2012_006 Isolation 0 0.20 0.40 0.60 0.80 1.00 1.20 1.40 1.60 1.80 2.00 2.20 2.40 2.60 2.80 3.00 3.20 3.40 3.60 3.80 Time 4.00 Standard ©2015 Waters Corporation 44 Summary UHPSFC (UPC2) UPC² SIMPLIFIES the workflow – Combines multiple techniques (GC/NP/RP) into ONE analytical plat form – Reduces sample prep and analysis times to streamline the analytical workflow o Direct injection of organic solvents/extracts o Reduces solvent usage o No derivitization required for free fatty acid analysis UPC² separates compounds with STRUCTURAL SIMILARITY – Optical isomers, positional isomers, structural analogs, conjugates UPC² provides ORTHOGONALITY – Complementary separation provides confidence in identifying compound of interest ©2015 Waters Corporation 45 Acknowledgements Waters Natural Products team Dr. Dhaval Patel Waters Singapore Dr. Lirui (Kevin) Qiao Waters, China Dr. Jimmy Yuk Waters Corporation Dr. Kate Yu Waters Corporation Dr. Kerri Smith Waters Corporation Mr. James Traub Waters Corporation Mr. Ronan Cleary Waters Corporation Mr. Darcy Shave Waters Corporation Mr. Andrew Aubin Waters Corporation ©2015 Waters Corporation 46 Thank you!!! Giorgis_Isaac@waters.com ©2015 Waters Corporation 47