Tissue Culture Lab Design & Layout: Aseptic Techniques

advertisement

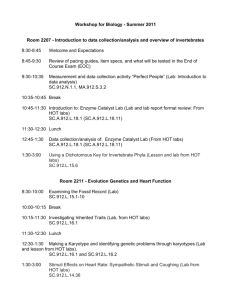

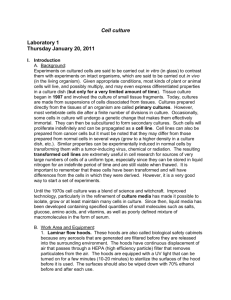

Laboratory Design and Layout Chapter 4 Planning of tissue culture labs Importance of asepsis Old labs – modifying ventilation and airconditioning, structural modifications will be expensive New labs – Integrative and innovative design - Facilities may be positioned for ergonomic and energy-saving reasons Planning of tissue culture labs - Ventilation – Pressure balance and Laminar Flow Hoods Positive pressure – Avoid influx of contaminated air into surroundings of lab Negative pressure – Usage of human material Positive-pressure buffer zone – Preparation area and microscope Laminar Flow Hoods – Positions of air inlets and extracts Planning of tissue culture labs Accommodation - How many people will work each week? - What kinds of culture will they perform? - Area required to handle bioreactors - 12 laminar hoods/50 people Planning of tissue culture labs Space – - Largest area – culture operation accommodating laminar-flow hoods, cell counters, centrifuges, incubators, microscopes, and arrangements for media, stocks of reagents, glassware and plastics etc. - Area for wash up, preparation and sterilization - Area for storage - Area for incubation Planning of tissue culture labs Aseptic area - Animal facility is accessible but not contiguous to tissue culture labs - Windows – high heat generation, UV influx and incursion of microorganisms Planning of tissue culture labs - Hoods – Space between hoods should be 500 mm (2 ft) Motion movement Minimize interference in airflow between hoods Space filled with removable cart or trolley Planning of tissue culture labs Incubation – - Large number of flasks or large volume flasks (sealed) incubated in hot rooms - Open plates and dishes incubated in humid Co2 incubator Planning of tissue culture labs Preparation area – - Facilities for washing up and for sterilization should be located - i) close to aseptic area that they service - ii) outside wall to allow for heat extractions from ovens and steam vents from autoclaves Planning of tissue culture labs Servicing aseptic areas – - Elevator or ramp suffice - Maximum load capacity of ramp without any mechanical help Storage – - Space required for disposable plastics - Cell line work with liquid nitrogen Planning of tissue culture labs Renovations – Choose location carefully Access – Doorways are wide and high to allow for installations Quarantine - Screening for Mycoplasma in new cell lines and biopsies - Containment of biopsies and cell lines posing biohazard Layout of aseptic room or suite Six main functions – sterile handling, incubation, preparation, washup, sterilization and storage Location for sterile handling should be at one end of room - Wash up and sterilization facilities at other end - In-between - Preparation, Storage and Incubation 4.3.1 Sterile handling area Sterile area restricted No traffic or disturbance Absence of laminar hoods – use separate room or cubicle - Plastic laminate topped bench - Freestanding or sealed to wall 4.3.2 Laminar Hood - Less expensive than sterile rooms Hoods – Operator’s arms enter Laminar flow wall or ceiling units – Operator is part of work area Wear sterile caps and gowns Legroom with space for pumps, aspirators Chairs with adjustable seat and height Cart or trolley or folding flap (300-500mm) 4.3.3 Quarantine and Containment Separate room with door or lock Separate incubators, freezer, refrigerator, centrifuge, supplies and disposal Newly imported cell lines or biopsies Act as Level II containment – biohazard cabinet or pathogen trap 4.3.4 Service bench Close to sterile handling area Drawer units below and open shelves above Store sterile glasswares, plastics, pipettes, screw caps, syringes etc 4.4 Incubation Incubators Less expensive Lose more heat and slow to recover Hot room Less expensive than two incubators Insulated to prevent cold spots Avoid wooden furnishings Stainless steel bench or plastic laminate Heat generation in hot room Heater – Fan heater provides heat, run continuously Air circulation – Fan positioned on opposite side of room of fan heater Thermostats – Two separate heaters with their thermostats Overheating – increase of room temperature, heat produced from apparatus etc 4.5 Preparation area 4.5.1 Area for media preparation - Accommodate balances, pH meter, osmometer etc - Preparation and sterilization in hoods 4.5.2 Wash up and sterilization facilities outside tissue culture lab - Space for drying glassware, sorting pipettes, packaging and sealing packs for sterilization 4.5 Preparation area 4.5 Wash up Raised edge – to avoid spillage Four taps Deionized water provision 4.5 Preparation area 4.5.3 Storage Sterile liquids – 25, 4 or -20 or – 70 degree Sterile and non sterile glassware Sterile disposable plastics Screw caps, stoppers Filters Gloves and disposal bags 4.5.3 Storage Liquid Nitrogen – Dewars (25-50 L) Large storage vessel (100-150 L) on trolley Storage tanks (500 – 1000 L) Safety – Ventilation + oxygen alarm + replace air in room Co2 storage units –tethered to wall or bench in a rack This project is funded by a grant awarded under the President’s Community Based Job Training Grant as implemented by the U.S. Department of Labor’s Employment and Training Administration (CB-15-162-06-60). NCC is an equal opportunity employer and does not discriminate on the following basis: against any individual in the United States, on the basis of race, color, religion, sex, national origin, age disability, political affiliation or belief; and against any beneficiary of programs financially assisted under Title I of the Workforce Investment Act of 1998 (WIA), on the basis of the beneficiary’s citizenship/status as a lawfully admitted immigrant authorized to work in the United States, or his or her participation in any WIA Title I-financially assisted program or activity. Disclaimer This workforce solution was funded by a grant awarded under the President’s Community-Based Job Training Grants as implemented by the U.S. Department of Labor’s Employment and Training Administration. The solution was created by the grantee and does not necessarily reflect the official position of the U.S. Department of Labor. The Department of Labor makes no guarantees, warranties, or assurances of any kind, express or implied, with respect to such information, including any information on linked sites and including, but not limited to, accuracy of the information or its completeness, timeliness, usefulness, adequacy, continued availability, or ownership. This solution is copyrighted by the institution that created it. Internal use by an organization and/or personal use by an individual for non-commercial purposes is permissible. All other uses require the prior authorization of the copyright owner.