Interconnect Layout Optimization Under Higher

advertisement

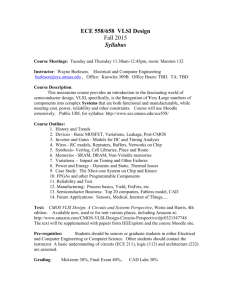

EE 201A/EE298 Modeling and Optimization for VLSI Layout Instructor: Lei He Email: LHE@ee.ucla.edu Outline Course logistics Overview What are covered in the course What are interesting trends for physical design Instructor Info Email: LHE@ee.ucla.edu Phone: 310-206-2037 Office: Engineering IV 68-117 Office hours: Tu/Th 2-3pm or by appointment The best way to reach me: Email with EE201 in subject line About this Course One of selective course for EE’s ECS Major Field Students Question in M.S. comprehensive exam / PhD prelims Offered every other spring Will be under another course number (EE205B) Related courses Mani’s EE202A Embedded Computing Systems (Fall) Ingrid’s EE201A on Advanced VLSI (Spring) Bill M-S’s EE204A on Compilers (Winter) My EE205A Fundamental to CAD (Winter) Mani’s EE206A Wireless Systems (Spring) My EE205B (every other Spring) Course Prerequisites Official prerequisite EE116B VLSI System Design But mainly self-contained Knowledge to help you appreciate more CS180 Introduction to algorithms EE205A and EE205B EE205A Fundamental to CAD of embedded systems System level performance/power/thermal modeling and optimization Synthesis – scheduling and allocation, logic optimization and technology mapping FPGA circuits and architectures and placement and routing for FPGA EE205B Modeling and Optimization for VLSI layout Advanced algorithms for physical design Fundamentals of combinatorial algorithm Detailed performance, signal integrity, power and thermal models Incorporating physical design into system design VLSI Design Cycle System Specification Functional Design X=(AB*CD)+(A+D)+(A(B+C)) Logic Design Circuit Design Y=(A(B+C))+AC+D+A(BC+D)) VLSI Design Cycle (cont.) Physical Design Fabrication Packaging Simplified Physical Design Cycle Partition Front-end physical design Floorplanning Placement Routing Back-end physical design Extraction and Verification Course Outline and Schedule Front-end physical design (4.5 weeks) Partitioning, floorplanning and placement Power and thermal modeling Algorithms: divided and conquer, simulated annealing, genetic algorithm Project proposal due by end of fifth week Back-end physical design (4.5 weeks) Interconnect extraction and modeling Interconnect synthesis Noise modeling and avoidance Clock and power supply design ** Algorithms: dynamic programming, linear programming Project report due the last day of the quarter Related VLSI CAD Conferences ACM IEEE Design Automation Conference (DAC) http://www.dac.com (San Diego, Young student program) International Conference on Computer Aided Design(ICCAD) Design, Automation and Test in Europe (DATE) Asia and South Pacific Design Automation Conference (ASPDAC) International symposium on physical design (ISPD) International symposium on low power electronics and design International symposium on field programmable gate array IEEE International Symposium on Circuits and Systems (ISCAS) Related VLSI CAD Journals IEEE Transactions on CAD of Circuits and systems (TCAD) ACM Trans. on Design Automation of Electronic Systems (TODAES) IEEE Transactions on Circuits and Systems (TCAS) IEEE Trans. on VLSI Systems (TVLSI) IEEE Trans. on Computer Integration Algorithmica SIAM journal of Discrete and Applied Mathematics Money Talk for VLSI CAD Synposys, Cadence, Magma, Mentor Graphics, … Over hundreds companies have booths at DAC Two of them are among the ten biggest software companies in the world But they are smaller than the biggest spin-off of EDA EDA is regarded as A-graded bonds for Venture Capitalists One of few IT segments still recruits heavily and offers salary higher than Intel/IBM EDA system is regarded as one of the most complicated software systems mankind ever built References for this Course Selected papers from TCAD, TODAES, and major CAD conferences such as DAC, ICCAD and ISPD Naveed A. Sherwani, "Algorithms for VLSI Physical Design Automation", 3rd Edition, 1998. H. Cormen, et al “Introduction to Algorithms” MIT Electrical Engineering and Computer Science Series 1990. H. Bakoglu, Circuits, Interconnects, and Packaging for VLSI, Addison Wesley Cong et al., Performance Optimization of VLSI Interconnect Layout, Integration, the VLSI Journal 21 (1996) 1--94. Grading Policy Homework Midterm (7th week) Course presentation Term project A score > 85 and programming project 15% 20% 15% 50% Course Presentation (15%) 2~3 student a team Survey an area (topics and resources specified by me on a continual basis) Prepare slides and do a 30-35 minute presentation in the class slides prepared jointly either all students share the presentation or I will select the speaker randomly at the presentation time Prepare a web site that should contain a report based on your survey, a bibliography, and links to resources and of course your slides Term Project (50%) One of the following two: One-person survey and critic of selected topic (at most 35%) Individual programming project for a team of 2 to 3 persons Coupled system design and physical design Floorplanning with thermal constraints 3D modeling and physical design Or any topic agreed by instructor Up to 30 minute presentation during the finals week, like a conference talk Up to 12 page report in the style of a technical conference paper ACM style http://www.acm.org/sigs/pubs/proceed/template.htm Who should take this course It is another course Discuss wide scope of knowledge But research (presentation + project) on your own focus For students who are motivated to Learn SI, power/thermal for advanced designs Learn algorithm basics without taking CS280 Understand CAD better Become a CAD professional Complexities of Physical Design More than 10 million transistor Performance driven designs Time-to-Market Design cycle …... High performance, high cost Moore’s Law and NTRS Moore’s Law The min. transistor feature size decreases by 0.7X every three years (Electronics Magazine, Vol. 38, April 1965) True in the past 30 years, and expected to hold for another 1015 years National Technology Roadmap for Semiconductors (NTRS’97) Technology (um) Year # transistors On-Chip Clock (MHz) Area (mm2) Wiring Levels 0.25 1997 11M 750 300 6 0.18 1999 21M 1200 340 6-7 0.15 2001 40M 1400 385 7 0.13 2003 76M 1600 430 7 0.10 2006 200M 2000 520 7-8 0.07 2009 520M 2500 620 8-9 10,000,000 100,000,000 1,000,000 100,000 10,000 10,000,000 58%/Yr. Complexity growth rate 1,000,000 100,000 1,000 10,000 xx 10 21%/Yr. Productivity growth rate x 100 xx x x x 1,000 100 1 10 1998 2003 Chip Capacity and Designer Productivity Source: NTRS’97 Transistor/Staff-Month Logic Transistors/Chip (K) Productivity Gap Design Challenges in Nanometer Technologies Interconnect-limited designs Small feature size Interconnect performance limitation Interconnect modeling complexity Interconnect reliability Impact of new interconnect materials Process variations Leakage (~50% of total power) High degree of on-chip integration Complexity and productivity Limitation of current design abstraction and hierarchy System on a chip and system in package or 3D technology Power/thermal barrier Design Styles Complexity of VLSI circuits Performance Size Cost Market time Different design styles Full custom Standard Cell Gate Array Cost ,Flexibility,Performance FPGA Full Custom Design Style Pad Metal Via Data Path PLA ROM/RAM Random logic A/D Converter Metal 2 I/O Standard Cell Design Style Cell Feedthrough VDD Metal 1 GND Metal 2 D C A D C Cell A Cell C C B C C C D C C B B Cell B Cell D Feedthrough cell Gate Array Design Style (or Structured ASIC) A C B VDD Metal1 Metal2 C A B Field-Programmable Gate-Arrays (FPGAs) Programmable logic Programmable interconnects Programmable inputs/outputs FPGA Design Style Comparisons of Design Styles style full-custom standard cell gate array FPGA cell size variable fixed height * fixed fixed cell type variable variable fixed programmable cell placement variable in row fixed fixed interconnections variable variable variable programmable * uneven height cells are also used Comparisons of Design Styles style full-custom standard cell compact gate array FPGA moderate large Area compact Performance high high to moderate moderate low Fabrication layers ALL ALL routing layers none to moderate Packaging Styles Packaging Printed Circuit Board PCB Multi-Chip Module MCM Wafer Scale Integration WSI or 3D Area Performance, cost The increasing complexity and density of the semiconductor devices are driving the development of more advanced VLSI packaging and interconnection approaches. Printed Circuit Board Model Plated through holes Package IC (a) (b) Large number of layers (150a pitch) Larger area Low performance Low cost MCM Model IC (a) (b) Up to 36 layers ( 75a pitch) Moderate to small area Moderate to high performance High cost Heat dissipation problems Wafer Scale Integration Small number of layers (VLSI technology- 6a pitch) Smallest area Significant yield problems Very high performance Significant heat dissipation problems Comparisons of Packaging Styles Technology Figure of Merit (inches/psec. density inches/sq in) WSI MCM PCB 28.0 14.6 2.2 Merit = propagation speed (inches/psec.) * interconnection density (inches/sq. in). Interconnect resistance was not considered Increasingly on the Same Chip or in the Same Package (SoC and SiP) SC3001 DIRAC chip (Sirius Communications) History of VLSI Layout Tools Year 1950 - 1965 Design Tools Manual Design 1965 - 1975 Layout editors Automatic routers( for PCB) Efficient partitioning algorithm 1975 - 1985 Automatic placement tools Well Defined phases of design of circuits Significant theoretical development in all phases 1985 – 1995 Performance driven placement and routing tools Parallel algorithms for physical design Significant development in underlying graph theory Combinatorial optimization problems for layout 1995 -- present Interconnect layout optimization, Interconnectcentric design, physical-logical codesign One of the new trends: SoC and SiP for 3D technology Summary Physical design is the most complicated step in the VLSI design cycle Physical design is further divided into clustering, partitioning, floorplanning, placement, global and detailed routing. Extraction and verification is an important aspect. There are four major design styles -- full custom, standard cell, gate array (structured ASIC), and FPGAs. There are three alternatives for packaging of chips -- PCB, MCM and WSI. But increasingly, we design for SoC and SiP and will use 3D technology Automation reduces cost, increases chip density, reduces time-to-market, and improves performance. CAD tools currently lag behind fabrication technology, which is hindering the progress of IC technology Homework (due April 14th) Read ITRS roadmap executive summary and write one page summary and critic on one aspect related to your research or field http://public.itrs.net/Files/2001ITRS/Home.htm Search literature or web related to SoC, SiP and 3D technology, summarize five papers on a coherent topic (e.g., technology, design, or CAD) and speculate potential need of CAD research Following style of conference paper With course project proposal in mind Submit homework in PDF via email Check out course website for notes of future lectures http://eda.ee.ucla.edu/EE201A-04Spring