Progress with the generic approach (WP 2/3)

advertisement

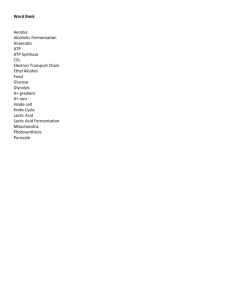

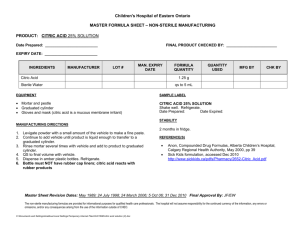

Progress on the generic approach for modelling production processes covered in BREW Morna Isaac, Martin Patel The aim: Analysis of the manufacturing process of products for which only basic data are available Relevancy: Products in an early stage of development and/or with data limitations due to competitive sensitivity Methodology: Available data are used to develop generic elements of processes. Focus: Energy use, as a first indication of environmental impact, and costs The main stages of a process: 1. 2. 3. 4. Feedstock treatment (activation): Biological conversion Product separation Waste treatment and utilities Fermentation: Theoretical vs. achieved Gluconic acid Glycerol yields Sorbitol Acetic acid Lactic acid Lactic acid Citric acid Citric acid Citric acid Propylene glycol Itaconic acid, Pfizer Itaconic acid, Von Fries Lysine cis, cis muconate Ethanol, Z mobilis Ethanol, batch Ethanol, cellulose, BCI Butanediol Dehydroshikimic acid P(3HB) Theoretical yield Actual yield Actual yield wt% of glucose 109% 102% 101% 100% 100% 100% 75% 106% 142% 84% 76% 76% 70% 54% 51% 51% 51% 50% 48% 48% wt% of glucose % of theory 87% 77% 96% 90% 95% 91% 68% 90-100% 80% 75% 95% 90% 95% 91% 90% 85-94% 55% 47% 60-65% 42% 24% 48% 46-48% 46% 30%, 45% 27% 30-40% 65% 62% 85% 60% 44% 94% 90-95% 90% 60%, 90% 56% 63-83% Productivity and yield of fermentation Product L-lactic acid Lactic acid (as sodium lactate) PDO Succinic acid (as sodium succinate) Representative best practice (yield of ethanol) Ethanol (lignocellulose) PHA PHA (Case 9) PHA (Case 2) L-lysine L-lysine Glutamic acid (ammonium glutamate monohydrate) Itaconic acid Citric acid (submerged) Hypothetical bacterial control agent Gluconic acid (as sodium gluconate) alpha amylase Porcine growth hormone Penicillin G, Cellulase Immobilized cells for acrylamide production Recombinant intracellular protein Productivity Conc. [kg/(m3*h)] [kg/m3] Yield [wt/wt%] 10 42 95% 5 6 120 100 95% 48% 2.5 1.92 95 115 100% 46% 1.38 50 47% 3.13 5 1.6 1.67 0.36 150 150 80 100 30% 37% 70% 40% 32% 1.36 1.06 0.69-0.75 0.39 56% 55% 87-92% 62 0.25 87% 103% 0.28 0.22 0.15 0.13 20 3.99 30 20% 4% 11% 33% 0.04 5 26% 0.03 0.8 1% Estimating the critical aqueous conc. When the product of a reaction is toxic, the concentration beyond which the reaction stops or Becomes too slow (Caqcrit) may be estimated using a correlation with the aqueous solubility (saq): aq crit log c 0.79 log saq 0.74 (Straathof, 2003) Theoretical energy consumption of fermenters Sterilization: for direct steam injection the mass of steam needed is: Fs M mediumC p DT DH vap C p (Tsteam Tster. ) If Cp=4.2 kJ/kg/ºC, initial medium temp. is 25ºC, sterilization temp. is 121ºC, steam temp. is 130ºC and DHvap=2180 kJ/kg, the steam required is 0.2 kg steam/l medium. Agitation and aeration: Can be in the range 1-10 kW/m3, usually 15 kW/m3. Larger fermenters have lower energy demands. Aeration: 0.5-2vvm. For compressed air at 4 bar using 17 kJ/m3 this consumes up to 0.6 kW/m3. Agitation only (anaerobic processes): 1-3 kW/m3 Cooling: Heat production in microbial growth is 420-500 kJ/mol O2 consumed. Typically in fermenters OTR is 40-60 mol O2/m3/hr, resulting in heat production of 5-8 kW/m3. Theoretical energy consumption of fermenters Steam for sterilization: 0.135 kg steam/kg substrate (converted to energy using 2.8 MJ/kg steam) Electricity: kWh/kg substrate Agitation Aeration Cooling Total Aerobic Anaerobic 0.096 0.096 0.381 0 0.228 0.046 0.705 0.142 Energy consumption for specific cases calculated using yield and productivity figures for each case (Lynd and Wang, 2003) Energy consumption in fermentation Anaerobic AVG Aerobic STDEV AVG STDEV Productivity [kg/(m3*h)] 4.98 3.01 2.05 1.23 Heat [MJ/kg] 0.38 0.13 2.87 3.13 0.53 0.21 0.70 0.31 2.68 2.33 3.85 1.88 Theoretical heat [MJ/m3.h] 2.46 1.55 1.55 1.42 Elect. [MJ/kg] 0.29 0.23 16.87 8.50 0.71 0.28 4.70 2.07 1.25 0.95 34.19 19.66 3.32 2.09 10.38 9.52 Theoretical heat [MJ/kg] Heat [MJ/(m3.h)] Theoretical elect. [MJ/kg] Elect. [MJ/(m3.h)] Theoretical elect. [MJ/m3.h] Energy consumption in fermentation Energy consumption per kg product and energy consumption per fermentor volume and residence time both vary widely between the different case studies. The variation in these values is not due to differences in the type of equipment between the cases. In comparing calculated values based on generic energy consumption as given in Lynd and Wang (2003) to energy consumption of detailed designs, the calculated values for aerobic processes are about three times too low. In comparing the values for anaerobic processes, the calculated steam use is close to the modelled use, but electricity use is about double the modelled values. Energy consumption for PHA production given in Akiyama et al. (2003) is relatively high. This might be due to the simulation program used to produce those values, SuperPro designer. Ethanol from corn stover: electricity consumption Comparison of two different simulations of the same process design: Battery Electricity limits Section Section Section (kW) Total 100 200 300 NREL model 5932 3200 1693 1038 SRI model 3708 981 2311 416 Difference -37% -69% 36% -60% Recovery Biomass separation: Centrifugation, filtration, membranes Product concentration – – – – – – – – Distillation (ethanol) Extraction (citric acid, lactic acid, acetic acid) Precipitation (citric acid, lactic acid) Direct crystallization/evaporation (gluconic acid, itaconic acid, PDO) Ion exchange (lysine) Electrodialysis (succinic acid) Adsorption Ultrafiltration Polishing: activated carbon, ion exchange, pH adjustment Final purification: evaporation, crystallization, drying A lot of research is being done on simultaneous fermentation and separation. Fermentation product Ethan Citric ol acid Lactic Acetic Citric acid acid acid (extraction) (extraction) Lactic LSuccin Citric acid lysine ic acid acid HCl (conventional) (conventional) (ED) PDO Gluco Itaconi nic c acid acid Process step Solid-liquid separation Evaporation Liquid-liquid extraction Distillation Precipitation Acidification Solid-liquid separation Ion exchange Activated carbon, pH Electrodialysis Evaporation Crystallization Drying Distillation Energy consumption of separation operations Operation Rotary vacuum filter (Mycelium) Centrifugation (Yeast) (Bacteria Microfiltration (Bacteria) (Yeast) (Mycelium) Ultrafiltration Nanofiltration ED Tower dryer Units MJe/m3 MJe/m3 MJe/m3 MJe/m3 MJe/m3 MJe/m3 MJe/m3 permeate MJe/m3 permeate MJe/m3 MJe/m3 removed Crystallization MJe/MJ transferred (Cooling) Evaporation Distillation, spray drying Value Source 8.64 1 5.04 1 22.32 1 5.76 1 4.32 1 9.36 1 18 2 3.6 3 540 3 360 4 1.08 3 MJ steam/m3 water evaporated 800-2500 MJ steam/m3 water evaporated 5600 5 6 Waste treatment Biomass waste: currently treated by inactivation, heating to 80ºC for 30-60 min (Degussa). It is then used as fertilizer. Will this continue to be an acceptable approach in future? • The amount of waste produced by a growing biotech. industry might be too large for this approach to be feasible. • Legislation might limit the possibilities. In this case, the waste will have to be digested or combusted. Wastewater: wastewater treatment is dealt with in the BREWtool. SuperPro Designer Process simulator specific to biochemical processes. Includes unit operations specific to bioprocessing, and batch as well as continuous processes. Energy use of unit operations could be extracted from the simulator for use in the generic approach. Some process designs could be modelled and the results used as a check for the results of the simplified generic approach. Costs Investment costs for a set of representative fermentation+recovery schemes will be estimated in cooperation with DSM using their functional unit method. With this method an estimate of the investment costs for a complete process is possible without performing detailed process design. The estimate is based on a specific mass balance. The recovery schemes presented earlier will be used for this.