2003 AMHS Backup - Advanced Silicon Device and Process Lab

advertisement

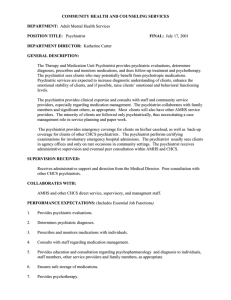

ITRS 2003 Factory Integration Chapter Material Handling Backup Section Details and Assumptions for Technology Requirements and Potential Solutions 09/04/03 1 AMHS Backup Outline 1. 2. 3. 4. 5. Contributors How Metrics were Selected Material Handling Technology Requirements Table Translating Material Handling Technology Reqs to Reality Supporting Material for Material Handling Technology Reqs 1. 2. 3. 4. System Throughput Requirements Reliability Hot Lot Delivery Time Delivery Time 6. Potential Solution Options 1. 2. 3. 4. 5. 6. Direct Transport (Includes capabilities needed from FICS) Direct Transport/Delivery Time: 3rd Party LP/Buffer Integrated Flow and Control Delivery Time & Storage Density: Under Track Storage Inert Gas Purging of FOUPs Factory Cross Linkage: Protocol Induced Constraints 7. Potential Research Topics 09/04/03 Page 3 Page 4 Page 5 Page 6 Pg 7-27 pages 7-17 pages 18-19 Pages 20-22 Pages 23-27 Pg 28-67 Pages 28-42 Pages 43-46 Pages 47-54 Pages 55-59 Pages 60-61 Pages 62-67 Pg 68-69 2 AMHS Contributors 09/04/03 Will Perakis, Asyst Joe Reiss, Asyst Thomas Mariano, Brooks Neil Fisher, SK Daifuku Dan Stevens, Hirata Doug Oler, Hirata Scott Pugh, Hirata Larry Hennessy, IDC Adrian Pyke, Middlesex Ron Denison, Murata Chung Soo Han, AMD Detlev Glueer, AMD Marlin Shopbell, SemaTech Dave Miller, IBM Melvin Jung, Intel Steve Seall, Intel Len Foster, TI Roy Hunter, TI Sven Hahn, Infineon Harald Heinrich, Infineon Mikio Otani, ASI Makoto Yamamoto, Murata Junji Iwaskai, Renasas Seiichi Nakazawa, F-RIC 3 How Metrics were selected Almost every metric is a best in class or close to best in class Sources are: Individual IC maker and AMHS Supplier feedback. It is likely a factory will not achieve all the metrics outlined in the roadmap concurrently Individual business models will dictate which metric is more important than others It is likely certain metrics may be sacrificed (periodically) for attaining other metrics. The Factory Integration metrics are not really tied to the technology nodes as in other chapters such as Lithography However, nodes offer convenient interception points to bring in new capability, tools, software and other operational potential solutions Inclusion of each metric is dependent on consensus agreement We think the metrics provide a good summary of stretch goals for most companies in today’s challenging environment. 09/04/03 4 Material Handling Technical Requirements Year of Production 2003 2004 2005 2006 2007 2008 2009/ 2010 2012 / 2013 2015 / 2016 2018 Wafer Diameter 300mm 300mm 300m m 300mm 300mm 300mm 300mm 450mm 450mm 450mm 15 12 10 9 9 8 8 8 7 6 30 25 25 25 20 20 20 20 15 10 Transport E-MTTR (min) per SEMI E10 Storage E-MTTR (min) per SEMI E10 Transport MMBF (Mean move between failure) 5,000 7,000 8,000 11,000 15,000 25,000 35,000 45,000 55,000 65,000 Storage MCBF (Mean cycle between failure) 22,000 25,000 30,000 35,000 45,000 55,000 60,000 70,000 80,000 100,000 Peak System throughput (40K WSPM) Interbay Transport (moves/hour) 2075 2150 2250 2500 Intrabay transport (moves/hour) – High Throughput Bay 190 200 210 230 4100 4240 4740 4900 5000 5000 5000 5000 5000 Transport (moves/hour) - unified system Stocker cycle time (seconds) (100 bin capacity) 14 12 12 10 10 10 10 10 10 10 Average delivery time (minutes) 8 6 6 5 5 5 5 5 5 5 Peak delivery time (minutes) 15 12 12 10 10 10 10 10 10 10 Hot Lot Avg. delivery time (minutes) 4 3 3 2 2 2 2 2 2 2 AMHS lead time (weeks) <12 <11 <10 <9 <8 <8 <8 <8 <8 <8 AMHS install time (weeks) <16 <14 <12 <10 <10 <10 <10 <10 <10 <10 Downtime to extend system capacity when previously planned (minutes) <90 <60 <30 <30 <15 <15 <0 <0 <0 <0 09/04/03 5 Translating Material Handling metrics to Reality Metric 09/04/03 Potential Solution it is driving Wafer Transport System Capability Direct transport (or integrated interbay & intrabay). Needed for hot lot, gating sendahead, & hand-carry TPT targets Transport MMBF, Storage MCBF, Transport E-MTTR, Storage E-MTTR Storage and transport redundancy schemes; fault tolerant MCS; e-Diagnostics, EES, APC for AMHS Stocker cycle time per system Fundamental capability that permits the AMH system to successfully transport hot lots, gating send-aheads and hand-carries Stocker storage density New storage ideas which significantly reduce stocker footprint in the fab cleanroom (Under Track Storage, Conveyors) Downtime required for adding increased system capacity when previously planned New track and stocker extension designs that permit AMHS retrofit/expansion in a working factory with minimum downtime 6 2003 Supporting Material for Material Handling Technology Requirements AMHS System Throughput 09/04/03 7 2003 Inputs, Assumptions & Output (Numbers used in 2003 AMHS Requirements Table) Inputs Coefficient of Variation (SD/Mean) for MPH % of Direct Tool-Tool Moves 20% 10% (was 41% in 2002 ITRS) (was 100% in 2002 ITRS. Changed based on FO input) Process Step Assumptions Wafer Diameter 300mm 300mm Technology Node/Year (from ITRS 2001) 2004 2005 Number of Mask Layers 25 25 Number of Process Steps per Layer 28 29 Wafer Starts per Month 40,000 40,000 Wafer Starts per Week 9231 9231 Hours per Month 728 728 Wafers per Carrier 25 25 Average Process Steps per Hour 1538 1593 AMHS Configuration - Unified Transport Avg MPH Peak MPH (Avg + 2 Std Dev) Output - AMHS Transport Moves 2004 2005 2923 3027 4092 4238 300mm 300mm 300mm 2006 27 30 40,000 9231 728 25 1780 2007 27 31 40,000 9231 728 25 1840 2008 27 32 40,000 9231 728 25 1899 2006 3382 4735 2007 3495 4893 2008 3608 5051 Avg AMHS MPH = ((%Tool to Tool moves*1)+((1-%Tool to Tool moves)*2))*Average Process Steps per Hour Peak AMHS MPH = Average AMHS MPH*(1+2std dev) Note: Assumption is 1 move for tool to tool delivery and 2 moves for all other deliveries. Note: Assumption is 5% direct tool to tool for Hot lots and upper limit of 10% (input from Factory Operations) Note: Updated Number of Mask Layers based on 2003 ITRS executive summary, Electrical Defect Density-Table 5page 49. M. Jung Intel 09/04/03 8 Peak AMHS MPH – Sample Calculation System Throughput Requirements for 2004-2005 transition to direct transport: Sample Calculation for 2005: 40K WSPM Process Steps = 25 layers X 29 steps/layer X 40k wspm (725 steps X 40k wspm) = = 1593 process steps per hour (727 Hrs/month X 25 wafers /lot) Direct Transport Average MPH = ((%Tool to Tool moves x 1 Move)+((1-%Tool to Tool moves) x 2 Moves)) x Process Steps per Hour = ((10% x 1) + ((1 – 10%) x 2)) x 1593 = 3027 MPH Direct Transport Peak MPH = Average AMHS MPH x (1+2std dev) = 3027 x (1 + 2 x .20) = ~4240 MPH 09/04/03 9 2001/2002 Inputs, Assumptions & Output (Reference) Inputs Coefficient of Variation (SD/Mean) for MPH % of Direct Tool-Tool Moves 41% 100% Process Step Assumptions 300mm Wafer Diameter 2005 Technology Node/Year (from ITRS 2001) 28 Number of Mask Layers 29 Number of Process Steps per Layer 40,000 Wafer Starts per Month 9231 Wafer Starts per Week 728 Hours per Month 25 Wafers per Carrier 1785 Average Process Steps per Hour 300mm 300mm 300mm 2006 29 30 40,000 9231 728 25 1912 2007 30 31 40,000 9231 728 25 2044 2008 31 32 40,000 9231 728 25 2180 2007 2044 3720 2008 2180 3968 Output - AMHS Transport Moves 2006 2005 AMHS Configuration - Unified Transport Avg MPH 1912 1785 3480 3248 Peak MPH (Avg + 2 Std Dev) M. Jung Intel 09/04/03 10 2001/2002 Inputs, Assumptions & Output (Reference) System Throughput Requirements for Intrabay (2004/2005): Sample Calculation: High throughput = Intrabay MPH 09/04/03 20 tools/bay X 125 wafers/hour 25 wafers/carrier = 100 Moves / Hr Average = ~200 Moves / Hr Peak ( i.e., Avg+ 2xStd Dev) 11 2003 Inputs, Assumptions, Outputs & Description (Additional AMHS Configurations) Inputs Coefficient of Variation (SD/Mean) for Moves per Hour % of Direct Tool-Tool Moves within a bay (TTiB) % of Direct Tool-Tool Moves between bays (TTbB) % of Moves within a bay (MiB) % of Moves Between bays (MbB) 20% 10.0% 10.0% 50% 50% Process Step Assumptions Wafer Diameter 300mm Technology Node/Year (from ITRS 2001) 2005 Number of Mask Layers 25 Number of Process Steps per Layer 29 Wafer Starts per Month 40,000 Wafer Starts per Week 9231 Hours per Month 728 Wafers per Carrier 25 Average Process Steps per Hour 1593 Peak Process Steps per Hour (Avg + 2 Std Dev) -(PPS) 2231 300mm 300mm 300mm 2006 27 30 40,000 9231 728 25 1780 2492 2007 27 31 40,000 9231 728 25 1840 2575 2008 27 32 40,000 9231 728 25 1899 2658 2007 6310 5537 4893 6310 2008 6513 5716 5051 6513 Output - Peak AMHS Transport Moves AMHS Configuration 2005 2006 Separate Interbay and Intrabay 5465 6106 Separate Interbay & Intrabay w/ Some Bays Connected 4796 5358 Unified Transport 4238 4735 Multiple Transport System w/ Handoff 5465 6106 Separate Interbay and Intrabay Separate Interbay & Intrabay w/ Some Bays Connected Unified Transport Multiple Transport System w/ Handoff Formula Description =(MiB*((TTiB*1)+((1-TTiB)*2))+MbB*((TTbB*3)+((1-TTbB)*3)))*PPS =(MiB*((TTiB*1)+((1-TTiB)*2))+MbB*((TTbB*1.5)+((1-TTbB)*2.5)))*PPS =(MiB*((TTiB*1)+((1-TTiB)*2))+MbB*((TTbB*1)+((1-TTbB)*2)))*PPS =(MiB*((TTiB*1)+((1-TTiB)*2))+MbB*((TTbB*3)+((1-TTbB)*3)))*PPS M. Jung Intel 09/04/03 12 Transport Move Definition/Details (AMHS Configuration & Move Type Definitions) AMHS Configuration 1.Between Tools in same bay Move Type and Number of Moves 2.Between Tools in 3.Between Tool and 4.Between two different bays Storage Storage devices 1 Transport Move 3 Transport Moves 1 Transport Move OR 2 Transport Moves if "Remote" Stocker Separate Interbay & Intrabay w/ Some Bays Connected 1 Transport Move 1 Transport Move (if bays connected) OR 3 Transport Moves 1 Transport Move OR 2 Transport Moves if "Remote" Stocker 1 Transport Move Unified Transport 1 Transport Move 1 Transport Move 1 Transport Move 1 Transport Move 3 Transport Moves 1 Transport Move OR 2 Transport Moves if "Remote" Stocker 1 Transport Move Separate Interbay and Intrabay Multiple Transport System w/ Handoff* 1 Transport Move 1 Transport Move M. Jung Intel 09/04/03 13 Separate Interbay & Intrabay Between Tools in same bay Between Tools in different bays Between Tool and Storage Between two Storage devices 1. 2. 3. 4. T1 -> L1 -> T2 T1 -> L1 -> S1 -> L5 -> S3 -> L2 -> T3 T1 -> L1 -> S1 S1 -> L5 -> S3 L5 S1 S2 T1 M. Jung Intel 09/04/03 T2 L1 S3 S4 T3 T4 L2 S5 S6 T5 T6 L3 S7 S8 T7 T8 L4 14 Separate Interbay & Intrabay w/ Some Bays Connected Between Tools in same bay Between Tools in different bays Between Tool and Storage Between two Storage devices 1. 2. 3. 4. T1 -> L1 -> T2 T1 -> L1 -> T3 T1 -> L1 -> S1 S1 -> L1 -> S3 OR T1 -> L1 -> S1 -> L3 -> S5 -> L2 -> T5 OR S1 -> L3 -> S3 L3 S1 T1 M. Jung Intel 09/04/03 S2 T2 S3 S4 T3 T4 L1 S5 S6 T5 T6 S7 T7 S8 T8 L2 15 Unified Transport System – Capable of Direct Tool to Tool 1. 2. 3. 4. Between Tools in same bay Between Tools in different bays Between Tool and Storage Between two Storage devices T1 -> L1 -> T2 T1 -> L1 -> T3 T1 -> L1 -> S1 S1 -> L1 -> S3 L1 S1 T1 S2 T2 S3 T3 S4 T4 S5 T5 S6 T6 S7 T7 S8 T8 M. Jung Intel 09/04/03 16 Multiple Transport System w/ Handoff Between Transport Systems – Capable of Direct Tool to Tool T1 -> L1 -> T2 2. Between Tools in different bays T1 -> L1 -> S1 -> L5 -> S3 -> L2 -> T3 OR T1 -> L1 -> X1 -> L5 -> X2 -> L2 -> T3 3. Between Tool and Storage T1 -> L1 -> S1 4. Between two Storage devices S1 -> L5 -> S3 L5 1. Between Tools in same bay X1 S1 S2 T1 M. Jung Intel 09/04/03 T2 L1 S3 S4 T3 T4 L2 X4 X3 X2 S5 S6 T5 T6 L3 S7 S8 T7 T8 L4 17 2003 Supporting Material for Material Handling Technology Requirements AMHS Reliability Metrics 09/04/03 18 AMHS MCBF – Translated into Failures/Day Inputs Current ITRS Proposal Year of Production Transport E-MTTR (min per SEMI E10) Storage E-MTTR (min per SEMI E10) Peak System throughput (40K WSPM) Interbay Transport (moves/hour) Intrabay transport (moves/hour) – High Throughput Bay Transport (moves/hour) - unified system Stocker cycle time (seconds) (100 bin capacity) 2003 15 30 2004 12 25 2005 10 25 2006 9 25 2007 9 20 2008 8 20 2009 8 20 2012 8 20 2015 7 15 2018 6 10 2075 190 2150 200 4100 12 2250 210 4240 12 2500 230 4740 10 4900 10 5000 10 5000 10 5000 10 5000 10 5000 10 14 Outputs Long term goal: 1 transport failure/13hr + 1 storage failure per >10.5hrs in a 40K WSPM Fab. ITRS Proposed Changes Year of Production Transport MMBF (Mean move between failure) Storage MCBF (Mean cycle between failure) What do changes translate into for the Factory? Year of Production Transport Time between Failure - Hours - MMBF/MPH Storage Time between Failure - Hours - MCBF/Stocker Cycles Storage Unscheduled Uptime = (1-(MTTR/(MTBFx100stks))). Note: Metric is dependent upon number of stockers! 09/04/03 2003 5,000 22,000 2004 7,000 25,000 2005 8,000 30,000 2006 11,000 35,000 2007 15,000 45,000 2008 25,000 55,000 2009 35,000 60,000 2012 45,000 70,000 2003 2004 1.7 3.2 2005 1.9 3.7 2006 2.3 3.9 2007 3.1 4.8 2008 5.0 5.8 2009 7.0 6.3 2012 9.0 7.4 2015 2018 55,000 65,000 80,000 100,000 2015 11.0 8.4 2018 13.0 10.5 99.87% 99.89% 99.89% 99.93% 99.94% 99.95% 99.95% 99.97% 99.98% 19 2003 Supporting Material for Material Handling Technology Requirements Hot Lot Delivery Time 09/04/03 20 AMHS Hot Lot Delivery Time Goal: Determine Regular AMHS Hot Lot Delivery Time to meet Cycle Time. 1) Factory Operations and process step assumptions are listed below. 2) If a Queue time of ~2 days is acceptable for Hot Lots then AMHS Delivery Times meet Cycle Time Requirements. Excerpt from Factory Operations Requirements Table: Year of Production 2003 2004 2005 2006 2007 2008 2009 2012 2015 2018 Hot Lot (ave top 5% of Lots) - Cycle time per mask layer (days) - X-Factor 0.62 1.4 0.62 1.4 0.62 1.4 0.55 1.5 0.55 1.3 0.55 1.3 0.51 1.3 0.51 1.3 0.51 1.3 0.51 1.3 2003 2004 2005 2006 2007 2008 2009 2012 2015 2018 Number of Mask Layers 25 25 25 27 27 27 27 29 29 29 Number of Process Steps / Layer Number of Process Steps 28 700 29 725 30 750 31 837 32 864 32 864 32 864 32 928 32 928 32 928 2003 2004 2005 2006 2007 2008 2009 2012 2015 2018 4 3 3 2 2 2 2 2 2 2 Process Step Assumptions: Year of Production AMHS Metric Recommendation: Year of Production Avg AMHS Hot Lot Delivery Time (min) M. Jung Intel 09/04/03 21 AMHS Hot Lot Delivery Time Cycle / Processing / Transport / Queue Time Output and Assumptions: 1) The following table outlines the Required Cycle Time and the expected processing time. 2) The transport time is directly dependent on the AMHS Delivery Time. 3) The Queue Time is determined by subtracting the Transport Time and Processing Time from the Cycle Time. Output from Factory Operations / Process Step and AMHS Hot Delivery Time Assumptions: Year of Production 2003 2004 2005 2006 2007 2008 2009 2012 2015 2018 Cycle Time (days) 15.5 15.5 15.5 14.85 14.85 14.85 13.77 14.79 14.79 14.79 Transport Time (days) 1.9 1.5 1.6 1.2 1.2 1.2 1.2 1.3 1.3 1.3 Processing Time (days) Queue Time (days) 11.1 2.5 11.1 2.9 11.1 2.9 9.9 3.8 11.4 2.2 11.4 2.2 10.6 2.0 11.4 2.1 11.4 2.1 11.4 2.1 Hot Lot (ave top 5% of Lots) Assumptions: Cycle Time = Number of Mask Layers x Cycle Time per Mask Layer Number Process Steps = Number of Mask Layers x Number of Process Steps per Layer Transport Time = Number Process Steps x AMHS Hot Lot Delivery Time X Factor = Cycle Time / Processing Time Cycle Time = Queue Time + Transport Time + Processing Time M. Jung Intel 09/04/03 22 2003 Supporting Material for Material Handling Technology Requirements Delivery Time 09/04/03 23 Carrier Delivery Time Values & Metrics #1 Timestamp Description Carrier is handed over to AMHS (e.g. at loadport, shuttle-I/O, nest) Carrier is handed over to hoist, vehicle or conveyor (“real transport media”) Hoist, vehicle or conveyor arriving at (final) destination Carrier is handed over from AMHS to equipment (e.g. at loadport, I/O, …) Operator, Host or Equipment requesting carrier Comment Example 09:13:12 may be = 09:13:50 9:20:02 may be = 11:05:07 11:04:11 D. Glueer AMD 09/04/03 24 Carrier Delivery Time Values & Metrics #2 Description Interval Example Travel Time Time carrier spends on vehicle, hoist or conveyor - 5 min Delivery Time Time required to transport a carrier from one production equipment to any other production equipment in the factory. - 7 min Lateness Time operator or equipment needs to wait for carrier, excluding minimum robot handling time at destination - - tRetrieve 2 min D. Glueer AMD 09/04/03 25 AMHS Updates for 2003 – ITRS & ISMT Metric Definitions Definitions: Transport move definition: A transport move is defined as a carrier move between loadports (stocker to stocker, stocker to production equipment, production equipment to stocker or production equipment to production equipment). Avg. Factory wide carrier delivery time: the time begins at the request for carrier movement from the host and ends when the carrier arrives at the load port of the receiving equipment. Maximum delivery time is considered the peak performance capability defined as the average plus two standard deviations. Handling time at destination tRetrieve: the (minimum) robot handling time required to move the carrier from the last storage location to the operator or the processing tool. Combined AMHS: delivery time and lateness are aggregated times, including optional changes of transportation media along the path to the destination. D. Glueer AMD 09/04/03 26 Strategic Goals for Delivery Time 1,2 1 5% p.a. Delivery Time decrease p.a. due to advances in AMHS technology Minutes 0,8 0,6 0,4 10% p.a. Lateness decrease due to Delivery Time, MES and dispatching improvements 0,2 0 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 Year Delivery Time [min/ 10 meter] Lateness [min] D. Glueer AMD 09/04/03 27 ITRS AMHS 2003 Potential solutions Direct Transport: Details and assumptions for Potential Solutions 09/04/03 28 AMHS is Changing to an On-Time Delivery System Inter-Bay AMHS Intra and Inter Separate System Intra-Bay H/W Efforts Key Indicator Intra-Bay Equipment View Reduce WIP Unified System (Dispatcher Base) S/W Efforts Push Pull Re-Route Ave & Max Time Punctuality (On-Time) On-Time Delivery Capacity Planning Transfer Time (Ave & Max) Lot View Schedule WIP Unified System (Scheduler Base) Transfer Throughput Wafer Level Tracking J. Iwasaki Renasas 09/04/03 29 The Next Generation Factory Concept Planning System ….. ….. Agile -Mfg. Mfg. System ….. ….. EES ….. Supporting System ….. ….. User’s SCM Supply Chain Management Direct Transport Wafer Level Control EDiagnostic Supplier’s SCM E-Mfg. Direct Transport - Plays key role in next generation factories 09/04/03 30 Direct Tool to Tool Transport Is Needed by 2005 Objectives: Reduce product processing cycle time Increase productivity of process tools Reduced storage requirements (# of stocker) Reduced total movement requirements Priorities for Direct Delivery: Several AMHS Mechanical & Layout Design Concept Options being considered S1 S2 S3 S4 S5 S6 S7 S8 T1 T2 T4 T5 T6 T8 T3 T7 Fully Connected OHV Super Hot Lots (< 1% of WIP) & Other Hot Lots (~5% of WIP) Ensure bottleneck equipment is always busy Gating metro and send ahead. Other lot movements opportunistically S1 S2 S3 T1 T2 S4 T3 T4 S5 S6 S7 T5 T6 S8 T7 T8 Capability Needs Tools indicate that WIP is needed ahead of time Event driven dispatching Transition to a delivery time based AMHS Integrated factory scheduling capabilities ID Read at Tools OHV with Interbay Transport Timing 09/04/03 Research Required Development Underway Qualification/Pre-Production 2001-2003 2003-2005 2004-2006 Partially Connected OHV With Conveyor Interbay 31 Material Handling: Vehicle Based Direct Transport System Concept Central Stocker (Large Capacity) (High Throughput) Upper Ceiling OHT Note: Current OHT systems cannot meet the longer-term throughput Branch Under Floor 09/04/03 Full Direct Transport 32 Material Handling: High Throughput Conveyor Based Direct Transport Concept Conveyor Type Transport 09/04/03 33 Material Handling: High Throughput Conveyor / Hoist Hybrid Based Direct Transport Concept Interbay Conveyor <-> Intrabay hoist Interbay/Intrabay Conveyor <-> Tool Delivery Hoist A. Pyke Middlesex 09/04/03 34 Material Handling: Interbay Vehicle <-> Intrabay Hoist handoff station. Interbay Conveyor <-> Intrabay RGV/AGV Alternate Concepts for achieving Direct Transport w/ multiple transport systems Interbay Vehicle <-> Intrabay Hoist handoff station with height translation Interbay vehicle <-> Intrabay RGV/AGV handoff station Interbay Vehicle (passive) <-> Intrabay Hoist handoff station A. Pyke Middlesex 09/04/03 35 Material Handling: High Throughput Subway Conveyor DirectX Transport Concept (Stocker to Stocker Moves) Stocker Stocker Section X-X Stocker X Stocker Stocker Stocker Subway Transport system 12’ceiling Conveyor Maintenance: Via the top for Subway system Via the bottom for Overhead system Raised metal floor 600mm max D. Pillai Intel Corp 09/04/03 Transparent cover Stocker robot 2nd transport loop (if needed) Conveyor installed on waffle slab Waffle slab 36 Material Handling: High Throughput Subway Conveyor Direct Transport Concept (Tool Moves) Loadport with Safety cover and Elevator Tool ME ME EB Tool Mini Environment D+D1 = 450mm Tool ME X ME Tool X Simple Gantry robot Tool body (side view) Tool ME ME Safety Cover Tool PGV Dock flange Tool ME ME Tool Raised Metal Floor D. Pillai Intel Corp 600mm Stocker Stocker FOUP gripper Conveyor on waffle slab door opener zone 900mm Tool Pedestal envelope Waffle slab 09/04/03 37 Material Handling: High Throughput Subway Conveyor Direct Transport Concept (Plan View w/ Gantry) EB D+D1 = 450mm Door opener Gantry Rails Safety cover Tool body Door opener Mini Environment D. Pillai Intel Corp 09/04/03 38 Material Handling: High Throughput Subway Conveyor Direct Transport Concept (Elevation View w/ Gantry) Gantry robot takes FOUP to Loadport and places on KC Tool front face Door opener flange Loadport 1 FOUP lifting Exclusion zones Empty loadport 2 900mm Raised Metal Floor Outline of pedestal Gantry robot picks up FOUP from Conveyor and raised to the top Subway conveyor D. Pillai Intel Corp 09/04/03 Waffle slab 39 Material Handling: High Throughput Subway Conveyor Direct Transport Concept (Layout) D. Pillai Intel Corp 09/04/03 40 Factors that affect opportunity for direct transport - AMHS Interbay and Intrabay Track Layout Unified track supporting interbay and intrabay systems “Crossovers” to reduce AMHS cycle time – increase empty vehicle availability Bypass capability for traffic jams Parking area for empty vehicles Advantage: Increased possibility for direct delivery. Reduced AMHS cycle time Disadvantage: Might increase complexity for MCS to manage overall AMHS system complexity increases w/ integrated system w/ multiple tracks & add’l complexity in layouts (bypasses, shortcuts) # of vehicles High: Traffic jams may occur Low: FOUP will wait to be picked up AMHS Controller/MCS Functionality Support MES and Dispatching systems Balance empty vehicles throughout the fab Currently in AMHS control, this is ok for today. In future, need further integrated system to provide add’l MES data (tools, WIP) to proactively optimize management of empty vehicles (stage vehicles). Integrate third party buffers Redirect vehicle route/destinations while on route C. Han AMD 09/04/03 41 Intrabay Side SEMI Standards Assessment Hoist type vehicle interface: Pickup: Carrier located by conveyor rails, pickup by top flange. Drop-off: Carrier lead-in by conveyor rails (similar to KC pins). Handoff by E84 RGV/AGV type vehicle interface (AGV/RGV uses KC pins or option fork lift flanges): Pickup: Carrier located by conveyor rails, KC pins available for robot. Drop-off: Carrier lead-in by conveyor rails (similar to KC pins). Handoff by E84 RGV/AGV type vehicle interface (AGV/RGV uses conveyor rails): Pickup: Carrier located by KC pin lifter, conveyor rails available for robot. Drop-off: Carrier placed on KC pins, robot uses conveyor rails Handoff by E84 Interbay Side Most “active vehicle” type vehicles should work without issue: E85 Option A – “Active Transport Delivers Carrier to Internal Stocker location” – “Internal Stocker location” replaced by Conveyor Buffer. E85 Option B - “Active Transport Delivers Carrier to External Stocker location” – “External Stocker location” replaced by Conveyor Buffer. Passive Vehicle Interface will require secondary active component: Dedicated pick and place unit or robot. Software A. Pyke Middlesex 09/04/03 IBSEM will work as-is for Interbay, Intrabay and Hybrid systems. E84 good handoff protocol for all low level handoffs. Also, IBSEM possible for interbay vehicle to intrabay vehicle handoff but may be overkill. STKSEM also possible for interbay vehicle to intrabay vehicle handoff but extreme overkill. Minor modifications in IBSEM (E82) may allow easier vehicle-vehicle handoff, through intermediate device. Could be investigated. Further work needed. 42 ITRS AMHS 2003 Potential solutions Direct Tool-to-Tool Delivery 3rd Party Loadport / Buffer. C. Han AMD 09/04/03 43 Key Factors - # of LP (FOUP Buffers) Three loadports (for normal process tool) can increase the direct tool-to-tool delivery possibility LP #1: Processing LP #2: Non-production wafer FOUP for Send Ahead or Test LP #3: To be processed Advantage Can deliver at any time (unless next FOUP to be processed is already on the non-processing LP) Tool dedicated Non-production FOUP reside on the process tool (instead of delivery back and forth from stocker) Reduced # of delivery cycles Disadvantage Tools usually have only two load ports, this approach requires an additional LP Tools may not support installation of additional LP due to their design Third party buffer is possible solution instead of additional LP Need to have “internal” transfer between buffer and LPs AMHS(OHT) to deliver FOUP to buffer C. Han AMD 09/04/03 44 Key Factors – Operation Scenario for NonProduction Wafer FOUP for two LP Non-production wafer (i.e. Send Ahead and test) FOUP resides on process tool only for the time required Transfer from Transfer from Transfer from scenario) Transfer from stocker to process tool (not required for the 3 LP scenario) process tool to metrology tool metrology tool to sorter for Send Ahead merge (may not be required for 3 LP sorter to Stocker (in 3 LP case, transfer to process tool) Advantage Can be done with two LP in the process tool Disadvantage Next lot can not be delivered until non-production wafers processed, and FOUP removed from the tool Increase deliveries C. Han AMD 09/04/03 45 Key Factors – Operation Scenario for NonProduction Wafer FOUP Non-Production Wafers Time Production Wafers LP #1 Three LP LP #2 LP #3 •Next lot can be delivered at any time •Non-production FOUP can be delivered back to LP #2 at any time Two LP LP #1 LP #2 •Next can be delivered after finishing non-production lot •Non-production FOUP need to be delivered to stocker C. Han AMD 09/04/03 46 ITRS AMHS 2003 Potential solutions Integrated Flow and Control: Details and assumptions for Potential Solutions 09/04/03 47 Material Handling Potential Solutions Backup Section Content Potential Solutions for Integrated Flow and Control Assumptions Carrier Level Solution with Concept Drawing Type 1: Sorter and Metrology Equipment Integration with Stockers Wafer level Solutions with Concept Drawings Type 2-1: Connected EFEMs (Equipment Front-end Modules) Type 2-2: Expanded EFEM Type 2-3: Continuous EFEM (Revolving “Sushi Bar”) 09/04/03 48 Material Handling Potential Solutions – Integrated Flow and Control Potential Solutions for Integrated Flow and Control - See concept diagrams on following pages Assumptions: Carrier Level integrated Flow and Control Type 1: Sorter and Metrology with Stockers Compatible with existing standard carrier Must be collaboration between sorter, metrology and AMHS suppliers to integrate stockers with other equipment Hardware integration primarily owned by stocker supplier Equipment integration work primarily controls interface Requires a carrier 180º rotation during hand-off from stocker robot to tool load port(s) Wafer Level Integrated Flow and Control Type 2-1: Connected EFEMs Transition from lot handling to single wafer handling systems may require new sorting equipment Contamination control must be addressed by way of a tunnel or mini-environment expansion Bypass required for individual equipment downtimes to prevent cluster shutdown Requires standardized EFEM interfaces (at the interface between the tunnel and EFEM) are recommended for ease of wafer transport "tunnel" integration. 09/04/03 49 Material Handling Potential Solutions – Integrated Flow and Control (continued) Assumptions (continued): Wafer Level Integrated Flow and Control Type 2-2: Expanded EFEM Transition from carrier handling to single wafer handling systems will require new sorting equipment There must be collaboration between equipment suppliers for EFEMs development Requires new standard physical interface between process/metrology equipment and EFEMs High throughput robot required – Concern about material handling robot downtime impact – Preventative maintenance and unscheduled downtime impact are not clear Required equipment to load port matching and lot integrity are key challenges Wafer Level Integrated Flow and Control Type 2-3: Continuous EFEM (Revolving “Sushi Bar”) Transition from lot handling to single wafer handling systems will require ultra high speed wafer handling equipment – Lot integrity a key issue Equipment interface robot required to replace current EFEMs wafer handling robot Targeted for 450mm transition 09/04/03 All configurations above are valid, however it is important to select appropriate solution for each factory situation 50 Type 1: Carrier Level integrated Flow and Control - Sorter and Metrology with Stockers OHT Loop Metro Tools OHT Loop Stockers Process Tools Stocker Sorter Metro Metro Tools Metro Sorter Process Tools Stocker robot interfaces directly with Sorters and Metro equip Stocker robot loads Sorters and Metro equipment Loadports End View Potential Solutions Require: Standardized Intrabay Operation Integrated Software 09/04/03 When Solutions Are Needed: •Development Underway in 2002 •Qualification/Production by 2003 •(Complete for Sorter) 51 Type 2-1 :Wafer Level Integrated Flow and Control (Connected EFEM) Equipment Supplier A Equipment Supplier B Equipment Supplier C Wafer Staging Carrier Staging Potential Solutions Require: I/F Standard (H/W, S/W) Standardized EFEM Software Integrated Wafer level APC Standardized Intrabay Operation 09/04/03 When Solutions Are Needed: •Research Required by TBD •Development Underway by TBD •Qualification/Production by TBD Conceptual Only 52 Type 2-2 :Wafer Level Integrated Flow and Control (Expanded EFEM) Standard Tool Widths Potential Solutions Require: System controller of Equipment Group Wafer Dispatcher Module structure of equipment Standardized I/F Standardized Width Modular Process Steps High Speed Wafer Transfer Standardized Intrabay Operation 09/04/03 When Solutions Are Needed: •Research Required by TBD •Development Underway by TBD •Qualification/Production by TBD Conceptual Only 53 Type 2-3: Wafer Level Integrated Flow and Control Continuous EFEM (Revolving Sushi Bar) Single Wafer Conceptual Only Wafer Transport Carrier Level Transport Stocker Multi-Wafer Carrier Single Chamber Process Tool Metrology Tool Target 450mm 09/04/03 Potential Solutions Require: Ultra High Speed Wafer Transfer Target M/C to M/C 7sec. Wafer Level Dispatching When Solutions Are Needed: •Research Required by 2007 •Development Underway by 2010 •Qualification/Production by 2013 54 ITRS AMHS 2003 Potential solutions Delivery Time: Under Track Storage 09/04/03 55 UTS Requirements Potential Benefits: Shorter delivery times based on storage closer to process tools Better support of quick-turn processes Hot lot handling Lower storage cost / Higher Storage Density (zero foot print, no robot) Higher AMHS reliability based on less complex storage solution Potential Solutions Require: Capable of OHT pick / place Handoff by E84 (optional) Lightweight to minimize ceiling loading issues WIP management algorithms important to realize the performance benefits of UTS Alignment with kinematic pins (optional) Carrier identification capabilities (optional) Ability to detect FOUP placement/presence and/or misplacement T. Mariano Brooks 09/04/03 When Solutions Are Needed: •Development Underway by 2003 •Qualification/Production by 2004 56 Potential UTS Solutions – Passive Shelf T. Mariano Brooks 09/04/03 57 Potential UTS Solutions – Re-circulating Buffer T. Mariano Brooks 09/04/03 58 Potential UTS Solutions – Linear Buffer T. Mariano Brooks 09/04/03 59 ITRS AMHS 2003 Potential solutions Inert Gas Purging of Foups 09/04/03 60 Potential Solutions – Inert Gas Purging of FOUPs Need: Option for Improvement in Wafer FOUP Level Environmental Conditioning along with Compliance to Industry Safety Standards FOUP OHT Loop Nest FOUP FOUP Output Input Current Port Versions: 2 Ports near Door and 4 Ports Potential Solutions Require: Inert Gas Injection Purge Nests in Wafer Stockers Gas Plumbing with High Flow Initial Purge & Low Sustaining Flow Rates Material & Stocker Control Systems to Support Partial Population of Purge Nests in Stockers User Consensus and/or Industry Hardware Standards Needed for FOUP / Purge Port Interoperability (E47.1 update – Locations on Foup Define interface in E47.1) Stocker FOUPs being Purged FOUP Out put FOUP Input Stocker robot loads to/from Purge & Non-Purge FOUP storage nests End View When Solutions Are Needed: •Development Underway in 2003 •(65nm / 90nm) •Qualification/Production starting 2004 L. Foster TI 09/04/03 61 ITRS AMHS 2003 Potential solutions Factory Cross Linkage: Protocol Induced Constraints 09/04/03 62 Facility Cross Linkage Issues Drivers: Area A Slurry (Polish) Copper Other hazardous materials Cleanliness requirements Shipping & receiving ... Area B Area A Protocol Change Traverse D. Glueer AMD 09/04/03 63 Facility Cross Linkage Approaches Protocol Change: Vehicle change: Transferring a carrier from one AMHS vehicle to another vehicle requiring robotic handlers and local buffers. Potential Solutions: See presentation Direct Transport material for option to “Transfer between transport devices”. FOUP change: - Potential Solutions A) Via Sorter: Transferring wafer by wafer B) Via Flipper: Transferring content as a whole, e.g. via comb 1) Integrated: Transfer device integrated in Stocker 2) External: Hoist delivering carrier to Transfer Device Traverse: - Potential Solutions through tunnels on dedicated vehicles using dedicated tracks and/or routes D. Glueer AMD 09/04/03 64 Facilitity Cross Linkage Considerations Directions: Unidirectional: Best separation Bi-directional: Lower COO (1 for 2, re-use of Empties) Multi-usage: E.g. from area A one transfer device both to B and to C + saving footprint - complex control structure, higher impact of down-events Availability of (appropriate) Empties: Empty vehicles / empty FOUPs Washing cycles Protocol restrictions esp. for multi-usage transfers Local buffer capacity of transfer device Facilities: Air pressure Fire protection D. Glueer AMD 09/04/03 65 Facility Cross Linkage Metrics Throughput = WSPM Wafers / Carrier Amount of Transfers/Layer Amount of Mask Layer „Bi-directional“ + Amount of Transfers due to other reasons „Unidirectional“ Sample: 40000 WSPM ÷ 25 Wafers/FOUP • (4 • 29 + 3) = 265 Transfers per Hour “Cycle Time” = 2 • Average Carrier Delivery Time + Transfer Time Sample: 2 • 8 Minutes + 5 Minutes = 21 Minutes Availability D. Glueer AMD 09/04/03 66 Facility Cross Linkage Conclusions Many ways to address Facility Cross Linkage issues Selection process is site-specific and needs to be made in close cooperation with CFM department High drawback to MES and AMHS control structure Transfer devices may turn out to be bottleneck, esp. when “multi-usage” Handling Empties increases AMHS duties significantly High impact to AMHS delivery times May lead to impact of whole wafer processing cycle time Usually trade-off between cleanliness concerns vs. AMHS performance Could be reduced by appropriate dispatching and scheduling “Just in Time” delivery of FOUPs Redundancy needs to be build-in D. Glueer AMD 09/04/03 67 Potential Research Topics – Vibration Requirements Proposed Research Title Background Proposal Project Scenario Deliverables Support Required Benefit 09/04/03 Characterization of Acceptable Vibration and Acceleration Limits on Wafers Current industry specs on vibration/acceleration applied to wafers by AMHS and not supported by data on potential damage to wafers Need to analyze potential negative effects (mechanical damage, defects, yield loss) to wafers induced by different levels or types of vibration during automated handling. Data Characterization threshold for acceptable vibration/acceleration would allow for speed and cycle time of AMHS products to be improved without inducing WIP Jeopardy. Recommended specifications for vibration applied to wafers by AMHS and supporting data Tools for characterization, wafer vibration, Skills in mechanical engineering, materials, process, yield Current vibration limits are constraining the AMHS cycle time (stockers, vehicles). New vibration limits have the potential to increase system throughput. Simulation results w/ new stocker and vehicle cycle time can be used to show system throughput benefits. 68 Potential Research Topics FOUP Cleanliness Methodology for measuring cleanliness of FOUPs (other than liquid particle counts). Need repeatable technique for characterization of cleaning FOUPS. Benefit – Better cleaning system, reduced cleaning Unified Transport System Validation Demonstrate, through simulation, a unified transport system capable of achieving system throughput requirements in requirements table. Ex. Empty vehicle management in a unified system. Need to demonstrate a peak system for 40K WSPM factory with unified transport system (vehicle based). Provide distribution strategy / rules that can be used by AMHS vendors. Benefit – Validate feasibility of unified transport system in a fully loaded fab. FOUP Purging 09/04/03 What are requirements for FOUP purging? 69