TRANSFER-OUT-1 - UniMAP Portal

advertisement

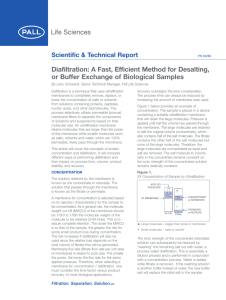

PTT303 /2 PROCESS MODELLING AND SIMULATION SEM 1 (2013/2014) Biochemical Case Study Student should be able to; Develop chromatographic process to achieve the desired final product purity, combination with membrane filtration to exchange buffers and concentrate the dilute product solutions. Create the process and identify uncertainty problem that might happen during the operations. OUTLINE FOR BIOCHEMICAL CASE STUDY A sequential modular approach to solve for a moderate complex flowsheet Some common unit operations in biochemical industries: Fermenter Disk-stack centrifugation Diafiltration Chromatography Part 1 Fermentation Section Part 3 Purification Section 2 Sequential modular approach Part 2 Purification Section 1 PROCESS DESCRIPTION Water, microorganisms, nutrients (glucose) and air are fed into a bioreactor where at 37°C a fermentation takes place, yielding an enzyme and impurities. Biomass is separated in a disk-stack centrifuge and the liquid is stored in tank. It is then processed in a diafilter where the remaining biomass is removed (with a small loss of product). It is stored again and then loaded onto a PBA chromatography column where the enzyme binds and eluted using a WFI/NaCl mixture. PROCESS DESCRIPTION Part 1 Fermentation Section Fermentation Unit Bioreactor Feed •Water •Microorganism •Nutrients (glucose) •air Condition 37 °C Output (yield) Enzyme + Impurities separated in a disk-stack centrifuge and the liquid is stored in tank. (storage 1) Biomass Part 2 Purification Section1 Diafiltration Remove remaining Biomass Blending/ Storage Store product (small loss of product) PBA Chromatography Column Bind the enzyme And eluted by using WFI/NaCl mixture Blending/ Storage Store product Part 3 Purification Section 2 Part 1 Fermentation Section Mode of operation: batch processing Component registration: Glucose Biomass CO2 WFI (water for injection) Enzyme (new-water as reference comp.) Impurities ( new-water as reference comp.) Process Flowsheeting for Fermentation Section UNIT PROCEDURE EQUIPMENT DESCRIPTION Fermentation Vessel Procedure/ In a Fermentor transformation of raw material into enzyme & impurities Centrifugation Centrifugation/ Disk- separation of biomass Stack Storage/ Bulk/ Batch/ temporary product in a Blending Tank) storage Rename as: Storage 1 (Right click equipment/ Edit labels) Storage 1 PRODUCT INITIALISATION FOR FERMENTATION SECTION Fermentation Centifugation Storage 1 FERMENTATION Initialising CHARGE operation (right click on unit procedure (Fermentation)then click add /remove operations.. Add Charge -1, Charge-2, Heat-1, Ferment-1, Transfer-Out-1. Continue… CHARGE OPERATION DATA CHARGE-1 Charge 10000 L of water @ 100 L/min CHARGE-2 Charge 1000kg glucose @ 40kg/min HEAT-1 Final temp :37 °C Efficiency: 90% Duration: calculated based on constant heating rate 0.5 °c/min TRANSFER-OUT-1 duration same as Centrifugation (use Master-Slave relationship) Continue… CHARGE OPERATION Ferment-1 (Stoichiometric) DATA Operation condition: Final temp: 37 °C Heat transfer agent: Cooling water Process time: 36 hrs Fermentor aeration: select air from stock mixture (auto adjust) Reaction (mass stoichiometry); 100Glucose + 80 O2 55 Water + 2 Enzyme + 3 Impurities + 80 CO2 + 40 Biomass Reaction extent: 98% based on limiting component Enthalpy: -3700 kcal/kg; ref. comp.: O2; ref. temp:37 °C Emission: 100% for CO2 (select “Perform emission calculation” & “Set By User” for CO2) Note: Leave other values as DEFAULT FERMENT-1 Final temp: 37 °C Process time: 36 hr Reaction extent Enthalpy data Aeration setting: Auto adjust for air (stock mixture) Mass stoichiometry CENTRIFUGATION UNIT PROCEDURE OPERATING CONDITION CENTRIFUGE-1 Equipment design based on: (default) Solid Removal Duration: 3 hr (Centrifugation time) MATERIAL BALANCE Component removal %: set by User UTILITIES Exist temp: 15 °C (Set by User) Solid component Agent: removal %: 98% chilled water for biomass; 0% for others Solids Concentration in Solid Streams: 500 g/L SCHEDULING Start when Transfer-out of Fermentation (P-1) starts STORAGE 1 CHARGE OPERATION DATA TRANSFER-IN-1: Operating conditions: Transfer in using: outlet stream from centrifuge Duration: same as Centrifuge (set by MasterSlave Relationship) STORAGE 1 Scheduling: Start when Centrifugation (P-2) starts operation Duration: to be determined Scheduling: start when TRANSFER-IN-1 starts Let’s simulate the flowsheet & solve the error message given (scheduling problem) PURIFICATION SECTION 1 Right click on storage; then click on add/remove operations/delete storage/add TRANSFER-OUT-1 Please delete “STORE-1” operation in P-3 & replace it with a “Transfer-Out-1” Process Flowsheeting for Purification Section 1 UNIT PROCEDURE Diafiltration (DF) EQUIPMENT Filtration/ Diafiltration DESCRIPTION Removal of all leftover biomass from Storage 1 Remark: Storage (P-3) outlet needs to be deleted before new stream can be connected to the diafilter Product Storage 2 Storage/ Bulk/ Batch/ In a Blending Tank Rename as: Storage 2 (Note; Right click on equipment & select “Flip (reverse direction)” to turn the equipment into reverse direction Temporary product stage PROCESS DESCRIPTION ; Diafiltration recycle Feed tank In diafiltration, water or some other solvent or buffer is added to the retentate to facilitate the removal of membranepermeating species along with the water (or other solvent) during filtration. The addition of water (or any other solvent) can be conducted either in batch or continuous mode. In batch operation, permeable solutes are: Cleared from the retentate by volume reduction (batch concentration); Followed by re-dilution with water ( or other solvent); and Re-concentration in repetitive steps Diafiltration in SuperPro In the current version of SuperPro Designer, batch concentration can precede and follow a continuous operation (true diafiltration) Any number of batch concentration stages can be specified for each discontinuous operation. In general, if the initial solution is dilute, a concentration step (to reduce the volume of the material) usually precedes a continuous diafiltration step. Retentate (Concentrate) Feed tank Recycle Loop If the initial solution concentration is rather high, one usually goes directly to continuous diafiltration Permeate (Filtrate) PRODUCT INITIALISATION FOR PURIFICATION SECTION-1 Diafiltration Storage 2 DIAFILTRATION UNIT PROCEDURE DIAFILTER-1 (diafiltration) OPERATING CONDITION Rejection coefficient (RC): biomass 100%, impurities 20%, enzyme 5% Max. solid concentration in retentate: 600 g/L Product denaturation (denaturation is due to shear forces during membrane filtration, common in bioprocessing): Denaturation: 4% Active product: enzyme Denaturated product: impurities Duration: 4 hrs (filtration time) Diluant: water (auto adjust) Diafiltration data: 5 (Volume Permeated) Concentration data: Prefiltration: YES, # of conc. stages: 1, Conc. Factor 5 Postfiltration: NO UTILITIES SCHEDULING Select “set by User” Start with TRANSFER-OUT of Storage 1 Exit temperature = 15°C Agent: Glycol Specific power: 0.2 kW/m2 Continue….. Additional task: Set TRANSFER-OUT-1 of Storage1 (P-3) to follow the duration of Filtration inDiafilter (P-4) using Master-Slave relationship STORAGE 2 UNIT PROCEDURE OPERATING CONDITION SCHEDULING TRANSFER-IN-1 Transfer in using: outlet stream from DF (P-4) Start (scheduling) and duration (Operating condition: MasterSlave) same as DF STORAGE 2 Scheduling: start when TRANSFERIN-1 starts Duration: to be determined Simulate the Flowsheet & Solve The Scheduling Error PURIFICATION SECTION 2 Again, replace “STORE -1” operation in P-5 with “TRANSFER-OUT-1” Process Flowsheeting for Purification Section 2 UNIT PROCEDURE EQUIPMENT DESCRIPTION PBA Chromatography Equipment: Chromatography/ Adsorption/ PBA Chromatography Description: binds and is elutes the enzyme using a WFI/ NaCl mixture (new mixture to be registered Product Storage 3 Storage/ Batch/ In a Blending Tank temporary product storage Rename as: Storage 3 (Note: Right click on equipment & select “Flip (reverse direction)” to turn the equipment into reverse direction NEW MIXTURE REGISTRATION We need a mixture of “NaCl/WFI(2M)” for this section, but this mixture is not found in the component database of SuperPro (verify this from Stock Mixture database) 2 ways of registering this mixture: A) MODIFY FROM EXISTING MIXTURE ‘Register as NaCl (2M) & replace the water compound in this mixture with WFI’ B) REGISTER FROM SCRATCH Register it from scratch & fill in the physical properties that you have A)MODIFY FROM EXISTING MIXTURE Path: Task/Edit Stock Mixtures Make sure the mass % is make up into 100% Highlight the water component, delete & replace it with WFI B)REGISTER FROM SCRATCH Path: Task/Edit stock Mixtures Create new mixture Choose this option if you know the density of the mixture Choose this option to modify from an existing mixture (e.g. NaCl mixture) Let’s try it … (Always remember to save your work …) PRODUCT INITIALISATION FOR PURIFICATION SECTION 2 PBA Chromatography Storage 3 GENERAL DESCRIPTION : PBA CHROMATOGRAPHY 4 different PBA Chromatography Column; 1)Column Loading (Load) 2)Column Washing (Wash) 3)Column Elution (Elute) 4)Column Regeneration (Regenerate) Regenerate COLUMN DESCRIPTION PBA column loading (Load) Estimate the time for loading a column, track recovery yield, & estimate the number and size of columns required Column washing (Wash) Wash away the undesired impurities that trap in the column A column may be used to bind either: Product component(s); or Impurity components Column elution (Elute) For retention of product components, for a component that binds to the resin, its amount in the product stream = (amount in the feed stream) x (binding fraction) x (elution yield) Colum regeneration (Regenerate) All component present in the feed stream, that do not bind to resin, exit into the waste stream Regenerate the resin using a solution CHARGE OPERATION LOAD-1 OPERATING CONDITION Loading flowrate: 200 cm/h (linear velocity) Resin’s primary function: Retain Product (default) Comp binding & yield; -enzyme 100%, 90% -impurity: 20 %, 30% Info; Binding refers to all components that bind to the resin; Yield represents the percentage of bound material that ends up in the product stream. SCHEDULING Starts when Transfer-Out of Storage 2 ADDITIONAL TASK For Storage 2: Make sure that the “Storage-1” operation in Storage 2 is replaced by “TRANSFER-OUT1” Set TRANSFEROUT-1 of Storage 2 to have the same duration as LOAD-1 using Master-Slave Relationship CHARGE OPERATION WASH-1 OPERATING CONDITION •Volume per cycle: 2 BV (bed volumes) •Wash stream: “Wash” stream which contains WFI (auto adjust) ELUTE-1 REGENERATE-1: •Eluant Volume: Total Volume: 8 bed vol. Volume in Product Stream: 2 bed vol •Flow rate Options: 200 cm/h (linear velocity) •Elution Strategy: Gradient •Key comp data: Name: NaCl Initial concentration: 0 mol/L Final concentration: 1 mol/L •Eluant A: NaCl/WFI (2M) in stock mixture •Eluant B: WFI (auto-adjust) •Linear velocity: 300 cm/h •Volume per Cycle: 2 BV •Wash stream: “Regen” stream with WFI (auto-adjust ADDITIONAL TASK Additional task: Delete “Equilibrate” operation in P-6 STORAGE 3 CHARGE OPERATION DATA SCHEDULING TRANSFERIN-1: Transfer from: PBA chromatography; using outlet stream from PBA chromatography Start (scheduling) and duration (Operating condition: Master-Slave) same as ELUTE-1 in PBA chromatography (Q: why not the last operation?) TRANSFEROUT-1: Transfer to: none; using Start when TRANSFER-IN-1 outlet stream from Storage completed 3 Check your simulation results Check the input to your PBA chromatography Since we specify comp binding & yield for: Enzyme to be 100%, 90% Impurity: 20%, 30% The amount of enzyme in the product stream: ___kg The amount of impurities in the product stream should be: ___kg •Please check this out & verify this from your simulation results. Biochemical Case Study REPORT Prepare a detail report of the BIOCHEMICAL CASE STUDY and attached together your simulation result (Gantt Chart)