Final Poster - Research

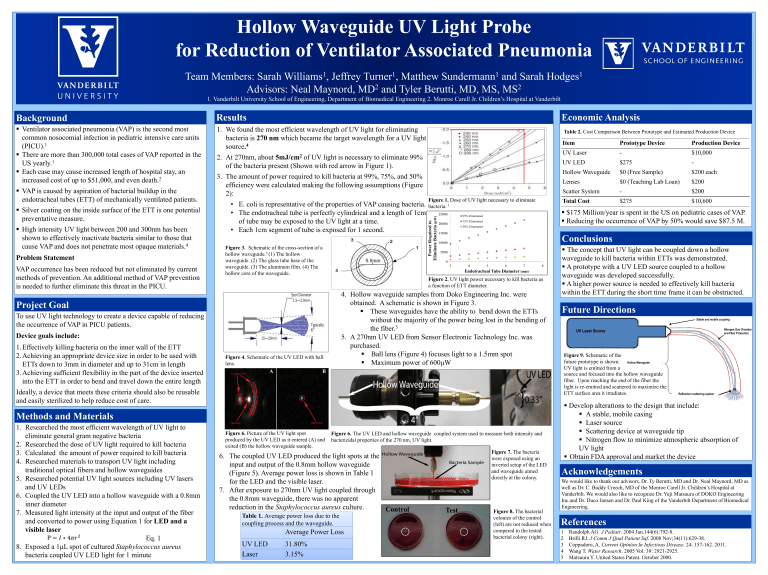

Hollow Waveguide UV Light Probe for Reduction of Ventilator Associated Pneumonia

Team Members: Sarah Williams

1

, Jeffrey Turner

1

, Matthew Sundermann

1

and Sarah Hodges

1

Advisors: Neal Maynord, MD

2

and Tyler Berutti, MD, MS, MS

2

1. Vanderbilt University School of Engineering, Department of Biomedical Engineering 2. Monroe Carell Jr. Children’s Hospital at Vanderbilt

Background

Ventilator associated pneumonia (VAP) is the second most common nosocomial infection in pediatric intensive care units

(PICU).

1

There are more than 300,000 total cases of VAP reported in the

US yearly.

1

Each case may cause increased length of hospital stay, an increased cost of up to $51,000, and even death.

2

VAP is caused by aspiration of bacterial buildup in the endotracheal tubes (ETT) of mechanically ventilated patients.

Silver coating on the inside surface of the ETT is one potential preventative measure.

High intensity UV light between 200 and 300nm has been shown to effectively inactivate bacteria similar to those that cause VAP and does not penetrate most opaque materials.

4

Problem Statement

VAP occurrence has been reduced but not eliminated by current methods of prevention. An additional method of VAP prevention is needed to further eliminate this threat in the PICU.

Project Goal

To use UV light technology to create a device capable of reducing the occurrence of VAP in PICU patients.

Device goals include:

1. Effectively killing bacteria on the inner wall of the ETT

2. Achieving an appropriate device size in order to be used with

ETTs down to 3mm in diameter and up to 31cm in length

3. Achieving sufficient flexibility in the part of the device inserted into the ETT in order to bend and travel down the entire length

Ideally, a device that meets these criteria should also be reusable and easily sterilized to help reduce cost of care.

Methods and Materials

1. Researched the most efficient wavelength of UV light to eliminate general gram negative bacteria

2. Researched the dose of UV light required to kill bacteria

3. Calculated the amount of power required to kill bacteria

4. Researched materials to transport UV light including traditional optical fibers and hollow waveguides

5. Researched potential UV light sources including UV lasers and UV LEDs

6. Coupled the UV LED into a hollow waveguide with a 0.8mm inner diameter

7. Measured light intensity at the input and output of the fiber and converted to power using Equation 1 for

LED and a visible laser

Eq. 1

8. Exposed a 1μL spot of cultured

Staphylococcus aureus

bacteria coupled UV LED light for 1 minute

Results

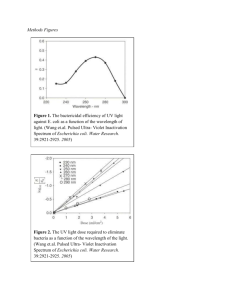

1. We found the most efficient wavelength of UV light for eliminating bacteria is

270 nm

which became the target wavelength for a UV light source

.

4

2. At 270nm, about

5mJ/cm

2 of UV light is necessary to eliminate 99% of the bacteria present (Shown with red arrow in Figure 1).

3. The amount of power required to kill bacteria at 99%, 75%, and 50% efficiency were calculated making the following assumptions (Figure

2):

•

E. coli is representative of the properties of VAP causing bacteria.

•

The endotracheal tube is perfectly cylindrical and a length of 1cm

Figure 1.

Dose of UV light necessary to eliminate bacteria. 1

25000

99% Eliminated of tube may be exposed to the UV light at a time.

•

Each 1cm segment of tube is exposed for 1 second.

20000

15000

75% Eliminated

50% Eliminated

Figure 3.

Schematic of the cross-section of a hollow waveguide.

5 (1) The hollow waveguide. (2) The glass tube base of the waveguide. (3) The aluminum film. (4) The hollow core of the waveguide.

Figure 4.

Schematic of the UV LED with ball lens.

A B

10000

5000

0.8mm

0

3 4 5 6 7

Endotracheal Tube Diameter (mm)

8

Figure 2.

UV light power necessary to kill bacteria as a function of ETT diameter.

4. Hollow waveguide samples from Doko Engineering Inc. were obtained. A schematic is shown in Figure 3.

These waveguides have the ability to bend down the ETTs without the majority of the power being lost in the bending of the fiber.

5

5. A 270nm UV LED from Sensor Electronic Technology Inc. was purchased.

Ball lens (Figure 4) focuses light to a 1.5mm spot

Maximum power of 600μW

Economic Analysis

Table 2.

Cost Comparison Between Prototype and Estimated Production Device

Item

UV Laser -

Prototype Device

UV LED $275

Hollow Waveguide $0 (Free Sample)

Production Device

$10,000

-

$200 each

Lenses

Scatter System

Total Cost

-

$0 (Teaching Lab Loan) $200

$200

$275 $10,600

$175 Million/year is spent in the US on pediatric cases of VAP.

Reducing the occurrence of VAP by 50% would save $87.5 M.

Conclusions

The concept that UV light can be coupled down a hollow waveguide to kill bacteria within ETTs was demonstrated.

A prototype with a UV LED source coupled to a hollow waveguide was developed successfully.

A higher power source is needed to effectively kill bacteria within the ETT during the short time frame it can be obstructed.

Future Directions

UV Laser Source

Stable and mobile coupling

Nitrogen Gas Chamber and Fiber Protection

Figure 6.

Picture of the UV light spot produced by the UV LED as it entered (A) and exited (B) the hollow waveguide sample.

Figure 6.

The UV LED and hollow waveguide coupled system used to measure both intensity and bactericidal properties of the 270 nm, UV light.

6. The coupled UV LED produced the light spots at the input and output of the 0.8mm hollow waveguide

(Figure 5). Average power loss is shown in Table 1 for the LED and the visible laser.

7. After exposure to 270nm UV light coupled through the 0.8mm waveguide, there was no apparent reduction in the

Staphylococcus aureus

culture.

Table 1. Average power loss due to the coupling process and the waveguide.

Average Power Loss

Control Test

Figure 7.

The bacteria were exposed using an inverted setup of the LED and waveguide aimed directly at the colony.

Figure 8.

The bacterial colonies of the control

(left) are not reduced when compared to the tested bacterial colony (right).

UV LED

Laser

31.80%

3.15%

Figure 9.

Schematic of the future prototype is shown.

Hollow Waveguide

UV light is emitted from a source and focused into the hollow waveguide fiber. Upon reaching the end of the fiber the light is re-emitted and scattered to maximize the

ETT surface area it irradiates.

Reflection/ scattering system

Develop alterations to the design that include:

A stable, mobile casing

Laser source

Scattering device at waveguide tip

Nitrogen flow to minimize atmospheric absorption of

UV light

Obtain FDA approval and market the device

Acknowledgements

We would like to thank our advisors, Dr. Ty Berutti, MD and Dr. Neal Maynord, MD as well as Dr. C. Buddy Creech, MD of the Monroe Carell Jr. Children’s Hospital at

Vanderbilt. We would also like to recognize Dr. Yuji Matsuura of DOKO Engineering

Inc.and Dr. Duco Jansen and Dr. Paul King of the Vanderbilt Department of Biomedical

Engineering.

References

1 Randolph AG.

J Pediatr

. 2004 Jun.144(6):792-8.

2 Brilli RJ.

J Comm J Qual Patient Saf

. 2008 Nov;34(11):629-38.

3 Coppadoro, A.

Current Opinion In Infectious Disease

. 24: 157-162. 2011.

4 Wang T.

Water Research

. 2005 Vol. 39: 2921-2925.

5 Matsuura Y. United States Patent. October 2000.