Basic Forensic Firearm Laboratory Exercise

advertisement

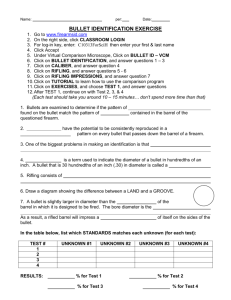

Firearm Identification Laboratory Exercises www.precisionforensictesting.com © Precision Forensic Testing Exercise #1: Measuring the Class Characteristics All of the measurements we will be doing require the use of vernier calipers Calipers are used to measure small distances within .05 of a millimeter. All measurements are to be measured in millimeters then converted to inches for use in the exercises. Measuring the Class Characteristics Caliber Number of Lands/Grooves Direction of Twist Width of Lands/Grooves Measuring Caliber Using a vernier caliper, measure the base of the bullet to the hundredths of a millimeter. This bullet measures 11.50 millimeters Multiply millimeters by 0.0394 to determine inch measurement 11.5 x 0.0394 = .453 (approx. .45 inches) Record your results 11 .50 Types of Rifling Rifling is classified as being either “Cut” or “Polygonal” Polygonal (P) rifling has a smooth transition between lands and grooves Cut (C) rifling has defined shoulders Polygonal Rifling Cut Rifling Counting the Lands and Grooves The grooves of the bullet are counted It may be necessary to place a small mark with a felt tip pen in the location where counting begins. 1 2 3 Direction of Twist The twist is determined by sitting the bullet on a flat surface and observing the direction of the rifling. Left Right Width of the Lands and Grooves Calipers are used to measure the width of the bullet lands and grooves Weighing the bullet The bullet weight is recorded in grams Convert the weight from grams to grains 1 gram = 15.43 grains Bullet Type Using the bullet diameter, weight, and construction characteristics, determine the bullet type. Exercise #2: Determining the Possible Make of Firearm Based on Class Characteristics Using the measurements of the class characteristics, a list of possible makes of firearms can be established Exercise #2: Determining the Possible Make of Firearm Based on Class Characteristics Use the appropriate GRC (General Rifling Characteristics) chart based on the bullet type being examined (9mm, .38/.357, .40, etc) Exercise #2: Determining the Possible Make of Firearm Based on Class Characteristics Use the rifling type in this column for determining type of firearm Exercise #2: Determining the Possible Make of Firearm Based on Class Characteristics Next we use the number of lands/grooves and direction of twist in evaluating possible makes of firearm Exercise #2: Determining the Possible Make of Firearm Based on Class Characteristics The last step of determining the possible make of firearm is to use the bullet land and groove width When using the GRC chart, remember that the bullet groove that you measured was made by the barrel land. Therefore, use the data from your bullet groove in the LAND column. The bullet land was produced by the barrel groove and should be used in the GROOVE column Exercise #2: Determining the Possible Make of Firearm Based on Class Characteristics The results of using the GRC chart will often result in multiple possibilities that fall within that bracket of measurements Exercise #3: Cartridge Case Characteristics The headstamp markings are located on the base of the cartridge The caliber is a numerical designation typically stamped on the base You will need to note the markings present on the cartridge cases you examine. Exercise #3: Cartridge Case Characteristics The breechface marks are made from the cartridge case coming in contact with the breechface of the slide of the firearm. The marks can come in a variety of patterns including: parallel, circular, smooth, and arched. The breechface marks present on the cartridge cases will need to be documented. Exercise #3: Cartridge Case Characteristics Firing pins are made in a variety of shapes and sizes and leave different types of marks. You will be asked to sketch the markings you observe in the firing pin of the cartridge cases. Exercise #3: Cartridge Case Characteristics The primer finish will generally be either nickel or brass. The finish will need to be noted on the worksheet. Exercise #3: Cartridge Case Characteristics Cartridge cases are typically made from brass, nickel plated brass, or aluminum. Nickel plated brass is shiny and silver in color. Aluminum cases are lighter in weight than brass cases and have a dull silver color The cartridge case finish will need to be documented Aluminum Brass Nickel Plated Exercise #3: Cartridge Case Characteristics Additional notes and diagrams can include any information observed on the cartridge including: Extractor Marks Ejector Marks Chamber Marks