m 2 /g

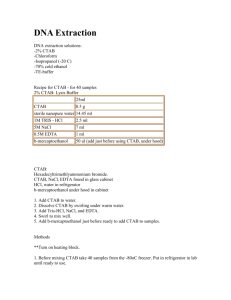

advertisement

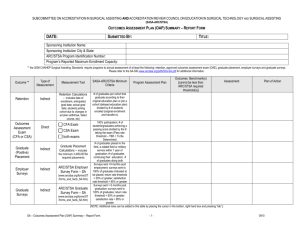

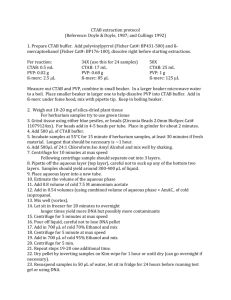

STSA – Life without CTAB April 26, 2004 by Ricky Magee Columbian Chemicals Company 1 Outline • Introduction • Theory • Results • Comparison with CTAB surface area • Surface Chemistry Effects • New Developments • 2 Conclusions Introduction 3 • Importance of Surface Area • Traditional Surface Area Techniques • Timeline of STSA at ASTM Importance of Surface Area 4 • Surface area is one of the most important characteristics of the carbon black. • Surface area of carbon black is a function of particle size, degree of aggregation and porosity. Therefore, surface area alone is not a reliable measure of particle size. • In the absence of porosity, surface area values are an indication of a carbon black’s particle size (fundamental property). • According to IUPAC convention, micropores are characterized by diameters less than 20 Å or 2 nm. Effect of Aggregation and Porosity on Surface Area 100 m2/g 5 80 m2/g 400 m2/g Traditional Surface Area Tests Attribute CTAB Iodine NSA Surface Type Measured External Total Total Affect of Oxidation Unknown Severe Minimal Precision Poor Good Good Difficulty High Low Low Set-up Costs Medium Low High 6 Timeline of STSA at ASTM 7 • D5816 – STSA approved as ASTM standard in 1995. • D1765 (CB Classification System)– In 1997, STSA was added as a typical value in Table 1, with corresponding CTAB values deleted. • D6556 – Combined NSA (D4820) and STSA (D5816) into a single standard in 2000. The NSA section was modernized and data interpretation simplified. • D3765 – In 2003, estimated CTAB values of SRB-6 carbon blacks was added to CTAB method. Theory 8 • Nitrogen Adsorption • Saturated Vapor Pressure • de Boer t-values and Va-t plots • Pore filling model • Application of CB t Equation Nitrogen Adsorption 9 • The concentration of nitrogen is expressed as relative pressure (P/Po). • A relative pressure of “0.0” is measured at absolute vacuum, while a value of “1.0” is measured at nitrogen’s saturated vapor pressure (Po). • The typical range for measuring NSA (BET) is P/Po = 0.05 to 0.30. Saturated Vapor Pressure 10 • Saturated vapor pressure is the pressure at which nitrogen gas condenses. • It is based on atmospheric pressure and the temperature of the liquid nitrogen in the dewar. • It is usually 10 - 20 mm Hg above ambient pressure due to impurities. • Critical for measuring accurate STSA values. Saturated Vapor Pressure Elevation • • • • • Sea Level 900 m Atm. Pressure 760 685 Sat. Vapor Press. 775 700 P/Po Value = 0.1 78 70 P/Po Value = 0.2 155 140 P/Po Value = 0.3 233 210 11 All values in mm Hg Thickness Model Small Particles 12 Large Particle Thickness Equations 13.99 de Boer t = 0.034 - log P/Po CB t = 0.88 (P/Po)2 + 6.45 (P/Po) + 2.98 Carbon Black t curve based on N762 13 Va–t Plot 60 Vol. Ads. (cc/g) 50 40 90 m2/g 30 60 m2/g 20 10 2 30 m /g 0 0 1 2 3 4 5 6 Thickness (Å) 14 7 8 9 Pore Filling Model P/Po = 0.0 P/Po = 0.2 15 P/Po = 0.05 P/Po > 0.2 Adsorption Isotherms 140 Vol. Adsorbed (cc/g) N472 120 100 N110 N326 80 N660 60 40 20 0 0.0 16 0.1 0.2 0.3 0.4 0.5 0.6 Relative Pressure 0.7 0.8 0.9 Va–t Plot for Standard Carbon Blacks based on CB t equation 120 P/P o = 0.5 P/P o = 0.2 N472 Vol. Adsorbed (cc/g) 100 80 N110 60 N326 40 20 N660 0 0 17 1 2 3 4 5 6 7 Thickness (Å) 8 9 10 11 12 Results 18 • STSA versus CTAB • Surface Chemistry • Precision Statements Tread Carbon Blacks 19 NSA STSA CTAB N110 135.3 119.7 123.6 N121 122.8 116.5 120.4 N220 116.0 107.7 109.5 N234 117.2 111.2 115.6 N330 76.6 74.7 80.0 N339 91.0 88.5 94.8 All values in m2/g Carcass Carbon Blacks 20 NSA STSA CTAB N539 38.4 37.7 41.0 N550 38.1 38.2 38.6 N650 36.4 35.3 38.9 N660 33.0 33.1 34.9 N762 25.7 25.7 26.9 N787 29.7 29.6 31.0 All values in m2/g CTAB versus STSA 140 CTAB (m 2/g) 120 100 80 60 40 R2 = 0.9985 20 0 0 21 20 40 60 80 STSA (m2/g) 100 120 140 Effect of Surface Oxidation on CTAB Measurements Sample #1 22 #2 #3 Oxygen (%) 2.0 1.9 1.5 STSA (m2/g) 86.4 85.7 90.8 CTAB (m2/g) 100.1 97.5 97.7 Difference -13.7 -11.8 -6.9 Effect of Surface Oxidation on CTAB Measurements #1 #3 STSA (m2/g) 86.3 86.3 90.0 Initial Value 86.4 85.7 90.8 CTAB (m2/g) 87.3 85.9 89.2 Initial Value 100.1 97.5 97.7 -1.0 0.4 0.8 Difference 23 Sample #2 Effect of Heat Treatment on ASTM SRB-5 25 NSA Iodine %Change 20 15 10 5 0 N135 24 N330 N220 N762 N660 N683 Effect of Heat Treatment on ASTM SRB-5 5.0 %Change 2.5 0.0 -2.5 -5.0 STSA -7.5 CTAB -10.0 N135 N330 N220 N762 N660 N683 25 Precision N121 Control Chart Diff. From Mean (m2/g) 2.5 CTAB STSA 1.5 0.5 -0.5 -1.5 -2.5 1 26 5 9 12 Run # 16 20 Effect of Solution Aging on CTAB Solutions 122 CTAB (m 2/g) 121 120 119 118 117 116 115 0 27 10 20 30 Run # 40 50 60 Surface Area Precision Study from Original STSA Paper Within Lab Between Lab Percent 6 5 4 3 2 1 0 NSA 28 STSA CTAB Potential Errors in NSA/STSA Measurements 29 • Improper degassing time/temperature. • Improper sample weight. • Inaccurate or changing Po value. NSA/STSA Control Chart using ASTM B-6 (N220) 112.0 Mean = 109.6 ± 1.1 111.5 111.0 (ASTM = 110.0 ± 1.6) 110.5 110.0 109.5 109.0 Surface Area (m2/g) 108.5 108.0 107.5 107.0 106.5 106.0 105.5 105.0 104.5 104.0 Mean = 105.4 ± 2.1 103.5 103.0 (ASTM = 105.4 ± 2.9) 102.5 102.0 101.5 1 30 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 Data collected over a 4 month period 22 23 24 25 26 27 28 29 30 31 NSA/STSA Control Chart with Po Outliers Removed (DP >20mm Hg) 112.0 Mean = 109.5 ± 1.1 111.5 111.0 (Previous = 109.6 ± 1.1) 110.5 110.0 109.5 109.0 Surface Area (m2/g) 108.5 108.0 107.5 107.0 106.5 106.0 105.5 105.0 104.5 104.0 Mean = 105.4 ± 1.5 (Previous = 105.4 ± 2.1) 103.5 103.0 102.5 102.0 101.5 1 31 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 Effect of Dewar Stability • A single sample of ASTM B-6 (N220) degassed at 300°C then run multiple times, measuring the Po after each run using the standard Gemini (600 ml) and a large volume (2 L) dewars. 32 Modified Gemini 33 Effect of Dewar Stability – 1 Hr. Equilibration Time NSA (m2/g) 1 Hour Equil. STSA (m2/g) Mean 3s Mean 3s Dewar #1 - Std (600 ml) 110.0 1.83 104.7 4.86 Dewar #2 - Std (600 ml) 110.0 1.23 104.3 2.16 Dewar #3 - Large (2 L)* 109.9 0.18 105.4 0.57 Dewar #3 - Large (+15 mm)* 109.9 0.15 105.3 0.33 34 * = Filled and covered overnight before analysis Effect of Dewar Stability – 2 Hr. Equilibration Time NSA (m2/g) 1 Hour Equil. STSA (m2/g) Mean 3s Mean 3s Dewar #1 - Std (600 ml) 110.2 0.60 105.2 0.87 Dewar #2 - Std (600 ml) 109.9 0.99 104.2 1.95 Dewar #3 - Large (2 L)* 109.9 0.15 105.3 0.33 Dewar #3 - Large (+15 mm)* 109.9 0.15 105.3 0.33 35 * = Filled and covered overnight before analysis Po Summary • A minimum 2 hour dewar equilibration is required (longer is better). • Large volume dewars allow improved precision. • Other Po options exist for newer, higher-end instruments. • 36 Changes to D6556 are required based on this study. Analysis Time Standard Value Standard Method (D6556) Modified Method (3 pt.) NSA STSA NSA STSA NSA STSA (m2/g) (m2/g) (m2/g) (m2/g) (m2/g) (m2/g) A-6 (N134) 143.9 135.7 142.1 133.7 142.7 133.7 B-6 (N220) 110.0 105.4 109.4 104.6 108.8 105.3 C-6 (N326) 78.3 79.2 78.3 79.1 77.6 79.8 D-6 (N762) 30.6 29.6 30.4 29.0 30.7 29.2 E-6 (N660) 36.0 35.1 35.5 34.7 35.1 33.8 F-6 (N683) 35.3 34.1 34.7 33.2 34.6 32.8 Mean Values 72.4 69.9 71.7 69.1 71.6 69.1 Sample ID 37 Analysis Time Standard Method (D6556) Sample ID 38 Modified Method (3 pt.) Analysis Degassing Total Analysis Degassing Total Time (min.) Time (min.) Time (min.) Time (min.) Time (min.) Time (min.) A-6 (N134) 33 30 63 20 10 30 B-6 (N220) 30 30 60 17 10 27 C-6 (N326) 23 30 53 17 10 27 D-6 (N762) 20 30 50 15 5 20 E-6 (N660) 19 30 49 15 5 20 F-6 (N683) 20 30 50 14 5 19 Mean Values 24.2 30.0 54.2 16.3 7.5 23.8 Conclusions STSA provides the following advantages over CTAB: 39 Improved precision and accuracy, provided proper attention to Po Less affected by surface oxidation Less operator time Measured simultaneously with NSA No reagent preparation