Transportation, Transshipment and Assignment Models

advertisement

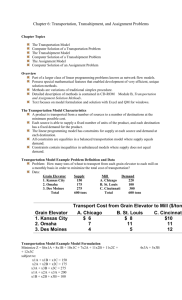

Transportation, Transshipment and Assignment Models Learning Objectives • Structure special LP network flow models. • Set up and solve transportation models • Extend basic transportation model to include transshipment points. • Set up and solve facility location and other application problems as transportation models. • Set up and solve assignment models Overview Part of a larger class of linear programming problems are known as network flow models. They possess special mathematical features that enabled the development of very efficient, unique solution methods. Transportation Model Transportation problem deals with the distribution of goods from several points of supply to a number of points of demand. They arise when a cost-effective pattern is needed to ship items from origins that have limited supply to destinations that have demand for the goods. Resources to be optimally allocated usually involve a given capacity of goods at each source and a given requirement for the goods at each destination. Most common objective of the transportation problem is to schedule shipments from sources to destinations so that total production and transportation costs are minimized Transshipment Model An extension of transportation problems is called transshipment problem in which a point can have shipments that both arrive as well as leave. Example would be a warehouse where shipments arrive from factories and then leave for retail outlets It may be possible for a firm to achieve cost savings (economies of scale) by consolidating shipments from several factories at a warehouse and then sending them together to retail outlets. Assignment Model Assignment problem refers to a class of LP problems that involve determining most efficient assignment of: People to projects, Salespeople to territories, Contracts to bidders, Jobs to machines, and so on Objective is to minimize total cost or total time of performing tasks at hand, although a maximization objective is also possible. Transportation Model Transportation Model Problem definition – There are m sources. Source i has a supply capacity of Si. – There are n destinations.The demand at destination j is D j. – Objective: To minimize the total shipping cost of supplying the destinations with the required demand from the available supplies at the sources. The Transportation Model Characteristics A product is to be transported from a number of sources to a number of destinations at the minimum possible cost. Each source is able to supply a fixed number of units of the product, and each destination has a fixed demand for the product. The linear programming model has constraints for supply at each source and demand at each destination. All constraints are equalities in a balanced transportation model where supply equals demand. Constraints contain inequalities in unbalanced models where supply is not equal to demand. Transportation Model- Example 1 Executive Furniture Corporation Transportation Model Example 1 Executive Furniture Corporation Transportation Costs Per Desk Transportation Model Example 1 Executive Furniture Corporation:LP Transportation Model Formulation Objective: minimize total shipping costs = 5 XDA + 4 XDB + 3 XDC + 3 XEA + 2 XEB + 1 XEC + 9 XFA + 7 XFB + 5 XFC Where: Xij = number of desks shipped from factory i to warehouse j i = D (for Des Moines), E (for Evansville), or F (for Fort Lauderdale). j = A (for Albuquerque), B (for Boston), or C (for Cleveland). Transportation Model Example 1 Executive Furniture Corporation: Supply Constraints Net flow at Des Moines = (Total flow in) - (Total flow out) = (0) - (XDA + XDB + XDC) Net flow at Des Moines = -XDA - XDB - XDC = -100 (Des Moines capacity) and -XEA - XEB - XEC = -300 (Evansville capacity) -XFA - XFB - XFC = -300 (Fort Lauderdale capacity) Multiply each constraint by -1 and rewrite as: XDA + XDB + XDC = 100 (Des Moines capacity) XEA + XEB + XEC = 300 (Evansville capacity) XFA + XFB + XFC = 300 (Fort Lauderdale capacity) Transportation Model Example 1 Executive Furniture Corporation: Demand Constraints Net flow at Albuquerque = (Total flow in) - (Total flow out) = (XDA + XEA + XFA) - (0) Net flow at Albuquerque = XDA + XEA + XFA = 300 (Albuquerque demand) and XDB + XEB + XFB = 200 (Boston demand) XDC + XEC + XFC = 200 (Cleveland demand) Transportation Model Example 1: The Optimum Solution SHIP: 100 desks from Des Moines to Albuquerque, 200 desks from Evansville to Albuquerque, 100 desks from Evansville to Boston, 100 desks from Fort Lauderdale to Boston, and 200 desks from Fort Lauderdale to Cleveland. Total shipping cost is $3,000. Transportation Model Example 2 Problem Definition and Data Problem: How many tons of wheat to transport from each grain elevator to each mill on a monthly basis in order to minimize the total cost of transportation? Data: Grain Elevator Supply Mill Demand 1. Kansas City 150 A. Chicago 200 2. Omaha 175 B. St. Louis 100 3. Des Moines 275 C. Cincinnati 300 Total 600 tons Total 600 tons Grain Elevator 1. Kansas City 2. Omaha 3. Des Moines Transport Cost from Grain Elevator to Mill ($/ton) A. Chicago B. St. Louis C. Cincinnati $ 6 $ 8 $10 7 11 11 4 5 12 Transportation Model Example 2 Model Formulation Transportation Model Example 2 Model Formulation Minimize Z = $6x1A + 8x1B + 10x1C + 7x2A + 11x2B + 11x2C + 4x3A + 5x3B + 12x3C subject to: x1A + x1B + x1C = 150 x2A + x2B + x2C = 175 x3A + x3B + x3C = 275 x1A + x2A + x3A = 200 x1B + x2B + x3B = 100 x1C + x2C + x3C = 300 xij 0 xij = tons of wheat from each grain elevator, i, i = 1, 2, 3, to each mill j, j = A,B,C Transportation Model- Example 3 Carlton Pharmateuticals • Carlton Pharmaceuticals supplies drugs and other medical supplies. • It has three plants in: Cleveland, Detroit, Greensboro. • It has four distribution centers in: Boston, Richmond, Atlanta, St. Louis. • Management at Carlton would like to ship cases of a certain vaccine as economically as possible. • Data – Unit shipping cost, supply, and demand To From Cleveland Detroit Greensboro Demand Boston $35 37 40 1100 Richmond 30 40 15 400 Atlanta 40 42 20 750 St. Louis 32 25 28 750 • Assumptions – Unit shipping cost is constant. – All the shipping occurs simultaneously. – The only transportation considered is between sources and destinations. – Total supply equals total demand. Supply 1200 1000 800 NETWORK REPRESENTATION Sources Destinations D1=1100 Boston Cleveland S1=1200 Richmond D2=400 Detroit S2=1000 Atlanta D3=750 Greensboro S3= 800 St.Louis D4=750 • The Mathematical Model – The structure of the model is: Minimize <Total Shipping Cost> ST [Amount shipped from a source] = [Supply at that source] [Amount received at a destination] = [Demand at that destination] – Decision variables Xij = amount shipped from source i to destination j. where: i=1 (Cleveland), 2 (Detroit), 3 (Greensboro) j=1 (Boston), 2 (Richmond), 3 (Atlanta), 4(St.Louis) Supply from Cleveland X11+X12+X13+X14 = 1200 Supply from Detroit X21+X22+X23+X24 = 1000 Supply from Greensboro X31+X32+X33+X34 = 800 The supply constraints Boston D1=1100 X11 Cleveland S1=1200 X12 X13 X21 X31 Richmond X14 X22 Detroit S2=1000 D2=400 X32 X23 X24 Atlanta X33 St.Louis Greensboro S3= 800 D3=750 X34 D4=750 • The complete mathematical model Minimize 35X11+30X12+40X13+ 32X14 +37X21+40X22+42X23+25X24+ 40X31+15X32+20X33+38X34 ST Supply constrraints: X11+ X12+ X13+ X14 X21+ X22+ X23+ X24 X31+ X32+ X33+ X34 Demand constraints: X11+ X12+ X13+ X21+ X31 X22+ X32 X23+ X14+ All Xij are nonnegative X33 X24+ X34 = 1200 = 1000 = 800 = 1000 = 400 = 750 = 750 Excel Optimal Solution CARLTON PHARMACEUTICALS UNIT COSTS BOSTON RICHMOND ATLANTA ST.LOUIS CLEVELAND $ 35.00 $ 30.00 $ 40.00 $ 32.00 DETROIT $ 37.00 $ 40.00 $ 42.00 $ 25.00 GREENSBORO $ 40.00 $ 15.00 $ 20.00 $ 28.00 DEMANDS 1100 400 750 750 SHIPMENTS (CASES) BOSTON RICHMOND ATLANTA ST.LOUIS CLEVELAND 850 350 0 0 DETROIT 250 0 0 750 GREENSBORO 0 50 750 0 TOTAL 1100 400 SUPPLIES 1200 1000 800 750 TOTAL 1200 1000 800 750 TOTAL COST = 84000 WINQSB Sensitivity Analysis If this path is used, the total cost will increase by $5 per unit shipped along it Shadow prices for plants - the cost savings realized for each extra case of vaccine available at the plant Shadow prices for warehouses - the cost incurred from having 1 extra case of vaccine demanded at the warehouse Interpreting sensitivity analysis results – Reduced costs • The amount of transportation cost reduction per unit that makes a given route economically attractive. • If the route is forced to be used under the current cost structure, for each item shipped along it, the total cost increases by an amount equal to the reduced cost. – Shadow prices • For the plants, shadow prices convey the cost savings realized for each extra case of vaccine available at plant. • For the warehouses, shadow prices convey the cost incurred from having an extra case demanded at the warehouse. Transportation Model- Example 4 Montpelier Ski Company: Using a Transportation model for production scheduling – Montpelier is planning its production of skis for the months of July, August, and September. – Production capacity and unit production cost will change from month to month. – The company can use both regular time and overtime to produce skis. – Production levels should meet both demand forecasts and end-ofquarter inventory requirement. – Management would like to schedule production to minimize its costs for the quarter. • Data: – Initial inventory = 200 pairs – Ending inventory required =1200 pairs – Production capacity for the next quarter is shown on the table – Holding cost rate is 3% per month per ski. – Production capacity, and forecasted demand for this quarter (in pairs of skis), and production cost per unit (by months) Month July August September Forecasted Demand 400 600 1000 Production Production Costs Capacity Regular Time Overtime 1000 25 30 800 26 32 400 29 37 • Analysis of demand: – Net demand to satisfy in July = 400 - 200 = 200 pairs Initial inventory – Net demand in August = 600 – Net demand in September = 1000 + 1200 = 2200 pairs • Analysis of Unit costs Forecasted demand In house inventory • Analysis Supplies: Unitofcost = [Unit production cost] + – Production capacities are thought of as supplies. [Unit holding cost per month][the number of months – There are two sets of “supplies”: stays in • Set 1- Regular time supply (production capacity) inventory] • Set 2 - Overtime supply Example: A unit produced in July in Regular time and sold in September costs 25+ (3%)(25)(2 months) = $26.50 Production Month/period 1000 800 July O/T Aug. R/T 25 25.75 26.50 0 30 30.90 31.80 +M 0 26 26.78 400 Aug. O/T Month sold July +M +M 32.96 200 Sept. R/T Sept. O/T 0 0 Aug. 600 Sept. 2200 Dummy 300 +M 0 29 400 +M +M 32 200 Demand Production Capacity 500 July July R/T R/T Network representation 37 0 Source: July production in R/T Destination: July‘s demand. Unit cost= $25 (production) Source: Aug. production in O/T Destination: Sept.’s demand 32+(.03)(32)=$32.96 Unit cost =Production+one month holding cost • Summary of the optimal solution – In July produce at capacity (1000 pairs in R/T, and 500 pairs in O/T). Store 1500-200 = 1300 at the end of July. – In August, produce 800 pairs in R/T, and 300 in O/T. Store additional 800 + 300 - 600 = 500 pairs. – In September, produce 400 pairs (clearly in R/T). With 1000 pairs retail demand, there will be (1300 + 500) + 400 - 1000 = 1200 pairs available for shipment Inventory + Production - Demand Unbalanced Transportation Problems • If supplies are not equal to demands, an unbalanced transportation model exists. • In an unbalanced transportation model, supply or demand constraints need to be modified. • There are two possible scenarios: (1) Total supply exceeds total requirement. (2) Total supply is less than total requirement. Total Supply Exceeds Total Requirement Total flow out of Des Moines ( XDA + XDB + XDC) should be permitted to be smaller than total supply (100). The constraint should be written as -XDA - XDB - XDC >= -100 -XEA - XEB - XEC >= -300 -XFA - XFB - XFC >= -300 XDA + XDB + XDC <= 100 XEA + XEB + XEC <= 100 XFA + XFB + XFC <= 100 (Des Moines capacity) (Evansville capacity) (Fort Lauderdale capacity) Total Supply Less Than Total Requirement Total flow in to Albuquerque (that is, XDA + XEA + XFA) should be permitted to be smaller than total demand (namely, 300). This warehouse should be written as: XDA + XEA + XFA <= 300 (Albuquerque demand) XDB + XEB + XFB <= 200 (Boston demand) XDC + XEC + XFC <= 200 (Cleveland demand) Transportation Example 5: Formulation Develop the linear programming model and solve using Excel: Plant 1 2 3 Demand (tons) A $ 8 15 3 150 Construction site B C $ 5 $ 6 10 12 9 10 70 100 Supply (tons) 120 80 80 Transportation Example 5: Formulation Minimize Z = $8x1A + 5x1B + 6x1C + 15x2A + 10x2B + 12x2C + 3x3A + 9x3B + 10x3C subject to: x1A + x1B + x1C = 120 x2A + x2B + x2C = 80 x3A + x3B + x3C = 80 x1A + x2A + x3A 150 x1B + x2B + x3B 70 x1C + x2C + x3C 100 xij 0 Transportation Model-Example 6 Hardgrave Machine Company - New Factory Location • Produces computer components at its plants in Cincinnati, Kansas City, and Pittsburgh. • Plants not able to keep up with demand for orders at four warehouses in Detroit, Houston, New York, and Los Angeles. • Firm has decided to build a new plant to expand its productive capacity. • Two sites being considered: – Seattle, Washington and – Birmingham, Alabama. • Both cities attractive in terms: labor supply, municipal services, and ease of factory financing. Transportation Model-Example 6 Hardgrave Machine Company: Demand Supply Data and Production Costs Transportation Model-Example 6 Hardgrave Machine Company: Shipping Costs Transshipment Model Transshipment Model In a Transshipment Problem flows can occur both out of and into the same node in three ways: 1. If total flow into a node is less than total flow out from node, node represents a net creator of goods (a supply point). - Flow balance equation will have a negative right hand side (RHS) value. 2. If total flow into a node exceeds total flow out from node, node represents a net consumer of goods, (a demand point). - Flow balance equation will have a positive RHS value. 3. If total flow into a node is equal to total flow out from node, node represents a pure transshipment point. - Flow balance equation will have a zero RHS value. The Transshipment Model Characteristics It is an extension of the transportation model. Intermediate transshipment points are added between the sources and destinations. Items may be transported from: Sources through transshipment points to destinations One source to another One transshipment point to another One destination to another Directly from sources to to destinations Some combination of these Executive Furniture Corporation – Revisited Assume it is possible for Executive Furniture to ship desks from Evansville factory to its three warehouses at very low unit shipping costs. Consider shipping all desks produced at other two factories (Des Moines and Fort Lauderdale) to Evansville. Consider using a new shipping company to move desks from Evansville to all its warehouses. Executive Furniture Corporation - Revisited • Revised unit shipping costs are shown here. • Note Evansville factory shows up in both the “From” and “To” entries. Executive Furniture Corporation Revisited LP Model for theTransshipment Problem Two new additional decision variables for new shipping routes are to be added. XDE= number of desks shipped from Des Moines to Evansville XFE = number of desks shipped from Fort Lauderdale to Evansville Objective Function: minimize total shipping costs = 5XDA + 4XDB + 3XDC + 2XDE + 3XEA + 2XEB + +1XEC + 9XFA + 7XFB + 5XFC + 3XFE Executive Furniture Corporation Revisited LP Model for theTransshipment Problem • Relevant flow balance equations written as: (0) - (XDA + XDB + XDC + XDE) = -100 (Des Moines capacity) (0) - (XFA + XFB + XFC + XFE) = -300 (Fort Lauderdale capacity) • Supplies have been expressed as negative numbers in the RHS. Net flow at Evansville = (Total flow in) - (Total flow out) = (XDE + XFE) - (XEA + XEB + XEC) • Net flow equals total number of desks produced (the supply) at Evansville. Net flow at Evansville = (XDE + XFE) - (XEA + XEB + XEC) = -300 • No change in demand constraints for warehouse requirements: XDA + XEA + XFA = 300 (Albuquerque demand) XDB + XEB + XFB = 200 (Boston demand) XDC + XEC + XFC = 200 (Cleveland demand) Transshipment Model Example 2 Problem Definition and Data Extension of the transportation model in which intermediate transshipment points are added between sources and destinations. An example of a transshipment point is a distribution center or warehouse located between plants and stores Data: Farm 1. Nebrasca 2. Colorado 3. Kansas City $16 15 Warehouses 6. Chicago 3. Kansas $6 4. Omaha 7 5. Des Moines 4 Grain Elevator 4. Omaha 10 14 Stores 7. St. Louis 8 11 5 5. Des Moines 12 17 8. Cincinnati 10 11 12 Transshipment Model Example 2 Problem Definition and Data Transshipment Model Example 2 Model Formulation Minimize Z = $16x13 + 10x14 + 12x15 + 15x23 + 14x24 + 17x25 + 6x36 + 8x37 + 10x38 + 7x46 + 11x47 + 11x48 + 4x56 + 5x57 + x58 subject to: x13 + x14 + x15 = 300 x23+ x24 + x25 = 300 x36 + x46 + x56 = 200 x37+ x47 + x57 = 100 x38 + x48 + x58 = 300 x13 + x23 - x36 - x37 - x38 = 0 x14 + x24 - x46 - x47 - x48 = 0 x15 + x25 - x56 - x57 - x58 = 0 xij 0 Assignment Model The Assignment Model Problem definition – m workers are to be assigned to m jobs – A unit cost (or profit) Cij is associated with worker i performing job j. – Minimize the total cost (or maximize the total profit) of assigning workers to jobs so that each worker is assigned a job, and each job is performed. The Assignment Model Characteristics It is a special form of linear programming models similar to the transportation model. Supply at each source and demand at each destination is limited to one unit. In a balanced model supply equals demand. In an unbalanced model supply is not equal to demand. The Assignment Model Assumptions – The number of workers is equal to the number of jobs. – Given a balanced problem, each worker is assigned exactly once, and each job is performed by exactly one worker. – For an unbalanced problem “dummy” workers (in case there are more jobs than workers), or “dummy” jobs (in case there are more workers than jobs) are added to balance the problem. Assignment Model Example 1 Fix-It Shop Example Received three new rush projects to repair: (1) a radio, (2) a toaster oven, and (3) a broken coffee table. Three workers (each has different talents and abilities). Estimated costs to assign each worker to each of the three projects. Assignment Model Example 1 Fix-It Shop • Rows denote people or objects to be assigned, and columns denote tasks or jobs assigned. • Numbers in table are costs associated with each particular assignment. Assignment Model Example 1 Fix-It Shop: Assignment Alternatives and Costs • Owner's objective is to assign three projects to workers in a way that result is lowest total cost. Assignment Model Example 1 Fix-It Shop • Owner's objective is to assign three projects to workers in a way that results in lowest total cost. Assignment Model Example 1 Fix-It Shop Formulate LP model Xij = “Flow” on arc from node denoting worker i to node denoting project j. Solution value will equal 1 if worker i is assigned to project j : i = A (for Adams), B (for Brown), or C (for Cooper) j = 1 (for project 1), 2 (for project 2), or 3 (for project 3) Objective Function: minimize total assignment cost = 11XA1 + 14XA2 + 6XA3 + 8XB1 + 10XB2 + 11XB3 + + 9XC1 + 12XC2 + 7XC3 Assignment Model Example 1 Fix-It Shop Constraints expressed using standard flow balance equations are as follows: -XA1 - XA2 - XA3 = -1 (Adams availability) -XB1 - XB2 - XB3 = -1 (Brown availability) -XC1 - XC2 - XC3 = -1 (Cooper availability) XA1 + XB1 + XC1 = 1 (Project 1 requirement) XA2 + XB2 + XC2 = 1 (Project 2 requirement) XA3 + XB3 + XC3 = 1 (Project 3 requirement) Assignment Model- Example 2 Ballston Electronics • Five different electrical devices produced on five production lines, are needed to be inspected. • The travel time of finished goods to inspection areas depends on both the production line and the inspection area. • Management wishes to designate a separate inspection area to inspect the products such that the total travel time is minimized. Assignment Model- Example 2 • Data: Travel time in minutes from assembly lines to inspection areas. Assembly Assembly Lines Lines 11 22 33 44 55 AA 10 10 11 11 13 13 14 14 19 19 BB 44 77 88 16 16 17 17 Inspection Inspection Area Area CC 66 77 12 12 13 13 11 11 DD 10 10 99 14 14 17 17 20 20 EE 12 12 14 14 15 15 17 17 19 19 Assignment Model Example 2: Network Representation (3 of 3) Assembly Line Inspection Areas S1=1 A D1=1 1 S2=1 2 B D2=1 S3=1 3 C D3=1 S4=1 4 D D4=1 S5=1 5 E D5=1 • Computer solutions – A complete enumeration is not efficient even for moderately large problems (with m=8, m! > 40,000 is the number of assignments to enumerate). – The Hungarian method provides an efficient solution procedure. • Special cases – A worker is unable to perform a particular job. – A worker can be assigned to more than one job. – A maximization assignment problem. Assignment Model Example 3 Problem Definition and Data Problem: Assign four teams of officials to four games in a way that will minimize total distance traveled by the officials. Supply is always one team of officials, demand is for only one team of officials at each game. Data: Assignment Model Example 3 Model Formulation Minimize Z = 210xAR + 90xAA + 180xAD + 160xAC + 100xBR + 70xBA + 130xBD + 200xBC + 175xCR + 105xCA + 140xCD + 170xCC + 80xDR + 65xDA + 105xDD + 120xDC subject to: xAR + xAA + xAD + xAC = 1 xBR + xBA + xBD + xBC = 1 xCR + xCA + xCD + xCC = 1 xDR + xDA + xDD + xDC = 1 xAR + xBR + xCR + xDR = 1 xAA + xBA + xCA + xDA = 1 xAD + xBD + xCD + xDD = 1 xAC + xBC + xCC + xDC = 1 xij 0 Summary Three network flow models have been presented: 1. Transportation model deals with distribution of goods from several supplier to a number of demand points. 2. Transshipment model includes points that permit goods to flow both in and out of them. 3. Assignment model deals with determining the most efficient assignment of issues such as people to projects.