Presentation (PowerPoint File)

Chemometric Considerations in

Proteomic Analyses by Mass

Spectrometry

Peter de B. Harrington* Mariela L. Ochoa*, Sanford P. Markey + ,

Claudine Laurent + , Kuniaki Saito + , & Alfred L. Yergey ^

*Ohio University, Center for Intelligent Chemical, Instrumentation,

Department of Chemistry and Biochemistry, Athens, OH 45701-

2979, Peter.Harrington@Ohio.edu

+ Laboratory of Neurotoxicology, National Institute of Mental Health,

Building 10 Room 3D42, MSC 1262, 10 Center Drive, Bethesda, MD

20892-1262

^ Section on Mass Spectrometry and Metabolism, Building 10, Room

9D52, National Institute of Child Health and Human Development,

10 Center Drive, Bethesda, MD 20892-1580

Center for Intelligent Chemical Instrumentation

1

Center for Intelligent Chemical Instrumentation

2

Chemometrics

Chemometrics is a discipline that is devoted to maximizing the amount and quality of information obtained from chemical or molecular measurements.

Chemometrics uses mathematical, statistical, logical, and computational tools.

For scientists, an important chemometric topic is the statistical design of experiments.

Center for Intelligent Chemical Instrumentation

3

‘Omics Era

• Besides the proteome over 50 other

‘omes*.

• Complex biological systems

• Reductionism is difficult because of the large degree of interaction.

• The interesting proteins are the ones that are difficult to detect.

*http://www.genomicglossaries.com/content/omes.asp, accessed on

16-Mar-2004.

Center for Intelligent Chemical Instrumentation

4

Chemometrics and

Proteomics

Data Information

Biology

Sample

Preparation

Instrumental

Measurement

Knowledge

Bases

Center for Intelligent Chemical Instrumentation

5

Some Statistics Concerning Foodborne

Bacteria Pathogens

• In the U.S., 76,000,000 foodborne illnesses occur each year (325,000 hospitalizations and up to 5,000 deaths).

• Escherichia coli O157:H7 foodborne poisoning:

– Largest outbreak (1993): more than 700 people ill and 4 deaths

– Up to 75,000 infections estimated annually

• Listeria monocytogenes foodborne poisoning:

– Largest outbreak reported in 1985

– About 2,500 cases of Listeriosis every year

– 500 deaths attributed to Listeriosis

Buzby, J. C., Frenzen, P. D. and Rasco, B., Product Liability and Microbial Foodborne Illness. Agricultural Economic

Report Nº 799; Food and Rural Economics Division, Economic Research Service, U.S. Department of Agriculture:

Washington, DC. April 2001 p 1., Website http://www.about-listeria.com/aer799.pdf

, (accessed Feb 2004).

Center for Intelligent Chemical Instrumentation

6

IMS and MALDI TOF-MS as Attractive Methods for

Foodborne Bacteria Characterization

1.

2.

3.

4.

Ion Mobility

Spectrometry ( IMS )

Presumptive technique

Ion mobility spectra may furnish useful information for bacteria species/ strains characterization and differentiation

Fast analysis time for rapid screening of foodborne pathogens

Portable instruments, attractive for on-site monitoring

Matrix-Assisted Laser

Desorption/Ionization

(MALDI) TOF-MS

1.

2.

3.

4.

Confirmatory technique

Provides a fingerprint of proteins for bacteria of interest

Comparison against database containing the bacteria genome alleviates the issue with spectral reproducibility

Rapid analysis time

Center for Intelligent Chemical Instrumentation

7

Identification of Foodborne Pathogens Using

Molecular Weight Database Search

Database Search for Organism’s Protein Molecular Weight

The ExPASy (Expert Protein Analysis System) proteomics server of the Swiss Institute of Bioinformatic

(SIB) Home Page http://us.expasy.org/srs/ (accessed Oct 2003).

Center for Intelligent Chemical Instrumentation

8

Problems Associated with

Microbiological Food Analysis

• Detection of small number of pathogens hampered by large numbers of harmless background microflora

• Culture enrichment steps necessary to amplify target analytes before traditional methods of detection can be applied

• Affinity capture techniques (i.e., immunomagnetic separations – IMS ) to isolate target bacteria from complex food matrices

Madonna, A. J.; Basile, F.; Furlong, E.; Voorhees, K. J. Rapid Commun. Mass Spectrom. 2001, 15, 1068-1074.

Center for Intelligent Chemical Instrumentation

9

MALDI as an Ionization

Method

• Introduced by Karas and Hillenkamp

(1987) as ionization method for nonvolatile polar biological and organic macromolecules and polymers

• Low concentration of analyte uniformly dispersed in solid or liquid matrix

• Matrix should have strong absorbance at laser excitation wavelength and low sublimation temperature

• Three main processes occur: formation of solid solution, matrix excitation, and analyte ionization

Karas, M.; Bachmann, D.; Bahr, U.; Hillenkamp, F. Int. J. Mass Spectrom. Ion Process. 1987, 78, 53-68.

Center for Intelligent Chemical Instrumentation

10

M@ldi-LR TM Mass Spectrometer

Time-of-Flight by Micromass (UK)

Instrumental parameters

• Laser: Nitrogen UV (337 nm)

– Firing rate: 5 Hz

– 10 shots/spectrum

• Ion optics: Linear TOF path length 0.7 m

• Ion source: Grounded “time lag focusing” source (delayed extraction) ~ 500 ns

• Accelerating voltage: 15 kV

• Detector: Fast dual microchannel plate (MCP)

Center for Intelligent Chemical Instrumentation

11

MALDI-Time-of-Flight Mass

Spectrometry (TOF-MS)

Center for Intelligent Chemical Instrumentation

12

Variation in the MALDI Mass

Spectrum

• Compare the signal averaged spectrum to a collection of single laser shots.

• Single scan spectra are from individual laser shots.

• Historically spectra were signal averaged because of computational limits on storing large amounts of data.

• Modeling the single scan spectra can be beneficial.

Center for Intelligent Chemical Instrumentation

13

Cytochrome c

Myoglobin

Trypsinogen

5

0

15

10

35

Average MALDI-MS Spectrum for a Protein Standard Mixture

30

25

Cytochrome c

Myoglobin

Trypsinogen

20

1 1.5

2 2.5

m/z x 10

4

Center for Intelligent Chemical Instrumentation

14

Baseline Correction

• Polynomial or exponential fit

The model usually depends on the instrument or matrix conditions

• Reduce the least squares error between the spectrum and the model

ˆ b

0

b e

Center for Intelligent Chemical Instrumentation

15

Cytochrome c

Myoglobin

Trypsinogen

10

5

0

-5

Baseline Corrected MALDI-MS Spectrum for a Protein Standard Mixture

30

25

Cytochrome c

Myoglobin

Trypsinogen

20

15

1 1.5

2 2.5

m/z x 10

4

Center for Intelligent Chemical Instrumentation

16

Wavelet Compression

• For large data sets, modest linear wavelet compression can improve efficiency.

• The biorthogonal wavelets, such as the

Villasenor preserve the peak locations and avoid the extra step of reconstruction.

• Compressed using 4 levels and a biorthogonal filter with 3 vanishing moments.

• Improves signal-to-noise ratio by removing high frequency components.

Center for Intelligent Chemical Instrumentation

17

3

2

1

0

7

6

5

4

8 x 10

4 Wavelet Compressed Average Spectrum

Average Spectrum 100K

Wavelet Coefficients 6K

Wavelet Compressed Average Spectrum

Average Spectrum 100K

Wavelet Coefficients 6K 10000

8000

6000

4000

2000

0

-2000

1.4

1.42

1.44

1.46

m/z

1.48

1.5

1.52

x 10

4

1 1.2

1.4

1.6

1.8

2 2.2

2.4

2.6

m/z x 10

Center for Intelligent Chemical Instrumentation

4

18

Modern Approach

• Compress single shot scans

• Baseline correct

• Align m/z drift for each individual scan (i.e., single laser shot spectrum).

• Model using multivariate curve resolution

Center for Intelligent Chemical Instrumentation

19

Multivariate Curve Resolution

• Simple linear models based on transient behavior of the data

• Separate correlated spectral information based on temporal response

• Simple-to-use interactive mixture analysis (SIMPLISMA).

• Alternating least squares (ALS)

Center for Intelligent Chemical Instrumentation

20

Model = Product of analyte concentration and analyte sensitivity

D = CS

T

E

Error

=

Spectra

+

Center for Intelligent Chemical Instrumentation

21

Principal Component Analysis

• Decomposition into orthogonal matrices C and S

• The matrices maximize variance

• The matrices are abstract in that they do not represent physical or chemical trends

Center for Intelligent Chemical Instrumentation

22

SIMPLISMA

Instead of detecting peaks, SIMPLISMA selects points or columns in the data matrix D that have a maximum purity.

The two criteria for a pure variable are:

1.

the point characterizes a variance

2.

the point varies independently with other points in the model p i ,2

i

i

r

11 r

1 i r i 1 r ii

Willem Windig and Jean Guilment, Anal. Chem.

1991, 63, 1425-1432 .

Center for Intelligent Chemical Instrumentation

23

SIMPLISMA Decomposition

• The columns of the data matrix

D are used as initial estimates for the concentration profiles C.

• Spectra are obtained by least squares regression of C onto D.

• The spectra are normalized to unit vector length.

• Concentration profiles are obtained from regression of the normalized spectra S onto D.

S = S/ S

2

T

-1

-1

Center for Intelligent Chemical Instrumentation

24

Alternating Least Squares (ALS)

• Alternating procedure of regression with constraints

• Concentrations and spectra should not be negative. Use non-negative constrained least squares for the regression.

S n+1

= D

T -1 f ( C n

)

C n+1

= D

-1 f ( S n+1

)

J. C. Hamilton and P. J. Gemperline, "Mixture Analysis Using Factor

Analysis II: Self Modeling Curve Resolution," J. Chemometrics,

1990, 4, 1-13.

Center for Intelligent Chemical Instrumentation

25

Center for Intelligent Chemical Instrumentation

26

0.25

0.2

0.15

0.1

0.05

0

-0.05

-0.1

Simplisma Spectra of Unaligned Scans

Component #1

Component #2

1 1.5

2 2.5

Mass-to-charge Ratio (m/z) x 10

4

Center for Intelligent Chemical Instrumentation

27

0.2

0.15

0.1

0.05

0

Simplisma Spectra of Unaligned Scans

Component #1

Component #2

2.38

2.4

2.42

2.44

2.46

Mass-to-charge Ratio (m/z)

2.48

2.5

x 10

4

Center for Intelligent Chemical Instrumentation

28

First 10 Unaligned Scans

80

60

40

20

0

160

140

120

100

2.39

2.4

2.41

2.42

2.43

2.44

2.45

2.46

Mass-to-charge Ratio (m/z) x 10

4

Center for Intelligent Chemical Instrumentation

29

Mass Alignment

• Before alignment each scan is wavelet compressed and baseline corrected.

• Align each spectrum so that the correlation with the average spectrum is maximized.

• The alignment is obtained by a quadratic fit of the m/z of each spectral scan.

• Linear interpolation is used to match the scan m/z to the average m/z of the data set.

Center for Intelligent Chemical Instrumentation

30

0.2

0.15

0.1

0.05

0

-0.05

0.4

0.35

0.3

0.25

Simplisma Spectra of Aligned Scans

Component #1

Component #2

1 1.5

2

Mass-to-charge Ratio (m/z)

2.5

x 10

4

Center for Intelligent Chemical Instrumentation

31

Simplisma Spectra of Aligned Scans

0.35

0.3

0.25

0.2

0.15

0.1

0.05

Component #1

Component #2

0

2.35

2.4

2.45

Mass-to-charge Ratio (m/z)

2.5

x 10

4

Center for Intelligent Chemical Instrumentation

32

First 10 Aligned Scans

100

80

60

40

20

160

140

120

0

2.38

2.39

2.4

2.41

2.42

2.43

2.44

2.45

Mass-to-charge Ratio (m/z)

4 x 10

Center for Intelligent Chemical Instrumentation

33

3000

2500

2000

1500

1000

500

0

-500

0

Concentration Profiles of Aligned Scans

Component #1

Component #2

100 200 300 400

Scan Number

500 600

Center for Intelligent Chemical Instrumentation

34

0.06

0.04

0.02

0

0.12

Comparison of Signal Averaged and SIMPLISMA Spectrum

Simplisma

Proc-Mean

0.1

0.08

2.38

2.4

2.42

2.44

2.46

Mass-to-charge Ratio (m/z)

2.48

x 10

4

Center for Intelligent Chemical Instrumentation

35

500

400

300

200

100

0

-100

-200

-300

-400

-500

PCA Score Plot for Processed MS

A

567

109 1718

541

307

194

304

507

19

78

198 1

618

591

35 386

24

10

274

589

440

434

142

137

467468

588

599

443

433

428

427

587

579

379

487

437

477

378

597

483

574

562563

570

559

558

555

553

556

554

552

560

-1000 0 1000

PC #1 (81%)

2000 3000

Plotted with respect to scan number.

Center for Intelligent Chemical Instrumentation

36

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-0.8

PCA Score Plot of Normalized Processed Scan

A

74

166

59

184 171

260

335

181

248

46

182

179

223

605

609

372

63

336

178

124

217

155

412

49

123

72

146

628

216

173

201

149

148

193

197

111

152

233

415

363

457

267

97

150

235

460

242

75

327

199

257

256

368

15

11

529

531 462

209

459

303

331

12

277

505

272

271

273

275

571

479

503

-0.8

-0.6

-0.4

-0.2

PC #1 (17%)

0 0.2

0.4

Center for Intelligent Chemical Instrumentation

37

0.1

0.05

0

-0.05

0.3

0.25

Variable Loadings of the First 2 Principal Components

Component #1

Component #2

0.2

0.15

1 1.5

2

Mass-to-charge Ratio (m/z)

2.5

x 10

4

Center for Intelligent Chemical Instrumentation

38

0.18

0.16

0.14

0.12

0.1

0.08

0.06

0.04

0.02

0

1

Comparison Between ALS and Mean Spectra

ALS Spectrum

Mean Spectrum

1.5

2

Mass-to-charge Ratio (m/z)

2.5

4

39

0.2

0.15

0.1

0.05

0

Comparison Between ALS and Mean Spectra

ALS Spectrum

Mean Spectrum

2.35

2.4

2.45

Mass-to-charge Ratio (m/z)

2.5

x 10

4

Center for Intelligent Chemical Instrumentation

40

Comparison Between ALS and Mean Spectra

0.02

0.015

0.01

ALS Spectrum

Mean Spectrum

0.005

0

1.4

1.42

1.44

1.46

1.48

Mass-to-charge Ratio (m/z)

1.5

1.52

x 10

4

Center for Intelligent Chemical Instrumentation

41

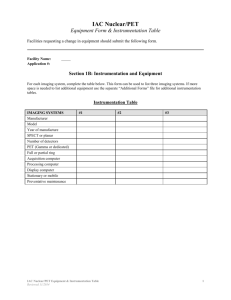

Prediction of Risk for Premature Delivery from MALDI-MS of Amniotic Fluid

• Control was a pooled amniotic fluid from women who produced excessive volumes of amniotic fluid (AF)

• Women who are at risk for premature delivery from two individuals

• Three replicates of each sample were studied at different times

• Each replicate was subject to one of four sample preparation procedures

• After sample preparation 3 more replicates were obtained to characterize measurement variations

Center for Intelligent Chemical Instrumentation

42

Sample Preparation

• The matrix was formed from saturated sinnapinic acid in a 1:1 mix of acetonitrile (ACN) and 0.1% trifluoroacetic acid (TFA)

• Four sample preparation procedures were evaluated

• The samples were diluted 10-fold to volume with

0.1% TFA

• Method 1 adds a 1.0 L of this solution to the

MALDI plate

• Method 2 extracts 15 L with a ZipTip and elute with 5 L of a 1:1 mix of TFA 0.1% and ACN

• Method 3 extracts a diluted 10-fold solution with 5

L of methylene chloride

• Method 4 is method 3 followed by method 2

Center for Intelligent Chemical Instrumentation

43

MALDI-MS Conditions for Amniotic

Fluid Study

• ABI Voyager DE-STR

– Linear mode

– Delayed extraction 375 ns

– Accelerating voltage 25 kV

– Grid 95%

– Guide wire 0.1%

– Mass range 3-20 kDa

– Low mass gate 2 kDa

– Laser shots per spectrum 250

Center for Intelligent Chemical Instrumentation

44

Analysis of Variance (ANOVA)

• The data set comprised 108 spectra with 38,970 mass measurements

• Additive variance model coupled with PCA x x ( x

( x

Pr ep

Treatment

x x

Patient x

Sample x

MS

x

Pr

ep x

Treatment x

Int

x

Sample x

MS

x

Patient x x

I nt

)

)

Center for Intelligent Chemical Instrumentation

45

0.6

0.4

Total Variance

94

95

96 106

100

90

102

101

Control

Pre

60

58

59

64

66

65

70

71 72

40

0.2

0

-0.2

-0.4

-0.6

91

62 50

37

38

51

39

79

92 93

8081

63

61

55

43

6768 69

46

99

47

48

4

17

18

16

10

28

11

1

34

27

26

31

15

7

8

25

13

33

-0.4

-0.2

0

PC #1 (28%)

0.2

0.4

Center for Intelligent Chemical Instrumentation

46

Treatment vs Residual Variance

Control

Pre 0.2

0.1

0

-0.1

-0.2

46

55

95

37

85 86

76

73

89

78

8081

48

87

70

106

88

108

74

64

72

69

75

47

100

94

2

22

6

32

7

24

23

34

14

13

19

16

1

10

-0.3

-0.4

82

-0.4

-0.3

-0.2

-0.1

0 0.1

0.2

0.3

0.4

0.5

PC #1 (47%)

Center for Intelligent Chemical Instrumentation

47

Variable Loadings of Treatment

0.15

0.1

0.05

0

-0.05

-0.1

0.2

0.4

0.6

0.8

1 1.2

1.4

1.6

1.8

m/z

2 2.2

x 10

4

Center for Intelligent Chemical Instrumentation

48

0

-0.1

-0.2

-0.3

-0.4

-0.5

-0.6

0.3

0.2

0.1

Study vs Residual Variance

Control

Study 1

Study 2

83

84

47

63

65

51 41

57 44

49 38

40

67

58

66

2

22

62

17

35

6

18

90

24

34

46

102

1

10

93

101

81

75 98 86 85

89

82

-0.2

-0.1

0

PC #1 (15%)

0.1

0.2

0.3

Center for Intelligent Chemical Instrumentation

49

Variable Loadings of Study

0.08

0.06

0.04

0.02

0

-0.02

-0.04

0.2

0.4

0.6

0.8

1 1.2

1.4

1.6

1.8

2 2.2

m/z

Center for Intelligent Chemical Instrumentation x 10

4

50

0

-0.05

-0.1

-0.15

-0.2

-0.25

0.15

0.1

0.05

Pretreatment vs Residual Variance

Ex-ZT

Ex

ZT

NoZT

2

97

63

85

74

37

73

14

39

75

25

49

13

62

17

90

18

29

65

6

54

78

40

4

101

52

28

22

96

46

58

71

108

106

107

48

23

94

9 21

20

69

93

104

81

55

79

103

8

91

7

19

1

82

-0.4

-0.3

-0.2

-0.1

0

PC #1 (35%)

0.1

0.2

0.3

0.4

Center for Intelligent Chemical Instrumentation

51

Variable Loadings of Pretreatment

0.08

0.06

0.04

0.02

0

-0.02

-0.04

0.2

0.4

0.6

0.8

1 1.2

1.4

1.6

1.8

2 2.2

m/z x 10

4

Center for Intelligent Chemical Instrumentation

52

0.3

0.2

0.1

0

-0.1

-0.2

2

3

Interaction vs Residual Variance

Ex-ZT

70

107

108

72

106

96

95

58

66

59

9

1

60 7

53 52

82 ZT

50

38

63

61

6

5

79

94

92

81

80

93

91 18

76

103

104

105

43

78

77

73

67

12

97

10

24

85

55

86

16

27

33

101

34

36

35

28

15

90

13

99

87

46

-0.3

-0.4

47 48

-0.6

-0.4

-0.2

0

PC #1 (18%)

0.2

0.4

0.6

Center for Intelligent Chemical Instrumentation

53

Follow-up Experiment

Day 1 Day 2 Day 3

SB1b-n PB2c-n SB3b-n

PA1a-ZT SB2c-ZT PA3b-n

PB1a-ZT SB2a-ZT PC3b-ZT

PA1b-n SA2a-n SC3a-n

PC1c-ZT PC2c-ZT SB3b-ZT

SC1c-n PB2b-n SA3c-n

PA1c-ZT PA2b-n SB3a-n

SC1c-ZT PB2c-ZT SA3a-n

SC1a-n SA2b-ZT SC3b-n

SC1a-ZT PC2b-n PC3a-ZT

PA1c-n SB2c-n SA3a-ZT

SA1b-n PB2b-ZT SC3a-ZT

SC1b-n PC2c-n SA3b-n

SB1b-ZT SC2b-ZT PB3a-n

PC1a-n SA2a-ZT SA3c-ZT

PB1b-n SA2c-ZT SC3b-ZT

PC1c-n SB2b-ZT PB3c-n

SB1a-ZT PA2c-n PA3a-n

Day 1 Day 2 Day 3

PB1b-ZT SC2c-n PB3b-ZT

SB1a-n SC2c-ZT PC3a-n

SB1c-n PB2a-n PA3c-ZT

SA1a-ZT SC2a-n PB3b-n

SA1a-n PC2a-n PA3b-ZT

PB1a-n PB2a-ZT PB3a-ZT

SA1c-ZT PA2a-n SA3b-ZT

PC1a-ZT SA2b-n SB3c-ZT

PC1b-n PC2a-ZT SB3c-n

SB1c-ZT SB2b-n PC3c-n

PA1b-ZT SC2a-ZT PB3c-ZT

PB1c-ZT PA2c-ZT SB3a-ZT

PB1c-n SB2a-n PA3c-n

PC1b-ZT SC2b-n PC3b-n

SA1b-ZT PC2b-ZT PC3c-ZT

SA1c-n PA2bZT SC3c-ZT

SC1b-ZT PA2a-ZT SC3c-n

PA1a-n SA2c-n PA3a-ZT

Center for Intelligent Chemical Instrumentation

54

0.15

0.1

0.05

0

-0.05

-0.1

-0.15

-0.2

-0.25

Total Variance

Single Patient

Pooled

5

83

11

81

43

41

73

39

37

9

3

36

18

32

16 14

38

20 13

56

49

96

95

23 21

107

19

27

35

67

74

85

97

61

1

7

26

-0.1

-0.05

0 0.05

PC #1 (49%)

0.1

0.15

0.2

Center for Intelligent Chemical Instrumentation

55

0.05

0.04

Treatment vs. Residual

5

11

Single Patient

Pooled

0.03

41 44

0.02

0.01

0

-0.01

-0.02

48

46

102 100

89

78

29

6 4

38

13

53

52 50

49 74

65

35

23

96 55

66

37

67

33 1

97

19 7

26

98

-0.03

-0.15 -0.1 -0.05

0 0.05

0.1

0.15

0.2

0.25

PC #1 (73%)

Center for Intelligent Chemical Instrumentation

56

0.05

0.04

Day vs. Residual

Day 1

7

Day 3

1

0.03

0.02

0.01

0

-0.01

48

46

102 100

65

89

78

29

6

35

15

9

37

43

27

12

96

107

33

2

79

75

61

13

106

83

49

56

93

91

26

44

98

-0.02

-0.03

-0.04

-0.15 -0.1 -0.05

5

11

0 0.05

0.1

0.15

0.2

0.25

PC #1 (76%)

Center for Intelligent Chemical Instrumentation

57

Sample vs. Residual

0.05

0.04

0.03

0.02

0.01

A

B

C

7

1

48

102

46

100

78

95

37

101

58 73

43

82

55 56

25

97

26

0

41

98

-0.01

11

89

44

-0.02

-0.03

5 53

16

51

14

50

49

13

85

-0.04

-0.15 -0.1

-0.05

0 0.05

0.1

0.15

0.2

0.25

PC #1 (68%)

Center for Intelligent Chemical Instrumentation

58

0.05

0

10

38

104

74

ZipTip

Nothing

89

65

5 11

29

35

23

39 19

25

13

1 7

-0.05

-0.1

-0.15

26

-0.2

-0.15

-0.1

-0.05

0

PC #1 (68%)

0.05

0.1

Center for Intelligent Chemical Instrumentation

59

The SELDI Process and ProteinChip

®

Arrays

•

Sample goes directly onto the ProteinChip™ Array

•

Proteins are captured, retained and purified directly on the chip (affinity capture)

•

Array is “read” by Surface-Enhanced Laser Desorption/Ionization (SELDI)

•

Retained proteins can be processed directly on the chip

Trace proteins (targets/markers)

Laser

Sample

“Homogeneous” Capture Surface

ProteinChip TM Array

Center for Intelligent Chemical Instrumentation

ProteinChip® Array Surfaces

Chromatographic Surfaces for General Profiling

(Reverse Phase) (Cation Exchange) (Anion Exchange) (Metal Ion) (Normal Phase)

Preactivated Surfaces for Specific Protein Interaction Studies

(PS-1 or PS-2)

(Antibody - Antigen) (Receptor - Ligand) (DNA - Protein)

Center for Intelligent Chemical Instrumentation

61

ProteinChip ® Detection Technology:

Laser Desorption Time-of Flight MS

• Retained proteins are detected Laser Desorption

Ionization

• Simple Linear, TLF TOF MS

• Orthogonal Quadrupole TOF MS and MS/MS

7.5

5

2.5

0

TOF-MS

Spectra View

6

4

2

2000 4730.4+H 4000

2185.8+H

2781.9+H

4618.2+H

3915.2+H

2528.2+H

2369.9+H

3172.3+H

4000.2+H

5045.2+H

4345.6+H

4000

8000

6000 8000

2000

Gel View

7977.1+H

62

Protein Profiling: Three Dimensions of

Resolution

Wash

Conditions

Measured m/z

7.5

5

2.5

0

2000 4000 6000 8000

12 x 8-spot

ProteinChip ®

Arrays match the footprint of a 96 well microplate

Center for Intelligent Chemical Instrumentation

63

Sample Preparation

• Pre-wash chips with 5%

ACN/Methanol

• Deposit 1 μL of sample

• Wash chips with 5% ACN

• Spot 0.5/1μL of matrix solution (

3,5-dimethoxy-4-hydroxycinnamic acid in ACN/H2O/TFA 50/50/0.1)

Center for Intelligent Chemical Instrumentation

64

600

400

200

0

-200

-400

-1000

166

164

162

167

141

45 single shot spectra from 5 control serum samples

201

154

148 150

211 219

192

194

216

61

48

184

187

03kr70

03kr76

03kr78

03kr79

03kr275

189

205

94

21

95

110

15

12

93

118

101

23

76

74

33

51

80

19

31

8

17

113

70

29

67

65

133

88

82

84

197

3

124

86

18

79

196

-500 0

PC #1 (59%)

500

Center for Intelligent Chemical Instrumentation

65

200

100

0

1

2

-100

3

Average Spectra

03kr70

03kr76

03kr78

03kr79

03kr275

4

-200

-300

-400 -200

5

0 200

PC #1 (85%)

400 600 800

Center for Intelligent Chemical Instrumentation

66

0

-0.01

-0.02

-0.03

-0.04

-0.05

0

0.05

Variable Loadings for the Distribution of the Average Spectra

0.04

PC #1

PC #2

0.03

0.02

0.01

2 4 6 8 10 m/z x 10

Center for Intelligent Chemical Instrumentation

4

67

600

400

200

0

-200

-400

-600

-1000

126

127

128

90

135

41

-500

Residual Spectra

221

224

222

209

195

214

67

65

2

213

60

30

28

03kr70

03kr76

03kr78

03kr79

03kr275

161

76 80

171

142

139

182

40

21

170

191

82 84

125

9

83

109

108

123

8

81

79

11

6

63

95

74

104

91

124

97

118

115

102

107

19

51

10

17

94

187

158

189

205

197

173

203

190

196

179

0

PC #1 (40%)

500 1000

176

Center for Intelligent Chemical Instrumentation

68

0.03

0.02

0.01

0

-0.01

-0.02

-0.03

-0.04

-0.05

0

Variable Loadings for the Residual Spectra

PC #1

PC #2

2 4 m/z

6 8 10 x 10

4

Center for Intelligent Chemical Instrumentation

69

SELDI Protein Profiles After Depletion of the

Highest-abundant Serum Proteins

(albumin, IgG, antitrypsin, IgA, transferrin, haptoglobin) a.

Pooled sera from 5 Japanese subjects (01/12/04) b. Individual sera from 5 Caucasian control subjects

(02/19/04) c.

Individual sera from 10 Japanese prostate cancer subjects and 10 matched controls (03/08/04) d. Individual sera from 5 Japanese control subjects, diluted to 20% and 50% of original concentration and spotted with 1 μL of matrix solution (03/12/04) e.

Individual sera from 3 Japanese control subjects, diluted to 20% and 50% of original concentration and spotted with 0.5 μL of matrix solution

Center for Intelligent Chemical Instrumentation

70

0.03

0.025

0.02

0.015

0.01

0.005

2000 4000 m/z

6000 8000 10000

Center for Intelligent Chemical Instrumentation

71

0

-0.05

-0.1

-0.15

0.15

0.1

0.05

85

84

46

Control

Prostate

74

13

83

58

12

10

15

18

8

16 72

81

14

65

50

56

64

7

36

53

51

9

3

24

2

67

23

22

60

47

11 57

68

30

4

40

31

73

71

28

63

89

29

91

44

27

66

37

69

-0.3

-0.2

-0.1

0

PC #1 (61%)

0.1

0.2

Center for Intelligent Chemical Instrumentation

72

-0.05

-0.1

-0.15

0.15

0.1

0.05

0

Treatment vs. Residual

85

84

46

74

13

83

58

12

10

15

18

8

16 72

81

14

65

50

56

64

7

36

53

51

9

3

24

2

67

23

22

60

47

11 57

68

30

Control

Prostate

4

40

31

73

71

28

63

89

29

91

44

27

66

37

69

-0.3

-0.2

-0.1

0 0.1

0.2

PC #1 (61%)

Center for Intelligent Chemical Instrumentation

73

Concluding Thoughts

• Variability of spectra from MALDI and SELDI sources are attributable to shot-to-shot variations that are not independent or random.

• Modeling single scans can display chemical and instrumental variations and provide higher quality spectra.

• Mass alignment should be accomplished prior to averaging as opposed to afterwards.

• All the above statements are likely to be attributable to ESI spectra as well.

• PCA coupled to separation of experimental sources of variation provides a useful graphical tool for evaluating experimental procedures.

Center for Intelligent Chemical Instrumentation

74

Acknowledgements

• Students

– Libo Cao

– George Bota

– Preshious Rearden

Matt Rainsberg

Ping Chen

Leyna Denapoli

– Leanna Kishler

• Federal Aviation Administration - Donation of a

Barringer Ionscan 350

• Ion Track Instruments for Support and Donation of the

Itemizer 2 and VaporTracer 1

• Sionex for the donation of DMS

– Erkin Nazarov for DMS Slides

• National Biscuit Company - Donation of a GC-MS

• U.S. Army EBCB - GeoCenters Donation of 4 Chemical

Agent Monitors and Funding

• Research Opportunity Award-Research Corporation

• Wright-Patterson Air Force Base-INNSSI Fuel Analysis

Center for Intelligent Chemical Instrumentation

75