133510_Corrigendum_Clarifications

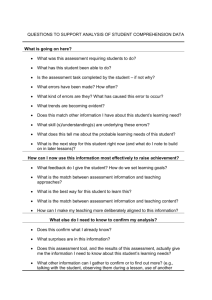

advertisement

EuropeAid/133510/D/SUP/GH RE-LAUNCH OF TENDER FOR THE SUPPLY OF LABORATORY AND METROLOGY EQUIPMENT FOR TESTING AND CALIBRATION LABORATORIES IN GHANA Clarifications DOCUMENT ITEM QUESTION ANSWER General Is there a need for a “manufacturers authorisation” There is no need to supply a manufacturer’s authorisation. It is assumed that when you make a technical and financial offer, you have arrangements with suppliers, for example through dealership agreement, specific contract, or an offer from a supplier or manufacturer, which legally entitle you to make the offer. Do you need brochures for all lots? It is not mandatory to supply a brochure for each item of equipment in each Lot. However, it is highly recommended to provide technical brochures and data sheets whenever relevant as they can be indispensable tools in clarifying the exact nature and specifications of the equipment you are offering. We like to draw your attention to the first page of the document C4f – Technical Specifications and Technical Offer (Annex II and Annex III). Your technical offer and the technical specifications should be detailed enough to make a good comparison with the requested technical specifications. Merely repeating and copying the requested technical specification as the technical specification of the equipment you are offering without any further details and/or additional documentation, is generally not considered sufficient to identify the equipment offered. You have stated that, many of the Some of the serious mistakes made tenderers made administrative errors, include: which culminated into the The company does not comply cancellation of those lots. Can you with the three selection criteria please clarify some of the errors so stated in Article 16 of the Contract that those of us coming for the first Notice. The company has to fulfil time would not make same mistakes? all the requirements concerning economic and financial capacity, professional capacity, and technical capacity. Violations of the rules of origin, meaning that goods are offered that come from manufacturers in countries that are not eligible for this specific tender. If one item in a lot has the wrong country of origin, the whole lot will be rejected. Offering equipment that does not fulfil all the technical specifications. If one item in a lot has wrong technical specifications, the whole lot will be rejected. Not providing all the documents that are required. See Article 11 of the Instructions to Tenderers on the content of the tender, as well as additional instructions in some of the required documents. Contract Notice Article 8 ITT Art. 4 Spec. Cond. Art. 10 Rules of origin In contract notice at page 2 it is accorded the following exception to the rule of origin: Lot 9/No. 314. Anyway Lot 9 does not contain item No. 314 that is instead present in Lot 20. Please confirm that derogation to the rule of origin is possible for item Lot 20/No. 314. Item 314 belongs indeed to Lot 20. The correct list of items and lots for which a derogation from the rules of origin is granted in the tender documents is, therefore, as follows: 1. Lot 6 / No.307 (Set of accessories for existing universal length machine) 2. Lot 7 / No.082 (Precision environmental monitor T/RH) 3. Lot 9 / No.334 (Rubidium clock with GPS comparison system) 4. Lot 20 / No.314 (Voltage reference scanner + DC nanovolt/micro-Ohm meter) 5. Lot 20 / No.317 (Air thermostat for standard resistors) 6. Lot 20 / No.318 (Resistance Bridge 1 mΩ to 100 MΩ, with Matrix Scanner) 7. Lot 20 / No.329 (Precision LCR meter with calibration set) 8. Lot 20 / No.333 (Precision load cell simulator) 9. Lot 20 / No.387 (Precision LCR meter) 10. Lot 21/ No.369 (3-phase isolation transformers for MTE Electricity Meter Test Bench) The above list is applicable to the Contract Notice (Article 8), the Instructions to Tenderers (Article 4), and the Draft Contract Special Conditions (Article 10). Is Turkey (being a candidate country for entrance towards European Community) being an eligible country from origin point of view? Please clarify. Eligibility is determined on the basis of “Annex IV of the Partnership Agreement ACP-EU signed in Cotonou on 23 June 2000 as last revised in Ouagadougou, on 22 June 2010” In summary, participation is open to natural and legal persons who are established in: One of the 29 Member States of the European Union An officially recognised EU candidate country (The former Yugoslav Republic of Macedonia, Turkey, Iceland, Montenegro) A Member State of the European Economic Area (Iceland, Lichtenstein, Norway) An ACP country (Angola - Antigua and Barbuda - Belize - Cape Verde Comoros - Bahamas - Barbados Benin - Botswana - Burkina Faso Burundi - Cameroon -– Central African Republic - Chad - Congo (Brazzaville) - Congo - Cook Islands – Côte d'Ivoire – Cuba - Djibouti Dominica - Dominican Republic Eritrea - Ethiopia - Fiji - Gabon Gambia - Ghana - Grenada - Republic of Guinea - Guinea-Bissau - Equatorial Guinea - Guyana - Haiti - Jamaica Kenya - Kiribati - Lesotho - Liberia Madagascar - Malawi - Mali Marshall Islands - Mauritania Mauritius - Micronesia (Federated States of) - Mozambique - Namibia Nauru - Niger - Nigeria - Niue - Palau Papua New Guinea - Rwanda - St. Kitts and Nevis - St. Lucia - St. Vincent and the Grenadines - Solomon Islands - Samoa - Sao Tome and Principe Senegal - Seychelles - Sierra Leone Somalia - South Africa - Sudan Suriname - Swaziland - Tanzania Timor Leste - Togo - Tonga - Trinidad and Tobago - Tuvalu - Uganda Vanuatu - Zambia – Zimbabwe) A least developed country according to the UN (Afghanistan, Angola, Bangladesh, Benin, Bhutan, Burkina Faso, Burundi, Cambodia, Central African Rep., Chad, Comoros, Congo Dem. Rep., Djibouti, Equatorial Guinea, Eritrea, Ethiopia, Gambia, Guinea, Guinea-Bissau, Haiti, Kiribati, Laos, Lesotho, Liberia, Madagascar, Malawi, Mali, Mauritania, Mozambique, Myanmar, Nepal, Niger, Rwanda, Samoa, Sao Tome & Principe, Senegal, Sierra Leone, Solomon Islands, Somalia, Sudan, South-Sudan, Tanzania, Timor-Leste, Togo, Tuvalu, Uganda, Vanuatu, Yemen, Zambia) It is emphasised that Ghana is classified as a middle income country, and therefore, it does not belong to the UN group of ‘least developed countries'. Consequently, the rules for automatic reciprocal access granted to OECD/DAC members for least developed countries is not applicable; hence the non-EU countries within the OECD/DAC group, in particular: Australia, Japan, Korea, New Zealand, Switzerland, United States, are non-eligible countries for this contract. Please kindly list which country See answer above outside Europe are acceptable for this project, for EDF program. Article 11 ITT Art. 22 Tender guarantee In case of tendering for more than one Lot, is it possible to open a single guarantee as a result of the sum of the guarantees of each lot? Article 7.2 of the Instructions to Tenderers states that each lot is a separate contract. Furthermore, Article 22 of the Instructions to Tenderers states that ‘Tender guarantees provided by tenderers who have not been selected shall be returned …The tender guarantee of the successful tenderer shall be released on the signing of the contract, once the performance guarantee has been submitted”. Providing a combined unique tender guarantee for all lots on which you intend to bid is therefore not acceptable; moreover, it could lead to practical problems if you would be the winner of only one or more, but not all of the lots that you tendered for. Please kindly confirm if it is acceptable if we provide a unique tender guarantee for the total of tender guarantee amount for all lots we intend to bid. Article 16.3 See answer above Selection criteria Contract notice - Selection Criteria 16.3 (Professional capacity of tenderer): For each of the lots 2, 6, 7, 8, 9, 10, 14, 15, 18, 19, 20 and/or 21 the tenderer is required to currently employ a minimum of 3 permanent staff specialised in fields related to the lot for which the tenderer is bidding. Does it mean that if a tenderer is applying for 2 different lots he has to have 6 permanent staff or could staff be the same for more than one lot? For example for Lots 9 and 20 electrical measurements I and II, a tenderer could consider the same staff to be specialized in the field. Is so possible to cover both lots with 3 permanent staff only? The same for Lots 8 and 18 (items for measurement of pressure). In other words, could a tenderer with 5 permanent staff apply for 2 different lots or should we choose only one of them? The criterion for professional capacity does requires that the tenderer has for each lot 3 members of staff that can be considered as specialists in that particular field. The aim of the criterion is to ascertain that the tenderer has the capacity to understand the technical specifications, and to provide the beneficiary with the necessary technical support if so required. However, the requirement does not exclude that a person can be a specialist in more than one field, especially if they are closely related. Therefore, it is possible that a company with a small number of specialists can cover more than one lot, as long as their expertise is adequate for all equipment in those lots. It is the responsibility of the tenderer to appraise the expertise of its staff in relation to the subject matter of the different lots when making a technical offer. Non-compliance with any of the selection criteria will lead to the exclusion of the tenderer. Instructions to tenderers Article 2 Article 10.3 Timetable Submission of tenders Could you allow the submission of tender documents at the same day as the opening of the tender, i.e. Monday 2nd of December 2013 09.00h? In this way Bidders who want to present their Bid can stay and attend the Bid opening on the same day like we see in other EU Tenders as well. Perhaps the deadline for tender submission could also be Monday 2nd of December at 10.00 or 12.00h and the opening of Bid at the same days at 14.00h. Please advise if this is possible. See the corrigendum No.2 published on the EuropeAid website, in which the deadline for submission of tenders and the tender opening session have been changed. Article 11 Content of Tenders Electronic version: do we have to For each Lot for which you submit a include only on CD or one CD for each tender, you should include and copy electronic version of the Financial Offer. One CD or one flash drive per Lot is sufficient. You are requested to provide one official version in a PDF format and one work version in an Excel format. Article 14 Clarification meeting / site visit Would you organize a pre-bid conference to walk us through what you expect from the tenderers? No. It is stated in Article 14 of the Instructions to Tenderers (Document C4b) that there will be no clarification meeting. Draft Contract: Special Conditions Article 19 and ITT Article 1.1 Period of implementation of the tasks Within the period of implementation do we have to consider also customs clearance times? If yes, which is the responsibility of the supplier concerning local bureaucracy and possible delays? If clearance times are included, should we ask for a suspension certificate or is this automatically accorded by the Contracting Authority? It is mandatory that the delivery, installation and training must be completed at the place of delivery for each instrument, within the time period stated in the tender documents. This period includes the time for custom clearance. Please, refer also to Article 20 of the General Conditions. Please note that the implementation period for the complete project is 120 days except for the items 301 and 318. We would like to ask extension for the implementation period for the following lots: Lot 2 we require 240 days. In this Lot is an ICP-MS provided and that instrument requires an export license. Please note this takes approximate 180 days to get this license. Lot 4 and 15 we require 180 days. For Lot 6 we require at least 220 to 240 days. The standard delivery time for the gauge blocks and calibration equipment is 120 to 180 days. You can consult yourself the reputable manufacturers for verification. For Lots 8 and 18 we would require at least 180 days according See the corrigendum No.2 published on the EuropeAid website, in which the period for the delivery, installation, and training for certain items of equipment has been changed. to manufacturers’ info, due to the nature of the products as these are not standard “stock-items” For Lot 19 we have been told that the production time is approx. 7-10 months (this counts for all manufacturers) so a delivery-time of 120 days in the tender does not seem to reflect the correct delivery time due to the nature and complicity of the products involved. Besides production these instrument should also be carefully calibrated (and this process take many months). Please extend the implementation time for this Lot at least to a 12 months delivery-time. Please communicate if it is possible to See answer above extend the implementation period to 180 days for all items of all lots, due to the complexity and the large no. of items, for each lot. 26.5 Payment terms Please kindly confirm that if the prefinancing requested is equal or below EUR 300 000 no pre-financing guarantee is required, in accordance with the derogation indicated in the Special conditions. By derogation to article 26.5 of the General conditions, a pre-financing guarantee may not be required if the requested pre-financing is below the threshold of € 300.000 but can be requested in case of lack of sufficient documentary proof that it complies with the selection criteria or based on a risk assessment by the contracting authority. Since computers are not described in table or technical specifications, we kindly ask you to specify if you prefer to receive a laptop or a desktop computer. Finally would be one set composed of computer + printer + UPS considered enough for each laboratory? It would avoid to offer a different pc and printer for each required item in the same laboratory. It is pointed out that the term ‘computer’ and ‘system controller’ are used interchangeably in the technical specifications. Technical Specifications Computers Computers have been included in the technical specification of a piece of equipment, if it is deemed essential for the operation of the system. In such a case the computer should come pre-installed with the software and tested with the instrument. In such cases a solution of one computer, and printer, and UPS per laboratory is not acceptable. If a computer is not specified in detail, it still has to comply with point 4 of the general remarks at the end of each lot. In cases that the technical specifications require data export to an external computer, only data cables and interfaces, as well as analysis software should be included in the offer. If new computers would be needed for such cases, they have been specified separately in Lot 12. There is a preference for desktop computers, which is indicated in the technical specifications for the majority of cases. However, if the equipment is intended for use in the field a laptop is the preferred option. Spare parts Please kindly indicate if the list of spare parts and consumables, not included in the final price of our offer, refer to the requirement Spare for 3 years in Annex II+III. In detail, please clarify if we have to offer the spare for 3 years only for items when it is explicitly required in Annex II+III and the price for spares has not to be included in our offer. The requirement for spare parts and consumables in Article 1.3 of the Instructions to Tenderers is a general one. It applies in principle to all items in a lot. However, it is left to the discretion of the tenderer to propose spare parts and consumables for an item. This decision should be based for example on past practical experiences and/or statistical evidence of the manufacturer / supplier with a particular item of equipment. It is not necessary to offer spare parts for each and every items, only for those that might reasonably require replacement of parts within the next 3 years. Please define the meaning of “Ancillary services” to avoid possible mistakes what is part if this service. The terms “ancillary services” is defined in the ‘Practical Guide’, General Annexes, Annex A ‘Glossary of Terms’. The definition is as follows: “All related services which the Contractor is required to implement in a supply contract in addition to deliver the goods procured. Where they are necessary they are specified in the contract and may include for example services such as unloading, installation, testing, commissioning, provision of expertise, supervision, After sales maintenance, repair, training and other such obligations connected with the goods to be provided under the contract.” Please confirm that the Maintenance and repair Contracts for a period of 36 months will exclude spare and consumable as the manufacturers have no idea about the frequency of use. Please refer to Draft Contract – Special Conditions, Article 33.1 Consumables are not included. However, the supplier will bear the costs of replacement of malfunctioning parts. For all practical purposes, the frequency of use of equipment will be in the same range or below as in an average laboratory in the EU. Should calibration services be included during the maintenance and repair period keeping in mind that all devices have to be send back to Europe and huge costs have to be calculated in the Tender document for carrying out these services, returning all devices back to the actual manufacturer. Please confirm. Yes, re-calibrations should be included on the basis of a calibration interval that is usual for the equipment concerned. Please clarify better what you intend for fast delivery of spare [parts] Please refer to Article 32 of the Draft Contract - Special Conditions about extended warranty. Fast delivery of spare parts should be within the timeframe specified in that article. Please kindly confirm you intend the After sales service when you require “Service/repair contract” in the Annex II+III for every single item. Please confirm that this service has to be included in the final price of the Lot. Please kindly confirm if a local agent in Ghana is strictly required as mandatory. There are 3 types of after sales services required The standard factory/supplier warranty for a period of one year. This warranty is for a period of 1 year (See General Conditions, Article 32). It is applicable to all items in a lot. The extended warranty, but only for those items for which it has been specifically demanded in the Technical Specifications (See Special Conditions, Article 32). This warranty is an extension of the factory/supplier warranty with an additional period of 24 months. The service and repair contract for specifically designated items. This contract comes on top of the warranty obligations. It covers a period of 36 months. Annex IV – Budget Breakdown shows clearly that the after sales services need to be budgeted separately, but then included in the total price for a lot. Having a local agent in Ghana is not mandatory. However, it can be a practical and less costly solution for providing warranty and service. Installation Please confirm that we have to provide onsite installation and testing only for items when it is explicitly required in Annex II+III. Installation is not limited only to the items for which it is explicitly required in the technical specifications. It is a general obligation to not only to supply and deliver, but also to install equipment as formulated in Article 1.1 of the Instructions to Tenderers and Article 1.1 of the Draft Contract. It will depend on the nature of the equipment whether or not installation is necessary, as well as on the professional experience of the contractors and the place of use. LOT 1 039 Laboratory grinding mill Could you please provide us with the sample volume of this laboratory grinding mill? 062 Rotary Flask Shaker The following is required: “Speed control for 40 - 400 RPM”. Please confirm whether a speed control of 40 to ≥300 rpm is acceptable or not. 077 40 to ≥300 rpm is acceptable Microscope, stereo The following is required: “Magnification from <7x to >45x”. Please confirm whether a magnification from ≤10x to ≥45x is acceptable or not. 093 A grinding mill works on the continuous grinding principle. The volume will therefore range from < 1g to infinite The proposed change is not acceptable. Shaker, Reciprocal In the technical specifications is From 20 rpm is acceptable. mentioned a speed in the range of < 20 to ≥ 250 rpm. Could you please clarify if a speed starting from 20 rpm is acceptable as well? 095 Refrigerator/freezer The following is required: +2 to ≥ +11°C is acceptable “Temperature range refrigerator: +2 12°C”. Please confirm whether a temperature range refrigerator of +2 to ≥+11°C is acceptable or not. 101 References for microbiology Can you give derogation of the rule of A derogation from the rules of origin origin of this item because these are is not needed. There are a sufficient originated in the United States? number of European suppliers of (certified) reference materials 138 Microscope, compound with camera The following is required: “Viewing head: Compensation Free Binocular Head”. Please confirm whether a compensation free trinocular head is acceptable or not. 158 Bottle Top Dispenser The following is required: “Volume range from 0.2 to 25 ml”. Please confirm whether a volume range of ≤2.5 to 25ml is acceptable or not. 166 A compensation free trinocular head is acceptable Volume range from 0.2 to 25 ml must be maintained. Shaking Incubator The following is required: “OrbitalSuggested specifications will be Shaking Range RPM < 100 - > 399, accepted Timer Minutes 1-999”. Please confirm whether an orbital-shaking range of <100 to ≥300 rpm and timer of 0 to 120 minutes and continuous is acceptable or not. 169 Centrifuge, bench top The following is required: “Max. RPM (speed) 20,000/min”. Please confirm whether a max. rpm (speed) of ≥18.000/min is acceptable or not. 370 RPM of ≥18.000/min is acceptable Fuel dispenser check measures set 5l, 10l and 20l The following is required: “constructed according to the international recommendation OIML R-120”. Please confirm whether the Specification for Working Standards of Capacity Metal & Epoxy Composite Material Contents Measures (No. 7321) of the National Measurement Office (NMO) of the United Kingdom is acceptable as a better equivalent of OIML R-120 or not. If the specifications according to the UK document are better than OIML and under the condition that SI units are used, this is acceptable. LOT 2 075 FT-IR An auto-sampler for 20 sample or An auto-sampler with 15 samples or more is asked. Could an auto-sampler more will be accepted. for 15 sample or more be acceptable? 096 Auto-sampler for THERMO AAS The item 096 Auto-sampler for THERMO AAS S4 (with serial number GE712063) is produced in the USA, as confirmed from Thermo to us. Will a derogation be issued, because no other manufacturer can offer a compatible system, which you will understand? 098 See the corrigendum No.2 published on the EuropeAid website, in which items 096 and 098 are deleted from Lot 2. Hollow cathode lamps The item 098 Hollow Cathode Lamps See answer above for THERMO AAS S4 (with serial number GE712063) is produced in the USA, as confirmed from Thermo to us. Will a derogation be issued, because no other manufacturer can offer a compatible system, which you will understand? 139 Protein/Nitrogen Analyser (Combustion Method) In the Instructions to Tenderers, Lot 2, Item 139 one “Protein/Nitrogen Analyser, combustion method” is required, but this item is missing in the Technical Specifications of Lot 2. Is this item required, and if yes, please provide the technical specifications. Item 139 belongs to Lot 2 and not to Lot 4. This mistake has been corrected with the corrigendum published on 12 November 2013 on the website of EuropeAid and the website of the Ghanaian Ministry of Finance and Economic Planning. Please note that the above mentioned See answer above. item is included in Lot 2 as mentioned under Instruction to Tenderers article 1.1. In the technical specifications Annex II the above mentioned item is included in Lot 4. So please clarify if item 139 Protein / Nitrogen analyser, combustion method is part of Lot 2 or Lot 4? 202 Gas Chromatograph – Single Quadrupole Mass Spectrometer We noted that the specifications are similar to Lot 2, Item 010 “Gas Chromatograph – Triple Quadrupole Mass Spectrometer”. As you know some characteristics are not the same to the two types of mass spectrometers (i.e. collision cell for triple quadrupole but not for single quadrupole instruments, resolution, etc.). Please provide us with the required specifications for item 202. LOT 4 We need a standard gas chromatograph with one quadruple. The user does not need the more expensive triple quadrupole. 025 Polarimeter, Semiautomatic The semi-automatic polarimeter is not To the best of our knowledge, it is produced in Europe. Will a derogation possible to purchase this instrument be issued? from an eligible source. 040 Protein/Nitrogen analyser, Kjeldahl principle Please confirm you will also accept a system that works according to Dumas method as this will exceed all specifications. Please confirm you will also accept a system with a sample size of <1g which will exceed the mentioned specs of >1g. 165 The Kjeldahl principle is required; Dumas combustion method will not be accepted. The technical specifications in the tender documents represent the minimum requirements. Better specifications are acceptable. DNA based Pathogen detection kits Is it possible to use as alternative the gold standard method of Real-Time PCR (RT-PCR)? The use of conventional PCR with detection of the targets through electrophoresis and imaging of the gels have a valid more recent alternative by the gold standard method of Real-Time PCR (RT-PCR). This method offers quicker detection but also quantification of pathogens. Making preparation of the sample, running conventional PCR, casting of the gels, migration and imaging will take about 6 to 7 hours whereas using RT-PCR will take only 2 to 3 hours. Furthermore, the RT- PCR will only need two devices (thermo mixer for sample preparation and RT-PCR) We are looking for a basic complete system for food microbiology. The technology is not important. It is important that the method is based on DNA found in the sample. The detection method of the multiplied DNA is not important None of the s under this header have See answer above been specified so we are not quit clear what it is you require exactly and what values you are looking for. Would you be able to provide us with some minimum specifications for the items? LOT 5 128 Distillation unit for testing fuels Could you please confirm that you can Confirmed accept an offer with two devices: one for ASTM D86, and one for ASTM D1160? Please confirm. LOT 7 026 Thermometer 0-250 °C We understood there is the need of a If the display cannot withstand the display, but also it foresees the possibility to insert the thermometer inside ovens and autoclaves where the display cannot resist. Do we have to consider a device with a display and do not insert it in a hot environment (anyway not over the display temperatures-resistance possibilities)? Workflow thus offering a simpler arrangement per sample 041 hot, it must be fitted with a device (cable or wireless) that makes it possible to place it outside. Moisture analyser, hand held 1. As per our experience and after consulting many specialized laboratories in this magnitude the only device that can meet the requirements is from a Swiss manufacturer (country not compliant with rules of origin). There are many alternatives but mainly based on construction materials, not for food and feed. Considering this, is it possible to make an exception of the origin rule similar to the one applied to item 082? 2. If an exception to the rule of Internet search shows that there is at least one company in Germany that produces hand-held equipment for measuring moisture in different media. origin is not allowed to this item, would it be acceptable to quote a moisture analyser based on the principle of measuring the weight of the “wet” product, dry it and measure the weight of the “dry” product considering that due to the power consumption of this kind of product portability would be affected? 3. Is it possible to have a more detailed specification for this product? Measuring principle, etc. 082 Thermo hygrometer Can you accept a Thermo hygrometer Specified uncertainties must be met. with a range of ±0.125°C in range 16°C -> 24°C RH is 1.5% in range 20% to 70% RH which is mains powered with battery backup in case of mains failure. Please confirm? 358 Water triple point bath Instead of offering a bath with bubble agitation could you accept a bath with propeller and stirring engine? Please confirm? Acceptable on condition that performance in terms of vibrations and electrical noise is comparable with bubble agitation (please provide proof). 359 Liquid bath Can you accept a stability of 0.001°C at 45°C [water] and 0.007°C at 100°C [oil] - this does not require the use of an optional high accuracy controller. Please re-confirm You request for a Thermometer Support Kit: assembly to hold up to 12 liquid in glass thermometers. Would a carousel that holds 8 LIG thermometers also be acceptable? Please confirm. 363 Stability requirements should be met as specified, 8 positions for LIG thermometers is acceptable but 12 is preferred. Working standard PRT 1. Could we offer a PRT with 1.8m 1. Acceptable cable length which is coated in Teflon? Please confirm 2. Acceptable 2. Could we offer a Probe with length 500mm and sensor length is 3. Acceptable 30mm+/-5mm - is this acceptable? 3. Could we offer an Alpha value is 0.0039250 Ω/Ω/ °C – Can this be accepted? Please confirm. 404 Working standard PRT Same questions as item 363 Same answers LOT 8 348 Absolute pneumatic pressure balance Since the pressure range of this item has been extended from 2 to 20 bar abs, please confirm the typical uncertainty of 8 Pa + 16 ppm can be accepted. This is in relation to the piston / cylinder Kn used to cover the pressure range specified. The local gravity can be stored directly in the absolute pressure balance for correction. Please confirm this is also accepted. 351 Not acceptable, please keep to the typical uncertainty as stated. Pneumatic pressure balance The typical uncertainty of 50 Pa + 30 ppm of reading has to be understood as the typical uncertainty on the measuring piston cylinder assembly of the deadweight tester. Please confirm. The resolution requested is the one related to the smallest mass required of 10 mg. Given typical uncertainty is to be understood as total measurement uncertainty at k=2. Please note that the specifications for this item were changed from those used for the cancelled lot in the first round of the tender. Unfortunately some of the changes were not correctly implemented in the new technical specifications for this item. Therefore, the following changes to the technical specifications have to be made: Under Features, delete: “Differential Pressure balance with two piston-cylinders mounting systems” (the intended system is a single piston-cylinder) Under Specifications: replace “Resolution: ≤ 10 Pa” by “Resolution: ≤ 100 Pa” 354 Pressure controller with digital reference gauge The specification does not state the temperature at which the 0.1 FS is applicable. This because requirement for the temperature effect is stated at 0-50°C temperature range. We offer a better uncertainty over a defined temperature range of 18-28°C including linearity, hysteresis, repeatability, resolution, reference uncertainty, 1 year long term stability, and temperature effects from 18 to 28 °C. For temperatures from 0 °C to 18 °C and 28 °C to 50 °C, add 0.003% FS/°C. Is that acceptable? Please confirm. 377 Reference temperature may be taken as 25 °C. Any specifications exceeding the requirements are acceptable. Tire pressure gauge calibrator 1. We would like to offer a product 1. Acceptable. that does not charges batteries inside the calibrator self but an 2. Electrical pump is preferred, but external charger and external hand pump is acceptable if easy batteries. This enables to swap the and light to operate. battery set and continue to work without the calibrator connected 3. Acceptable, as long as extra to mains power for charging. Is batteries are provided to cover that acceptable? Please confirm. the indicated measuring period 2. The specification do not state if the under regular conditions of use. pump is hand operated of electrical pump operated via key pad. Please clarify 3. Our battery life depends the mode of operation of the calibrator. Due to external charged batteries the use of the calibrator is very flexible when multiple battery sets are used. Is that acceptable? Please confirm. 400 Portable pressure calibrator pneumatic 0 to 200 bar 1. We would like to offer a calibrator that has a precision high pressure 1. Acceptable regulator and needle valves to 2. Correct control and set pressure. For the low pressure range we use an integrated volume adjuster in combination with the precision pressure regulator and needles valves to set and control pressure. Our experience has learned that this is a very good way to quickly generate a test pressure at low range. Is this acceptable? Please confirm. 2. The output of the sensor under test is not specified but assumed to be mA of V. Is that a correct assumption? Please confirm. 401 Portable pressure calibrator 0 to 700 bar 1. The output of the sensor under test is not specified, but assumed to be mA of V. Is that a correct assumption? Please confirm. 2. The pressure indicator we would like to offer does not include a filter, internal/external sensor and leak test function, but other features like 24 Volt power supply for sensor under test, dual read out of pressure and electrical values and Hart compatibility which is commonly requested for calibration of pressure transmitters. Is this acceptable? Please confirm. 3. We would like to offer a better specification for the pressure measurement over a wider temperature range than requested but do not state any temperature effects outside our compensated range. Is that acceptable? Please confirm 4. We would like to offer a better specification for the electrical measurement over a wider temperature range than requested but do not state any temperature effects outside our compensated range. Is that acceptable? Please confirm 5. Instead of an overload protection of 1.5 the range we offer an overpressure range at 120% of range. This over range warning is visible on the display. Is this 1. Correct 2. Acceptable, as long as essential requirements such as range and uncertainty are met. 3. If temperature range is close enough to specified range, this may be acceptable. 4. If temperature range is close enough to specified range, this may be acceptable. 5. Acceptable, but overpressure protection valve must be provided acceptable? Please confirm. 425 Precision barometric pressure monitor The precision barometric pressure Acceptable, as long as automatic monitor we would like to offer sends readout and logging can be done on the barometric value via the RS232 to computer using provided software. the calibration software instead of logging this data in an internal memory. Is that acceptable? Please confirm. LOT 10 378 Water meter test bench DN15 to DN40 with controller hardware and software 1. It is stated under installation that 1. It is not mandatory to use the large existing tank with pipework existing tank and pump, if your and pump of 18 m3/hr. capacity is system has a solution that can to be used for the water supply. satisfy the requirements. Our product is designed in a 2. For some pictures of the exterior compact mode including both and interior of the intended space pump and tank, this solution is the for the installation of the water most cost-effective and presents meter test bench we refer you to advantages in terms of space and the website of EuropeAid possible future moves of the (https://webgate.ec.europa.eu/e system. uropeaid/online2. Regarding the installation place, is services/index.cfm?do=publi.welc it possible to get some other ome&nbPubliList=15&orderby=u information as available surface, pd&orderbyad=Desc&searchtype pictures, access to the building? =RS&aofr=133510). There is a file, 3. Calibration uncertainty to be named “Annex to Clarifications 2 achieved: typical 0.05 % – photos Lot 10 Item 378”, (gravimetric). The expanded published on 29 May 2013 and uncertainty of our whole bench is which contains some photos of around 0.2% (taking in to the building; it was published as calculation the water meters); part of the clarification to the while the uncertainty of the mass previous round of this tender. or volume sensors is closer to the 0.05 % which has been written. Is The dimensions of the inside of this ok for you? the building are: 4. Test flow rates Qn ranging from 1.5 Length 7.85 m; width 5.10 m; m3/hr. to 10 m3/hr. DN40 water height 2.80 m meters reach a Qmax up to 20 m3/h. Would this be taken in to account? The dimensions of the entrance Our standard benches reach that door are: width 1.80 m and height Qmax, and we understand it’s a 1.95 m better solution. 3. Acceptable 4. This would exceed the specifications and is therefore acceptable. LOT 13 156 Penetrometer, field Please could you further specify which We need the simplest possible field accessories would be required for the penetrometer. Penetrometer, for example: CPT Sounding equipment, Electrical & Mechanical CPT testing, Seismic SCPT(U) testing etc.? LOT 14 125 Tensile strength testing machine What materials are to be tested & to what Standard? Are any accessories required, e.g. Grips, Extensometers etc.? The machine would not function without these. The primary purpose of this machine is testing of plastic tubes for clean water and sewage. The machine will be used in combination with Item 124, Plastic Pipe Testing Machine. Accessories are required to complement this testing. This will be stretching as well as bending. LOT 15 205 DNA Sequencer You are asking for a bench top We prefer the 16 capillary type. semiconductor–based platform and it also must have 16 capillary. This are two different types of sequencer. Can you please confirm what type of sequencer do you prefer? LOT 16 018 Incubator, microbiology, 250 l The following is required: “Capable of Temperature range of ambient operating in the temperature range +≤10°C to ≥70°C is acceptable ambient +5 °C to ≥ 70 °C”. Please confirm whether a temperature range of ambient +≤10°C to ≥70°C is acceptable or not. 021 Autoclave, front loading The following is required: Programmable sterilisation “Programmable sterilisation temperature range of ≤105°C to temperature in the range 100 to ≥134°C is acceptable ≥134°C”. Sterilisation cycles are pressure controlled, while the sterilisation temperature is guarded in the drain of the sterilisation chamber. To be able to do this you need a pressure which is higher than the atmospheric pressure in the sterilisation chamber. This automatically results in a minimum sterilisation pressure at 105°C. The maximum temperature is limited due to the design pressure of the sterilisation chamber. This is 2,8Bar, which results in a maximum temperature of 137°C. Internationally sterilisation temperatures of 121°C and 134°C are the standard (most common) values. These temperatures are functional compliant and provide better results. Please confirm whether a programmable sterilisation temperature range of ≤105°C to ≥134°C is acceptable or not. 024 Oven, hot air, 80 l The following is required: “Heat-up rate: ambient to 100°C in 12 min, ambient to 200°C in 24 min, ambient to 260°C in 45 min”. These specifications refer to and fit only one specific brand in particular, which may not be sold in the eligible countries, because the relevant equipment does not meet the EC conformity and CE marking (European safety guidelines). Please confirm whether heat-up rate: ambient to 100°C in 12 min, ambient to 200°C in 24 min and ambient to 260°C in 45 min can be ignored / deleted or not. 046 It is essential that the heat-up time is short. Long periods will interfere with the routine work and should be avoided. Taking this into account the given heat-up times can be ignored Drying cabinet Please clarify if the maximum 50°C above ambient is acceptable temperature of 50°C above ambient is acceptable as well? Because in the technical specifications was mentioned > 50°C above ambient. 057 Muffle furnace, > 10 l The following is required: “Nominal heat up time: 60 minutes or less”. Because of European safety guidelines, this nominal heat-up time is not always possible. Please confirm whether a nominal heat-up time in the range of 60 to ≤120 minutes is acceptable or not. 060 Nominal heat-up time in the range of 60 to ≤120 minutes is acceptable Oven, hot air, 30 l The following is required: “Heat-up rate: ambient to 100°C in 12 min, ambient to 200°C in 24 min, ambient to 260°C in 45 min”. These specifications refer to and fit only one specific brand in particular, which may not be sold in the eligible countries, because the relevant equipment does not meet the EC conformity and CE marking It is essential that the heat-up time is short. Long periods will interfere with the routine work and should be avoided. Taking this into account the given heat-up times can be ignored (European safety guidelines). Please confirm whether heat-up rate: ambient to 100°C in 12 min, ambient to 200°C in 24 min and ambient to 260°C in 45 min can be ignored / deleted or not. 063 Oven, drying The following is required: “Temperature range: ambient +5 to >250°C, Volume: > 110 l”. Please confirm whether temperature range: ambient +≤10 to >250°C and volume: ≥108 l is acceptable or not. 089 Ambient +≤10 to >250°C and volume ≥108 l is acceptable Muffle furnace, > 40 l The following is required: “Nominal A nominal heat-up time in the range heat up time: 60 minutes or less”. of 60 to ≤95 minutes is acceptable Because of European safety guidelines, this nominal heat-up time is not always possible. Please confirm whether a nominal heat-up time in the range of 60 to ≤95 minutes is acceptable or not. 137 Muffle furnace, > 20 l The following is required: “Nominal A nominal heat-up time in the range heat up time: 60 minutes or less”. of 60 to ≤95 minutes is acceptable Because of European safety guidelines, this nominal heat-up time is not always possible. Please confirm whether a nominal heat-up time in the range of 60 to ≤95 minutes is acceptable or not. 168 Anaerobic Jar The following is required: “Volume max 2.5 litre”. Please confirm whether a volume max. 3 litre is acceptable or not. 171 A volume max. 3 litre is acceptable. Microwave oven The following is required: “Operating features TCP: Code Cooking, Sensor Cook Options”. These features are patented under TCP (TrueCookPlus) and licensed to only two specific microwave oven brands in particular, which are not manufactured in the eligible countries. Thereto, the applicable microwave ovens are only provided with the wrong voltage and frequency, not suitable for Ghana. Please confirm whether the operating features TCP: code cooking, sensor cook options with the related The operating features TCP: code cooking, sensor cook options with the related humidity sensor can be ignored/deleted humidity sensor can be ignored / deleted or not. 175 Oven, hot air, 150 l The following is required: “Heat-up rate: ambient to 100°C in 12 min, ambient to 200°C in 24 min, ambient to 260°C in 45 min”. These specifications refer to and fit only one specific brand in particular, which may not be sold in the eligible countries, because the relevant equipment does not meet the EC conformity and CE marking (European safety guidelines). Please confirm whether heat-up rate: ambient to 100°C in 12 min, ambient to 200°C in 24 min and ambient to 260°C in 45 min can be ignored / deleted or not. 176 It is essential that the heat-up time is short. Long periods will interfere with the routine work and should be avoided. Taking this into account the given heat-up times can be ignored Autoclave, Front loading, > 23 l The following is required: Programmable sterilisation “Programmable sterilisation temperature range of ≤105°C to temperature in the range 100 to ≥134°C is acceptable ≥134°C”. Sterilisation cycles are pressure controlled, while the sterilisation temperature is guarded in the drain of the sterilisation chamber. To be able to do this you need a pressure which is higher than the atmospheric pressure in the sterilisation chamber. This automatically results in a minimum sterilisation pressure at 105°C. The maximum temperature is limited due to the design pressure of the sterilisation chamber. This is 2,8Bar, which results in a maximum temperature of 137°C. Internationally sterilisation temperatures of 121°C and 134°C are the standard (most common) values. These temperatures are functional compliant and provide better results. Please confirm whether a programmable sterilisation temperature range of ≤105°C to ≥134°C is acceptable or not. LOT 17 110 Glass ware for chemistry II In the technical specifications are mentioned boiling tubes large. Could you please clarify if these boiling tubes are the same as test tubes and The size is 10-20 ml and they must fit the Boiling Tube Rack mentioned below in the specification. also specify the dimensions? 173 Consumables, microbiology Please specify the length of the platinum Iridium wire? Approximately one meter as stated in the specification In point 4 of General Remarks, the sentence is incomplete. Could you please provide to bidders a complete version of this file? The complete version of point 4 of the General Remarks is as follows (missing part is underlined and bold): LOT 18 General Remarks For computers/system controllers and related supplementary equipment (e.g. flat screen, printer, UPS) that are considered to be an integrated part of the equipment configuration and that are not further specified, the contractor will provide systems of good quality and reputable brands, based on latest technology, and latest software for operating systems (Windows 8, or equivalent), for office applications (MS Office, or equivalent), and antivirus protection at least for a period of 36 months. 347 Deadweight tester 8000 bar (hydraulic) It would be really useful, also to ensure uniformity of technical offers received, if you could add some details about the list of connectors, adaptors and tubing needed for connecting the equipment under test or alternatively if you could tell us which tests you are expected to perform with the provided equipment so that we could include the most suitable accessories. Types of equipment that will be calibrated on the system are: Bourdon Tube Pressure Gauges Pressure Chart Recorders Pressure Transmitters/Transducers Digital Pressure Gauges Vacuum Gauges Types of adapters: ¼” NPT (Female) 9 ¼ A (Male) ½ “ NPT (Female) ½ “ A (Male) ½ “ NPT Male ½ “ BSP 3/8 “ NPT Male 3/8 “ NPT Female 3/8 “ BSP Male 3/8 “ Female ¼ “ BSP Female ¼ “ BSP Male Connection tubes: 5/3 “ Connection Tube 2/08 “ Connection Tube 1/07 “ Connection Tube LOT 19 343 Torque transducers ranges 50 Nm, 200 Nm, 1000 Nm and 5000 Nm clockwise and counter-clockwise (class 0.05%) with dual input amplifier/indicator, accessories, controller hardware and software Should the calibration meet the ISO 376 procedures? 343/380/414 1. Which type of transducer will be calibrated in the future? Only torque transducers with mV/V output signal or also all the industrial sensors with frequency output, VDC, CAN bus signal a.s.o. In this case a dual input amplifier cannot be used for synchronous measurement of reference transducer (mV/V) and piece under test (others than mV/V output signal). The synchrony measurement is the most important property for the best measurement capability. We offer can a multichannel amplifier with all options for the future. Should this be included? 2. The mode of application is only the use as national standard or also as an accredited torque laboratory? 3. How to control the stability of the amplifier. We need a calibrator for the reference transducer signal (mV/V). Please advise. 4. The machine has a big range (the beginning of the used range is not defined). We offer the range from 5 Nm to 5000 Nm. In this case you have to spend a second set of elastic couplings for the range up to 200 Nm, otherwise you have influence from the generated parasitic components). Should this be included? 5. The environmental conditions in the lab of the user are not defined (temperature and humidity) Please clarify? 6. In manual operated machines with all influences from creep of the Yes, that would be preferred, as it is the standard procedure for such equipment 1. mV/V is required, other inputs are added advantage, but not mandatory according to requirements. 2. Mainly for accredited calibrations but initially also as national standard. 3. Electrical precision calibrators are available. 4. 5 Nm is acceptable as the lower end of the range, include all necessary accessories to achieve specs over the range. 5. Temperature will be controlled at 20°C or 23°C at stability of a few °C. Both temperature and humidity will be monitored. Humidifiers or de-humidifiers can be employed when needed. The relative humidity in Accra typically ranges from 48% to 96% over the course of the year, rarely dropping below 30% and reaching as high as 100%.The air is driest around the middle of January, at which time the relative humidity drops below 58% three days out of four; it is most humid around the beginning of June, exceeding 93% (very humid) three days out of four. 6. As a complete system for calibration of torque transducers all these optimisations should be included as needed for optimal frame it's necessary to use special performance at least meeting the software for interpolation to the required specifications. defined steps or continuous calibration operation. Otherwise 7. Inclusion of this option is an the operation is very time added advantage, but not consuming and there is no mandatory. guarantee for exact read out on the defined step. We can offer a 8. Documented proof of motor and manual drive mode to performance of the proposed realise steps in 15 s and preloading equipment will assist in better in all ranges <30 s and software for evaluation of technical continuous calibration procedure. specifications and is very Do you need a visualisation of the welcome. calibration result of every calibration step a graphic in the 9. The transducer adaptation is calibration software for cylindrical shaft and square drive observation of the calibration work but the measurement for the in time? Do you need the sizes have not been taken exactly. possibility of calibration result for The supplier should use the alternation torque (e.g. in acc. to common sizes. DKD-R 3-5), recording software for stability test and creep test? 7. There is an option to calibrate also in the future transfer torque wrenches which are very important for the on-site calibration of torque wrench calibration equipment or torque wrench testers at industry (in development countries ca. 90% of industrial calibration requirements). 8. Do you need a reference list about costumers who used such type of reference torque calibration machines in the past, because we know that various manufacturers can not present such document. 9. What type of transducer adaptation is necessary? E.g. cylindrical shaft, square drive (in/out) adapter, sizes, and flange plates a.s.o. Please define.