Graduate SMB Training

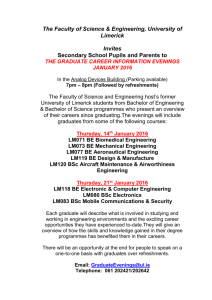

advertisement

FDS MBS Grad Student Biosafety Orientation Lorraine A. McConnell WSU Biosafety Manager 509-335-4462 lorrmcc@wsu.edu September 3, 2008 http://www.bio-safety.wsu.edu/biosafety/ Outline • Introduction • Biosafety Levels Practices Facilities • Biosafety Cabinet • Case Study • Resources • Regulations Biosafety Introduction Practicing Science Safely Means That Before Any Activity... YOU KNOW the risks YOU KNOW the worst things that could happen YOU KNOW what to do if they should happen YOU KNOW AND USE the prudent practices, protective facilities, and protective equipment needed to mitigate the risks Biosafety Levels – Know the Risks • • • • BSL 1: Material not known to consistently cause disease in healthy adults. BSL 2: Associated with human disease. Hazard is from percutaneous injury, ingestion, or mucous membrane exposure. Some agents with environmental or agricultural impact. BSL 3: Indigenous or exotic agents with potential for aerosol transmission; disease may have serious or lethal consequences. BSL 4: Dangerous/exotic agents which pose a high risk of lifethreatening disease, aerosol-transmitted lab infections or related agents with unknown risk of transmission Appropriate Biosafety Level Agent Risk Group + Risk Assessment = Appropriate Biosafety Level Agent Risk Group Resource: http://www.absa.org/riskgroups/index.html Risk Group Examples: RG-1 E. coli (standard host vector systems) Most plant pathogens e.g., Aschochyta spp. Adenovirus type 1-4, most human cell lines RG-2 Shigella, Salmonella, Listeria, E. coli O157, Human Adenovirus, Candida spp. Giardia lamblia, Some human cell lines HEK-293 HeLa (characterized agents) RG-3 Mycobacterium tuberculosis, M. bovis, Coccidioides immitis, HIV, R. richettsii A Complete Risk Assessment includes • Agent Characterization (Risk Group RG) • Personnel Factors (experience) • Work Activity Factors • Environmental Factors • Equipment Factors • Risk Consequences • Probability Profile Risk Assessment • Risk of Activity – same agent can have different containment levels: Procedures that produce aerosols have higher risk Procedures using needles or other sharps have higher risk Handling blood, serum or tissue samples may have lower risk Purified cultures or cell concentrates may have higher risk Large volumes (>10 L) have higher risk Protection Should Match the Risk: What is the Expected Route of Infection? AGENT / LAI* PRIMARY HAZARDS *LAI= Laboratory Acquired Infections Mycobacterium bovis Incidence of tuberculosis in laboratory workers working with M. tuberculosis is three times higher than those not working with agent; fourth most commonly reported laboratory infection; 176 reported cases with 4 deaths PRIMARY HAZARDS: Inhalation of infectious aerosols; accidental parenteral inoculation, direct contact of mucous membranes, ingestion; naturally or experimentally infected nonhuman primates are a known cause of human infection; litter of infected animals (e.g. mice and hamsters) serve as source of infectious aerosols Not common but is associated with stillbirths. PRIMARY HAZARDS: Ingestion is the common mode of exposure, however may cause eye and skin infection following direct exposure; parenteral inoculation, ingestion, exposure to highly concentrated aerosols. Pregnant women should avoid exposure to this agent. Salmonella spp. PRIMARY HAZARDS: Ingestion, parenteral inoculation; LAI; 48 reported cases importance of aerosol exposure not known Listeria monocytogenes Know What to Do • What Constitutes a Biological • • • Exposure Risk? What to do When There has Been a Potential Exposure? How to Clean up a Biological Spill? When Should you Seek Assistance With a Spill Clean up? What Constitutes a Biological Exposure Risk? What to do when there is a breach? Tell your supervisor and the Biosafety Manager for WSU. Fill out an incident report, and all other paper work as required. What to do when there is a near miss? Fill out an incident report. • Breach in Primary or Secondary Containment • What is Primary Containment? • What is Secondary Containment? Primary Containment • Lab practices – standard lab practice, limited access, biohazard warning sign, sharps/needle precautions, SOPs, decontamination, waste. • Safety equipment – biosafety cabinets (BSC), sharps containers, sealed rotors. • Personal protective equipment (PPE) – lab coat, gloves, goggles, respirators. Establishing Precautions to Minimize Risk Primary containment Secondary Containment - Facilities • Facility provides containment through traditional construction BSL-1 & BSL-2 Best practices HVAC provides negative pressure in BSL-2 labs. Depending on risk assessment this may be required. • Facility provides containment through special design features BSL-3 Anterooms Double doors Alarmed redundant HVAC systems Possible Biological Release Scenarios Is This a Release? • Open a centrifuged tube at the open bench that contains a BSL-2 organism. • Using a wire transfer loop and a bunsen burner pick a Campylobacter colony and streak for isolation work in the BSC. Is This a Release? • BSL-3 potentially aerosolizing work performed in uncertified BSC. • Transfer liquid cultures with a transfer pipette to produce BSL-2 organism serial dilutions. Work performed at the open bench. Spill Clean up of Biological Agents Surface Contamination: Alert co-workers Define/isolate contaminated area Put on appropriate PPE (personal protective equip.) to include gloves, lab coat and face shield (if appropriate) Remove/glass/glass shards with forceps or scoop Apply absorbent towels to spill – Do NOT apply disinfectant directly to the spill as this may aerosolize the agent Apply disinfectant to towel surface Allow adequate contact time (generally 10-60 minutes) Remove towels, mop up; clean with alcohol or soap/water or other agent as appropriate. Dispose of materials in biohazardous waste Notify lab instructor Spill in a BSC • If the spill of an infectious agent was enough to create puddles or liquid in the drain pan then the following procedure should be followed: a. Leave the cabinet running and close the view screen for about 5 minutes. This will allow aerosols to settle before starting cleanup. b. The drain pan should be flooded with appropriate disinfectant. Leave the disinfectant in the pan for required contact time, longer if the spill involved a high organic load and 10% bleach is used. The disinfectant then needs to be drained out and the surfaces thoroughly cleaned with water to prevent corrosion. Spill Clean up of Biological Agents Personal Exposure: • Clean exposed surface with soap/water, (1 minute), eyewash (eyes) 15-20 min., or rinse mouth 3x’s with water • Apply first aid and treat as an emergency • Notify lab instructor – fill out incident report and other forms as requested • If appropriate report to medical clinic for treatment/counseling Major Spills • This is a spill of a potentially biohazardous material that will take more than 30 minutes to clean up (not including the agent deactivation period of 10-60 minutes depending on the biological agent and disinfectant in use) Call 911 for assistance General Guidelines for Surface Decontamination AGENT DISINFECTANT INACTIVATION TIME Recombinant DNA 10% Bleach 20 minutes Bacterial Spores >6% Hydrogen Peroxide 30 minutes Vegetative Bacteria 10% Bleach 20 minutes Viruses & Viroids 10% Bleach 20 minutes Fungi 10% Bleach 20 minutes Feline Parvovirus 20% Bleach 30 minutes Free Living Cryptosporidium 70% Ethanol 10 minutes Most Parasites 10% bleach 30 minutes Prions 50% bleach 60 minutes Practical Disinfectants for use in Recombinant DNA Research NE=Not Effective, b=variable results dependent on virus Reference: NIH Guidelines for working with Recombinant DNA Lab Safety Monograph (Appendix D updated) Liquid Disinfectants Practical Requirements Use/Dilution Category Contact time minutes Lipo virus Broad Spectrum Inactivates Vegetative Bacteria Lipoviruses Nonlipid Viruses Important Characteristics Bacterial Spores Quaternary Ammonia Compounds 0.1-2.0% 10 NE + + Phenolic Compounds 1.0-5.0% 10 NE + + b Chlorine Compounds 500ppm(a) 10 30 + + + + Iodophor 251600ppm(a) 10 30 + + + + Alcohol, Ethyl 70-85% 10 NE + + Alcohol, isopropyl 70-85% 10 NE + Formaldehyde 0.2-8.0% 10 30 Glutaraldehyde 2.0% 10 30 Effective Shelf life > 1week Effective for Surface Decontam ination + + + + + + + b + + + b + + + + + + + + + + + + + + Liquids For Discard + Know and Use • prudent practices, • protective facilities, and • protective equipment needed to mitigate risks Recommended Biosafety Containment & Practices – Infectious Agents BSL 1 Agents Not known to consistently cause disease in healthy adults Practices Primary Containment • Wash hands after • • • • • • handling viable materials No smoking, eating, handling contact lenses, applying cosmetics No mouth pipetting Minimize aerosols& splashes Decontaminate work surfaces daily Do NOT wear gloves out of lab Remove gloves before touching door handles phones etc. Safety Equipment Primary Barriers None required Facilities (Secondary Barriers) •Doors •Sink required •Work surfaces easily cleaned & impervious to water •Sturdy furniture Recommended Biosafety Containment & Practices – Infectious Agents BSL 2 Agents Associated with human disease, hazard = percutaneous injury, ingestion, mucous membrane exposure Practices (Primary Containment) BSL-1 practice plus: •Limited access Lab entry and exit policies. •Biohazard warning signs at entrance of lab •“Sharps” precautions •Decontaminate stock cultures prior to disposal •BSM - SOP •Report Spills & Accidents •Leak-proof containers for transport •PPE required (as approp.) •Documented training Safety Equipment (Primary Barriers) Facilities (Secondary Barriers) Primary barriers = BSL-1 plus: BSC I or II or other Autoclave available physical barriers, Locking Doors e.g. splash shields, BSC (as needed) covered centrifuges etc. -For all open L Eyewash readily manipulations of available agents that cause Negative pressure in splashes or aerosols laboratory (ideal) HEPA filters required on vacuum lines Personal Protective Equipments PPE’s: laboratory coats; gloves; face protection as needed BSL-3 Special Requirements • Appropriate Containment Risk assessments@ • Primary Containment -Practices All Waste decontaminated • Secondary Containment Physical separation Negative pressure – Exhausted air not recirculated, 10-12 air changes per hour Double access doors Enclosures for aerosol generating equipment Room penetration seals Walls floor and ceiling are water resistant for easy cleaning Vacuum lines protected with HEPA filters and may require additional disinfectant traps as per risk assessment. • Tertiary Barriers Lab Structure & Ventilation • Biosafety Manual must be developed that is specific to the risks of the agent and the work activities@* • Facility must have autoclave Decontamination of all reusable lab clothing, (coats) before laundering Security (controlled access)* Select Agent (if applicable)* Base line serum (as appropriate) • • Primary containment –Equip. &PPE BSC*- Or other physical barriers For all open manipulations of agents PPE –Respiratory protection as required Sealed rotors/safety buckets (as needed) Emergencies Emergency Response Plans* must be posted in the lab Biosafety Cabinet • What is a Biosafety Cabinet (BSC)? • Understand Equipment Limitations • Safe Use of a BSC Why & When to Use a BSC • SOP for BSC • BSC Maintenance / Certification Decontamination What is a Biosafety Cabinet? • A BSC is a piece of equipment that is only as • good as the users understanding of how to appropriately use and maintain it There are different Classes of BSC’s Class I – user protection but no product protection Class II – product, user and environment protection • Provides a ~100ft/min protective air barrier Class III- Air tight - use with Risk Group 3/4 agents • Fume hoods and laminar flow clean work benches are NOT Biosafety Cabinets. What is a Biosafety Cabinet Outline • What is a Biosafety Cabinet (BSC)? • Understand Equipment Limitations • Safe Use of a BSC Why & When to Use a BSC • SOP for BSC • BSC Maintenance / Certification Decontamination Understand Equipment Limitations • Fume Hoods • Not for use with infectious materials or environmentally dangerous organisms • Exhaust air not HEPA filtered; not easily decontaminated • Laminar Clean Air Horizontal • Air blows through HEPA at rear of work surface across work surface and into face of user • NOT for use with lab animals, potentially infectious materials, drug formulations. Vertical • Air blows through HEPA on top of work surface downward • Air may flow under a sash and into the room. Some models don’t even have sashes • Turbulence can distribute aerosols into user’s breathing zone • Not for use with potentially infectious materials Reverse-flow • Pull air from front of cabinet through pre-filter and HEPA at rear • Used to reduce user’s exposure to animal urine, dander etc. (with PPE) • Not for work with biohazards (no containment) Understand Equipment Limitations • BSC class I Inward airflow protects worker Exhaust to outside w/wo HEPA filter No product protection Not for use with tissue culture • BSC class II “Sterile” work surface Protects worker, product and environment For use with RG 2-3 agents Restrictions for flammables and chemicals depending on type of class II BSC Understand Equipment Limitations • Class II BSC Type A2 – 30% exhausted to the room • Not recommended for hard ducting or chemical usage All Type B cabinets – air flow from the rear grill is discharged into the exhaust system so activities that may generate chemical vapors should be conducted towards the rear of the BSC Type B3 – 30% exhausted to outside • Minute chemical usage allowed Type B1 – 70% exhausted to outside • Minute amount of volatile chemicals allowed Type B2 – 100% exhausted to outside • Small amount of volatile chemicals allowed • Not a good choice for tissue culture work Outline • What is a Biosafety Cabinet (BSC)? • Understand Equipment Limitations • Safe Use of a BSC Why & When to Use a BSC • SOP for BSC • BSC Maintenance / Certification Decontamination • Resources Safe Use of a Biosafety Cabinet Must be isolated from other work areas, lab entry, high traffic areas and away from air ducts Must be operated properly to minimize risk (more info later in SOP section) • Sash must be kept at manufacturers recommended height while in use with biological agents. Safe Use of a Biosafety Cabinet Flames are not a constant temperature and therefore can cause air turbulence inside a BSC • Compromise protective air barrier integrity Are not spark/fire proof. Gas Bunsen burners should not be used in BSC’s • 70% recirculated (Class II type A2) Uncombusted gas (yellow flame) captured in plenums. UV light – microscopic holes in gas tubing. Net result high explosion hazard Bunsen Burner - BSC Fire Safe Use of a Biosafety Cabinet UV lights • Cause skin cancer and cataracts. Therefore eyes and skin should not be exposed. • Not reliable as primary decontamination Line of site Poor penetration UV light turns on at 80 micro watts /square cm UV light only kills at 160 micro watts/square cm • Secondary decontamination 15 minutes generally sufficient More than 15 minutes eats up plastics and glue in HEPA filter and in long term can destroy BSC integrity and cause cabinet leak test to fail Safe Use of a Biosafety Cabinet • Do’s Keep supplies to a minimum and ~6” from sides Discard all infectious materials inside the BSC (disinfectant) Understand how the BSC works Turn the cabinet on for manufacturer recommended time before using it Inform your supervisor if you are immuno-compromised Wear a mask if you are coughing or sneezing • Don’ts Rely on the UV light to decontaminate Put anything on the front grill Move quickly Use sweeping motions Keep supplies close to the sides and back Move the sash below or above the recommended standard Use a gas flame in the hood Remove material before disinfecting. When working with potentially infectious material FDS Safe Use of a Biosafety Cabinet 1. What happens if the front sash is up too high? Safe Use of a Biosafety Cabinet 1. Question: Front sash up too high Answer: Down flow of clean (HEPA filtered) air will provide more pressure than inflow of air through the front sash and safety is compromised i.e. agent contamination of the user and environment is likely. FDS 2. What Happens If The Front Sash Is Down Too Low? Safe Use of a Biosafety Cabinet 2. Question: Front sash down too low. Answer: In flow of air through front sash is stronger than down flow of air. Net result is compromised product integrity, i.e. outside air flows into the cabinet providing a source of potential contamination. FDS 3. What Happens If Objects Are Placed On The Front Grill Of The BSC? Safe Use of a Biosafety Cabinet 3. Question: Effect of objects placed on the front grill. Answer: The front grill is one of the dirtiest areas of the entire lab so placing items on this grill is not a good idea. Additionally this interferes with air balance and causes too much down flow of air which creates safety issues, i.e. release of agent outside of the cabinet. FDS 4. What Happens When Your Arm Moves Over The Work Inside The BSC? Safe Use of a Biosafety Cabinet 4. Question: Arm moves over work area. Answer: Down flow air moves contaminants on your arm/lab coat down onto the work surface compromising product sterility. Note: If you are right handed the waste container should be on the right side of the BSC. FDS 5. What Happens When People Walk Behind The BSC? Safe Use of a Biosafety Cabinet 5. Question: Person walks behind the Biosafety Cabinet. Answer: Protective air current is ~100 feet / minute = a little over one mile an hour. People walk at 2-3 miles per hour and this can disrupt the protective air current of the biosafety cabinet. Outline • What is a Biosafety Cabinet (BSC)? • Understand Equipment Limitations • Safe Use of a BSC When to Use a BSC • SOP for BSC • BSC Maintenance / Certification Decontamination • Resources When to Use a BSC • Product Protection Tissue Culture • User /Environmental Protection Aerosolizing activities with Risk Group 2 and 3 agents. Aerosol Producing Activities • Sonication, blending, mixing, vortexing • Almost any liquid manipulation • Centrifuging • Pouring • Pipetting • Opening containers at non-ambient pressures, (e.g. fermenters, freezer vial) • Loading syringes and injections Aerosol Producing Activities • Intranasal inoculation of animals • Changing animal bedding • Harvesting tissue, eggs • Tissue grinder/homogenizers • Lasers • Cell sorters • Necropsy (cont.) Aerosol Control Procedures • Biosafety Cabinet (BSC) properly • • • • • maintained, used and certified No blow-out of pipettes Sidewall contact when delivering liquids Use of aerosol-minimizing tips Secondary enclosure for sonicators, etc. Capped centrifuge tubes, sealed cups, carriers and rotors Outline • What is a Biosafety Cabinet (BSC)? • Understand Equipment Limitations • Safe Use of a BSC Why Use a BSC • SOP for BSC • BSC Maintenance / Certification Decontamination • Resources Why Use a BSC? – User Protection Account for 50% of LAI’s (Lab Acquired Infections) 1. Inhalation exposure to infectious aerosols Account for 20% of LAI’s 1. Parenteral Inoculation (to include animal bites and scratches) 2. Spills, splashes, skin and mucous membrane exposure 3. Ingestion Outline • What is a Biosafety Cabinet (BSC)? • Understand Equipment Limitations • Safe Use of a BSC Why & When to Use a BSC • SOP for BSC • BSC Maintenance / Certification Decontamination • Resources BSC Standard Operating Procedure Start up Procedure • Pre-plan to minimize supplies and movements in and out of the cabinet • Turn on for manufacturer’s recommended time prior to use • Ensure that back grill paper catch is clear Start up Procedure • Verify air flow • Verify drain valve is closed • Disinfect cabinet surfaces • Place all materials inside the cabinet (disinfect as appropriate) • Verify view screen height is appropriate BSC Standard Operating Procedure Work in the Cabinet • Wash hands and arms • Do NOT cover the front or back grill with anything • Use slow movements • Avoid door and people movement beside cabinet • Avoid open flames Work in the Cabinet • Place pipettes exposed to infectious materials in disinfectant inside the cabinet before removing • Safe work area is 6 inches from sides of cabinet • Enclose all potentially contaminated material & disinfect surfaces before removing from BSC • Disinfect work surfaces Standard Operation Procedure - BSC • Develop from Manufacturer’s guidelines • Baker SOP available in BSL-2 Biosafety Manual Template (supplemental resource D) http://www.bio-safety.wsu.edu/forms.asp Outline • What is a Biosafety Cabinet (BSC)? • Understand Equipment Limitations • Safe Use of a BSC Why & When to Use a BSC • SOP for BSC • BSC Certification • Resources BSC Certification Certification • Must be certified every year / after installation / and after the BSC is moved • NSF certifier to provide certification to NSF standards requires 2 HP compressor *Pump designed for aerosol challenge Certification • Check air-flows 100-110 ft/min in-flow (A2) 75 ft/min in-flow (A1) 65-75 ft/min down-flow • Check HEPA filter Particle generator* – 18-20 lbs pressure to produce 0.3 micron particle size (99.9% efficiency test) Outline • What is a Biosafety Cabinet (BSC)? • Understand Equipment Limitations • Safe Use of a BSC Why & When to Use a BSC • SOP for BSC • BSC Maintenance • Resources BSC Maintenance Maintenance Maintenance • • • • Keep the cabinet clean If cabinet is off keep front sash down to minimize dust Clean up spills that get under the cabinet immediately http://www.bio- • • safety.wsu.edu/biosafety/ • • • Disinfect before & after use Bleach pits stainless steel Monitor minihelic gauge • Don’t store materials in the hood Verify that the front grill/back grill and paper catch are unobstructed Once a month disinfect the bottom of the hood and then drain >10-12 year old BSC’s - stop stocking parts Outline • What is a Biosafety Cabinet (BSC)? • Understand Equipment Limitations • Safe Use of a BSC Why & When to Use a BSC • SOP for BSC • Decontamination • Resources Decontamination • Microorganisms can be grouped in terms of resistance to disinfectants. Highly Susceptible Susceptible Resistant Highly Resistant Extremely Resistant Microbial Chemical Resistance Highly Susceptible Mycoplasmas Susceptible Gram +&- bacteria Fungal Spores Resistant Non-Enveloped Viruses Mycobacteria Highly Resistant Bacterial Endospores Protozoal Oocytes Extremely Resistant Prions Effectiveness of Chemical Disinfectants • Effectiveness is influenced by: Composition of chemical disinfectants Concentration of microorganisms and chemical disinfectants Contact time with the Disinfectant Presence of organic matter Presence of interfering substances Temperature at which they are used Summary of Disinfectant Activities Disinfectant Disinfection Level Bacteria Lipophil. Viruses HydroPhilic Viruses M. tuberculosis Fungi Comments Quaternary Ammonium (0.5-1.5%) low + + - - +/ Ineffective against bacterial spores. May be ineffective against Pseudomonas and other gram negative bacteria; recommendation limited to environmental sanitation Alcohols (ethyl and isopropyl) 60-85% Intermed. + + - +/ + Ethyl or isopropyl alcohol at 70-80% concentration is a good general purpose disinfectant; not effective against bacterial spores. , high concentrations of organic matter diminish effectiveness; flammable Phenolics (0.4%-5%) Intermed. + + +/- + + Not sporicidal; phenol penetrates latex gloves; eye/skin irritant; remains active upon contact with organic soil; may leave residue Chlorine (1001,000 ppm) Intermed. + + + +/ + Not generally sporicidal; inactivated by organic matter; fresh solutions of hypochlorite (chlorox) should be prepared weekly; corrosive; irritating to eyes and skin + + + +/ +/ Recommended for general use. Wescodyne diluted 1 to 10 is a popular disinfectant for washing hands. Inactivated by organic matter + + + + + Used to sterilize surgical instruments that can not be autoclaved; strong odor; use with adequate ventilation. Not for use on environmental surfaces. Because it is a sensitizer and causes asthma it is not recommended for laboratory use. Iodophors (301,000 ppm iodine) Glutaraldehyde (2-5%) Intermed. high Case Study – Putting it all Together • Work with M. bovis. rDNA M. bovis culture • Agent Risk Group http://www.absa.org/riskgroups/bacteriasearch.php?genus=Mycobacterium • Risk Assessment • Appropriate BSL • Special Considerations Practicing Science Safely Means That Before Any Activity... YOU KNOW the risks • MSDS YOU KNOW the worst things that could happen • Sick/Die YOU KNOW AND USE the prudent practices, protective facilities, and protective equipment needed to mitigate the risks • Risk Assessment YOU KNOW what to do • Follow BSM A Complete Risk Assessment includes • Agent Characterization (Risk Group RG) • Personnel Factors (experience) • Work Activity Factors • Environmental Factors • Equipment Factors • Risk Consequences • Probability Profile A- Agent Characterization • Pathogenicity of material – disease incidence and severity • Routes of Transmission – parenteral, airborne or ingestion • Agent Stability – ease of decontamination • Infectious Dose – LD50 • Concentration – infectious material/volume & working volume • Origin of material - Wild Type, exotic, primary cells • Availability of effective prophylaxis – Hepatitis B vaccine • Medical surveillance – effectiveness & availability of treatment A- Agent Characterization • Pathogenicity of material – 4th most common LAI, MDR strain • • • • • • • used increases the risk. Routes of Transmission – parenteral, airborne & ingestion Agent Stability – Resistant to many disinfectants Infectious Dose – 10 bacilli by inhalation Concentration – cultures grown on plates Origin of material - Wild Type Availability of effective prophylaxis – INH (Isoniazid) available, ineffective for most MDR strains Medical surveillance – treatment of MDR Mycobacterium problematic B - Personnel Factors • Biosafety training • SOP training • Health Assessment (immunosuppressed) • Experience with the Agent (B, I, A) • • • • • Beginner, Intermediate, Advanced MSDS read Experience with the procedures (B,I,A) Use of PPE training Job hazard analysis undertaken Allergies (animal, environmental) C- Work Activity Factors • Aerosol generating potential • Potential for selfinoculation (needle stick, lesion) • Sample origin and concentration • Volume of pathogen used • Animal use (types, potential viral shedding, bites and scratches) • Replication competency • Recombinants • Cell line characteristics • Toxin production (y/n, MSDS)) • Modification of pathogen (y/n, result / implication) • Vector use (y/n, describe) • Inventory Records • Contingency plan (exposure, accidental releases / spills) • Techniques – cryogenics, cytometry • Disinfectant used as directed D – Environmental Factors • • • • • • • Level of containment available Degree of monitoring of containment factors Impact of external activities Biosecurity (access and inventory control) Availability and status of emergency support Housekeeping and Trades Personnel Access by public E – Equipment Factors • • • • • • Equipment Maintenance (frequency, status) Manual Reservoirs empty &disinfected Standard Operating Procedures Location of use Ventilation Consideration F - Rating of Risk Consequences • Rating of Risk Consequences Class Rating Consequences 4 Catastrophic People: Environment: Business: fatalities, evacuation outside site area irreversible, long-term damage outside site area total loss: > $2 million Interruption: > 2 months image: severely damaged, > 1 week, national 3 Critical People: Environment: Business: serious injuries, effects outside site area reversible, short-term damage outside site area total loss: > $100,000 - $2 million Interruption: > 2 – 8 weeks image: damaged, > 1 week, regional 2 Marginal People: Environment: Business: minor injuries, annoyance outside site area only site area effected total loss: > $5,000 - $100,000 Interruption: > 1 – 2 weeks Image: < 1 week, local 1 Negligible People: Environment: Business: no effects only building effected total loss: < $ 10,000 Interruption: > 1 week Image: no effects F - Rating of Risk Probability Table 2 - Rating of Probability Class Rating Probability Definition A Frequent More than once a year Likely to occur repeatedly in life cycle system B Moderate Once per year Likely to occur several times in life cycle system C Occasional Once in 5 years Likely to occur sometime in life cycle system D Rare Once in 25 years (e.g. once in the life cycle of the system) Not likely to occur in system life cycle, but possible E Unlikely Once in 100 years Will occur once in a lifetime of a site F Very Unlikely Once in 1,000 years Almost impossible to occur G -Probability Profile Risk Profile/Probability Consequences Probability Frequent A Moderate B Occasional C Rare D Unlikely E Very Unlikely F Negligible 1 Marginal 2 Critical 3 Catastrophic 4 Resources - People • WSU – Biosafety Pullman and offsite campuses Lorraine McConnell 509-335-4462 lorrmcc@wsu.edu • WSU- EH&S Pullman Mike Kluzik 509-335-9553 mkluzik@wsu.edu Resources • • Biosafety in Microbiological and Biomedical Laboratories: http://www.cdc.gov/od/ohs/biosfty/bmbl5/bmbl5toc. htm American Biosafety Association: http://www.absa.org/XriskgroupsX/index.html • Canadian Biological MSDS’s: http://www.phacaspc.gc.ca/msds-ftss/index.html • WSU Biosafety Web Page: http://www.biosafety.wsu.edu/biosafety Web Resources - BSC • CDC / NIH Guidelines on Biosafety Cabinets: http://www.ors.od.nih.gov/ds/pubs/bsc/contents.html • AIHA – BSC Safety Information: http://www2.umdnj.edu/eohssweb/aiha/accidents/BSC.ht m#Biosafety%20Cabinet • CDC / NIH 2nd ed. “Primary Containment for Biohazards”: file:///Z:/Biosafety%20Cabinets/CDCPrimary%20Containment%20for%20Biohazards%20(BS C's).htm • Ohasis – Office of Health & Safety Primary Containment for Biohazards Section V. file:///Z:/Biosafety%20Cabinets/Primary%20Containment %20for%20Biohazards.htm Web Resources - BSC • CDC – Laboratory Biosafety Guidelines 3rd edition: http://209.85.173.104/search?q=cache:h373QUWmYfEJ: www.phac-aspc.gc.ca/publicat/lbg-ldmbl04/pdf/lbg_2004_e.pdf+CDC+2007+3rd+edition+of+Selec tion+Installation+and+Use+of+BSC&hl=en&ct=clnk&cd= 5&gl=us&client=firefox-a • ABSA Position Paper on the Use of Ultraviolet Lights in Biological Safety Cabinets: http://209.85.173.104/search?q=cache:tbuGD9FOadAJ:w ww.ehs.umass.edu/ABSA%2520UV%2520light%2520pap er.pdf+position+paper+on+the+use+of+ultraviolet+lights +in+biological+safety+cabinets&hl=en&ct=clnk&cd=1&g l=us&client=firefox-a Web Resources - BSC • BMBL Biosafety Cabinet Appendix A (4th ed): http://www.cdc.gov/od/ohs/biosfty/bmbl4/b4aa.htm • The Baker Company http://www.bakerco.com/resources/intro.php • NUAIRE How to select a BSC http://www.nuaire.com/products/biological_safety_cabin ets/select_a_bio_cabinet.htm • NSF Accreditation Standards http://www.nsf.org/business/biosafety_accreditation/ind ex.asp?program=BiosafetyCabCert Regulations • OSHA Bloodborne Pathogen Standard: • • • • • http://www.osha.gov/SLTC/bloodbornepathogens/ind ex.html Centers for Disease Control and Prevention (CDC): http://www.cdc.gov/od/sap/ NIH Recombinant DNA Guidelines: http://www4.od.nih.gov/oba/rac/guidelines/guidelines .html CDC Interstate Shipment of Etiological Agents: http://www.cdc.gov/od/ohs/biosfty/shipregs.htm CDC Etiologic Agent Import Permit Program: http://www.cdc.gov/od/eaipp/ APHIS – USDA: http://www.aphis.usda.gov/vs/ncie/ THANK YOU