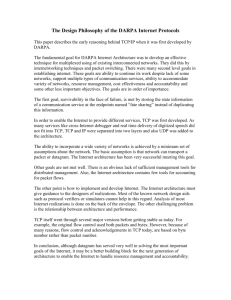

Data Communication & Networking in

advertisement