DOE VTP Battery Presentation 2010-10-05 final (2)

advertisement

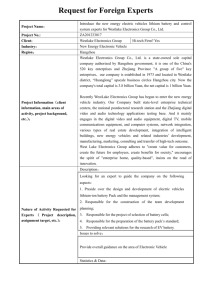

Vehicle Technologies Program The Parker Ranch installation in Hawaii Electric Drive Vehicle Battery R&D David Howell Tien Duong November 18, 2009 1 Energy Storage Program eere.energy.gov Vehicle Technology Battery R&D Activities CHARTER: Advance the development of batteries and other electrochemical energy storage devices to enable a large market penetration of hybrid and electric vehicles. Program targets focus on enabling market success (increase performance at lower cost while meeting weight, volume, and safety targets.) FY2010 Budget: $76 M $16 M $44 M PEV HEV Exploratory $16M FY2011 Request: $96M 2015 GOALS: Reduce production cost of a PHEV battery to $270/kWh (70%) Intermediate: By 2012, reduce the production cost of a PHEV battery to $500/kWh. Vehicle Technologies Program eere.energy.gov Potential to Reduce Oil Consumption Electric traction drives have the potential to significantly reduce oil consumption and provide a clear pathway for low-carbon transportation. Vehicle Types and Benefits HEV PHEV EV Toyota Prius 50 MPG Chevy Volt MPGe TBD Nissan Leaf All Electric • 1 kWh battery • Power Rating: 150kW (200 hp) • Vehicle Cost est $23,000 • 5.7 cents/mile • 16 kWh battery • Power Rating: 170kW (230 hp) • Vehicle Cost est. $41,000 • 3.5 cents/mile • ≥ 24 kWh battery • Power Rating: ≥ 80 kW (107 hp) • Vehicle Cost $32,780 • 2.1 cents/mile Achieving large national benefits depends on significant market penetration Performance and Affordability are the keys Vehicle Technologies Program 3 eere.energy.gov DOE and USABC Battery Performance Targets DOE Energy Storage Goals Equivalent Electric Range (miles) HEV (2010) N/A PHEV (2015) 10-40 EV (2020) 200-300 Discharge Pulse Power (kW) Regen Pulse Power (10 seconds) (kW) Recharge Rate (kW) Cold Cranking Power @ -30 ºC (2 seconds) (kW) Available Energy (kWh) 25 20 N/A 5 0.3 38-50 25-30 1.4-2.8 7 3.5-11.6 80 40 5-10 N/A 30-40 Calendar Life (year) Cycle Life (cycles) 15 3000 10 750+, deep discharge Maximum System Weight (kg) Maximum System Volume (l) Operating Temperature Range (ºC) 40 32 -30 to +52 10+ 3,000-5,000, deep discharge 60-120 40-80 -30 to 52 Vehicle Technologies Program 300 133 -40 to 85 eere.energy.gov Lithium-ion Technology e e Anode: e.g., Graphite Separator Conductive additives e Cathode: e.g., LiNi0.8Co0.15Al0.05O2 Binder Electrolyte • Liquid organic solvents • Polymers • Gels • Ionic liquids Cathode • Layered transition-metal oxides • Spinel-based compositions • Olivine-based compositions Li+ Anode • Carbon-based • Alloys and intermetallics • Oxides • Lithium-metal • • • Vehicle Technologies Program Presently three classes of cathodes, three classes of anodes, and three classes of electrolytes under consideration for Li-ion cells for transportation applications Four important criteria for selection of a battery chemistry: Cost, life, abuse tolerance, and performance None of the presently-studied chemistries appear to satisfy all four criteria 5 eere.energy.gov Battery Cell Form Factors Schematic of Cylindrical Cell Top cover Gasket Cathode lead Safety vent and CID (PTC) Separator Insulator Anode lead Anode can Insulator Cathode Vehicle Technologies Program Anode eere.energy.gov Battery Cell Form Factors Schematic of Prismatic Cell Terminal plate Insulator Cathode pin Top cover Gasket Insulator case Safety vent Spring plate Cathode lead Anode can CID Separator Anode Cathode Wound or Stacked Electrodes Vehicle Technologies Program eere.energy.gov Vehicle Technology Battery R&D Activities The Vehicle Technologies’ battery R&D is engaged in a wide range of topics, from fundamental materials work through battery development and testing Advanced Materials Research • High energy cathodes • Alloy, Lithium anodes High Energy & High Power Cell R&D • High rate electrodes • High energy couples Full System Development And Testing Commercialization • Hybrid Electric Vehicle (HEV) systems • 10 and 40 mile Plug-in HEV systems • Advanced lead acid • Ultracapacitors • High voltage electrolytes • Fabrication of high E cells • Lithium Metal/ Li-air • Ultracapacitor carbons 60 Lab & University projects to address cost, life, & safety of lithium-ion batteries & to develop next generation materials 35 Industry contracts to design, build, test battery prototype hardware, to optimize materials & processing specs, & reduce cost Vehicle Technologies Program eere.energy.gov Status of Conventional HEV Battery Development • Mature Li-ion chemistries have demonstrated more than 300,000 cycles and 10-year life (through accelerated aging) • R&D focus remains on cost reduction, improved abuse tolerance and the development of alternative technologies such as ultracapacitors. Energy and Power Density of USABC HEV Technologies - 3 Sample Data Sets Wh/l Most HEV performance targets met by Li-ion batteries. 80 70 60 50 40 30 20 1999 10 2000 Calendar Life (years) Cost ($/25kW battery pack) 25kW HEV Battery Pack Cost 2500 2000 1500 1000 500 0 1997 1999 2001 Li ion Vehicle Technologies Program 2003 Year NiMH 2005 2007 2009 16 14 12 10 8 6 4 2 0 2003 2008 2003 3000 4000 W/l ♦ Nickelate/Carbon ♦ Fe Phosphate/Carbon 3500 3000 2007 2008 2005 2006 2007 2008 5000 6000 ♦ Mn Spinel/Carbon Calendar Life -- Two Sample Data Sets 2004 2005 2006 2007 Year 2008 2009 2010 eere.energy.gov PHEV Technology Development Roadmap Several lithium battery chemistries exist, including: 1 2 3 4 Graphite/Nickelate Graphite/Iron Phosphate Graphite/Manganese Spinel Li-Titanate/High Voltage Nickelate Exploratory Research 7 6 Vehicle Technologies Program 5 6 7 Battery Cost Reduction Battery Cell and Module Development 5 4 Li alloy & High capacity carbon negatives /High Voltage Positive Li/Sulfur Li Metal/Li-ion Polymer 2 Commercialization 3 1 eere.energy.gov Performance Status of PHEV Batteries (Subset of goals) STATUS (PHEV-10) PHEV – 10 2012 PHEV-40 2014 10 10 40 50 / 45 50 / 45 46 / 38 Peak Regen Pulse Power (10 sec) (kW) 30 30 25 Available Energy: Charge Depleting @10 kW (kWh) 3.4 3.4 11.6 2,500+ 5,000 / 17 5,000 / 58 300,000 300,000 300,000 6-12 15 15 60-80 60 120 50+ 40 80 $2,500+ 1,700 3,400 Characteristics (End of Life) Reference Equivalent Electric Range (miles) POWER AND ENERGY Peak Pulse Discharge Power - 2 Sec / 10 Sec (kW) BATTERY LIFE Charge Depleting Life / Discharge Throughput (Cycles/MWh) Charge sustaining (HEV) Cycle Life (cycles) Calendar Life, 35°C (years) WEIGHT, VOLUME, & COST Maximum System Weight (kg) Maximum System Volume (liter) Battery Cost ($) Vehicle Technologies Program eere.energy.gov Battery Cost Models Objectives of Battery Cost Modeling • Provide a common basis for calculating battery costs • Provide checks and balances on reported battery costs • Gain insight into the main cost drivers • Provide realistic indication of future cost reductions possible USABC model – • Detailed hardware-oriented model for use by DOE/USABC battery developers to cost out specific battery designs with validated cell performance Argonne model – • Optimized battery design for application • Small vs. large cell size • Effect of cell impedance and power on cost • Effect of cell chemistry • Effect of manufacturing production scale 4000 3500 PHEV (40) Battery Cost ($) 3000 • Assess the cost implications of different battery chemistries for a frozen design • Identify factors with significant impact on cell pack costs (e.g., cell chemistry, active materials costs, electrode design, labor rates, processing speeds) • Identify potential cost reduction opportunities related to materials, cell deign and manufacturing 2500 2000 PHEV (20) HEV 1500 PHEV (10) 1000 500 0 0 2 4 6 8 10 12 14 16 Battery Energy Storage Capacity (kWh) Vehicle Technologies Program TIAX model – 18 20 eere.energy.gov Key Results • Current high volume PHEV lithium-ion battery cost estimates are $700 -$950 /kWh. – Cost ($/kWh) should be determined on “useable” rather than “total” capacity of a battery pack – ANL & TIAX models project that lithium-ion battery costs of $300/kWh of useable energy are plausible. • Material Technology Impacts Cost – Cathode materials cost is important, but not an over-riding factor for shorter range PHEVs Cathode & anode active materials represent less than 15% of total battery pack cost. – In contrast, for longer range PHEV’s and EVs, materials with higher specific energy and energy density have a direct impact on the battery pack cost, weight, and volume. – Useable State-of-Charge Range has direct impact on cost for a given technology – Capacity fade can dramatically influence total cost of the battery pack • Manufacturing scale matters – Increasing production rate from 10,000 to 100,000 batteries/year reduces cost by ~30-40% (Gioia 2009, Nelson 2009) – For example, consumer cells are estimated to cost about $250/kWh. Vehicle Technologies Program eere.energy.gov Lithium-Ion Abuse Tolerance • Li-ion Safety Issues • High energy density • Reactive materials • Flammable electrolytes • Abusive Conditions • Mechanical (crush, penetration, shock) • Electrical (short circuit, overcharge, over discharge) • Thermal (over temperature from external or internal sources) • Mitigation Methods • Reduced reaction materials for electrode • Lower gas generation and flammability for electrolytes • Increased separator integrity and temperature range • Mechanical and electrical mitigation techniques and battery control systems employed by battery developers • Several members of the VTP Team participated on the committee to develop the new SAE Abuse Test Manual J2464 Vehicle Technologies Program eere.energy.gov Lithium Supply Status and the Impact of Lithium Recycling Are we trading petroleum dependence for dependence on lithium? Light-Duty Vehicle Sales Projection to 2050 • No. Unlike gasoline, lithium is not consumed when the battery is discharged. Batteries can be recharged up to 5000 more times. After that, lithium can be recycled and be reused. • Major sources of lithium are salt brines in South America. There are also brine and rock sources in the U.S. and throughout the world. • Current estimates by the International Energy Agency show no serious lithium supply problem until more than 50% of the world's vehicle fleet is electrified. (Per IEA Blue Scenario for Carbon Reduction). Future U.S. Lithium Demand Compared to Historical Production 60000 Large batteries no recycling 6,474 USGS Reserves 4,100 USGS Reserve Base 11,000 Other Reserve Estimates Vehicle Technologies Program 30,000+ Effect of recycling World Production US Battery Demand US Consumption Available for recycle Net virgin material needed 50000 Tonnes contained lithium Cumulative demand to 2050 (Contained lithium, 1000 Metric tons) 40000 30000 20000 10000 0 1990 2000 2010 2020 2030 2040 2050 eere.energy.gov Research Directions • Concentrated search for high-capacity cathode materials. • Develop new solvents and salts that allow for high-voltage electrolytes with stable electrochemical voltage windows up to 5 Volts. • Develop advanced tin and silicon alloys with low irreversible loss and stable cycle life at capacity under 1,000 mAh/g. • Initiate a new Integrated Laboratory/Industry Research Program – Explore the feasibility of pre-lithiated high capacity anodes. – Explore novel ideas to address the dendrite problem in using lithium metal. Vehicle Technologies Program eere.energy.gov Laboratory and University Applied and Exploratory Research Cell analysis and Construction 10 Projects Modeling 5 Projects LBNL, ANL, NREL, INL, U of Michigan Electrolytes 12 Projects V I Lawerance Berkley, BNL, ANL, SNL, Hydro-Quebec - Advanced Anodes 11 Projects ANL, PNNL, ORNL SUNY Binghamton U of Pittsburgh Vehicle Technologies Program + LBNL, ANL, ARL, JPL, BYU, CWRU, NCSU, UC Berkeley, U of Rhode Island, U of Utah Diagnostics 6 Projects Advanced Cathodes 15 Projects LBNL, BNL, ANL SUNY Stony Brook, MIT ANL, PNNL, LBNL UT Austin, SUNY Binghamton eere.energy.gov Mid-Term R&D Next Generation Lithium-ion Issues Advanced anode materials such as silica (Sn) & tin (Si) have capacities in excess of 1,000 mAh/g, these alloys undergo significant volume change (up to 300%) during operation. Advanced Li-rich, layered-cathode (MnO3/Mn2O4) provides capacity up to 220 mAh/g at potentials much greater than 4.3V; low rate capability presently available electrolytes are not stable above 4.3V. Approaches Current research is focused on controlling the volume expansion of these alloys and developing electrolytes that are stable above 5V. Provided these issues are resolved, an advanced lithium-ion battery operating at 300–350 Wh/kg at cell level is possible. 18 Vehicle Technologies Program eere.energy.gov Long-Term R&D Beyond Li-ion • • • Li-metal Anode – Capacity: 3,862 mAh/g (practical: 500 – 650 Wh/kg). – Dendrite formation → loss of lithium and possible safety hazard. – Solvent reduction → loss of lithium and electrolyte. Sulfur Cathode – Theoretical energy density: 2,550 Wh/kg (practical: 500 – 650 Wh/kg). – Overall reaction: 16Li + S8 ↔ 8Li2S – Dissolution of lithium polysulfides in the electrolyte → high self-discharge. – Insoluble sulfur species (e.g., Li2S2 and Li2S) → passivation of the electrodes. Air Cathode – Theoretical specific energy: ~11,000 Wh/kg (without O2), ≤ 5,000 Wh/kg (with O2). – practical: 500 – 650 Wh/kg – Need bifunctional air cathode to reversibly convert oxygen to Li2O2. – Reaction products passivate the air electrode and block the O2 diffusion → low discharge rate. – Large over-voltage in charging → poor energy efficiency. – Need oxygen/moisture separation membrane for long-term ambient operation. Protection of lithium metal surface from chemical interactions is critical. 19 Vehicle Technologies Program eere.energy.gov QUESTIONS? www.vehicles.energy.gov Vehicle Technologies Program eere.energy.gov