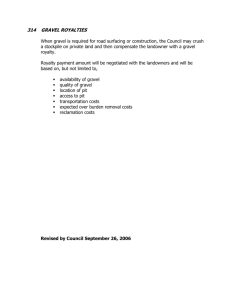

Gravel Behavior Threshold

advertisement

Performance of Embedded Gravel Roof Systems in Extreme Wind Loading Photo Courtesy of Gene Whiting Forrest Masters, PhD and Kurt Gurley, PhD UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Motivation for Study Pursuant to Section 2 of SB 2836, Section 2. (1) Before eliminating gravel or stone roofing systems in the Florida Building Code, the Florida Building Commission shall determine and document: (a) Whether there is a scientific basis or reason for eliminating this option UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Motivation for StudyUPDATED • Other (not UF) researchers are investigating whether – There is an available alternative that is equivalent in cost and durability (FRSA to speak on this issue); – Eliminating this option will unnecessarily restrict or eliminate business or consumer choice in roofing systems (FRSA to speak on this issue); and – Eliminating this option will negatively affect the nesting habitat of any species of nesting bird (Fish and Wildlife Conservation Commission) • Full text of the bill may be found at: www.myfloridahouse.gov/Sections/Bills/billsdetail.aspx?BillId=36579 UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Approach • A defensible rationale for eliminating gravel roofing in Florida must include reasonable evidence that – Gravel blow-off occurs at or below design-level event wind speeds – The wind carries gravel over a distance and with sufficient velocity to damage the buildings downwind UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Topical Overview 1. 2. 3. 4. 5. Post Hurricane Observations Gravel Scour and Blow-Off Gravel Transport Gravel Impact on Downwind Structures Conclusion (so far) UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Post Hurricane Observations: Sources • Government sources – Federal Emergency Management Agency (FEMA) – National Institute of Standards and Technology • Industry sources – Florida Roofing, Sheet Metal and Air Conditioning Contractors Association (FRSA) – Roofing Industry Committee on Weather Issues (RICOWI) • Academic Journals (e.g., ASCE Structural Engineering, Wind Engineering and Industrial Aerodynamics) • The authors requested information from stakeholders at the August 27, 2007 Hurricane Research Advisory Committee UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Evidence for Elimination • Numerous studies of post-hurricane damage specifically cite roof gravel as a significant source of damaging debris • Both low-rise and high-rise gravel roof systems with and without parapets have been documented as a primary source of window breakage and subsequent water penetration and roof system loss from internal pressurization • Minor (1994) presents a synopsis of such observations over many years, including Hurricanes Celia (1970), Frederick (1979), Allen (1980), Alicia (1983), and Andrew (1992). UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Evidence for Elimination • RICOWI field investigation teams (Croft et al. 2006) documented gravel scour and blow-off in Hurricanes Charley and Ivan (2004) • The SouthTrust Bank Building in Pensacola “lost its gravel surface BUR… Gravel from this roof was blown downwind onto the Judicial Center. This gravel almost certainly caused the window damage noted there.” • Damage to cars was also attributed to windborne gravel generated from roof of the Baptist Hospital Medical Facility UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Evidence for Elimination • FEMA 488 attributed breakage of tempered glass windows to BUR gravel generated by 100-115 mph winds during Hurricane Charley • At a hospital in Arcadia, several windows at the intensive care area were broken, in part, by aggregate from the hospital’s roofs. Three of the eight intensive care rooms were taken out of service, and windows were broken in other patient rooms • At a school in Port Charlotte, aggregate flew over an 11” parapet and traveled a considerable distance downwind UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Evidence for Elimination • FEMA 489 noted gravel blow-off during Hurricane Ivan • FEMA 490 refers to roofing aggregate as a major cause of window breakage, including essential facilities (e.g., during Hurricane Frances windborne gravel broke several of the patient room windows at Indian River Memorial Hospital) • The report recommends the removal of aggregate systems from essential facilities and the development of technically based criteria for aggregate surfacing in other applications. UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Evidence for Elimination • Notre Dame researchers Kareem and Bashor (2006) studied glass and cladding failures in New Orleans after Hurricane Katrina • Found roof gravel at the site of many broken windows, and documented gravel blow-off from inspected roofs (Kareem 2006, personal communication July 29, 2007). UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Evidence against Elimination • Whiting Construction has observed that other than minor scouring on the roof corners, gravel roofs perform adequately during extreme winds. Over several decades, thousands of these roofs were installed in SE Florida, including areas affected by Hurricanes Andrew (1992), Frances (2004), Jeanne (2004) and Wilma (2005) • RICOWI’s wind investigation report on Hurricane Katrina (2007) concluded that “aggregate and stone blowoff was not identified as a major problem in this investigation.” UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Evidence against EliminationNEW • Increased parapet height reduces the maximum suction near the upstream corner of the rooftop and broadens the low-pressure region • This phenomenon was attributed to the vortex cores becoming broader and lying farther above the roof • Baskaran et al. (2007) and RICOWI conducted post-storm damage assessments after Hurricane Charley (2004) and found that a 3 ft parapet height is of sufficient to prevent stone blow-off UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Evidence against EliminationNEW • “If gravel is to blame for so much damage why are there gravel covered roofs on Jackson Memorial Hospital in downtown Miami? How did the gravel stay on in Hurricane Andrew & Wilma?” [personal communication with Gene Whiting, 1/21/2008] • Typically post-storm damage assessments, journal articles, etc. focus on underperforming systems not success stories • Compelling evidence may not have surfaced?... UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Post Hurricane Observations: Summary • Independent observations from different investigating groups over many storms go back to at least 1970 • Gravel blow-off is not just anecdotal or a rare event unworthy of careful consideration • However, these reports have not produced statistically quantifiable results concerning the performance of gravel roof systems • It is unclear if gravel blow-off is a problem that affects one in ten roofs or one in a thousand UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Scour and Blow-OffUPDATED • Two major comprehensive wind tunnel studies: – National Research Council of Canada (1970s). Dow Chemical of Canada Limited sponsored a series of tests at to investigate roof gravel scour and windborne debris generation – Colorado State (late 1990s). Developed a theoretical model for the UN Internationale Decade for Natural Disaster Reduction Programme • Note that no full-scale experiments investigations of gravel performance have been made. However, during FIU preliminary investigation of vortex suppression technologies gravel blow-off was observed UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Scour and Blow-Off: NRC • In the first round of tests, Kind (1974a) found that the critical wind speed at which stone motion began is proportional to the square root of the nominal stone size • In the second round of tests, found that the lowest wind speed thresholds required to cause gravel scour and blowoff occurred when the winds traveled diagonally over the corner parapet (i.e. where the WIND walls on a full-scale structure are oriented 45º from the mean wind direction UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Scour and Blow-Off: NRC • These tests did not consider the effects of the building shape (only the roof itself was tested) • Kind (1974b) followed with a second series of experiments using three 1:10 scale warehouse/factory building models with four interchangeable parapets of varying height • Tests were performed in the National Aeronautical Establishment 30 ft x 30 ft wind tunnel, calibrated to produce a open exposure terrain conditions UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Scour and Blow-Off: NRCNEW • Kind (1974a) – Pea Gravel – ¾ in Natural Gravel – ¾ in Crushed Limestone • Kind (1974b) provided sieve results for natural gravel used UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Scour and Blow-Off: NRC • During testing, wind speeds were gradually increased, and research personnel recorded four critical gust speeds: Threshold Vc1 Vc2 Vc3 Vc4 Gravel Behavior first stone motion observed scouring occurs more or less indefinitely gravel propelled over windward parapet gravel propelled over leeward parapet OUR FOCUS UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Scour and Blow-Off: NRC • • Results of these experiments were condensed into a rational procedure to estimate critical design gust speeds Reproduced on the next slide for a nom. 0.63” gravel size – – • Sieving of aggregate samples provided by FRSA indicated that > ½” is a reasonable assumption for a “large” gravel size The most comprehensive experimental investigation of minimum breakage velocities for windborne gravel impacts on glazing was conducted using a “representative” projectile mass of 5.55 grams (Harris 1978) Choosing a smaller nominal size would have resulted in a lower wind speed threshold UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Scour and Blow-Off: NRC • • A range of building (0-60 ft) and parapet heights (6”-3 ft) are tabulated below These are rooftop speeds Tall parapets: greatest uncertainty in model UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Scour and Blow-Off: NRC • • Next, the rooftop wind speeds were converted (increased) to equivalent ASCE 7 Basic Wind Speeds Assumed Exposure B conditions Windward Leeward UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Scour and Blow-Off: NRCNEW • • • • In 1990, NCFI Polyurethanes reviewed the Kind and Wardlaw documents in depth and performed design calculations based on their methodology Found that the methodology did not produce results that agreed field experience, which included hundreds of on-site inspections Asserts that it is not appropriate for loose-laid gravel on spray foam roofing systems Personal communication: Roger Morrison (3/11/08) UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Scour and Blow-Off: CSU • Wills et al (1998) developed and tested a theoretical model for the flight speed threshold for compact objects • Compares favorably with the NRC studies Sieve Size in 0.093 0.187 0.374 0.492 0.630 0.748 0.984 mm 2.36 4.75 9.50 12.50 16.00 19.00 25.00 Threshold of Flight m/s 9.8 13.9 19.7 22.6 25.6 27.8 31.9 mph 22 31 44 51 57 62 71 UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Transport: Holmes (2002) • Following Wills et al. (1998), Holmes (2002) developed a theoretical flight model for several idealized debris shapes, including a compact projectile • The basis of the models is that once gravel takes flight, drag forces continues to accelerate it UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Transport: Holmes (2002) Rooftop Wind Speed = 84 mph, Gravel Diameter = 0.63 in, Gravel Mass = 5.4 g Velocity (mph) 60 40 20 Distance Traveled (ft) 0 0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2 0.2 0.4 0.6 0.8 1 Time (s) 1.2 1.4 1.6 1.8 2 100 50 0 0 Vertical Fall (ft) 0 -20 -40 -60 0 UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Transport: Holmes (2002) • While it is not possible for the gravel to achieve the full wind speed, it can reach approximately 50% of that value in less than two seconds, traveling horizontally almost 100 ft and falling about 60 ft • Only horizontal drag forces were considered. Holmes (2004) subsequently evolved this model to account for the effects of vertical air resistance, which were found to be significant. In reality, the vertical air resistance would extend the time of flight shown UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Transport: FEMA (2003) • Applied Research Associates numerically modeled the expected number of aggregate impacts on a building downwind of a gravel roof for a range of common low-rise residential and commercial structures located in a suburban exposure • Developed for FEMA’s risk assessment software, HAZUSMH, and has been approved by the Florida Commission on Hurricane Loss Projection Methodology (FEMA 2003) • Developed independently of the Holmes (2002) model UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Transport: FEMA (2003) • Model provides enveloped results based on – Four roof area / height combinations – Gravel diameters linearly distributed from 0–0.87 in, which approximately bounds the gradation requirements found in ASTM D 1863-03 – Gravel depth set to 1.6 in, approximately three times the standard depth for built-up roofs installed in Florida (Johns Manville 2004a, 2004b). This choice affects the supply of windborne debris but not the propensity for gravel to take flight in extreme winds. UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Transport: FEMA (2003) 110 150 mph 100 140 mph 2 Impacts per hour per m at 2 m 90 80 130 mph 70 60 120 mph 50 40 110 mph 30 20 100 mph 10 0 0 20 40 60 80 100 120 140 160 Center-to-Center Spacing between Buildings (m) UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Impact • It has been shown that gravel blow-off occurs at wind speeds less than the design level requirements for the State of Florida and that gravel, once airborne, continues to accelerate before reaching the ground or striking a structure downwind • Now we consider the effects of unprotected, non-impact resistant fenestration to gravel impact • Numerous studies have been conducted on annealed/tempered (e.g., Beason 1974, Harris 1978) and laminated (e.g., Pantelides et al. 1993, Ji et al. 1998, Saxe et al. 2002, Dharani et al. 2004) glazing UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Impact • Variation of the target’s surface area has been shown to have little effect on the mean minimum breaking velocity (Minor 1974) • Minor et al. (1976) also found that the presence of a uniform wind pressure on the glazing affects the character of the breakage but does not lower the missile speed required to break glass • The most comprehensive set of results are found from a series of experiments conducted by Harris (1978) and Minor et al. (1978) at Texas Tech University UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Impact: TTU • Under the direction of Minor, Harris (1978) conducted tests on 257 samples of annealed and tempered glass of varying thickness to determine the missile impact velocities required to break glass • A 5.55 gram steel ball, representative of an “average” large size aggregate from a conventional tar and gravel roof was chosen for the projectile • Regression analysis was performed on the results to determine missile impact velocities associated with a 5% probability of failure. UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu Gravel Impact: TTU Glass Thickness (in) 3/16 1/4 5/16 3/8 1/2 3/4 Annealed Rooftop Gust Speed m/s mph 10.2 9.5 8.6 10.9 11.8 17.3 23 21 19 24 26 39 Mom. kg · m/s 0.057 0.053 0.048 0.061 0.065 0.096 Intermediate Temper Rooftop Gust Speed Mom. m/s mph kg · m/s -10.9 ----- -24 ----- -0.060 ----- Highly Tempered Rooftop Gust Speed Mom. m/s mph kg · m/s 20.0 -19.6 18.9 15.2 16.6 45 -44 42 34 37 Range of Wind Speeds: 19-39 mph Range of Wind Speeds: 37-45 mph UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu 0.111 -0.109 0.105 0.085 0.092 Gravel Impact: TTU + Holmes (2002) Glass Thickness (in) 3/16 1/4 5/16 3/8 1/2 3/4 Annealed Rooftop Gust Speed m/s mph 10.2 9.5 8.6 10.9 11.8 17.3 Intermediate Temper Rooftop Gust Speed Mom. m/s mph kg · m/s Mom. kg · m/s 23 21 19 24 26 39 0.057 0.053 0.048 0.061 0.065 0.096 -10.9 ----- -24 ----- -0.060 ----- Highly Tempered Rooftop Gust Speed Mom. m/s mph kg · m/s 20.0 -19.6 18.9 15.2 16.6 45 -44 42 34 37 0.111 -0.109 0.105 0.085 0.092 Comparing to Holmes (2002) Rooftop Wind Speed = 84 mph, Gravel Diameter = 0.63 in, Gravel Mass = 5.4 g Velocity (mph) 60 40 20 0 0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 d (ft) Time (s) 100 UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu 1.8 2 Conclusion • Research shows that roof gravel used in built-up roofing is susceptible to blow-off in wind speeds lower than the design (basic) wind speeds stipulated for the Florida • At the onset of hurricane force winds, – A portion of roof gravel will become airborne – A portion of that airborne gravel will impact structures downwind – A percentage of the airborne gravel that impacts glazing has achieved sufficient momentum to cause damage UNIVERSITY OF FLORIDA ∙ CIVIL AND COASTAL ENGINEERING ∙ www.ce.ufl.edu