Nanocrystalline Hydroxyapatite

advertisement

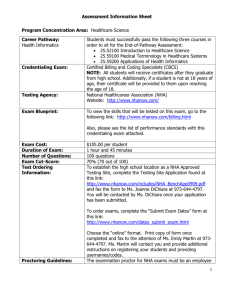

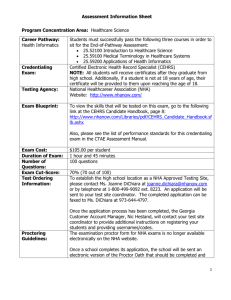

Fundamentals of Nanotechnology Cornelia Cretiu Vasiliu 12-01-2007 1 Motivation Methods of synthesis Characterization of structure Morphology and particle size distribution Properties & Applications 2 Bone: 2nd most implanted tissue after blood Protein matrix containing type 1 collagen and minerals Calcium as: (Ca 2+)10-x(H3O+)2x*(PO4)6(OH-)2 Synthetic vs. homo-, allo-, xeno-geneic implants Properties: biocompatibility, biodegradability, mechanical integrity, vascularization inductivity, osteoconductivity, and osteoinductivity http://www.uabhealth.org/16313 3 HA Wet methods5 Solid-state reactions6 Sol-gel7 Ellectrocrystallization8 Spray pyrolysis9 Emulsion processing10 Hydrothermal treatment11 nHA Chemical precipitation1 Hydrothermal treatment12 Microwave synthesis2 To be considered: stoichiometry, pH, rate of addition, ionic strength 4 nHA Methods of synthesis Co precipitation 1) Ca(OH)2 + H3 PO4 nHA Aqueous, pH 8, 38oC • • Microwave synthesis 2) 10 Ca(OH)2+6 (NH4)2HPO4 850W, 20 min. Ca10(PO4)6(OH)2+6H2O+12NH4OH 13)Aq. Sol. NaNO3, Ca(NO3)2·4H2O and KH2PO4 precursor 600W, 5 min. stirred in H2O ( room temperature , 1 h) nHA particles. 5 XRD(1 Powder XRD of the HA precipitate: (a) as-prepared, (b) calcined at 700 °C, (c) calcined at 800 °C, (d) calcined at 900 °C and (e) calcined at 1200 °C. [specific peaks :(H) HAP; (b) β-TCP; (a) α-TCP].( 1 6 IR(1 spectra of the nHA precipitates: (a) as-dried, (b) calcined at 700 °C, (c) calcined at 800 °C, (d) calcined at 900 °C and (e) calcined at 1200 °C. 7 SEM micrograph of the as-prepared nHA(1 TEM micrograph of as-synthesized nano HA crystals(14 8 DLS: Histogram representation of the mean diameters of asprepared nHA suspended in aqueous solution. (1 9 Coatings (2 Cell morphology after being cultured for 15 min on the different nHA coated(G2) and uncoated(G1H) titanium surfaces. Surface roughness decreased(2 Fibers, tubes nHA doped PLGA composite (30% nHA) hollow fiber membrane fabricated using wet phase inversion technique (13 (13 10 Bone filler(4 (A) Preoperative axial CT (B) Lateral preoperative view (C) After reduction, the remaining defect was filled with nHA paste. (D) Postoperative radiograph (E) 6 weeks after surgery . The patient progressed to full weight bearing at this point in time. (F) 12 months postoperatively, only a marginal loss of correction could be measured. 11 CT scan Computer file Choose customized design Print, sinter implant Seed cells, growth factors Implant 12 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. http://www.sciencedirect.com/science/article/B6THV-4JVK5671/2/501b2d84c7d81d8e9dc5771941065db1 Phase Xiaolong Zhu et al 2006 Nanotechnology 17 2711-2721 http://www.sciencedirect.com/science/article/B6TWH-4KY88TT3/2/2a01537a8d0b528852bb67f079d7e91a Rapid densification F. Huber, J. Hillmeier, N. McArthur, H. Kock and P. J. Meeder, The Use of Nanocrystalline Hydroxyapatite for the Reconstruction of Calcaneal Fractures: Preliminary Results, J. of Foot and Ankle Surgery Vol. 45/ 5, 2006, pp. 322-328. C. Liu, Y. Huang, W. Shen and J. Cui, Biomaterials 22 (2001), pp. 301–306. X. Yang and Z. Wang, J. Mater. Chem. 8 (1998), pp. 2233–2237 W. Feng, L. Mu-sen, L. Yu-peng and Q. Yong-xin, Mater. Lett. 59 (2005), pp. 916–919 S.K. Yen and C.M. Lin, Mater. Chem. Phys. 77 (2003), pp. 70–76. K. Itatani, T. Nishioka, S. Seike, F.S. Howell, A. Kishioka and M. Kinoshita, J. Am. Ceram. Soc. 77 (1994), pp. 801–805 C.-W. Chen, R.E. Riman, K.S. TenHuisen and K. Brown, J. Cryst. Growth 270 (2004), pp. 615– 623 G.Z. Hui, Z. Qingshan and H.X. Zhao, Mater. Res. Bull. 40 (2005) (8), pp. 1326–1334. W.L. Suchanek, K. Byrappa, P. Shuk, R.E. Riman, V.F. Janas and K.S. TenHuisen, J. Solid State Chem. 177 (2004), pp. 793–799 N. Zhang et al. / Materials Science and Engineering C 27 (2007) 599–606 S. Ramesh et al. / Ceramics International 33 (2007) 1363–1367 13 HA:βTCP 60:40 1270oC/4h HA:βTCP 60:40 1100oC/4h 14